Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

10 01 Breather Filters GB

Caricato da

osueng0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

324 visualizzazioni8 pagineCombined air breather and filler filters (TLF, EF, EFK, FEF, FES, BE) Low pressure drop Special high efficient filter media, also for water absorbing air flow up to 3500 m3 / h connection up to DN 250 Quality assured!

Descrizione originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCombined air breather and filler filters (TLF, EF, EFK, FEF, FES, BE) Low pressure drop Special high efficient filter media, also for water absorbing air flow up to 3500 m3 / h connection up to DN 250 Quality assured!

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

324 visualizzazioni8 pagine10 01 Breather Filters GB

Caricato da

osuengCombined air breather and filler filters (TLF, EF, EFK, FEF, FES, BE) Low pressure drop Special high efficient filter media, also for water absorbing air flow up to 3500 m3 / h connection up to DN 250 Quality assured!

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

Ordering ® Installation, Starting and Maintenance ®

Breather Filters Dimensions

Information Filter Assembly TLF I..., TLF II...,TLF III...,

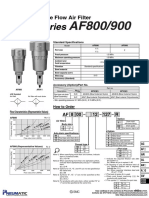

Selection of filter size: BF 15 S 130 – F 0 0

Filter Installation

using the computer program

"EPE - FILTERSELECT" or Industrial Filters · Accumulators Flange filter assembly at mounting device or in reservoir opening. Industrial Filters · Accumulators BF...,BE...,EF...,EFK...

performance characteristics Seal Kit D BF 15 S 130 – F 0

in this brochure. BF 8-32 BFS 7… /BFS 20… BFV 20

Special designs Starting

available on request. Switch on system pump and start system. Pay attention to flow noise

at breather filter. If flow noise can be heard, check size selection in

accordance to air flow rate (Initial flow resistance < 20 mbar).

Filter Type Nominal Size Filtration Grade Seal Material Add. Info.

BF = Breather filter 8; 15; 20; 25; 32 S 130 0 = standard 0 = without

Maintenance

BFV = Breather with 5 = silicon free BE, B7SL45/21... : If a vacuum or overpressure of 0,02 bar is displayed,

20 S 130

Bypass Valve Q = dip stick BF, EF the spin on filter 80.45/21 needs to be replaced. 10

BFS = Breather with 7 and EFK only All other breather filters do not have any maintenance indicators.

20 P5 P10 P25

Filter Element F = Fibre (standard) Z = inspection

FEF = Breather and 0 certificate

We therefore recommend to check or to replace breather filters in

1 S10 S20 S40 regularly periods according to following table:

Filler Filter

EF = Breather and 1-25 0 = without

Filler Filter 2-32

3-40 filter application environmental service interval

4-50 G 130

5-65 conditions

EFK = Filler Filter 6-80 P = Buna N average dust

concentration

Dimensions general mechanical

engineering

9 - 25 mg/m3 4000 h

Size Weight in kg A B C D E F G SW NW

BF 81 0,05 55 10 20 ø 30 9 55 G 1/4 19 9 heavy industry 50 - 80 mg/m3 3000 h

BF 15 0,1 105 25 ø 50 12 105 G 1/2 27 13 mobile hydraulics 30 - 100 mg/m3 3000 h

BF 20 0,15 140

12

26 13 140 G 3/4 35 18 EF 1-6 EFK 1-6 FEF 0 and FEF 1

ø 60

BF 25 0,2 175 27 15 175 G1 41 23

16

BF 32 0,3 225 35 ø 80 17 225 G 1 1/4 55 32

BFS 70 0,03 11 41 ø 46 6 G 1/4 19 7

Filter Element Service

BFS 20 57 ø 81 15

0,3 12 G 3/4 32 18 TLF:

BFV 20 54 ø 77 14

open cover (Part 1) by unscrewing wing nut (Part 2).

EF 100 36 ø 60

0,4 107 17 ø 28 G1 46 25 Replace (H..SL, P and VS...) or clean (G...material) filter element in the

EFK 10 37 ø 38

case of visual contamination.

EF 200 39 17 ø 67

0,5 131 ø 34 G 1 1/4 55 32 Insert filter element (Part 4) in filter housing and refit cover while

EFK 20 40 19 ø 47

tighten wing nut hand screwed.

EF 300 44 18 ø 75

0,7 155 ø 42 G 1 1/2 60 40

EFK 30 41 19 ø 54

BF, BS, BE, B 7SL... :

EF 400 48 18 ø 93

0,8 187 ø 53 G2 75 50 unscrew spin-on filter (Part 1) and refit new one with seal (Part 2)

EFK 40 46 22 ø 66

hand screwed.

EF 500 58 20 ø 120

1,4 218 ø 67 G 2 1/2 90 65

EFK 50 51 24 ø 83

BF 8-32, BFS, BFV... :

EF 600

1,6 256

69 22 ø 140

ø 82 G3 105 80 unscrew filter, replace completely and screw on again using a new Filters for tank mounting

EFK 60 55 26 ø 96

fibre seal (Part 10).

FEF 00 0,17 62 48 ø 50 ø 45 ø 28

FEF 10 0,23 98 54 ø 83 ø 76 ø 49

Efficient filtration of air

EF... :

unscrew cover (Part 1)and replace filter disc (Part 5).

Air breather filters with

Spare Parts EFK... : changeable spin-on filters

hole pattern FEF 0 hole pattern FEF 1

BF 8-32 EF 1 EFK 1 EF 2 EFK 2 EF 3 EFK 3 EF 4 EFK 4 EF 5 EFK 5 EF 6 EFK 6 FEF 0 FEF 1

Size BFS 7, BFS 20 unscrew cover (Part 1) and check strainer (Part 4) for contamination, (BF and BE) lockable design on request

BFV 20 clean if necessary, check seal (Part 9) for damage and refit cover.

Part Qty. Designation Material Part No.

1 1 Cover Various please indicate ordering information "Filter Assembly"

Combined air breather and filler

FEF... : Air flow up to 3500 m³/h

2 1 Flange Steel please indicate ordering information "Filter Assembly" open cover (Part 1) , release from security chain and replace, close

filters (TLF, EF, EFK, FEF, FES, BE)

3 1 Filler nozzle Aluminium 3650 3658 3659 3660 3661 3662 security chain.

Connection up to DN 250

4 1 Filler strainer Various 3651 3663 3664 3665 3666 3667 5779 5767 Flange mounted filters

5 1 Filter plate Sika-B 200 5635 5636 5637 5638 5639 5640 Check filler filters during maintenance for contamination Quality and Standardisation

6 1 Locking ring Spring steel 5641 5642 5643 5644 5645 5646 K. & H. Eppensteiner GmbH & Co. KG The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within

Hardtwaldstraße 43 · D-68775 Ketsch/Rh.

and clean if necessary. Low pressure drop

7 3 Oval head screw 4.8 5783 the guidelines of a certified quality management system according to DIN EN ISO 9001.

Postfach 1120 · D-68768 Ketsch/Rh.

8 6 Socket head cap screw 4.8 5770 The calculation of strength and the filter tests are done in compliance to actual pressure vessel regulations and

Telefon: 0 62 02 / 6 03-0

9 1 Seal Buna N

Telefax: 0 62 02 / 6 03-199 Special high efficient filter media, national & international standards.

10 1 Seal Fibre please indicate ordering information "Seal Kit" A filter inspection by accredited certification bodies

E-Mail: Eppensteiner@compuserve.com also for water absorbing Quality assured!

11 1 Seal Fibre (e.g. TÜV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc.) is possible on request.

Internet: www.Eppensteiner.de Technical modifications reserved! 10/01/10.99/6000

Filler nozzle and filler strainer only available as unit

Ordering Filter Type Magnet Maintenance Indicator Connection Material

Breather Filters Performance Characteristics Ordering Filter Type Magnet Maintenance Indicator Connection Material Dimensions TLF I... TLF II...

BF 7 SL = Breather Filter 0 = without 0= without 00= standard 0 = standard

Information with flange A= pressure gauge M 010

Air flow characteristics

Test temperature: 20°C Information

TLF... = reservoir breather

filter, flange mountable

0 = without 0 =without 00= standard 0 = standard

Selection of filter size: BS 7 SL = Breather with TLF 0... = reservoir breather

welded hexagon

only for B 7 SL and BE 7 SL Connection for TLF0..., TLF..., BF..., BFS..., BFV... Selection of filter size: filter, flange mountable

using the computer program B 7 SL and

"EPE - FILTERSELECT" or

nipple

BE 7 SL = Breather with For technical data see our BE 7 SL = with EF..., EFK..., FEF... using the computer program TLF I... =

with filler strainer

reservoir breather

performance characteristics Filler Filter brochure "Maintenance Indicator" welded nipple BS 7SL..., BE 7 SL..., B 7 SL... "EPE - FILTERSELECT" or filter with female

thread, abbr. DIN

in this brochure. B 7 SL = Breather without

Operating temperature performance characteristics connection

Filler Filter

Special designs in this brochure. TLF II... = reservoir breather

available on request. -20°C to +100°C filter with male thread

connection

Filter Assembly BF 7 SL 90 P 10 – S 00 – 0 0 A – 00 P 0 0 Special designs TLF III... = reservoir breather

Application available on request. filter wit male thread

connection, abbr. DIN

Seal Kit D BF 7 SL 90 H10SL – A – 00 P 0 Filtration and dehumidifying of intake air for flange and filler strainer

industrial systems.

Filter Assembly TLF III 7 - 125 P 10 – S 00 – 0 0 0 – 00 P 0 0

Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional

Pressure Information Design TLF III...

