Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saudi Aramco Test Report

Caricato da

karthi51289Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Saudi Aramco Test Report

Caricato da

karthi51289Copyright:

Formati disponibili

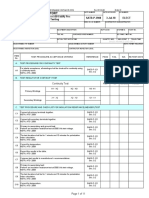

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

High Voltage Power Cable (Installed), Continuity and Megger

SATR-P-3212 3-Jul-18 ELECT-

Insulation Resistance Testing

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A. TEST PROCEDURE FOR SHIELD CONTINUITY TEST

Schedule Q

A1 Check and review the test equipment documents for calibration validity. Att. IV

Sec. 7.1

Inspection shall be performed by the project approved Quality Control Schedule Q

A2 Inspector (QCI) and witness point shall be coordinated with the Contractor Att. IV

and Company. Sec. 5.1

Check physical condition of cable for apparent jacket damage. Schedule Q

A3

(NETA ATS, Sec. 7.3.3.1.10) Sec. 1.3

Perform a shield-continuity test to ensure shield is not broken, on each

Schedule Q

A4 shield with a certified and calibrated ohm-meter.

Sec. 1.3

(NETA ATS, Sec. 7.3.3.2.3)

Perform a Core-continuity test to ensure conductor is not broken, on each

SAES-P-104

A5 power cable with a certified and calibrated ohm-meter.

Sec. 3.2

(NEC 110.3 B and Manufacturer's Instructions)

Check the installed cables for test. Ensure the circuit is de-energized,

remove any temporary grounds and disconnect cable from equipment. If

Schedule Q

A6 equipment cannot be disconnected, a reduced voltage should used for the

Sec. 1.3

test.

(NETA ATS, Sec. 7.3.3 & Sec. 5.1.4)

Check for correct cable test voltage. Erect safety barriers and post safety

SAES-P-104

A7 man at cable end remote from the test equipment.

Sec. 3.1

(SA Pre-Commissioning Form # P-042)

Using a four-point, low-resistance ohmmeter, connect both C1 and P1 of

SAES-P-104

A8 the test set to one end of the cable shield.

Sec. 3.2

(NEC 110.3 B and Manufacturer's Instructions)

Connect C1 and P1 of the test set to one end of the cable shield. SAES-P-104

A9

(NEC 110.3 B and Manufacturer's Instructions) Sec. 3.2

Connect the C2 and P2 of the test set to the other end of the cable shield.

NOTE: Observe the correct orientation for the current circuit (C2) and the

SAES-P-104

A10 potential circuit (P2) hook-ups at the opposite end (P2 connection closer

Sec. 3.2

to the specimen than C2). (NEC

110.3 B and Manufacturer's Instructions)

On completion of test, each core shall be grounded to allow residual

SAES-P-104

A11 charge to dissipate.

Sec. 3.1

(S A Pre-Commissioning Form # P-042)

Check and Insulate cable cores from ground. SAES-P-104

A12

(S A Pre-Commissioning Form # P-042) Sec. 3.1

Check conductors are identified as per specifications and drawings. Schedule Q

A13

(NETA ATS, Sec. 7.3.3.1.1) Sec. 1.3

Saudi Aramco: Company General Use

Test Records and Receipt documents are to be carefully presented in

Schedule Q

A14 original.

Sec. 1.3

(NETA ATS, Sec. 5.4.3)

Saudi Aramco: Company General Use

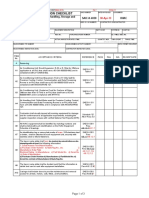

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

High Voltage Power Cable (Installed), Continuity and Megger

SATR-P-3212 3-Jul-18 ELECT-

Insulation Resistance Testing

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No.

The integrity of the overall jacket of direct buried cables rated 5 KV and

higher shall be tested by conducting a 5 kV megger test between the

cable insulation metallic shield (and sheath or armor, if any) and ground. SAES-P-104

A15

The DC high potential value shall be 4 kV/1 mm for one minute and not to Sec. 13.4

exceed 10 kV. IEC 60229 shall be used for HV cable jacket integrity

testing.

