Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CWC-BookletF1 15

Caricato da

satnamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CWC-BookletF1 15

Caricato da

satnamCopyright:

Formati disponibili

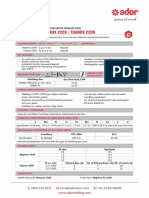

AUTOMIG 90S-B3 / GMAW/GTAW

LOW ALLOY STEEL

TIGFIL 90S-B3 (High Temperature)

2.25Cr–1Mo COPPER COATED LOW ALLOY WIRE FOR CREEP RESISTANCE

CLASSIFICATION : EN ISO 21952-A AWS A/SFA 5.28 APPROVALS :

Automig 90S-B3: G CrMo2Si ER90S-B3 IBR

Tigfil 90S-B3: W CrMo2Si ER90S-B3 IBR/NPCIL/BHEL

KEY FEATURES :

• Copper coated low alloy steel solid filler wire & rod • Typical 2.25 Cr-1 Mo weld deposit

• Uniform copper coating • Superior strength and toughness after PWHT

• Deposit notch free welds with excellent mechanical • Radiographic quality weld

properties

GMAW: DCEP

WELDING POSITION :

GTAW: DCEN

Shielding Gas Gas Flow Rate, LPM Stickout, mm

GMAW: Ar/1-5O2 15-22 10-20

GTAW: Ar 10-15 -

TYPICAL APPLICATIONS :

• Welding of 2.25Cr-0.5Mo and 2.25Cr-1Mo type • Joining of P5A materials

creep resistant steels • Cr-Mo and Cr-Mo-V bearing steels for high

• Joining ASTM A 335 Gr.P22, A 387 Gr.22 materials temperature applications

• Refineries, Petrochemicals and fertilizers plant • Suitable for 12CrMo9-10, 10CrSiMoV7 German steels

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si Cr Mo Cu* S P

Specification 0.07-0.12 0.40-0.70 0.40-0.70 2.30-2.70 0.90-1.20 0.35 max 0.025 max 0.025 max

* Including Cu in the coating

MECHANICAL PROPERTIES OF ALL WELD METAL :

Condition UTS, MPa YS at 0.2% offset, MPa EL%

Specification PWHT: 690°C for 1 Hr 620 min 540 min 17 min

Mechanical properties will vary with the type of shielding gas used.

CREEP TEST DATA FOR TIGFIL 90S-B3:

Temperature,OC Stress, MPa Duration, Hrs Strain% after 1000 Hrs

550 140 1000 0.92

PWHT: 690°C for 1 Hr

600 80 1000 1.28

PACKING DATA :

Ø, mm Kg/Spool

Automig 90S-B3 1.2 15

1.6 15

Ø x L, mm Primary Box, Kg No. of Primary Boxes Net Wt. of Carton, Kg

1.6 x 1000 5 4 20

Tigfil 90S-B3

2.0 x 1000 5 4 20

2.5 x 1000 5 4 20

EQUIVALENT : SMAW Electrode: Cromoten C

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

15

Potrebbero piacerti anche

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- CWC-BookletF1 24Documento1 paginaCWC-BookletF1 24Jagannath SahuNessuna valutazione finora

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocumento1 paginaAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Documento1 paginaAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Automig 70S A1 - Tigfil 70S A1Documento1 paginaAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNessuna valutazione finora

- Automig 80s G Tigfil 80s GDocumento1 paginaAutomig 80s G Tigfil 80s Gvijaysvm999Nessuna valutazione finora

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Documento1 paginaAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNessuna valutazione finora

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Documento1 paginaAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- GBTDocumento1 paginaGBTRaviTeja BhamidiNessuna valutazione finora

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Documento1 paginaAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Automig FC 71 T1Documento1 paginaAutomig FC 71 T1Sushil BhansaliNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Documento1 paginaAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNessuna valutazione finora

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Automig 70S-61Documento1 paginaAutomig 70S-61tarun kaushalNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocumento1 paginaMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocumento1 paginaMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNessuna valutazione finora

- Ador - Auto Mig 720 E71t1Documento1 paginaAdor - Auto Mig 720 E71t1RaviTeja BhamidiNessuna valutazione finora

- Bronze C86300 SpecificationsDocumento2 pagineBronze C86300 SpecificationsDoss MartinNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- T700S Technical Data Sheet PDFDocumento2 pagineT700S Technical Data Sheet PDFjairoNessuna valutazione finora

- 3dprint AM P22: Material TypeDocumento1 pagina3dprint AM P22: Material TypeKara WhiteNessuna valutazione finora