Type: nominal filtration grade in µm 0... = standard adhesive 0 = without P= 0 – 00 P 0

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60

Maximum T = 100°C Buna N 0 = without TLF...: filter housing for breathing and ventilation Seal Kit* D TLF III 7 - 125 H10SL –

BF 7 SL 45/21 P = paper, not cleanable allowable 5 = silicon free with changeable filter element inside. Filter

90 pressure drop E... = special adhesive E = vent valve

P5 P10 P25

across the Z = inspection

elements H...SL up to 1µm filtration grade with

Filter 130 absolute filtration grade (ISO4572) in µm

T = 160°C

glass-fibre filter media, water absorbing filter Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional Design with filler nozzle

filter element certificate

Element BS 7 SL 45/21 H...SL = micro glass-fibre, not cleanable TLF I, II, III 1-25 TLF nominal filtration grade in µm Pressure Information and filler strainer

90 H1SL H3SL H6SL H10SL media AS optional. Types: I with female thread or 2-32 0... = standard adhesive 0 = without 0=

Type: S = standard 2-32 TLF 0 G = stainless steel wire mesh, cleanable Maximum T = 80°C without 0 = without

130 H20SL

5 = silicon free DIN flange ( for size TLF I 8-20), II with male 3-40 G10 G25 G40 G60 G80 G100

AS = micro glass-fibre, water

TLF I, III 7-125 allowable P= 5 = silicon free

BE 7 SL 45/21 absorbing, not cleanable ...0 = standard material Z = inspection thread, III with male thread (with flange for size 4-50 VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60 pressure drop Buna N E = vent valve

80. B 7 SL 45/21 AS1 AS3 AS6 AS10 AS20 certificate

TLF III 7-125) and filler filter(130 µm strainer). 5-65

P = paper, not cleanable across the Z = inspection

TLF I 8-250

Type TLF 0 with 500 µm synthetic strainer. 6-80 P5 P10 P25 filter element certificate

Filter- Filter Element Size absolute filtration grade(ISO4572)in µm S = standard

BF, BFS, BFV...: compact housing for breathing Element Nominal

Size

Element Nominal Element

Size Size Size

H...SL = micro glass-fibre, not cleanable 5 = silicon free

and ventilation with integrated filter media (BF ) H1SL H3SL H6SL H10SL

Filter Element 80. 90 P 10 – S 00 – 0 – P Type: 1-25 002 6-80 006 H20SL ...0 = standard material C = silicagel

or pleated filter element made out of paper ( BFS, 2-32

AS = micro glass-fibre, water ...Z = zinc free Z = inspection Design with filler nozzle

3-40 7-125 007 certificate

BFV ). Design with a dip stick possible. 7. 004

absorbing, not cleanable

4-50

BE 7 SL 45/21, B 7 SL 45/21 BS 7 SL 45/21, BF 7 SL 45/21, 8-250 008 AS1 AS3 AS6 AS10 AS20

Bypass valves 0,1 bar for in and outflowing air 5-65

BS 7 SL 90 and 130 BF 7 SL 90 and 130 for type BFV.

Size Weight A B C D E F G H J K SW

in kg

EF...: 130 µm filler strainer with screwed on Filter Element 7. 007 P 10 – S 00 – 0 – P TLF I 1-25 0,5 G1 53

breather cap and interior sintered bronze plate. ø 102 24 ø 92 43

TLFI 2-32 0,6 G 1 1/4 63

Dimensions TLF I 3-40 2,1 G 1 1/2

EFK...: 130 µm filler strainer with screwed cap,

without breather.

TLF 02-32 TLF 2-32 TLF I 7-125 TLF III 7-125 TLF I 8-250 TLFI 4-50 2,1 ø 177 46 ø 162 G2 98 88

TLFI 5-65 1,6 G 2 1/2

Manometer TLFI 6-80 1,9 ø 210 45 ø 190 G3 88 78

M 010 FEF..: combination out of a flangeable filler filter TLFII 1-25 0,6 G1 53 46

(0 - 6 bar) ( 500 µm strainer ) and a breather cap including TLFII 2-32 0,7

ø 102 24 ø 92 17

G 1 1/4 63

43 6

55

a 40µm foamed material. TLFII 3-40 2,3 G 1 1/2 60

The breather cap can be removed through a TLFII 4-50 2,3 ø 177 46 ø 162 18 G2 98 88

7

75

bayonet joint and is secured with a chain. TLFII 5-65 2,0 20 G 2 1/2 8 90

TLFII 6-80 2,3 ø 210 45 ø 190 22 G3 78 78 9 105

Dimensions BF 7 SL...:, BS 7 SL...: breather filter with a spin TLFIII 1-25 0,7 ø 27 101 G1 53 46

A B D E F G H on filter and pleated filter element with filter ø 102 24 ø 92 17 43 6

Size Weight C TLFIII 2-32 0,8 ø 36 123 G 11/4 63 55

in kg paper P. Design with flange connection ( BF 7 TLFIII 3-40 2,5 ø 42 147 G 1 1/2 60

BF 7 SL 45/21 0,8 191 SL...) or female thread (BS 7 SL ...). 18 7

146 ø 60 ø 92 7 - G¾ - TLFIII 4-50 2,5 ø 177 46 ø 162 ø 52,5 177 G2 98 88 75

BF 7 SL 90 1,4 229 183 ø 85 ø 128 10 - G 1¼ - TLFIII 5-65 2,3 ø 67 209 20 G 2 1/2 8 90

BF 7 SL 130 1,5 277 231 ø 85 ø 127 10 - G 1¼ - B 7 SL..., BE 7 SL...: design as BF... and BS 7 SL, TLFIII 6-80 2,7 ø 210 45 ø 190 ø 82 246 22 G3 78 78 9 105

BS 7 SL 45/21 0,7 191 146 ø 35 ø 92 - - G¾ - however with connection for maintenance

BS 7 SL 90 1,3 229 183 ø 50 ø 128 - - G 1¼ - indicator ( B 7 SL...) and /or extension with a

BS 7 SL 130 1,4 277 231 ø 50 ø 127 - - G 1¼ - filler filter (500 µm strainer).

BE 7 SL 45/21 1,3 68 146 ø 85 ø 92 10 98 G 1 ø 49 Spare Parts Spare parts

B 7 SL 45/21 1,2 73 146 ø 60 ø 92 16 - G 1 ø 36 Materials: as per spare parts list in this brochure.

Size TLF 2-32 TLF 2-32 TLF 2-32 TLF 2-32 Size TLF I, TLF II, TLF III

Spare Parts Weight in kg 0,5 0,6 8,0 33,0 Part Qty. Designation Material 1 - 25 2 - 32 3 - 40 4 - 50 5 - 65 6 - 80

BF 7 SL 45/21, BF 7 SL 90 and 130 BE 7 SL 45/21 Part Qty. Designation Material 1 1 Cover Steel please indicate ordering information "Filter Assembly"

Size BS 7 SL45/21, BS 7 SL 90 and 130 1 1 Cover Steel please indicate ordering information "Filter Assembly" 2 1 Wing nut Steel Part No. 4349

Bs 7 SL 45/21 2 1 Wing nut Steel Part No. 4349 Part No. 5233 3 1 Filter element Various please indicate ordering information "Filter Element"

Part Qty. Designation Material 3 1 Filter Element Various please indicate ordering information "Filter Element" 4 1 Filter housing Various please indicate ordering information "Filter Assembly"

1 1 Spin-on filter Various please indicate ordering information "Spin On Filter" 4 1 Filter housing Various please indicate ordering information "Filter Assembly" 5 1 Filler nozzle Aluminium Part No. 3650 Part No. 3658 Part No. 3659 Part No. 3660 Part No. 3661 Part No. 3662

2 1 Seal Buna N - Part No. 5767 6 1 Filler strainer Various _ Part No. 5767 Part No. 5784 _

6 1 Filler strainer Various Part No. 3651 Part No. 3663 Part No. 3664 Part No. 3665 Part No. 3666 Part No. 3667

3 1 Strainer PA 6 please indicate ordering information "Seal Kit" 7 1 Seal Buna N please indicate ordering information "Seal Kit"

4 1 Seal Buna N please indicate ordering information "Seal Kit" 8 1 Seal Buna N please indicate ordering information "Seal Kit" Filler nozzle and filler strainer only available as unit

5 1 Flat Head Screw 4.8 - Part No. 4285 * Seal Kit only for TLF/TLF 0 2-32, TLF I/III 7-125 and TLF I 8-250 Seal kit is not possible

Ordering Filter Type Magnet Maintenance Indicator Connection Material

Breather Filters Performance Characteristics Ordering Filter Type Magnet Maintenance Indicator Connection Material Dimensions TLF I... TLF II...

BF 7 SL = Breather Filter 0 = without 0= without 00= standard 0 = standard

Information with flange A= pressure gauge M 010

Air flow characteristics

Test temperature: 20°C Information

TLF... = reservoir breather

filter, flange mountable

0 = without 0 =without 00= standard 0 = standard

Selection of filter size: BS 7 SL = Breather with TLF 0... = reservoir breather

welded hexagon

only for B 7 SL and BE 7 SL Connection for TLF0..., TLF..., BF..., BFS..., BFV... Selection of filter size: filter, flange mountable

using the computer program B 7 SL and

"EPE - FILTERSELECT" or

nipple

BE 7 SL = Breather with For technical data see our BE 7 SL = with EF..., EFK..., FEF... using the computer program TLF I... =

with filler strainer

reservoir breather

performance characteristics Filler Filter brochure "Maintenance Indicator" welded nipple BS 7SL..., BE 7 SL..., B 7 SL... "EPE - FILTERSELECT" or filter with female

thread, abbr. DIN

in this brochure. B 7 SL = Breather without

Operating temperature performance characteristics connection

Filler Filter

Special designs in this brochure. TLF II... = reservoir breather

available on request. -20°C to +100°C filter with male thread

connection

Filter Assembly BF 7 SL 90 P 10 – S 00 – 0 0 A – 00 P 0 0 Special designs TLF III... = reservoir breather

Application available on request. filter wit male thread

connection, abbr. DIN

Seal Kit D BF 7 SL 90 H10SL – A – 00 P 0 Filtration and dehumidifying of intake air for flange and filler strainer

industrial systems.

Filter Assembly TLF III 7 - 125 P 10 – S 00 – 0 0 0 – 00 P 0 0

Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional

Pressure Information Design TLF III...