After single core cables are installed in the ground, a shield to ground test

shall be performed to check the integrity of the outer jacket, at 10 KV of 1 SAES-P-104

A16

minute. (SA Sec. 13.4

Pre-Commissioning Form # P-042)

B. TEST EQUIPMENT AND MATERIALS CRITERIA

Schedule Q

B1 Test shall be performed using a Ductor, DLRO. Att. IV

Sec. 7.1

Schedule Q

B2 The test equipment calibration cycle shall not exceed twelve months. Att. IV

Sec. 7.1

Test Equipment Manufacturer: Serial Number:

Scale Range and accuracy: Calibration date:

Calibration Company and Technician: Calibration Expiration Date:

C. TEST RESULTS

Cable Identification tag # Cable type Cable length Shield Resistance (Ω) Pass Fail Re-Test Date

D. CONCLUSIONS

Shielding shall exhibit continuity. Investigate any breaks in continuity,

along with any resistance values in excess of 10 ohms per 1000 feet of Schedule Q

D1

cable. Sec. 1.3

(NETA ATS, Sec 7.3.3.2.3 & 7.3.3.3.3)

Test results are acceptable and in accordance with Saudi Aramco

Schedule Q

D2 Engineering Standards and contractual requirements.

Sec. 1.3

(NETA ATS, Sec. 5.4.1.5)

E. INSULATION RESISTANCE (MEGGER) TEST PROCEDURES

Saudi Aramco: Company General Use

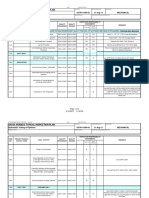

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

High Voltage Power Cable (Installed), Continuity and Megger

SATR-P-3212 3-Jul-18 ELECT-

Insulation Resistance Testing

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No.

Perform resistance measurements through bolted connections with a low-

resistance ohmmeter, if applicable, in accordance with NETA ATS Section Schedule Q

E1

7.3.3.1. (NETA Sec. 1.3

ATS, Sec 7.3.3.2.1)

Perform an insulation-resistance test individually on each conductor with

all other conductors and shields grounded. Apply voltage in accordance

Schedule Q

E2 with manufacturer’s published data. In the absence of manufacturer’s

Sec. 1.3

published data, use Table 100.1. (NETA

ATS, Sec 7.3.3.2.2)

Connect megohmmeter between each phase-to-phase and each phase-

SAES-P-104

E3 to-ground.

Sec. 3.1

(S A Pre-Commissioning Form # P-042)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

High Voltage Power Cable (Installed), Continuity and Megger

SATR-P-3212 3-Jul-18 ELECT-

Insulation Resistance Testing

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No.

Measure insulation resistance at one minute following the application of

SAES-P-104

E4 the test voltage.

Sec. 3.1

(S A Pre-Commissioning Form # P-042)

Record the megohm values of each phase-to-ground and between each

SAES-P-104

E5 phase-to-phase, along with the description of the equipment, the voltage

Sec. 13.5

level, humidity, temperature, time, and the date of the test.

Ground each conductor at the completion of the test. SAES-P-104

E6

(S A Pre-Commissioning Form # P-042) Sec. 3.1

Values of insulation resistance less than manufacturer's minimum or KV

+1 in mega ohms should be investigated. Over potential or high potential

SAES-P-104

E7 test should not proceed unless insulation resistance levels equal to or

Sec. 3.1

above the listed minimum values.

(S A Pre-Commissioning Form # P-000)

Cable ends shall be sealed with heat shrinkable end caps after Continuity

SAES-P-104

E8 and Insulation resistance testing of the cable. (NEC

Sec. 3.2

110.3 B and Manufacturer's Instructions)

The testing organization shall furnish a copy or copies of the complete

report to the owner as specified in the acceptance testing contract. Schedule Q

E9

(NETA ATS, Sec. 1.3

Sec. 5.4.3)

F. TEST EQUIPMENT

Test shall be performed using an Insulation Resistance Test Set

SAES-P-104

F1 (Megohmeter) 5000 V dc minimum.

Sec. 3.1

(S A Pre-Commissioning Form # P-042)

Schedule Q

F2 The test equipment calibration cycle shall not exceed twelve months. Att. IV

Sec. 7.1

Test Equipment Manufacturer: Serial Number:

Scale Range and accuracy: Calibration date:

Calibration Company and Technician: Calibration Expiration Date:

G. TEST RESULTS

Test Voltage level__________ Humidity____________ Temperature_______________ Time/Date of Test____________

Temp. MEASURED INSULATION RESISTANCE (MΩ)

Adjusted

Cable

Insulation Pass Fail Re-Test date

tag #

Resistance A-G B-G C- G A-B B-C C-A

(MΩ)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

High Voltage Power Cable (Installed), Continuity and Megger

SATR-P-3212 3-Jul-18 ELECT-

Insulation Resistance Testing

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No.

H. CONCLUSIONS

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No.

