Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060

Caricato da

satnamDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060

Caricato da

satnamCopyright:

Formati disponibili

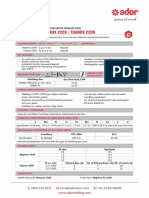

AUTOMIG NiCu-7 /

GMAW/GTAW

TIGFIL NiCu-7 NICKEL ALLOYS

MONEL SOLID WIRE FOR NICKEL-COPPER ALLOY WELDING

CLASSIFICATION : EN ISO 18274 AWS A/SFA 5.14 APPROVALS :

SNi 4060 ERNiCu-7 -

KEY FEATURES :

• Monel solid wire • Low iron in the deposit exhibit maximum

• Typical 65Ni/30Cu/3Mn/2Ti alloy corrosion resistance

• Easily machinable deposit in as welded and • Radiographic weld quality

stress relieved condition

GMAW: DCEP

WELDING POSITION :

GTAW: DCEN

Shielding Gas Gas Flow Rate, LPM Stickout, mm

GMAW: Ar or Ar/He 15-22 10-20

GTAW: Ar 10-15 -

TYPICAL APPLICATIONS :

• Welding Monel and NiCu alloys to itself, to • Welding of ASTM B127/163/164/165

mild and low alloyed steels • Heat exchanger, Piping, Vessels, Salt

• Overlaying on steel to obtain a corrosion purification

resistant surface • Food, Pumps and Valves manufacturing units

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Fe S P

Specification 0.15 max 4.0 max 2.5 max 0.015 max 0.02 max

Si Cu Al Ti Ni

Specification 1.25 max Bal. 1.25 max 1.5-3.0 62.0-69.0

MECHANICAL PROPERTIES OF ALL WELD METAL :

Condition UTS, MPa EL%

Typical As Welded 480 32

Mechanical properties will vary with the type of shielding gas used.

PACKING DATA :

Ø, mm Kg/Spool

Automig NiCu-7 1.2 12.5

1.6 12.5

Ø x L, mm Primary Box, Kg No. of Primary Boxes Net Wt. of Carton, Kg

2.0 x 1000 5 4 20

Tigfil NiCu-7

2.4 x 1000 5 4 20

3.2 x 1000 5 4 20

EQUIVALENT :

SMAW Electrode: Supermonel

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

51

Potrebbero piacerti anche

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Documento1 paginaAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 24Documento1 paginaCWC-BookletF1 24Jagannath SahuNessuna valutazione finora

- Automig 70S A1 - Tigfil 70S A1Documento1 paginaAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- Automig 80s G Tigfil 80s GDocumento1 paginaAutomig 80s G Tigfil 80s Gvijaysvm999Nessuna valutazione finora

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Documento1 paginaAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Documento1 paginaAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Documento1 paginaAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocumento1 paginaAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocumento1 paginaMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- GBTDocumento1 paginaGBTRaviTeja BhamidiNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- CWC-BookletF1 36 PDFDocumento1 paginaCWC-BookletF1 36 PDFJagannath SahuNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocumento1 paginaMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNessuna valutazione finora

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 paginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNessuna valutazione finora

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Automig FC 71 T1Documento1 paginaAutomig FC 71 T1Sushil BhansaliNessuna valutazione finora

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocumento1 paginaMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Supabase X Plus 2Documento1 paginaSupabase X Plus 2Michael FortunaNessuna valutazione finora

- Automig 4043 - Tigfil 4043Documento1 paginaAutomig 4043 - Tigfil 4043Muhammad Whisnu NugrahaNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Miginox 307: Classification: en Iso 14343-ADocumento1 paginaMiginox 307: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Bronze C86300 SpecificationsDocumento2 pagineBronze C86300 SpecificationsDoss MartinNessuna valutazione finora

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 paginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- Primacore MW 71Documento2 paginePrimacore MW 71rjan7peNessuna valutazione finora

- Tigfil Cuni: Classification: ApprovalsDocumento1 paginaTigfil Cuni: Classification: ApprovalssatnamNessuna valutazione finora

- ARCAP - Grades and PropertiesDocumento7 pagineARCAP - Grades and PropertiesEminent RishNessuna valutazione finora

- X Bond: Welding Electrode For Structural Welding ApplicationDocumento1 paginaX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNessuna valutazione finora

- CWC-BookletF1 29 PDFDocumento1 paginaCWC-BookletF1 29 PDFJagannath SahuNessuna valutazione finora

- POLYTUNG-NICRBWC DatasheetDocumento1 paginaPOLYTUNG-NICRBWC Datasheetrajeevkv4Nessuna valutazione finora

- T700S Technical Data Sheet PDFDocumento2 pagineT700S Technical Data Sheet PDFjairoNessuna valutazione finora

- Merit S-G: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNessuna valutazione finora

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocumento1 paginaWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78Nessuna valutazione finora

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Documento1 paginaWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78Nessuna valutazione finora

- Tiginox 308H: Classification: ApprovalsDocumento1 paginaTiginox 308H: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNessuna valutazione finora

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Automig 70S-61Documento1 paginaAutomig 70S-61tarun kaushalNessuna valutazione finora

- Stainless SteelDocumento1 paginaStainless SteelSadashiva sahoo100% (1)

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- PDS - Bohler N ER 70 S-2 NACE PDFDocumento1 paginaPDS - Bohler N ER 70 S-2 NACE PDFwesley59Nessuna valutazione finora