Type: nominal filtration grade in µm 0... = standard adhesive 0 = without P= 0 – 00 P 0

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60

Maximum T = 100°C Buna N 0 = without TLF...: filter housing for breathing and ventilation Seal Kit* D TLF III 7 - 125 H10SL –

BF 7 SL 45/21 P = paper, not cleanable allowable 5 = silicon free with changeable filter element inside. Filter

90 pressure drop E... = special adhesive E = vent valve

P5 P10 P25

across the Z = inspection

elements H...SL up to 1µm filtration grade with

Filter 130 absolute filtration grade (ISO4572) in µm

T = 160°C

glass-fibre filter media, water absorbing filter Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional Design with filler nozzle

filter element certificate

Element BS 7 SL 45/21 H...SL = micro glass-fibre, not cleanable TLF I, II, III 1-25 TLF nominal filtration grade in µm Pressure Information and filler strainer

90 H1SL H3SL H6SL H10SL media AS optional. Types: I with female thread or 2-32 0... = standard adhesive 0 = without 0=

Type: S = standard 2-32 TLF 0 G = stainless steel wire mesh, cleanable Maximum T = 80°C without 0 = without

130 H20SL

5 = silicon free DIN flange ( for size TLF I 8-20), II with male 3-40 G10 G25 G40 G60 G80 G100

AS = micro glass-fibre, water

TLF I, III 7-125 allowable P= 5 = silicon free

BE 7 SL 45/21 absorbing, not cleanable ...0 = standard material Z = inspection thread, III with male thread (with flange for size 4-50 VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60 pressure drop Buna N E = vent valve

80. B 7 SL 45/21 AS1 AS3 AS6 AS10 AS20 certificate

TLF III 7-125) and filler filter(130 µm strainer). 5-65

P = paper, not cleanable across the Z = inspection

TLF I 8-250

Type TLF 0 with 500 µm synthetic strainer. 6-80 P5 P10 P25 filter element certificate

Filter- Filter Element Size absolute filtration grade(ISO4572)in µm S = standard

BF, BFS, BFV...: compact housing for breathing Element Nominal

Size

Element Nominal Element

Size Size Size

H...SL = micro glass-fibre, not cleanable 5 = silicon free

and ventilation with integrated filter media (BF ) H1SL H3SL H6SL H10SL

Filter Element 80. 90 P 10 – S 00 – 0 – P Type: 1-25 002 6-80 006 H20SL ...0 = standard material C = silicagel

or pleated filter element made out of paper ( BFS, 2-32

AS = micro glass-fibre, water ...Z = zinc free Z = inspection Design with filler nozzle

3-40 7-125 007 certificate

BFV ). Design with a dip stick possible. 7. 004

absorbing, not cleanable

4-50

BE 7 SL 45/21, B 7 SL 45/21 BS 7 SL 45/21, BF 7 SL 45/21, 8-250 008 AS1 AS3 AS6 AS10 AS20

Bypass valves 0,1 bar for in and outflowing air 5-65

BS 7 SL 90 and 130 BF 7 SL 90 and 130 for type BFV.

Size Weight A B C D E F G H J K SW

in kg

EF...: 130 µm filler strainer with screwed on Filter Element 7. 007 P 10 – S 00 – 0 – P TLF I 1-25 0,5 G1 53

breather cap and interior sintered bronze plate. ø 102 24 ø 92 43

TLFI 2-32 0,6 G 1 1/4 63

Dimensions TLF I 3-40 2,1 G 1 1/2

EFK...: 130 µm filler strainer with screwed cap,

without breather.

TLF 02-32 TLF 2-32 TLF I 7-125 TLF III 7-125 TLF I 8-250 TLFI 4-50 2,1 ø 177 46 ø 162 G2 98 88

TLFI 5-65 1,6 G 2 1/2

Manometer TLFI 6-80 1,9 ø 210 45 ø 190 G3 88 78

M 010 FEF..: combination out of a flangeable filler filter TLFII 1-25 0,6 G1 53 46

(0 - 6 bar) ( 500 µm strainer ) and a breather cap including TLFII 2-32 0,7

ø 102 24 ø 92 17

G 1 1/4 63

43 6

55

a 40µm foamed material. TLFII 3-40 2,3 G 1 1/2 60

The breather cap can be removed through a TLFII 4-50 2,3 ø 177 46 ø 162 18 G2 98 88

7

75

bayonet joint and is secured with a chain. TLFII 5-65 2,0 20 G 2 1/2 8 90

TLFII 6-80 2,3 ø 210 45 ø 190 22 G3 78 78 9 105

Dimensions BF 7 SL...:, BS 7 SL...: breather filter with a spin TLFIII 1-25 0,7 ø 27 101 G1 53 46

A B D E F G H on filter and pleated filter element with filter ø 102 24 ø 92 17 43 6

Size Weight C TLFIII 2-32 0,8 ø 36 123 G 11/4 63 55

in kg paper P. Design with flange connection ( BF 7 TLFIII 3-40 2,5 ø 42 147 G 1 1/2 60

BF 7 SL 45/21 0,8 191 SL...) or female thread (BS 7 SL ...). 18 7

146 ø 60 ø 92 7 - G¾ - TLFIII 4-50 2,5 ø 177 46 ø 162 ø 52,5 177 G2 98 88 75

BF 7 SL 90 1,4 229 183 ø 85 ø 128 10 - G 1¼ - TLFIII 5-65 2,3 ø 67 209 20 G 2 1/2 8 90

BF 7 SL 130 1,5 277 231 ø 85 ø 127 10 - G 1¼ - B 7 SL..., BE 7 SL...: design as BF... and BS 7 SL, TLFIII 6-80 2,7 ø 210 45 ø 190 ø 82 246 22 G3 78 78 9 105

BS 7 SL 45/21 0,7 191 146 ø 35 ø 92 - - G¾ - however with connection for maintenance

BS 7 SL 90 1,3 229 183 ø 50 ø 128 - - G 1¼ - indicator ( B 7 SL...) and /or extension with a

BS 7 SL 130 1,4 277 231 ø 50 ø 127 - - G 1¼ - filler filter (500 µm strainer).

BE 7 SL 45/21 1,3 68 146 ø 85 ø 92 10 98 G 1 ø 49 Spare Parts Spare parts

B 7 SL 45/21 1,2 73 146 ø 60 ø 92 16 - G 1 ø 36 Materials: as per spare parts list in this brochure.

Size TLF 2-32 TLF 2-32 TLF 2-32 TLF 2-32 Size TLF I, TLF II, TLF III

Spare Parts Weight in kg 0,5 0,6 8,0 33,0 Part Qty. Designation Material 1 - 25 2 - 32 3 - 40 4 - 50 5 - 65 6 - 80

BF 7 SL 45/21, BF 7 SL 90 and 130 BE 7 SL 45/21 Part Qty. Designation Material 1 1 Cover Steel please indicate ordering information "Filter Assembly"

Size BS 7 SL45/21, BS 7 SL 90 and 130 1 1 Cover Steel please indicate ordering information "Filter Assembly" 2 1 Wing nut Steel Part No. 4349

Bs 7 SL 45/21 2 1 Wing nut Steel Part No. 4349 Part No. 5233 3 1 Filter element Various please indicate ordering information "Filter Element"

Part Qty. Designation Material 3 1 Filter Element Various please indicate ordering information "Filter Element" 4 1 Filter housing Various please indicate ordering information "Filter Assembly"

1 1 Spin-on filter Various please indicate ordering information "Spin On Filter" 4 1 Filter housing Various please indicate ordering information "Filter Assembly" 5 1 Filler nozzle Aluminium Part No. 3650 Part No. 3658 Part No. 3659 Part No. 3660 Part No. 3661 Part No. 3662

2 1 Seal Buna N - Part No. 5767 6 1 Filler strainer Various _ Part No. 5767 Part No. 5784 _

6 1 Filler strainer Various Part No. 3651 Part No. 3663 Part No. 3664 Part No. 3665 Part No. 3666 Part No. 3667

3 1 Strainer PA 6 please indicate ordering information "Seal Kit" 7 1 Seal Buna N please indicate ordering information "Seal Kit"

4 1 Seal Buna N please indicate ordering information "Seal Kit" 8 1 Seal Buna N please indicate ordering information "Seal Kit" Filler nozzle and filler strainer only available as unit

5 1 Flat Head Screw 4.8 - Part No. 4285 * Seal Kit only for TLF/TLF 0 2-32, TLF I/III 7-125 and TLF I 8-250 Seal kit is not possible

Ordering Filter Type Magnet Maintenance Indicator Connection Material

Breather Filters Performance Characteristics Ordering Filter Type Magnet Maintenance Indicator Connection Material Dimensions TLF I... TLF II...

BF 7 SL = Breather Filter 0 = without 0= without 00= standard 0 = standard

Information with flange A= pressure gauge M 010

Air flow characteristics

Test temperature: 20°C Information

TLF... = reservoir breather

filter, flange mountable

0 = without 0 =without 00= standard 0 = standard

Selection of filter size: BS 7 SL = Breather with TLF 0... = reservoir breather

welded hexagon

only for B 7 SL and BE 7 SL Connection for TLF0..., TLF..., BF..., BFS..., BFV... Selection of filter size: filter, flange mountable

using the computer program B 7 SL and

"EPE - FILTERSELECT" or

nipple

BE 7 SL = Breather with For technical data see our BE 7 SL = with EF..., EFK..., FEF... using the computer program TLF I... =

with filler strainer

reservoir breather

performance characteristics Filler Filter brochure "Maintenance Indicator" welded nipple BS 7SL..., BE 7 SL..., B 7 SL... "EPE - FILTERSELECT" or filter with female

thread, abbr. DIN

in this brochure. B 7 SL = Breather without

Operating temperature performance characteristics connection

Filler Filter

Special designs in this brochure. TLF II... = reservoir breather

available on request. -20°C to +100°C filter with male thread

connection

Filter Assembly BF 7 SL 90 P 10 – S 00 – 0 0 A – 00 P 0 0 Special designs TLF III... = reservoir breather

Application available on request. filter wit male thread

connection, abbr. DIN

Seal Kit D BF 7 SL 90 H10SL – A – 00 P 0 Filtration and dehumidifying of intake air for flange and filler strainer

industrial systems.