Compare test results with previous test results and with manufacturer data

corrected for temperature variations using manufacturer recommended Schedule Q

H1

correction factors. (NETA ATS, Sec. 1.3

Sec. 7.3.3.3.2.2 and Table 100.1 Notes - Attachment 1)

Insulation-resistance values shall be in accordance with manufacturer’s

published data. Values of insulation resistance less than the Schedule Q

H2

manufacturer’s recommendations should be investigated. Sec. 1.3

(NETA ATS, Sec. 7.3.3.3.2.2)

Test results are acceptable and in accordance with Saudi Aramco

Schedule Q

H3 Engineering Standards and contractual requirements.

Sec. 1.3

(NETA ATS, Sec. 5.4.1.5)

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (MP-LSTK & LSPB Pro Forma, Contract Specific)

2. Schedule Q -- Quality Requirements (MP LSTK & LSPB Pro Forma, Contract Specific)

3. NFPA 70 National Electrical Code (NEC), 2014 Edition

4. Acceptance Testing Specifications for Electric Power Distribution Equipment and Systems- NETA (2009)

5. SAES-P-104 Wiring Methods and Materials, 01 January 2018

6. S A Pre-Commissioning Form # P-000 Testing Guidelines, Issue Date (March 2006)

7. S A Pre-Commissioning Form # P-042 High Voltage Cables (69kV-115kV), Issue Date (March 2006) - supersedes S A Pre-Commissioning

Form # P-005 High Voltage Cables, Issue Date (10/97)

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the manufacturer

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

Potrebbero piacerti anche

- Saudi Aramco Test ReportDocumento11 pagineSaudi Aramco Test Reportkarthi51289100% (1)

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocumento4 pagineSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNessuna valutazione finora

- Satr-P-3210 Rev 7 FinalDocumento11 pagineSatr-P-3210 Rev 7 FinalzhangNessuna valutazione finora

- Saudi Aramco Test ReportDocumento7 pagineSaudi Aramco Test Reportkarthi51289Nessuna valutazione finora

- Saudi Aramco Test ReportDocumento10 pagineSaudi Aramco Test Reportkarthi51289100% (1)

- Saudi Aramco Test ReportDocumento7 pagineSaudi Aramco Test Reportkarthi51289Nessuna valutazione finora

- Saudi Aramco Test Report: SATR-P-3407 3-Jul-18 Elect LV SCIM - Motor Insulation Resistance and Functional TestingDocumento6 pagineSaudi Aramco Test Report: SATR-P-3407 3-Jul-18 Elect LV SCIM - Motor Insulation Resistance and Functional Testingkarthi51289Nessuna valutazione finora

- QMISDocumento14 pagineQMISLopez Gardo0% (1)

- QC Question AnswerDocumento19 pagineQC Question AnswerMallick100% (1)

- SAIC-P-3701 Rev 0Documento3 pagineSAIC-P-3701 Rev 0mkalidas2006Nessuna valutazione finora

- Satip W 014 01Documento12 pagineSatip W 014 01spravin231Nessuna valutazione finora

- Saic J 6001Documento7 pagineSaic J 6001sureshNessuna valutazione finora

- Sa P 041Documento5 pagineSa P 041Haleem Ur Rashid BangashNessuna valutazione finora

- Summary of SAES-J-902Documento7 pagineSummary of SAES-J-902Afzal Asif100% (1)

- SATIP-P-104-01 Rev 7 FinalDocumento4 pagineSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNessuna valutazione finora

- QM-QA-QC Basic Infos, LinksDocumento8 pagineQM-QA-QC Basic Infos, LinksbehringerzsoltNessuna valutazione finora

- QCP 040 QCP CrmsDocumento7 pagineQCP 040 QCP Crmsarockiyathass100% (1)

- Curriculum Vitae: David GrahamDocumento7 pagineCurriculum Vitae: David GrahamMohamad ShafeyNessuna valutazione finora

- SAIC-L-2136 Rev 0Documento3 pagineSAIC-L-2136 Rev 0philipyapNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocumento7 pagineSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNessuna valutazione finora

- Summary of SAES-P-111Documento5 pagineSummary of SAES-P-111Afzal Asif100% (2)

- Saudi Aramco Inspection ChecklistDocumento8 pagineSaudi Aramco Inspection Checklistnisha_khan0% (1)

- 14 Samss 533 PDFDocumento14 pagine14 Samss 533 PDFMudabbir HussainNessuna valutazione finora

