Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elvacite® 2016 Acrylic Resin: Applications

Caricato da

Paola LopezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elvacite® 2016 Acrylic Resin: Applications

Caricato da

Paola LopezCopyright:

Formati disponibili

TECHNICAL DATA SHEET

Ineos Acrylics • 7275 Goodlett Farms Parkway, Cordova TN 38018-4909

(800) 458-2483 • WWW.INEOSACRYLICS.COM

A R

Elvacite® 2016 Acrylic Resin

Elvacite® 2016 is a low molecular weight methyl methacrylate / n-butyl methacrylate

copolymer. Elvacite® 2016 is useful in clear, translucent or pigmented metal lacquers. It is a

fast dissolving, low viscosity general purpose resin for lacquer and toner use.

Applications

• Clear, translucent or pigmented metal coatings.

• Heat seal lacquers.

• Traffic marking paints.

Physical Properties

Glass Transition Temperature (°C): 50

Molecular Weight: 60,000

Form: Spherical beads

Particle Size (D50): 180-240 microns

Specific Gravity: 1.13

Inherent Viscosity1: 0.23-0.255

Acid Number: 3.5

Moisture (% max): 0.5

Tukon Hardness, Knoop No. 8

Tensile Strength, psi 2,300

Elongation at break (23°C, 50% RH): 2%

Packaging: 300 lb. net, non-returnable fiber drums

1

Inherent viscosity of a solution containing 0.25 g polymer in 50 ml of methylene chloride measured at 20°C using a No. 50 Cannon-

Fenske viscometer.

E2016 6-00.doc Revised 6/00 Page 1 of 4

Solvent Solubility

a

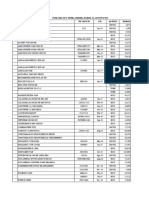

Table I: Solubility of Elvacite® 2016

S=Soluble, C=Cloudy solution, I=Insoluble Table I shows the solubility of Elvacite® 2016 at 20%

Alcohols solids in various solvents.

Methyl Alcohol I

Ethyl Alcohol I

n-propyl alcohol I

Isopropyl alcohol I

Isoamyl alcohol I

Cyclohexanol I

Ethylene glycol I

Glycerol I

Amides

Formamide I

Viscosity

Dimethyl formamide (DMF) S

Elvacite® 2016 is a low molecular weight methyl

Chlorohydrocarbons

Methylene Chloride S methacrylate / n-butyl methacrylate copolymer. Table

Ethylene dichloride - II illustrates typical viscosities of Elvacite® 2016 by

Perchloroethylene -

1,1,1-Trichloroethane S varying both solvent and resin concentration.

Esters

Methyl Formate S

Ethyl acetate S Table II: Elvacite® 2016 Viscosity (cP)

Isopropyl acetate S

n-Butyl acetate S

n-Amyl acetate S Concentration (% Solids)

Butyl lactate S

Propylene glycol monoethyl Solvent 20% 30% 40%

ether acetate S

Methyl amyl acetate S

Toluene 20 50 250

Ethers Methyl Ethyl Ketone 9 30 140

Diethyl Ether S

Diisopropyl ether - Isopropyl Acetate 13 60 750

Tetrahydrofuran (THF) S Cellosolve Solvent 70 1000 >25000

“Cellosolve” Solvent S

Hydrocarbons

Toluene S

Xylene S

n-Hexane I

Cyclohexane I

VM & P Naphtha I

Mineral Spirits

Turpentine

I

I

Resin Compatibility

Ketones Elvacite® 2016 is compatible with the following

Acetone S

Methyl Ethyl Ketone S Elvacite® Resin Grades: 2013, 2014, 2028, 2042, and

Methyl Isobutyl Ketone S 2043. It is also compatible with the other types of

Diisobutyl ketone S

Cyclohexanone S resins, as illustrated in the following table:

Isophorone -

Diacetone Alcohol S

Methyl amyl ketone S

Nitrile

Acetonitrile -

Nitroparaffins

Nitromethane S

Nitroethane -

Vegetable Oils

Castor oil I

Linseed oil (alkali-refined) I

E2016 6-00.doc Revised 6/00 Page 2 of 4

Elvacite / Blending

Form of Blended Resin*

Blending Resin Description Resin Tested Supplier (by solids weight)

Alkyd 75/25 50/50 25/75

Aroplaz 1271 Long linseed drying oil 30% in MEK Spencer Kellog C H H

Aroplaz 1351 Long castor nondrying oil 30% in MEK Spencer Kellog C C C

Chempol 13-1410 Safflower drying oil, acrylate 50% in Xylene Freeman Chemical C C C

modified

Paraplex RG-2 Nondrying oil, sebacic 30% in MEK Rohm & Haas Co. I I I

Plaskon 3105 Short coconut nondrying oil 60% in Xylene Cargill, Inc. --- H H

Cellulosic

Cellulose acetate 39-5- 30% in Acetone or Hercules Inc. I I I

5B MEK

Cellulose Acetate 30% in MEK Eastman Chemical C C C

Butyrate, ½ - sec.

Ethyl Cellulose N-7 30% in MEK Hercules Inc. I I I

Nitrocellulose “RS”, ½- MEK/alcohol Hercules Inc. C C C

sec Isopropyl soln.

Epoxy

Epon 828 100% Resin Shell Chemical Co. C --- C

Epon 1001 30% in MEK Shell Chemical Co. C C C

Elastomers

EMD-504 Polyisobutylene 30% in Toluene Exxon Chemical I I --

Hypalon 30 Clorosulfonated polyethylene 15% in Toluene Dupont Polymers I I ---

Neoprene AC-Soft Polychloroprene 15% in Toluene Dupont Polymers I I ---

Rosin Derivatives

Ester Gum 8L 30% in MEK Hercules Inc. -- H H

Pentalyn 255 Pentaerythritol ester 30% in MEK Hercules Inc. H H H

Pentalyn 830 Pentaerythritol ester 30% in MEK Hercules Inc. H H H

Vinyl Chloride Resins

Bakelite VAGH Copolymer 30% in MEK Union Carbide C C C

Bakelite VMCH Copolymer 30% in MEK Union Carbide C C C

Bakelite VYHH Copolymer 30% in MEK Union Carbide C C C

Bakelite VYNS Copolymer 15% in MEK Union Carbide C C C

Exon 450 Copolymer 15% in MEK Firestone Plastics C C --

Exon 9290 Homopolymer 15% in THF Firestone Plastics C C C

Geon 103 EP Homopolymer 15% in THF B.F. Goodrich C C C

Other Types

Arochem 650 Maleic-modified hard resin 30% in MEK Spencer Kellog C C C

Aroset 4110 Acrylic resin 30% in MEK Spencer Kellog C C C

Dammar 30% in Toluene I I H

DC-840 Silicone resin 60% in Toluene Dow Corning Corp. C C C

Parlon S 10 Chlorinated rubber 30% in MEK Hercules Inc. C C C

Piccoumaron Coumarone-indene resin 30% in MEK Hercules Inc. C C C

Santolite MHP Sulfonamide-formaldehyde 30% in MEK Monsanto Co. C C C

Shellac 30% in Methanol H I I

Super-Bechacite 2000 Permanently fusible phenolic 30% in MEK Reichold Chemicals C C C

Uformite MX-61 Triazine-formaldehyde resin 30% in MEK Rohm & Haas Co. C H I

* 2016 was not tested, but is expected to be similar to 2013.

E2016 6-00.doc Revised 6/00 Page 3 of 4

Plasticizer Compatibility

Elvacite® 2016 is compatible at a 50/50 resin/plasticizer ratio with the following plasticizers:

Santicizer 8 (N-ethyl toluene sulfonamides)

Santicizer 97 (dialkyl adipate)

Santicizer 160 (butyl benzyl phthalate)

Tricresyl phosphate.