Filter Assembly TLF III 7 - 125 P 10 – S 00 – 0 0 0 – 00 P 0 0

Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional

Pressure Information Design TLF III...

Type: nominal filtration grade in µm 0... = standard adhesive 0 = without P= 0 – 00 P 0

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60

Maximum T = 100°C Buna N 0 = without TLF...: filter housing for breathing and ventilation Seal Kit* D TLF III 7 - 125 H10SL –

BF 7 SL 45/21 P = paper, not cleanable allowable 5 = silicon free with changeable filter element inside. Filter

90 pressure drop E... = special adhesive E = vent valve

P5 P10 P25

across the Z = inspection

elements H...SL up to 1µm filtration grade with

Filter 130 absolute filtration grade (ISO4572) in µm

T = 160°C

glass-fibre filter media, water absorbing filter Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional Design with filler nozzle

filter element certificate

Element BS 7 SL 45/21 H...SL = micro glass-fibre, not cleanable TLF I, II, III 1-25 TLF nominal filtration grade in µm Pressure Information and filler strainer

90 H1SL H3SL H6SL H10SL media AS optional. Types: I with female thread or 2-32 0... = standard adhesive 0 = without 0=

Type: S = standard 2-32 TLF 0 G = stainless steel wire mesh, cleanable Maximum T = 80°C without 0 = without

130 H20SL

5 = silicon free DIN flange ( for size TLF I 8-20), II with male 3-40 G10 G25 G40 G60 G80 G100

AS = micro glass-fibre, water

TLF I, III 7-125 allowable P= 5 = silicon free

BE 7 SL 45/21 absorbing, not cleanable ...0 = standard material Z = inspection thread, III with male thread (with flange for size 4-50 VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60 pressure drop Buna N E = vent valve

80. B 7 SL 45/21 AS1 AS3 AS6 AS10 AS20 certificate

TLF III 7-125) and filler filter(130 µm strainer). 5-65

P = paper, not cleanable across the Z = inspection

TLF I 8-250

Type TLF 0 with 500 µm synthetic strainer. 6-80 P5 P10 P25 filter element certificate

Filter- Filter Element Size absolute filtration grade(ISO4572)in µm S = standard

BF, BFS, BFV...: compact housing for breathing Element Nominal

Size

Element Nominal Element

Size Size Size

H...SL = micro glass-fibre, not cleanable 5 = silicon free

and ventilation with integrated filter media (BF ) H1SL H3SL H6SL H10SL

Filter Element 80. 90 P 10 – S 00 – 0 – P Type: 1-25 002 6-80 006 H20SL ...0 = standard material C = silicagel

or pleated filter element made out of paper ( BFS, 2-32

AS = micro glass-fibre, water ...Z = zinc free Z = inspection Design with filler nozzle

3-40 7-125 007 certificate

BFV ). Design with a dip stick possible. 7. 004

absorbing, not cleanable

4-50

BE 7 SL 45/21, B 7 SL 45/21 BS 7 SL 45/21, BF 7 SL 45/21, 8-250 008 AS1 AS3 AS6 AS10 AS20

Bypass valves 0,1 bar for in and outflowing air 5-65

BS 7 SL 90 and 130 BF 7 SL 90 and 130 for type BFV.

Size Weight A B C D E F G H J K SW

in kg

EF...: 130 µm filler strainer with screwed on Filter Element 7. 007 P 10 – S 00 – 0 – P TLF I 1-25 0,5 G1 53

breather cap and interior sintered bronze plate. ø 102 24 ø 92 43

TLFI 2-32 0,6 G 1 1/4 63

Dimensions TLF I 3-40 2,1 G 1 1/2

EFK...: 130 µm filler strainer with screwed cap,

without breather.

TLF 02-32 TLF 2-32 TLF I 7-125 TLF III 7-125 TLF I 8-250 TLFI 4-50 2,1 ø 177 46 ø 162 G2 98 88

TLFI 5-65 1,6 G 2 1/2

Manometer TLFI 6-80 1,9 ø 210 45 ø 190 G3 88 78

M 010 FEF..: combination out of a flangeable filler filter TLFII 1-25 0,6 G1 53 46

(0 - 6 bar) ( 500 µm strainer ) and a breather cap including TLFII 2-32 0,7

ø 102 24 ø 92 17

G 1 1/4 63

43 6

55

a 40µm foamed material. TLFII 3-40 2,3 G 1 1/2 60

The breather cap can be removed through a TLFII 4-50 2,3 ø 177 46 ø 162 18 G2 98 88

7

75

bayonet joint and is secured with a chain. TLFII 5-65 2,0 20 G 2 1/2 8 90

TLFII 6-80 2,3 ø 210 45 ø 190 22 G3 78 78 9 105

Dimensions BF 7 SL...:, BS 7 SL...: breather filter with a spin TLFIII 1-25 0,7 ø 27 101 G1 53 46

A B D E F G H on filter and pleated filter element with filter ø 102 24 ø 92 17 43 6

Size Weight C TLFIII 2-32 0,8 ø 36 123 G 11/4 63 55

in kg paper P. Design with flange connection ( BF 7 TLFIII 3-40 2,5 ø 42 147 G 1 1/2 60

BF 7 SL 45/21 0,8 191 SL...) or female thread (BS 7 SL ...). 18 7

146 ø 60 ø 92 7 - G¾ - TLFIII 4-50 2,5 ø 177 46 ø 162 ø 52,5 177 G2 98 88 75

BF 7 SL 90 1,4 229 183 ø 85 ø 128 10 - G 1¼ - TLFIII 5-65 2,3 ø 67 209 20 G 2 1/2 8 90

BF 7 SL 130 1,5 277 231 ø 85 ø 127 10 - G 1¼ - B 7 SL..., BE 7 SL...: design as BF... and BS 7 SL, TLFIII 6-80 2,7 ø 210 45 ø 190 ø 82 246 22 G3 78 78 9 105

BS 7 SL 45/21 0,7 191 146 ø 35 ø 92 - - G¾ - however with connection for maintenance

BS 7 SL 90 1,3 229 183 ø 50 ø 128 - - G 1¼ - indicator ( B 7 SL...) and /or extension with a

BS 7 SL 130 1,4 277 231 ø 50 ø 127 - - G 1¼ - filler filter (500 µm strainer).

BE 7 SL 45/21 1,3 68 146 ø 85 ø 92 10 98 G 1 ø 49 Spare Parts Spare parts

B 7 SL 45/21 1,2 73 146 ø 60 ø 92 16 - G 1 ø 36 Materials: as per spare parts list in this brochure.

Size TLF 2-32 TLF 2-32 TLF 2-32 TLF 2-32 Size TLF I, TLF II, TLF III

Spare Parts Weight in kg 0,5 0,6 8,0 33,0 Part Qty. Designation Material 1 - 25 2 - 32 3 - 40 4 - 50 5 - 65 6 - 80

BF 7 SL 45/21, BF 7 SL 90 and 130 BE 7 SL 45/21 Part Qty. Designation Material 1 1 Cover Steel please indicate ordering information "Filter Assembly"

Size BS 7 SL45/21, BS 7 SL 90 and 130 1 1 Cover Steel please indicate ordering information "Filter Assembly" 2 1 Wing nut Steel Part No. 4349

Bs 7 SL 45/21 2 1 Wing nut Steel Part No. 4349 Part No. 5233 3 1 Filter element Various please indicate ordering information "Filter Element"

Part Qty. Designation Material 3 1 Filter Element Various please indicate ordering information "Filter Element" 4 1 Filter housing Various please indicate ordering information "Filter Assembly"

1 1 Spin-on filter Various please indicate ordering information "Spin On Filter" 4 1 Filter housing Various please indicate ordering information "Filter Assembly" 5 1 Filler nozzle Aluminium Part No. 3650 Part No. 3658 Part No. 3659 Part No. 3660 Part No. 3661 Part No. 3662

2 1 Seal Buna N - Part No. 5767 6 1 Filler strainer Various _ Part No. 5767 Part No. 5784 _

6 1 Filler strainer Various Part No. 3651 Part No. 3663 Part No. 3664 Part No. 3665 Part No. 3666 Part No. 3667

3 1 Strainer PA 6 please indicate ordering information "Seal Kit" 7 1 Seal Buna N please indicate ordering information "Seal Kit"

4 1 Seal Buna N please indicate ordering information "Seal Kit" 8 1 Seal Buna N please indicate ordering information "Seal Kit" Filler nozzle and filler strainer only available as unit

5 1 Flat Head Screw 4.8 - Part No. 4285 * Seal Kit only for TLF/TLF 0 2-32, TLF I/III 7-125 and TLF I 8-250 Seal kit is not possible

Ordering Filter Type Magnet Maintenance Indicator Connection Material

Breather Filters Performance Characteristics Ordering Filter Type Magnet Maintenance Indicator Connection Material Dimensions TLF I... TLF II...

BF 7 SL = Breather Filter 0 = without 0= without 00= standard 0 = standard

Information with flange A= pressure gauge M 010

Air flow characteristics

Test temperature: 20°C Information

TLF... = reservoir breather

filter, flange mountable

0 = without 0 =without 00= standard 0 = standard

Selection of filter size: BS 7 SL = Breather with TLF 0... = reservoir breather

welded hexagon

only for B 7 SL and BE 7 SL Connection for TLF0..., TLF..., BF..., BFS..., BFV... Selection of filter size: filter, flange mountable

using the computer program B 7 SL and

"EPE - FILTERSELECT" or

nipple

BE 7 SL = Breather with For technical data see our BE 7 SL = with EF..., EFK..., FEF... using the computer program TLF I... =

with filler strainer

reservoir breather

performance characteristics Filler Filter brochure "Maintenance Indicator" welded nipple BS 7SL..., BE 7 SL..., B 7 SL... "EPE - FILTERSELECT" or filter with female

thread, abbr. DIN

in this brochure. B 7 SL = Breather without

Operating temperature performance characteristics connection

Filler Filter

Special designs in this brochure. TLF II... = reservoir breather

available on request. -20°C to +100°C filter with male thread

connection

Filter Assembly BF 7 SL 90 P 10 – S 00 – 0 0 A – 00 P 0 0 Special designs TLF III... = reservoir breather

Application available on request. filter wit male thread

connection, abbr. DIN

Seal Kit D BF 7 SL 90 H10SL – A – 00 P 0 Filtration and dehumidifying of intake air for flange and filler strainer

industrial systems.