- PLS Refer The Remarks Column All 68 Points Are Not Related To YME: Ready To Close9 Ready To Close1Documento6 paginePLS Refer The Remarks Column All 68 Points Are Not Related To YME: Ready To Close9 Ready To Close1Haleem Ur Rashid BangashNessuna valutazione finora

- Portacabin Inspection ChecklistDocumento2 paginePortacabin Inspection ChecklistApm FoumilNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocumento11 pagineSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNessuna valutazione finora

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Documento2 pagineSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNessuna valutazione finora

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocumento2 pagineWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289Nessuna valutazione finora

- Satip P 121 01 Rev 7 MPDocumento7 pagineSatip P 121 01 Rev 7 MPmohamedqcNessuna valutazione finora

- SAIC-K-4038 Rev 7Documento3 pagineSAIC-K-4038 Rev 7shahzadaNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearDocumento2 pagineSaudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearHaleem Ur Rashid BangashNessuna valutazione finora

- Saic-P-3003 Rev 0 PDFDocumento4 pagineSaic-P-3003 Rev 0 PDFHesham HelalNessuna valutazione finora

- QC Notes For Intruments AramcoDocumento4 pagineQC Notes For Intruments AramcoManda Khel Apna DesNessuna valutazione finora

- PIM AgendaDocumento1 paginaPIM Agendagayas416100% (1)

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistZia ur RehmanNessuna valutazione finora

- Schedule QDocumento36 pagineSchedule QPrabu Baskaran100% (1)

- Saudi Aramco Pre-Commissioning Form: Uninterruptible Power Supply SystemDocumento2 pagineSaudi Aramco Pre-Commissioning Form: Uninterruptible Power Supply SystemHaleem Ur Rashid BangashNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento15 pagineSaudi Aramco Inspection Checklistnisha_khanNessuna valutazione finora

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocumento2 pagineSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanNessuna valutazione finora

- Answers To QC QuestionDocumento37 pagineAnswers To QC QuestionDot PidotNessuna valutazione finora

- 00 Saip 10aDocumento1 pagina00 Saip 10amalika_00Nessuna valutazione finora

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocumento2 pagineSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNessuna valutazione finora

- SAIC-P-3007 Rev 7 FinalDocumento20 pagineSAIC-P-3007 Rev 7 FinalEnginerShahzadGhaffarNessuna valutazione finora

- Satip D 001 01Documento11 pagineSatip D 001 01Rijwan Mohammad0% (1)

- SAIC-S-4056 Rev 7Documento3 pagineSAIC-S-4056 Rev 7Eswari AnandNessuna valutazione finora

- Instrumentation Inspection and Quality Control InterviewDocumento3 pagineInstrumentation Inspection and Quality Control InterviewzhangyiliNessuna valutazione finora

- Satip A 004 03Documento3 pagineSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNessuna valutazione finora

- SQAE Velosi Interview PreparationDocumento10 pagineSQAE Velosi Interview PreparationSebastian RajeshNessuna valutazione finora

- 00 Saip 51Documento5 pagine00 Saip 51Rodolius LibaoNessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento10 pagineSaudi Aramco Typical Inspection Plankarthi51289Nessuna valutazione finora

- Saudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201Documento3 pagineSaudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201nadeem shaikhNessuna valutazione finora

- Saep 380 PDFDocumento10 pagineSaep 380 PDFbassamNessuna valutazione finora

- Shaik Yousufuddin (Welding Inspector)Documento3 pagineShaik Yousufuddin (Welding Inspector)Mohamed AdelNessuna valutazione finora

- Itp Forabove Grade and Embedded Conduits Rev. 0Documento6 pagineItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Sa P 070Documento3 pagineSa P 070mahdi_gNessuna valutazione finora

- Saep 119Documento11 pagineSaep 119Demac SaudNessuna valutazione finora

- SATIP-P-104-01 Rev 8 Final LV Cables PDFDocumento2 pagineSATIP-P-104-01 Rev 8 Final LV Cables PDFSabheeh AliNessuna valutazione finora

- Saudi Aramco Test ReportDocumento5 pagineSaudi Aramco Test Reportkarthi51289Nessuna valutazione finora

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingDocumento10 pagineSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento10 pagineSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocumento2 pagineTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocumento17 pagineSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento1 paginaSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento6 pagineSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento13 pagineSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocumento4 pagineSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocumento8 pagineSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocumento4 pagineSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocumento2 pagineSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Documento5 pagineSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocumento1 paginaSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocumento8 pagineSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Nessuna valutazione finora