Hercoflex 600 (pentaerythritol ester)

Typical Formulations

The following formulation(s) is given as starting points only. The final formulation will be

determined by the coating properties desired.

High Gloss Metal Top Coat (#D2-10)

Ingredients % by Wt

Elvacite® 2016 } 29.18

Xylene } Blend 35.01

Solvent 100 } 8.75

Disperbyk 0.21

Advitrol 240 0.50

Tioxide TR92 17.49

Butyl Benzyl Phthalate 1.27

Xylene 6.06

Solvent 100 1.52

100.00

Closed cup flash point = 24° C

The information and recommendations in this publication are, to the best of our knowledge, reliable. Users should make their own tests to determine the suitability of these products for their own particular purposes.

Ineos Acrylics Inc. MAKES NO WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, other than that the material

conforms to its applicable current Standard Specifications. Statements herein, therefore, should not be construed as representations or warranties. The responsibility of Ineos Acrylics Inc, for claims arising out of

breach of warranty, negligence, strict liability or otherwise is limited to the purchase price of the material. Statements concerning the use of the products or formulations described herein are not to be construed as

recommending the infringement of any patent, and Ineos Acrylics Inc, assumes no liability for infringement arising out of such use.

ELVACITE is a registered trademark of Ineos Acrylics Inc. Ineos Acrylics Inc. is a wholly owned subsidiary of the INEOS Group.

E2016 6-00.doc Revised 6/00 Page 4 of 4

Potrebbero piacerti anche

- 21 - Resins For Road Marking PaintsDocumento4 pagine21 - Resins For Road Marking Paintsraj jangid100% (1)

- TEGODocumento49 pagineTEGOMiguelAlegriaNessuna valutazione finora

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Da EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Nessuna valutazione finora

- Alkyd Resins synthesis-PET PDFDocumento5 pagineAlkyd Resins synthesis-PET PDFDonald_12Nessuna valutazione finora

- 20 - Alkyd Emulsifier - ES 4045 - 2019 EditionDocumento4 pagine20 - Alkyd Emulsifier - ES 4045 - 2019 Editionumar buttNessuna valutazione finora

- Handbook of Vinyl FormulatingDa EverandHandbook of Vinyl FormulatingRichard F GrossmanValutazione: 3 su 5 stelle3/5 (1)

- AkzoNobel Paint Eng Tcm54-18194Documento20 pagineAkzoNobel Paint Eng Tcm54-18194a2009sNessuna valutazione finora

- Recommended Epoxy FormulationsDocumento2 pagineRecommended Epoxy Formulationsuzzy2Nessuna valutazione finora

- EvonikDocumento20 pagineEvonikMohit Singhal0% (1)

- Starting Formulation 1kDocumento1 paginaStarting Formulation 1kForever100% (1)

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDocumento10 pagineAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFraahul_nNessuna valutazione finora

- Li Edaplan Metolat Dispersing TechnologyDocumento15 pagineLi Edaplan Metolat Dispersing TechnologyPulbere NeagraNessuna valutazione finora

- Can Coating Formulations (Sheet 1 To 4)Documento3 pagineCan Coating Formulations (Sheet 1 To 4)No NameNessuna valutazione finora

- 24 391 01 Coatings and Inks Additive Selection GuideDocumento16 pagine24 391 01 Coatings and Inks Additive Selection GuideLong An DoNessuna valutazione finora

- Jo GradeDocumento40 pagineJo GradeEvonne TanNessuna valutazione finora

- Tds Eterac 73626-S-70 (En)Documento1 paginaTds Eterac 73626-S-70 (En)Liliana Higuera NítolaNessuna valutazione finora

- Jan 2010 Oxylink Updated Sales Presentation PDFDocumento44 pagineJan 2010 Oxylink Updated Sales Presentation PDFdainguyenlamNessuna valutazione finora