Filter Assembly TLF III 7 - 125 P 10 – S 00 – 0 0 0 – 00 P 0 0

Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional

Pressure Information Design TLF III...

Type: nominal filtration grade in µm 0... = standard adhesive 0 = without P= 0 – 00 P 0

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60

Maximum T = 100°C Buna N 0 = without TLF...: filter housing for breathing and ventilation Seal Kit* D TLF III 7 - 125 H10SL –

BF 7 SL 45/21 P = paper, not cleanable allowable 5 = silicon free with changeable filter element inside. Filter

90 pressure drop E... = special adhesive E = vent valve

P5 P10 P25

across the Z = inspection

elements H...SL up to 1µm filtration grade with

Filter 130 absolute filtration grade (ISO4572) in µm

T = 160°C

glass-fibre filter media, water absorbing filter Nominal Size Filtration Grade Differential Filter Element Design Bypass Valve Seal Additional Design with filler nozzle

filter element certificate

Element BS 7 SL 45/21 H...SL = micro glass-fibre, not cleanable TLF I, II, III 1-25 TLF nominal filtration grade in µm Pressure Information and filler strainer

90 H1SL H3SL H6SL H10SL media AS optional. Types: I with female thread or 2-32 0... = standard adhesive 0 = without 0=

Type: S = standard 2-32 TLF 0 G = stainless steel wire mesh, cleanable Maximum T = 80°C without 0 = without

130 H20SL

5 = silicon free DIN flange ( for size TLF I 8-20), II with male 3-40 G10 G25 G40 G60 G80 G100

AS = micro glass-fibre, water

TLF I, III 7-125 allowable P= 5 = silicon free

BE 7 SL 45/21 absorbing, not cleanable ...0 = standard material Z = inspection thread, III with male thread (with flange for size 4-50 VS = nonwoven media, not cleanable

VS 25 VS 40 VS 60 pressure drop Buna N E = vent valve

80. B 7 SL 45/21 AS1 AS3 AS6 AS10 AS20 certificate

TLF III 7-125) and filler filter(130 µm strainer). 5-65

P = paper, not cleanable across the Z = inspection

TLF I 8-250

Type TLF 0 with 500 µm synthetic strainer. 6-80 P5 P10 P25 filter element certificate

Filter- Filter Element Size absolute filtration grade(ISO4572)in µm S = standard

BF, BFS, BFV...: compact housing for breathing Element Nominal

Size

Element Nominal Element

Size Size Size

H...SL = micro glass-fibre, not cleanable 5 = silicon free

and ventilation with integrated filter media (BF ) H1SL H3SL H6SL H10SL

Filter Element 80. 90 P 10 – S 00 – 0 – P Type: 1-25 002 6-80 006 H20SL ...0 = standard material C = silicagel

or pleated filter element made out of paper ( BFS, 2-32

AS = micro glass-fibre, water ...Z = zinc free Z = inspection Design with filler nozzle

3-40 7-125 007 certificate

BFV ). Design with a dip stick possible. 7. 004

absorbing, not cleanable

4-50

BE 7 SL 45/21, B 7 SL 45/21 BS 7 SL 45/21, BF 7 SL 45/21, 8-250 008 AS1 AS3 AS6 AS10 AS20

Bypass valves 0,1 bar for in and outflowing air 5-65

BS 7 SL 90 and 130 BF 7 SL 90 and 130 for type BFV.

Size Weight A B C D E F G H J K SW

in kg

EF...: 130 µm filler strainer with screwed on Filter Element 7. 007 P 10 – S 00 – 0 – P TLF I 1-25 0,5 G1 53

breather cap and interior sintered bronze plate. ø 102 24 ø 92 43

TLFI 2-32 0,6 G 1 1/4 63

Dimensions TLF I 3-40 2,1 G 1 1/2

EFK...: 130 µm filler strainer with screwed cap,

without breather.

TLF 02-32 TLF 2-32 TLF I 7-125 TLF III 7-125 TLF I 8-250 TLFI 4-50 2,1 ø 177 46 ø 162 G2 98 88

TLFI 5-65 1,6 G 2 1/2

Manometer TLFI 6-80 1,9 ø 210 45 ø 190 G3 88 78

M 010 FEF..: combination out of a flangeable filler filter TLFII 1-25 0,6 G1 53 46

(0 - 6 bar) ( 500 µm strainer ) and a breather cap including TLFII 2-32 0,7

ø 102 24 ø 92 17

G 1 1/4 63

43 6

55

a 40µm foamed material. TLFII 3-40 2,3 G 1 1/2 60

The breather cap can be removed through a TLFII 4-50 2,3 ø 177 46 ø 162 18 G2 98 88

7

75

bayonet joint and is secured with a chain. TLFII 5-65 2,0 20 G 2 1/2 8 90

TLFII 6-80 2,3 ø 210 45 ø 190 22 G3 78 78 9 105

Dimensions BF 7 SL...:, BS 7 SL...: breather filter with a spin TLFIII 1-25 0,7 ø 27 101 G1 53 46

A B D E F G H on filter and pleated filter element with filter ø 102 24 ø 92 17 43 6

Size Weight C TLFIII 2-32 0,8 ø 36 123 G 11/4 63 55

in kg paper P. Design with flange connection ( BF 7 TLFIII 3-40 2,5 ø 42 147 G 1 1/2 60

BF 7 SL 45/21 0,8 191 SL...) or female thread (BS 7 SL ...). 18 7

146 ø 60 ø 92 7 - G¾ - TLFIII 4-50 2,5 ø 177 46 ø 162 ø 52,5 177 G2 98 88 75

BF 7 SL 90 1,4 229 183 ø 85 ø 128 10 - G 1¼ - TLFIII 5-65 2,3 ø 67 209 20 G 2 1/2 8 90

BF 7 SL 130 1,5 277 231 ø 85 ø 127 10 - G 1¼ - B 7 SL..., BE 7 SL...: design as BF... and BS 7 SL, TLFIII 6-80 2,7 ø 210 45 ø 190 ø 82 246 22 G3 78 78 9 105

BS 7 SL 45/21 0,7 191 146 ø 35 ø 92 - - G¾ - however with connection for maintenance

BS 7 SL 90 1,3 229 183 ø 50 ø 128 - - G 1¼ - indicator ( B 7 SL...) and /or extension with a

BS 7 SL 130 1,4 277 231 ø 50 ø 127 - - G 1¼ - filler filter (500 µm strainer).

BE 7 SL 45/21 1,3 68 146 ø 85 ø 92 10 98 G 1 ø 49 Spare Parts Spare parts

B 7 SL 45/21 1,2 73 146 ø 60 ø 92 16 - G 1 ø 36 Materials: as per spare parts list in this brochure.

Size TLF 2-32 TLF 2-32 TLF 2-32 TLF 2-32 Size TLF I, TLF II, TLF III

Spare Parts Weight in kg 0,5 0,6 8,0 33,0 Part Qty. Designation Material 1 - 25 2 - 32 3 - 40 4 - 50 5 - 65 6 - 80

BF 7 SL 45/21, BF 7 SL 90 and 130 BE 7 SL 45/21 Part Qty. Designation Material 1 1 Cover Steel please indicate ordering information "Filter Assembly"

Size BS 7 SL45/21, BS 7 SL 90 and 130 1 1 Cover Steel please indicate ordering information "Filter Assembly" 2 1 Wing nut Steel Part No. 4349

Bs 7 SL 45/21 2 1 Wing nut Steel Part No. 4349 Part No. 5233 3 1 Filter element Various please indicate ordering information "Filter Element"

Part Qty. Designation Material 3 1 Filter Element Various please indicate ordering information "Filter Element" 4 1 Filter housing Various please indicate ordering information "Filter Assembly"

1 1 Spin-on filter Various please indicate ordering information "Spin On Filter" 4 1 Filter housing Various please indicate ordering information "Filter Assembly" 5 1 Filler nozzle Aluminium Part No. 3650 Part No. 3658 Part No. 3659 Part No. 3660 Part No. 3661 Part No. 3662

2 1 Seal Buna N - Part No. 5767 6 1 Filler strainer Various _ Part No. 5767 Part No. 5784 _

6 1 Filler strainer Various Part No. 3651 Part No. 3663 Part No. 3664 Part No. 3665 Part No. 3666 Part No. 3667

3 1 Strainer PA 6 please indicate ordering information "Seal Kit" 7 1 Seal Buna N please indicate ordering information "Seal Kit"

4 1 Seal Buna N please indicate ordering information "Seal Kit" 8 1 Seal Buna N please indicate ordering information "Seal Kit" Filler nozzle and filler strainer only available as unit

5 1 Flat Head Screw 4.8 - Part No. 4285 * Seal Kit only for TLF/TLF 0 2-32, TLF I/III 7-125 and TLF I 8-250 Seal kit is not possible

Ordering ® Installation, Starting and Maintenance ®

Breather Filters Dimensions

Information Filter Assembly TLF I..., TLF II...,TLF III...,

Selection of filter size: BF 15 S 130 – F 0 0

Filter Installation

using the computer program

"EPE - FILTERSELECT" or Industrial Filters · Accumulators Flange filter assembly at mounting device or in reservoir opening. Industrial Filters · Accumulators BF...,BE...,EF...,EFK...

performance characteristics Seal Kit D BF 15 S 130 – F 0

in this brochure. BF 8-32 BFS 7… /BFS 20… BFV 20

Special designs Starting

available on request. Switch on system pump and start system. Pay attention to flow noise

at breather filter. If flow noise can be heard, check size selection in

accordance to air flow rate (Initial flow resistance < 20 mbar).