- Aluminium-Welding: Course Book GBDocumento58 pagineAluminium-Welding: Course Book GBlilux519Nessuna valutazione finora

- Sheet Coil & Plate Alloy 6061Documento2 pagineSheet Coil & Plate Alloy 6061Sarat SrinivasNessuna valutazione finora

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDa EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantValutazione: 3.5 su 5 stelle3.5/5 (3)

- Tigfil Cuni: Classification: ApprovalsDocumento1 paginaTigfil Cuni: Classification: ApprovalssatnamNessuna valutazione finora

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Documento1 paginaAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Documento1 paginaAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNessuna valutazione finora

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 paginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 59Documento1 paginaCWC-BookletF1 59satnamNessuna valutazione finora

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocumento1 paginaAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 paginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 2Documento1 paginaCWC-BookletF1 2satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 5Documento1 paginaCWC-BookletF1 5satnamNessuna valutazione finora

- CWC-BookletF1 3Documento1 paginaCWC-BookletF1 3satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- CWC-BookletF1 4Documento1 paginaCWC-BookletF1 4satnamNessuna valutazione finora

- CWC-BookletF1 1Documento1 paginaCWC-BookletF1 1satnamNessuna valutazione finora

- MIG MAG - Series-Brochure KOLARCDocumento16 pagineMIG MAG - Series-Brochure KOLARCDarko NikolovskiNessuna valutazione finora

- 165 Gmaw Zug Asme (Imam Mustofa 3g) WPQDocumento4 pagine165 Gmaw Zug Asme (Imam Mustofa 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- The Australian Welding Guide PDFDocumento220 pagineThe Australian Welding Guide PDFThành Nguyễn XuânNessuna valutazione finora

- Migmatic 271/273/333/383: June 2005 Effective With Serial Number 210 344Documento44 pagineMigmatic 271/273/333/383: June 2005 Effective With Serial Number 210 344fuclaNessuna valutazione finora

- MIG Flow Rate ChartDocumento4 pagineMIG Flow Rate ChartdhanendrapardhiNessuna valutazione finora

- Welding Processes: EN358 - Ship StructuresDocumento27 pagineWelding Processes: EN358 - Ship Structuressuri345Nessuna valutazione finora

- T-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Documento110 pagineT-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Akansha SharmaNessuna valutazione finora

- TransTig 1750 Puls PDFDocumento88 pagineTransTig 1750 Puls PDFDallas WilsonNessuna valutazione finora

- UTP Chemical GBDocumento12 pagineUTP Chemical GBajaychackotecsoNessuna valutazione finora

- Welding TechnologyDocumento77 pagineWelding TechnologySrinivasadarshan A M100% (1)

- IP23 - Procedure For Welder Performance QualificationDocumento25 pagineIP23 - Procedure For Welder Performance QualificationsajiNessuna valutazione finora

- Design of Welded Connections - Lincoln ElectricDocumento234 pagineDesign of Welded Connections - Lincoln Electrickyletgerber100% (3)

- Welding 3&4 REV21Documento40 pagineWelding 3&4 REV21Muhd Shabeeb ANessuna valutazione finora

- WPS AWS D1.1 WeldNote MetricDocumento1 paginaWPS AWS D1.1 WeldNote MetricGoutham RathinamNessuna valutazione finora

- ELECTREX General CatalogueDocumento52 pagineELECTREX General CatalogueO TottaNessuna valutazione finora

- Steel Penstocks and Tunnel Liners PDFDocumento114 pagineSteel Penstocks and Tunnel Liners PDFFrancisco Jose Camacho Amaya100% (1)

- INDUSTRIAL ELECTRONICS - EdgeDocumento212 pagineINDUSTRIAL ELECTRONICS - EdgeReynald John PastranaNessuna valutazione finora

- Fundamentals of WeldingsDocumento96 pagineFundamentals of WeldingsBurag HamparyanNessuna valutazione finora

- WeldingDocumento556 pagineWeldingluisbmwm691% (11)

- Welding Terms & DefinitionsDocumento42 pagineWelding Terms & DefinitionsDamotharan S100% (1)

- Metal-Cored: Gmaw-CDocumento16 pagineMetal-Cored: Gmaw-CChandrajeet ShelkeNessuna valutazione finora

- CatalogDocumento44 pagineCataloglangtu2011Nessuna valutazione finora

- Chapter 4. Welding Welding Safety HazardsDocumento52 pagineChapter 4. Welding Welding Safety HazardsKefene GurmessaNessuna valutazione finora

- Industrial Training Report PDFDocumento71 pagineIndustrial Training Report PDFNitin KumarNessuna valutazione finora

- Fixed AutomationDocumento3 pagineFixed AutomationAnan AghbarNessuna valutazione finora

- Question and AnswerDocumento32 pagineQuestion and AnswervasuNessuna valutazione finora

- Jetline BrochureDocumento8 pagineJetline BrochureKauane FeliniNessuna valutazione finora

- MAQUINA DE SOLDAR Traiblazer Pro 350 D PDFDocumento84 pagineMAQUINA DE SOLDAR Traiblazer Pro 350 D PDFVictor HerreraNessuna valutazione finora

- Welding 10Documento64 pagineWelding 10Ammar Izzy0% (1)

- KEI-PL-2102T 0 - Flowline Carbon Steel SpecDocumento41 pagineKEI-PL-2102T 0 - Flowline Carbon Steel Specajaykg100% (1)