- AMPSEAL Automotive Plug Assemblies 776268-, 776273-, 770680-, and 776164Documento2 pagineAMPSEAL Automotive Plug Assemblies 776268-, 776273-, 770680-, and 776164Андрей9Nessuna valutazione finora

- Laptop Power SequenceDocumento2 pagineLaptop Power SequenceGabriel Meneses100% (1)

- Cavity Quantum Electrodynamics For Superconducting Electrical Circuits - An Architecture For Quantum ComputationDocumento14 pagineCavity Quantum Electrodynamics For Superconducting Electrical Circuits - An Architecture For Quantum ComputationHuỳnh NguyênNessuna valutazione finora

- Comparative Analysis of Hysteresis and PWM Current Controllers For PMSM Drive.Documento6 pagineComparative Analysis of Hysteresis and PWM Current Controllers For PMSM Drive.Abdalkader2 Alibrahim2Nessuna valutazione finora

- Full Length Test - 60 Qs (60 Mins)Documento6 pagineFull Length Test - 60 Qs (60 Mins)Junaid MushtaqNessuna valutazione finora

- Cell Site DesignDocumento37 pagineCell Site DesignRina Dwi YunitasariNessuna valutazione finora

- High - K Dielectric Materials in MicroelectronicsDocumento31 pagineHigh - K Dielectric Materials in MicroelectronicsAadil ShNessuna valutazione finora

- Module 1 Introduction To ElectronicsDocumento4 pagineModule 1 Introduction To ElectronicsAldrin VillanuevaNessuna valutazione finora

- Huawei Cost OsnDocumento122 pagineHuawei Cost OsnSam AwiNessuna valutazione finora

- Pressure SwitchDocumento2 paginePressure Switchayyaz123Nessuna valutazione finora

- 2022catalog FinalVersionDigital-2Documento72 pagine2022catalog FinalVersionDigital-2Dagoberto Cifuentes RodriguezNessuna valutazione finora

- Frigidaire LTF2940ES1 Tech SheetDocumento6 pagineFrigidaire LTF2940ES1 Tech SheetSamurai Appliance Repair Man100% (2)

- ECD Lab 12 - Darlington840Documento7 pagineECD Lab 12 - Darlington840Syed WasiNessuna valutazione finora

- Hitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyDocumento8 pagineHitachi - Energy - High K Dielectrics For SiC Power MOSFET TechnologyApe DieNessuna valutazione finora

- Multiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryDocumento66 pagineMultiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryAbcNessuna valutazione finora

- Energies 12 01425 PDFDocumento19 pagineEnergies 12 01425 PDFArianit ZeqiriNessuna valutazione finora

- Final Exam 20162017 Sem 1 SolutionDocumento16 pagineFinal Exam 20162017 Sem 1 Solutiongdd ddNessuna valutazione finora

- Ul 94Documento2 pagineUl 94ParagNessuna valutazione finora

- HRC Application 1.6 - Hotel Room Solution - PA-00712Documento4 pagineHRC Application 1.6 - Hotel Room Solution - PA-00712Robson FernandesNessuna valutazione finora

- Thyristors, Triacs, DiacsDocumento5 pagineThyristors, Triacs, DiacsAnonymous n50GmJNessuna valutazione finora

- Errores HitachiDocumento4 pagineErrores HitachiToni Pérez Lago50% (2)

- Cable CalculationDocumento6 pagineCable CalculationparameshvkrNessuna valutazione finora

- .. STDocs Tender TND 088754 172250Documento57 pagine.. STDocs Tender TND 088754 172250Bimal DeyNessuna valutazione finora

- Ap326310 Tc1765bootstraploader v1.0 2002 03Documento32 pagineAp326310 Tc1765bootstraploader v1.0 2002 03Poon Electronic Training CentreNessuna valutazione finora

- Cat 15Documento2 pagineCat 15Gustavo Vargas0% (1)

- 605B Quick StartDocumento6 pagine605B Quick StartNguyen Hoàng HuyNessuna valutazione finora

- Introduction To Electrical and Computer Engineering Lab ManualDocumento124 pagineIntroduction To Electrical and Computer Engineering Lab Manualkstu1112Nessuna valutazione finora

- Info Satelit ParabolaDocumento3 pagineInfo Satelit ParabolaSetya MontanaNessuna valutazione finora

- Stinger GuideDocumento13 pagineStinger GuidejrfjNessuna valutazione finora

- Bread BoardDocumento4 pagineBread BoardSathish BalaNessuna valutazione finora