Filter Type Nominal Size Filtration Grade Seal Material Add. Info.

BF = Breather filter 8; 15; 20; 25; 32 S 130 0 = standard 0 = without

Maintenance

BFV = Breather with 5 = silicon free BE, B7SL45/21... : If a vacuum or overpressure of 0,02 bar is displayed,

20 S 130

Bypass Valve Q = dip stick BF, EF the spin on filter 80.45/21 needs to be replaced. 10

BFS = Breather with 7 and EFK only All other breather filters do not have any maintenance indicators.

20 P5 P10 P25

Filter Element F = Fibre (standard) Z = inspection

FEF = Breather and 0 certificate

We therefore recommend to check or to replace breather filters in

1 S10 S20 S40 regularly periods according to following table:

Filler Filter

EF = Breather and 1-25 0 = without

Filler Filter 2-32

3-40 filter application environmental service interval

4-50 G 130

5-65 conditions

EFK = Filler Filter 6-80 P = Buna N average dust

concentration

Dimensions general mechanical

engineering

9 - 25 mg/m3 4000 h

Size Weight in kg A B C D E F G SW NW

BF 81 0,05 55 10 20 ø 30 9 55 G 1/4 19 9 heavy industry 50 - 80 mg/m3 3000 h

BF 15 0,1 105 25 ø 50 12 105 G 1/2 27 13 mobile hydraulics 30 - 100 mg/m3 3000 h

BF 20 0,15 140

12

26 13 140 G 3/4 35 18 EF 1-6 EFK 1-6 FEF 0 and FEF 1

ø 60

BF 25 0,2 175 27 15 175 G1 41 23

16

BF 32 0,3 225 35 ø 80 17 225 G 1 1/4 55 32

BFS 70 0,03 11 41 ø 46 6 G 1/4 19 7

Filter Element Service

BFS 20 57 ø 81 15

0,3 12 G 3/4 32 18 TLF:

BFV 20 54 ø 77 14

open cover (Part 1) by unscrewing wing nut (Part 2).

EF 100 36 ø 60

0,4 107 17 ø 28 G1 46 25 Replace (H..SL, P and VS...) or clean (G...material) filter element in the

EFK 10 37 ø 38

case of visual contamination.

EF 200 39 17 ø 67

0,5 131 ø 34 G 1 1/4 55 32 Insert filter element (Part 4) in filter housing and refit cover while

EFK 20 40 19 ø 47

tighten wing nut hand screwed.

EF 300 44 18 ø 75

0,7 155 ø 42 G 1 1/2 60 40

EFK 30 41 19 ø 54

BF, BS, BE, B 7SL... :

EF 400 48 18 ø 93

0,8 187 ø 53 G2 75 50 unscrew spin-on filter (Part 1) and refit new one with seal (Part 2)

EFK 40 46 22 ø 66

hand screwed.

EF 500 58 20 ø 120

1,4 218 ø 67 G 2 1/2 90 65

EFK 50 51 24 ø 83

BF 8-32, BFS, BFV... :

EF 600

1,6 256

69 22 ø 140

ø 82 G3 105 80 unscrew filter, replace completely and screw on again using a new Filters for tank mounting

EFK 60 55 26 ø 96

fibre seal (Part 10).

FEF 00 0,17 62 48 ø 50 ø 45 ø 28

FEF 10 0,23 98 54 ø 83 ø 76 ø 49

Efficient filtration of air

EF... :

unscrew cover (Part 1)and replace filter disc (Part 5).

Air breather filters with

Spare Parts EFK... : changeable spin-on filters

hole pattern FEF 0 hole pattern FEF 1

BF 8-32 EF 1 EFK 1 EF 2 EFK 2 EF 3 EFK 3 EF 4 EFK 4 EF 5 EFK 5 EF 6 EFK 6 FEF 0 FEF 1

Size BFS 7, BFS 20 unscrew cover (Part 1) and check strainer (Part 4) for contamination, (BF and BE) lockable design on request

BFV 20 clean if necessary, check seal (Part 9) for damage and refit cover.

Part Qty. Designation Material Part No.

1 1 Cover Various please indicate ordering information "Filter Assembly"

Combined air breather and filler

FEF... : Air flow up to 3500 m³/h

2 1 Flange Steel please indicate ordering information "Filter Assembly" open cover (Part 1) , release from security chain and replace, close

filters (TLF, EF, EFK, FEF, FES, BE)

3 1 Filler nozzle Aluminium 3650 3658 3659 3660 3661 3662 security chain.

Connection up to DN 250

4 1 Filler strainer Various 3651 3663 3664 3665 3666 3667 5779 5767 Flange mounted filters

5 1 Filter plate Sika-B 200 5635 5636 5637 5638 5639 5640 Check filler filters during maintenance for contamination Quality and Standardisation

6 1 Locking ring Spring steel 5641 5642 5643 5644 5645 5646 K. & H. Eppensteiner GmbH & Co. KG The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within

Hardtwaldstraße 43 · D-68775 Ketsch/Rh.

and clean if necessary. Low pressure drop

7 3 Oval head screw 4.8 5783 the guidelines of a certified quality management system according to DIN EN ISO 9001.

Postfach 1120 · D-68768 Ketsch/Rh.

8 6 Socket head cap screw 4.8 5770 The calculation of strength and the filter tests are done in compliance to actual pressure vessel regulations and

Telefon: 0 62 02 / 6 03-0

9 1 Seal Buna N

Telefax: 0 62 02 / 6 03-199 Special high efficient filter media, national & international standards.

10 1 Seal Fibre please indicate ordering information "Seal Kit" A filter inspection by accredited certification bodies

E-Mail: Eppensteiner@compuserve.com also for water absorbing Quality assured!

11 1 Seal Fibre (e.g. TÜV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc.) is possible on request.

Internet: www.Eppensteiner.de Technical modifications reserved! 10/01/10.99/6000

Filler nozzle and filler strainer only available as unit

Ordering ® Installation, Starting and Maintenance ®

Breather Filters Dimensions

Information Filter Assembly TLF I..., TLF II...,TLF III...,

Selection of filter size: BF 15 S 130 – F 0 0

Filter Installation

using the computer program

"EPE - FILTERSELECT" or Industrial Filters · Accumulators Flange filter assembly at mounting device or in reservoir opening. Industrial Filters · Accumulators BF...,BE...,EF...,EFK...

performance characteristics Seal Kit D BF 15 S 130 – F 0

in this brochure. BF 8-32 BFS 7… /BFS 20… BFV 20

Special designs Starting

available on request. Switch on system pump and start system. Pay attention to flow noise

at breather filter. If flow noise can be heard, check size selection in

accordance to air flow rate (Initial flow resistance < 20 mbar).

Filter Type Nominal Size Filtration Grade Seal Material Add. Info.

BF = Breather filter 8; 15; 20; 25; 32 S 130 0 = standard 0 = without

Maintenance

BFV = Breather with 5 = silicon free BE, B7SL45/21... : If a vacuum or overpressure of 0,02 bar is displayed,

20 S 130

Bypass Valve Q = dip stick BF, EF the spin on filter 80.45/21 needs to be replaced. 10

BFS = Breather with 7 and EFK only All other breather filters do not have any maintenance indicators.

20 P5 P10 P25

Filter Element F = Fibre (standard) Z = inspection

FEF = Breather and 0 certificate

We therefore recommend to check or to replace breather filters in

1 S10 S20 S40 regularly periods according to following table:

Filler Filter

EF = Breather and 1-25 0 = without

Filler Filter 2-32

3-40 filter application environmental service interval

4-50 G 130

5-65 conditions

EFK = Filler Filter 6-80 P = Buna N average dust

concentration

Dimensions general mechanical

engineering

9 - 25 mg/m3 4000 h

Size Weight in kg A B C D E F G SW NW

BF 81 0,05 55 10 20 ø 30 9 55 G 1/4 19 9 heavy industry 50 - 80 mg/m3 3000 h

BF 15 0,1 105 25 ø 50 12 105 G 1/2 27 13 mobile hydraulics 30 - 100 mg/m3 3000 h

BF 20 0,15 140

12

26 13 140 G 3/4 35 18 EF 1-6 EFK 1-6 FEF 0 and FEF 1

ø 60

BF 25 0,2 175 27 15 175 G1 41 23

16

BF 32 0,3 225 35 ø 80 17 225 G 1 1/4 55 32

BFS 70 0,03 11 41 ø 46 6 G 1/4 19 7

Filter Element Service

BFS 20 57 ø 81 15

0,3 12 G 3/4 32 18 TLF:

BFV 20 54 ø 77 14

open cover (Part 1) by unscrewing wing nut (Part 2).

EF 100 36 ø 60

0,4 107 17 ø 28 G1 46 25 Replace (H..SL, P and VS...) or clean (G...material) filter element in the

EFK 10 37 ø 38

case of visual contamination.

EF 200 39 17 ø 67

0,5 131 ø 34 G 1 1/4 55 32 Insert filter element (Part 4) in filter housing and refit cover while

EFK 20 40 19 ø 47

tighten wing nut hand screwed.

EF 300 44 18 ø 75

0,7 155 ø 42 G 1 1/2 60 40

EFK 30 41 19 ø 54

BF, BS, BE, B 7SL... :

EF 400 48 18 ø 93

0,8 187 ø 53 G2 75 50 unscrew spin-on filter (Part 1) and refit new one with seal (Part 2)

EFK 40 46 22 ø 66

hand screwed.

EF 500 58 20 ø 120

1,4 218 ø 67 G 2 1/2 90 65

EFK 50 51 24 ø 83

BF 8-32, BFS, BFV... :

EF 600

1,6 256

69 22 ø 140

ø 82 G3 105 80 unscrew filter, replace completely and screw on again using a new Filters for tank mounting

EFK 60 55 26 ø 96

fibre seal (Part 10).

FEF 00 0,17 62 48 ø 50 ø 45 ø 28

FEF 10 0,23 98 54 ø 83 ø 76 ø 49

Efficient filtration of air

EF... :

unscrew cover (Part 1)and replace filter disc (Part 5).