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDocumento2 pagineSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraNessuna valutazione finora

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDocumento24 pagineUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunNessuna valutazione finora

- ExtendersDocumento33 pagineExtenderssbttbsNessuna valutazione finora

- Additive Coatings and Inks Ver 2.1 2021Documento8 pagineAdditive Coatings and Inks Ver 2.1 2021nano100% (1)

- Acrysol rm-8w 3Documento4 pagineAcrysol rm-8w 3Forever0% (1)

- Adekanol Uh-420: Thickener Rheology ModifiersDocumento6 pagineAdekanol Uh-420: Thickener Rheology ModifierszxcvxcvxzcvNessuna valutazione finora

- Der 331 PDFDocumento5 pagineDer 331 PDFTamer BidakNessuna valutazione finora

- Eastman Coatings: Formulating Solutions: Meeting VOC Regulations With CoalescentsDocumento4 pagineEastman Coatings: Formulating Solutions: Meeting VOC Regulations With Coalescentsvijay662Nessuna valutazione finora

- Epoxy 2kDocumento3 pagineEpoxy 2kMitra YuningsihNessuna valutazione finora

- Surfactant AnalysisDocumento5 pagineSurfactant Analysisjuli_radNessuna valutazione finora

- Pergut EDocumento17 paginePergut ECesar MartinezNessuna valutazione finora

- OMG Americas - Additives BrochureDocumento8 pagineOMG Americas - Additives BrochureUsama AwadNessuna valutazione finora

- RosinDocumento42 pagineRosinVingiu Katre100% (1)

- Alkyd Resin 2Documento5 pagineAlkyd Resin 2Pace AjjaNessuna valutazione finora

- Rhodoline Ote 500Documento2 pagineRhodoline Ote 500ReginaldojoaquimNessuna valutazione finora

- Crop Solutions BrochureDocumento30 pagineCrop Solutions BrochureThe PopeNessuna valutazione finora

- 8 Interior and Exterior Emulsion PaintsDocumento28 pagine8 Interior and Exterior Emulsion PaintsAPEX SON100% (1)

- Long Durability Exterior CoatingDocumento1 paginaLong Durability Exterior CoatingAmit BholaNessuna valutazione finora

- Paints and CoatingsDocumento10 paginePaints and CoatingsJesus Erazo100% (1)

- FoamStar ST 2412 August 2018 R3 ED2Documento2 pagineFoamStar ST 2412 August 2018 R3 ED2APEX SONNessuna valutazione finora

- Antifoam Solutions Brochure InddDocumento0 pagineAntifoam Solutions Brochure Inddhisham_00Nessuna valutazione finora

- Equivalent Weight: Technical Center Guide To Urethane CalculationsDocumento4 pagineEquivalent Weight: Technical Center Guide To Urethane CalculationsAbdullah SahlyNessuna valutazione finora

- Evonik-Ancamide 221-X70 - EUDocumento5 pagineEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- Multifunctional Additives: For Paints and CoatingsDocumento2 pagineMultifunctional Additives: For Paints and Coatingspandep22Nessuna valutazione finora

- Soyol Polyol FormulationsDocumento3 pagineSoyol Polyol FormulationsurethanNessuna valutazione finora

- NeoResin DTM Presentation 9-01Documento22 pagineNeoResin DTM Presentation 9-01idreesgisNessuna valutazione finora

- Croda How To LoVOCoatDocumento6 pagineCroda How To LoVOCoatkarla100% (1)

- Analysis of Alkyd ResinsDocumento22 pagineAnalysis of Alkyd ResinsHimanshu PanchalNessuna valutazione finora

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDocumento4 paginePaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriNessuna valutazione finora

- Unsaturated Polyester ResinDocumento2 pagineUnsaturated Polyester Resingunawan refiadi0% (1)