Air breather filters with

Spare Parts EFK... : changeable spin-on filters

hole pattern FEF 0 hole pattern FEF 1

BF 8-32 EF 1 EFK 1 EF 2 EFK 2 EF 3 EFK 3 EF 4 EFK 4 EF 5 EFK 5 EF 6 EFK 6 FEF 0 FEF 1

Size BFS 7, BFS 20 unscrew cover (Part 1) and check strainer (Part 4) for contamination, (BF and BE) lockable design on request

BFV 20 clean if necessary, check seal (Part 9) for damage and refit cover.

Part Qty. Designation Material Part No.

1 1 Cover Various please indicate ordering information "Filter Assembly"

Combined air breather and filler

FEF... : Air flow up to 3500 m³/h

2 1 Flange Steel please indicate ordering information "Filter Assembly" open cover (Part 1) , release from security chain and replace, close

filters (TLF, EF, EFK, FEF, FES, BE)

3 1 Filler nozzle Aluminium 3650 3658 3659 3660 3661 3662 security chain.

Connection up to DN 250

4 1 Filler strainer Various 3651 3663 3664 3665 3666 3667 5779 5767 Flange mounted filters

5 1 Filter plate Sika-B 200 5635 5636 5637 5638 5639 5640 Check filler filters during maintenance for contamination Quality and Standardisation

6 1 Locking ring Spring steel 5641 5642 5643 5644 5645 5646 K. & H. Eppensteiner GmbH & Co. KG The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within

Hardtwaldstraße 43 · D-68775 Ketsch/Rh.

and clean if necessary. Low pressure drop

7 3 Oval head screw 4.8 5783 the guidelines of a certified quality management system according to DIN EN ISO 9001.

Postfach 1120 · D-68768 Ketsch/Rh.

8 6 Socket head cap screw 4.8 5770 The calculation of strength and the filter tests are done in compliance to actual pressure vessel regulations and

Telefon: 0 62 02 / 6 03-0

9 1 Seal Buna N

Telefax: 0 62 02 / 6 03-199 Special high efficient filter media, national & international standards.

10 1 Seal Fibre please indicate ordering information "Seal Kit" A filter inspection by accredited certification bodies

E-Mail: Eppensteiner@compuserve.com also for water absorbing Quality assured!

11 1 Seal Fibre (e.g. TÜV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc.) is possible on request.

Internet: www.Eppensteiner.de Technical modifications reserved! 10/01/10.99/6000

Filler nozzle and filler strainer only available as unit

Ordering ® Installation, Starting and Maintenance ®

Breather Filters Dimensions

Information Filter Assembly TLF I..., TLF II...,TLF III...,

Selection of filter size: BF 15 S 130 – F 0 0

Filter Installation

using the computer program

"EPE - FILTERSELECT" or Industrial Filters · Accumulators Flange filter assembly at mounting device or in reservoir opening. Industrial Filters · Accumulators BF...,BE...,EF...,EFK...

performance characteristics Seal Kit D BF 15 S 130 – F 0

in this brochure. BF 8-32 BFS 7… /BFS 20… BFV 20

Special designs Starting

available on request. Switch on system pump and start system. Pay attention to flow noise

at breather filter. If flow noise can be heard, check size selection in

accordance to air flow rate (Initial flow resistance < 20 mbar).

Filter Type Nominal Size Filtration Grade Seal Material Add. Info.

BF = Breather filter 8; 15; 20; 25; 32 S 130 0 = standard 0 = without

Maintenance

BFV = Breather with 5 = silicon free BE, B7SL45/21... : If a vacuum or overpressure of 0,02 bar is displayed,

20 S 130

Bypass Valve Q = dip stick BF, EF the spin on filter 80.45/21 needs to be replaced. 10

BFS = Breather with 7 and EFK only All other breather filters do not have any maintenance indicators.

20 P5 P10 P25

Filter Element F = Fibre (standard) Z = inspection

FEF = Breather and 0 certificate

We therefore recommend to check or to replace breather filters in

1 S10 S20 S40 regularly periods according to following table:

Filler Filter

EF = Breather and 1-25 0 = without

Filler Filter 2-32

3-40 filter application environmental service interval

4-50 G 130

5-65 conditions

EFK = Filler Filter 6-80 P = Buna N average dust

concentration

Dimensions general mechanical

engineering

9 - 25 mg/m3 4000 h

Size Weight in kg A B C D E F G SW NW

BF 81 0,05 55 10 20 ø 30 9 55 G 1/4 19 9 heavy industry 50 - 80 mg/m3 3000 h

BF 15 0,1 105 25 ø 50 12 105 G 1/2 27 13 mobile hydraulics 30 - 100 mg/m3 3000 h

BF 20 0,15 140

12

26 13 140 G 3/4 35 18 EF 1-6 EFK 1-6 FEF 0 and FEF 1

ø 60

BF 25 0,2 175 27 15 175 G1 41 23

16

BF 32 0,3 225 35 ø 80 17 225 G 1 1/4 55 32

BFS 70 0,03 11 41 ø 46 6 G 1/4 19 7

Filter Element Service

BFS 20 57 ø 81 15

0,3 12 G 3/4 32 18 TLF:

BFV 20 54 ø 77 14

open cover (Part 1) by unscrewing wing nut (Part 2).

EF 100 36 ø 60

0,4 107 17 ø 28 G1 46 25 Replace (H..SL, P and VS...) or clean (G...material) filter element in the

EFK 10 37 ø 38

case of visual contamination.

EF 200 39 17 ø 67

0,5 131 ø 34 G 1 1/4 55 32 Insert filter element (Part 4) in filter housing and refit cover while

EFK 20 40 19 ø 47

tighten wing nut hand screwed.

EF 300 44 18 ø 75

0,7 155 ø 42 G 1 1/2 60 40

EFK 30 41 19 ø 54

BF, BS, BE, B 7SL... :

EF 400 48 18 ø 93

0,8 187 ø 53 G2 75 50 unscrew spin-on filter (Part 1) and refit new one with seal (Part 2)

EFK 40 46 22 ø 66

hand screwed.

EF 500 58 20 ø 120

1,4 218 ø 67 G 2 1/2 90 65

EFK 50 51 24 ø 83

BF 8-32, BFS, BFV... :

EF 600

1,6 256

69 22 ø 140

ø 82 G3 105 80 unscrew filter, replace completely and screw on again using a new Filters for tank mounting

EFK 60 55 26 ø 96

fibre seal (Part 10).

FEF 00 0,17 62 48 ø 50 ø 45 ø 28

FEF 10 0,23 98 54 ø 83 ø 76 ø 49

Efficient filtration of air

EF... :

unscrew cover (Part 1)and replace filter disc (Part 5).

Air breather filters with

Spare Parts EFK... : changeable spin-on filters

hole pattern FEF 0 hole pattern FEF 1

BF 8-32 EF 1 EFK 1 EF 2 EFK 2 EF 3 EFK 3 EF 4 EFK 4 EF 5 EFK 5 EF 6 EFK 6 FEF 0 FEF 1

Size BFS 7, BFS 20 unscrew cover (Part 1) and check strainer (Part 4) for contamination, (BF and BE) lockable design on request

BFV 20 clean if necessary, check seal (Part 9) for damage and refit cover.

Part Qty. Designation Material Part No.

1 1 Cover Various please indicate ordering information "Filter Assembly"

Combined air breather and filler

FEF... : Air flow up to 3500 m³/h

2 1 Flange Steel please indicate ordering information "Filter Assembly" open cover (Part 1) , release from security chain and replace, close

filters (TLF, EF, EFK, FEF, FES, BE)

3 1 Filler nozzle Aluminium 3650 3658 3659 3660 3661 3662 security chain.

Connection up to DN 250

4 1 Filler strainer Various 3651 3663 3664 3665 3666 3667 5779 5767 Flange mounted filters

5 1 Filter plate Sika-B 200 5635 5636 5637 5638 5639 5640 Check filler filters during maintenance for contamination Quality and Standardisation

6 1 Locking ring Spring steel 5641 5642 5643 5644 5645 5646 K. & H. Eppensteiner GmbH & Co. KG The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within

Hardtwaldstraße 43 · D-68775 Ketsch/Rh.

and clean if necessary. Low pressure drop

7 3 Oval head screw 4.8 5783 the guidelines of a certified quality management system according to DIN EN ISO 9001.

Postfach 1120 · D-68768 Ketsch/Rh.

8 6 Socket head cap screw 4.8 5770 The calculation of strength and the filter tests are done in compliance to actual pressure vessel regulations and

Telefon: 0 62 02 / 6 03-0

9 1 Seal Buna N

Telefax: 0 62 02 / 6 03-199 Special high efficient filter media, national & international standards.

10 1 Seal Fibre please indicate ordering information "Seal Kit" A filter inspection by accredited certification bodies

E-Mail: Eppensteiner@compuserve.com also for water absorbing Quality assured!

11 1 Seal Fibre (e.g. TÜV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc.) is possible on request.

Internet: www.Eppensteiner.de Technical modifications reserved! 10/01/10.99/6000

Filler nozzle and filler strainer only available as unit

Potrebbero piacerti anche

- Pressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsDocumento12 paginePressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsOleg080Nessuna valutazione finora

- HY11-3362 Press Control PPCC UKDocumento40 pagineHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- Cat Hy14 1600 Denison Products PDFDocumento438 pagineCat Hy14 1600 Denison Products PDFEmiliano MercadoNessuna valutazione finora

- Filter DF LFengDocumento9 pagineFilter DF LFengAbbasNessuna valutazione finora

- Duplex Filter PDFDocumento4 pagineDuplex Filter PDFmd abNessuna valutazione finora

- CP CatalogDocumento20 pagineCP CatalogCentral Hydraulics100% (1)

- Re 15190Documento24 pagineRe 15190Ahmed Abd ElhakeemNessuna valutazione finora

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Documento12 pagineDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981Nessuna valutazione finora

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocumento10 pagineHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataNessuna valutazione finora

- Table of ContentsDocumento27 pagineTable of ContentsEng-Mohammed SalemNessuna valutazione finora

- 1600 SERIES: Gear Pumps and MotorsDocumento16 pagine1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- A4VG - Data Sheet - Serie 40Documento68 pagineA4VG - Data Sheet - Serie 40Aurimas BendinskasNessuna valutazione finora

- Hydraulic Remote ControlsDocumento64 pagineHydraulic Remote Controlswalk111Nessuna valutazione finora

- Cruce de Filtros Stauff Re Hydac PDFDocumento7 pagineCruce de Filtros Stauff Re Hydac PDFHIDRAFLUIDNessuna valutazione finora

- Re 91401Documento20 pagineRe 91401JozefNessuna valutazione finora

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocumento8 pagine4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNessuna valutazione finora

- HydraulicsDocumento253 pagineHydraulicsvelavansuNessuna valutazione finora

- Accumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesDocumento27 pagineAccumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesPedro MendozaNessuna valutazione finora

- TDV 100Documento6 pagineTDV 100林育豪Nessuna valutazione finora

- S1 AM019 C DenisonDocumento25 pagineS1 AM019 C DenisonEmerson MazzaroloNessuna valutazione finora

- PVG 16 and PVG 32 Service Assembly/ Disassembly GuideDocumento28 paginePVG 16 and PVG 32 Service Assembly/ Disassembly Guidephankhoa83-1Nessuna valutazione finora

- D155E 10.02 (DOWMAX English)Documento50 pagineD155E 10.02 (DOWMAX English)Nastase Dan NicusorNessuna valutazione finora

- Hägglunds - Choice of Hydraulic Fluid PDFDocumento2 pagineHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNessuna valutazione finora

- Kpa Pump SealDocumento6 pagineKpa Pump Sealedwin edarNessuna valutazione finora

- Bargawan Attendence AugDocumento38 pagineBargawan Attendence Auggolu23_1988Nessuna valutazione finora

- Series PVS32EH140 ParkerDocumento20 pagineSeries PVS32EH140 ParkerAlejandro DuranNessuna valutazione finora

- PVB PVBQ A10vso PVHDocumento38 paginePVB PVBQ A10vso PVHWilliam ValenciaNessuna valutazione finora

- Atos - Modular Relief Valve - HMP HM KMDocumento4 pagineAtos - Modular Relief Valve - HMP HM KMClaudecir PereiraNessuna valutazione finora

- Control LR2G RexrothDocumento10 pagineControl LR2G RexrothMiguel Angel LopezNessuna valutazione finora

- WP Cross ReferenceDocumento12 pagineWP Cross ReferenceCentral HydraulicsNessuna valutazione finora

- Differential Pressure GaugeDocumento2 pagineDifferential Pressure GaugeManikandan SenthilNessuna valutazione finora

- Open Center Control Block in Mono Block DesignDocumento12 pagineOpen Center Control Block in Mono Block DesignnksiavashNessuna valutazione finora

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsDocumento14 pagineService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaNessuna valutazione finora

- W1500 Series Hydraulic Pump: Concentric ABDocumento12 pagineW1500 Series Hydraulic Pump: Concentric ABvut73 a100% (1)

- Aa2fm Model CodeDocumento27 pagineAa2fm Model CodeCristianNessuna valutazione finora

- Part Number TW600: Installation, Operation, and MaintenanceDocumento20 paginePart Number TW600: Installation, Operation, and MaintenanceLuis AlbarracinNessuna valutazione finora

- Excava e PDFDocumento22 pagineExcava e PDFFaserphi SacNessuna valutazione finora

- Installation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpDocumento14 pagineInstallation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpAPURV GOYALNessuna valutazione finora

- Denison HydraulicsDocumento48 pagineDenison HydraulicsPartagon PowNessuna valutazione finora

- Re92060 2014-04Documento28 pagineRe92060 2014-04Ibrahim GökmenNessuna valutazione finora

- Hydraulic Cartridge SystemsDocumento14 pagineHydraulic Cartridge SystemsJas SumNessuna valutazione finora

- Atos Servo Valve TFS330Documento10 pagineAtos Servo Valve TFS330back1949Nessuna valutazione finora

- 3-5400 GB PDFDocumento16 pagine3-5400 GB PDFShijumon KpNessuna valutazione finora

- Hagglunds CADocumento84 pagineHagglunds CAVINAY VISHWAKARMANessuna valutazione finora

- Rcoa1806 03 03Documento36 pagineRcoa1806 03 03Fernando Sabino100% (1)

- Mas 7 PDFDocumento16 pagineMas 7 PDFAbbas ALhasnawyNessuna valutazione finora

- Rotary PowerDocumento2 pagineRotary Powerclaudiu hohotaNessuna valutazione finora

- Bladder-Type Accumulator HAB: RE 50170/03.2014, Bosch Rexroth AGDocumento20 pagineBladder-Type Accumulator HAB: RE 50170/03.2014, Bosch Rexroth AGShariq KhanNessuna valutazione finora

- D7150 en PDFDocumento4 pagineD7150 en PDFSasko Dimitrov100% (1)

- Motores HagglundsDocumento8 pagineMotores HagglundsThiago SilvaNessuna valutazione finora

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Documento42 paginep1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosNessuna valutazione finora

- Denison Calzoni Type MRT Mrte MRTFDocumento24 pagineDenison Calzoni Type MRT Mrte MRTFSilvio RomanNessuna valutazione finora

- P 16 SeriesDocumento17 pagineP 16 SeriesJas SumNessuna valutazione finora

- Pages From Two - Stage - Booster PDFDocumento16 paginePages From Two - Stage - Booster PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIA100% (1)

- Re92105 01 X b2 - 2017 08Documento56 pagineRe92105 01 X b2 - 2017 08cln100% (1)

- Eaton EN-0201 ® Hydraulic MotorDocumento8 pagineEaton EN-0201 ® Hydraulic Motormemelo3Nessuna valutazione finora

- 7 PVG ActuatorsDocumento87 pagine7 PVG ActuatorsJose Manuel Barroso PantojaNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- FitTestAdapters PDFDocumento1 paginaFitTestAdapters PDFStivens Marin MedinaNessuna valutazione finora

- Series: Large Flow Air FilterDocumento2 pagineSeries: Large Flow Air FilterRafael LimaNessuna valutazione finora

- American University of Beirut Aub Thesis TemplateDocumento12 pagineAmerican University of Beirut Aub Thesis TemplateHassane EzzeddineNessuna valutazione finora

- WaterproofingDocumento29 pagineWaterproofingAakansha DNessuna valutazione finora

- Centum VPDocumento101 pagineCentum VPgopalNessuna valutazione finora

- Thermal Processing - Quality Management Is Vital in Heat-TreatingDocumento1 paginaThermal Processing - Quality Management Is Vital in Heat-TreatingJader PitangueiraNessuna valutazione finora

- PC700-8 Uess15301 1208Documento24 paginePC700-8 Uess15301 1208LTATECNICONessuna valutazione finora

- Kill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualDocumento7 pagineKill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualGourav RanaNessuna valutazione finora

- Training CoursesDocumento16 pagineTraining CoursesFeroz KhanNessuna valutazione finora

- Brilliance - 64 - (ct101) - Site - Guidefor TrailerDocumento19 pagineBrilliance - 64 - (ct101) - Site - Guidefor Trailerbody2030Nessuna valutazione finora

- Annex12 Technical Cards For Accessible ConstructionDocumento44 pagineAnnex12 Technical Cards For Accessible Constructionarchitectfemil6663Nessuna valutazione finora

- Physics I Problems PDFDocumento1 paginaPhysics I Problems PDFbosschellenNessuna valutazione finora

- Refrigerator: Service ManualDocumento44 pagineRefrigerator: Service ManualBetileno QuadAlexNessuna valutazione finora

- Projeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosDocumento7 pagineProjeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosLuís Paulo CardosoNessuna valutazione finora

- Building Applications in C# - InTLDocumento682 pagineBuilding Applications in C# - InTLMustehsan Armaghan Ghouri Magkacgck100% (1)

- RA 7920 Section 33Documento1 paginaRA 7920 Section 33Renz Emil ReyesNessuna valutazione finora

- STK412 150 Sanyo PDFDocumento4 pagineSTK412 150 Sanyo PDFroger.Nessuna valutazione finora

- Uk Fat 2017Documento178 pagineUk Fat 2017Christopher J MillsNessuna valutazione finora

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocumento15 pagine000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- D91 PDFDocumento3 pagineD91 PDFJuan Diego ArizabalNessuna valutazione finora

- TDG11Documento100 pagineTDG11Splycho GoranNessuna valutazione finora

- EnglishDocumento6 pagineEnglishThineswary Siva naiduNessuna valutazione finora

- Un 2 Terrazzo FlooringDocumento6 pagineUn 2 Terrazzo FlooringRNessuna valutazione finora

- Castrol - Iceomatic SW 68Documento7 pagineCastrol - Iceomatic SW 68advantage025Nessuna valutazione finora

- Physics 02-07 Centripetal Force and Banked CurvesDocumento2 paginePhysics 02-07 Centripetal Force and Banked CurveslatteNessuna valutazione finora

- Pipe Color CodeDocumento1 paginaPipe Color CodePatricia de los SantosNessuna valutazione finora

- Hitachi EX3600 Hydraulic Excavator PDFDocumento11 pagineHitachi EX3600 Hydraulic Excavator PDFChaerul Umami100% (1)

- 496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFDocumento40 pagine496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFbenjaminhuku100% (5)

- Group 2 (ME 03) - Hoa Phat GroupDocumento42 pagineGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhNessuna valutazione finora

- C#.Net Interview Questions and AnswersDocumento11 pagineC#.Net Interview Questions and AnswersManoj ManuNessuna valutazione finora

- Comparison Between Zvs and ZVS-ZCS Bidirectional DDocumento6 pagineComparison Between Zvs and ZVS-ZCS Bidirectional DSUNIL MANJHINessuna valutazione finora

- Synopsis of Power FactorDocumento10 pagineSynopsis of Power FactorRavi TiwariNessuna valutazione finora