- Catalogo General Clariant CerasDocumento20 pagineCatalogo General Clariant CerasCarlos CardenasNessuna valutazione finora

- Emulsion Polymerization MachanismDocumento13 pagineEmulsion Polymerization MachanismLuan GabrielNessuna valutazione finora

- Epoxy Curing Agents - Americas PDFDocumento74 pagineEpoxy Curing Agents - Americas PDFMuhammad FahadNessuna valutazione finora

- LUBRIZOL General BrochureDocumento20 pagineLUBRIZOL General BrochureMuhammad Ali100% (1)

- Epoxy Resins: Manufacturing Process of With FormulationDocumento48 pagineEpoxy Resins: Manufacturing Process of With FormulationMuhammad Shafiq SaadiqNessuna valutazione finora

- Care Chemicals & Formulators. Luwax A Granules Luwax A Powder. Technical InformationDocumento10 pagineCare Chemicals & Formulators. Luwax A Granules Luwax A Powder. Technical InformationCatalina Isidora Molina OlivaresNessuna valutazione finora

- Cong Thuc SonDocumento23 pagineCong Thuc Sonvanhung68Nessuna valutazione finora

- Elvacite Brochure 06 02Documento40 pagineElvacite Brochure 06 02manox007Nessuna valutazione finora

- Tego® Addbond - For Maximum AdhesionDocumento8 pagineTego® Addbond - For Maximum AdhesionDanail AkuzovNessuna valutazione finora

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocumento32 pagineOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNessuna valutazione finora

- HELIBAR Tecnología para Extrusoras de Alta Productividad y Desempeño - Philipp ThielekeDocumento41 pagineHELIBAR Tecnología para Extrusoras de Alta Productividad y Desempeño - Philipp ThielekePaola LopezNessuna valutazione finora

- Evolution of Extrusion Tecnologies - María Del Pilar Noriega E. - ICIPC ActualizadaDocumento36 pagineEvolution of Extrusion Tecnologies - María Del Pilar Noriega E. - ICIPC ActualizadaPaola LopezNessuna valutazione finora

- Dr. Monika Gneuss - ICIPC2017 ActualizadaDocumento33 pagineDr. Monika Gneuss - ICIPC2017 ActualizadaPaola LopezNessuna valutazione finora

- Dr. Monika Gneuss - ICIPC2017Documento32 pagineDr. Monika Gneuss - ICIPC2017Paola LopezNessuna valutazione finora

- 1834-Solplus K240Documento2 pagine1834-Solplus K240Paola LopezNessuna valutazione finora

- Rules The North KoreaDocumento1 paginaRules The North KoreaPaola LopezNessuna valutazione finora

- Rules The North KoreaDocumento1 paginaRules The North KoreaPaola LopezNessuna valutazione finora

- Heliogen Green K 8730 TdsDocumento6 pagineHeliogen Green K 8730 TdsPaola LopezNessuna valutazione finora

- 2020 01 22 PDFDocumento3 pagine2020 01 22 PDFMirza RehmanNessuna valutazione finora

- Study Guide Unit 2.1 - Dna, Rna, & ProteinsDocumento31 pagineStudy Guide Unit 2.1 - Dna, Rna, & ProteinsGraceNessuna valutazione finora

- 28 CyclopropanationDocumento11 pagine28 CyclopropanationRajesh TammanaNessuna valutazione finora

- Fix's BrowDocumento438 pagineFix's BrowFransNessuna valutazione finora

- Alkaloids Derived From Anthranilic Acid and HistidineDocumento2 pagineAlkaloids Derived From Anthranilic Acid and HistidineGiselle Clarisse D. CelizNessuna valutazione finora

- Problem - Chapter18 - 2Documento19 pagineProblem - Chapter18 - 2張湧浩Nessuna valutazione finora

- 11 Chemistry Notes Ch13 HydrocarbonsDocumento2 pagine11 Chemistry Notes Ch13 HydrocarbonsAdarsh GautamNessuna valutazione finora

- EED 5 Unit 2Documento15 pagineEED 5 Unit 2Lara Mariz FragataNessuna valutazione finora

- USFDA Approvals by CompanyDocumento136 pagineUSFDA Approvals by CompanyAsthaNessuna valutazione finora

- Atropine Bio SynthesisDocumento3 pagineAtropine Bio SynthesisManjusha KondepudiNessuna valutazione finora

- Biochemistry Answer Key-RED PACOPDocumento31 pagineBiochemistry Answer Key-RED PACOPArk Olfato ParojinogNessuna valutazione finora

- Chapter 05: Oral Medications Mulholland: The Nurse, The Math, The Meds, 3rd EditionDocumento14 pagineChapter 05: Oral Medications Mulholland: The Nurse, The Math, The Meds, 3rd EditionadenNessuna valutazione finora

- I. Objectives: Lesson Plan in Grade 9Documento3 pagineI. Objectives: Lesson Plan in Grade 9Maria Karina Ferreras100% (1)

- List Stok MMF 29 Agustus 2022Documento8 pagineList Stok MMF 29 Agustus 2022Inna TrissNessuna valutazione finora

- (Tomon) Efek Antioksidan Pada Teh Hijau Terhadap Kadar Kolesterol Darah - KatekinDocumento9 pagine(Tomon) Efek Antioksidan Pada Teh Hijau Terhadap Kadar Kolesterol Darah - KatekinPutri PutriNessuna valutazione finora

- Called Saccharides Most Abundant Molecules On Earth Essential Component of All Living OrganismsDocumento32 pagineCalled Saccharides Most Abundant Molecules On Earth Essential Component of All Living OrganismsShyla ManguiatNessuna valutazione finora

- An Efficient Procedure For The Demethylation of Aryl-Methyl Ethers in Optically Pure Unusual Amino Acids PDFDocumento4 pagineAn Efficient Procedure For The Demethylation of Aryl-Methyl Ethers in Optically Pure Unusual Amino Acids PDFFelipe MonteroNessuna valutazione finora

- Section2 Disaccharides PDFDocumento11 pagineSection2 Disaccharides PDFSHNessuna valutazione finora

- NuezateAccords PDFDocumento2 pagineNuezateAccords PDFWu WeiNessuna valutazione finora

- Chapter I - Introduction To CumeneDocumento4 pagineChapter I - Introduction To CumeneQilah Kamarudin100% (1)

- Chapter 14 Test BankDocumento20 pagineChapter 14 Test BankquynhphamftNessuna valutazione finora

- PolyDocumento24 paginePolysavisuNessuna valutazione finora

- Catálogo DescripciónDocumento7 pagineCatálogo DescripciónAlexis RuanoNessuna valutazione finora

- Enzymes ShortDocumento83 pagineEnzymes ShortWaleed ShamsiNessuna valutazione finora

- Sơ Đ T NG Quát Chu Trình KrebsDocumento3 pagineSơ Đ T NG Quát Chu Trình KrebsNghĩa VõNessuna valutazione finora

- Biochem 1 NotesDocumento141 pagineBiochem 1 NotesJyNadarilNessuna valutazione finora

- OFERTA COMPLETA Alfabetica 2019 Vet+petDocumento311 pagineOFERTA COMPLETA Alfabetica 2019 Vet+petFlorin SilaghiNessuna valutazione finora

- Chapter 12 Aldehyde & KetonesDocumento10 pagineChapter 12 Aldehyde & KetonesForzen flamesNessuna valutazione finora

- Acidity of Tea Leaves: Chemistry Investigatory ProjectDocumento17 pagineAcidity of Tea Leaves: Chemistry Investigatory ProjectTanya SinghNessuna valutazione finora

- Colour Reaction of Amino AcidsDocumento27 pagineColour Reaction of Amino AcidsJacqueline Ann71% (7)