- Supabase X Plus 2Documento1 paginaSupabase X Plus 2Michael FortunaNessuna valutazione finora

- Midalloy ER80S B6 EB6Documento1 paginaMidalloy ER80S B6 EB6joel cisnerosNessuna valutazione finora

- SA 387 Grade 91 Class 2Documento4 pagineSA 387 Grade 91 Class 2briang-2Nessuna valutazione finora

- Ampcoloy 95: Technical Data SheetDocumento1 paginaAmpcoloy 95: Technical Data Sheetmarceloalves.dsNessuna valutazione finora

- CWC-BookletF1 29 PDFDocumento1 paginaCWC-BookletF1 29 PDFJagannath SahuNessuna valutazione finora

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocumento2 pagineDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNessuna valutazione finora

- Er100s GDocumento1 paginaEr100s GAhmed Abdel NabiNessuna valutazione finora

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocumento1 paginaCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNessuna valutazione finora

- Rod - Union I Crmo 910Documento1 paginaRod - Union I Crmo 910Rushita SolankiNessuna valutazione finora

- Copper Cu-Dhp / Sf-Cu: Page 1/2Documento2 pagineCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNessuna valutazione finora

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Documento2 pagineUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNessuna valutazione finora

- Ficha Técnica CarborodDocumento1 paginaFicha Técnica CarborodAndres NuñezNessuna valutazione finora

- Nickel Aluminium Bronce SB-148 C95800Documento2 pagineNickel Aluminium Bronce SB-148 C95800matteo_1234Nessuna valutazione finora

- Primacore MW 71Documento2 paginePrimacore MW 71rjan7peNessuna valutazione finora

- Supabase-X-Plus AdorDocumento1 paginaSupabase-X-Plus AdorJagan TnNessuna valutazione finora

- Stainless SteelDocumento1 paginaStainless SteelSadashiva sahoo100% (1)

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- X Bond: Welding Electrode For Structural Welding ApplicationDocumento1 paginaX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNessuna valutazione finora

- Typical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormDocumento2 pagineTypical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormzahraNessuna valutazione finora

- Ampcoloy 972: Technical Data SheetDocumento1 paginaAmpcoloy 972: Technical Data SheetmazaherramazaniNessuna valutazione finora

- ASTM A106 Data SheetDocumento4 pagineASTM A106 Data Sheetmarcelomaster88Nessuna valutazione finora

- Midalloy ER70S B2LDocumento1 paginaMidalloy ER70S B2LNhien ManNessuna valutazione finora

- Midalloy ER70S B2LDocumento1 paginaMidalloy ER70S B2LNhien ManNessuna valutazione finora

- Cu ZN 15 TombacDocumento2 pagineCu ZN 15 TombacPetrus UngureanuNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Documento1 paginaAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNessuna valutazione finora

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Documento1 paginaAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNessuna valutazione finora

- CWC-BookletF1 59Documento1 paginaCWC-BookletF1 59satnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocumento1 paginaAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNessuna valutazione finora

- Tigfil Cuni: Classification: ApprovalsDocumento1 paginaTigfil Cuni: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 paginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNessuna valutazione finora

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Documento1 paginaAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNessuna valutazione finora

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 paginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNessuna valutazione finora

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 36 PDFDocumento1 paginaCWC-BookletF1 36 PDFJagannath SahuNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- CWC-BookletF1 38 PDFDocumento1 paginaCWC-BookletF1 38 PDFsatnamNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- B16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesDocumento12 pagineB16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesInaamNessuna valutazione finora

- Duplex Stainless SteelsDocumento7 pagineDuplex Stainless SteelsRizalzi BachtiarNessuna valutazione finora

- Batteries: Periyanayaga Kristy.A, Ph.D. Research Scholar SRM Universtiy ChennaiDocumento20 pagineBatteries: Periyanayaga Kristy.A, Ph.D. Research Scholar SRM Universtiy ChennaiYashwanth S DNessuna valutazione finora

- Msds Constellium Aluminium AlloysDocumento6 pagineMsds Constellium Aluminium AlloysDhani PriyambodoNessuna valutazione finora

- DisinfectantsDocumento4 pagineDisinfectantsPhu NguyenNessuna valutazione finora

- Stainless Steel GradesDocumento1 paginaStainless Steel GradesRm1262Nessuna valutazione finora

- CHM13P Learning Task 4Documento7 pagineCHM13P Learning Task 4Paolo GochingcoNessuna valutazione finora

- CinnamylDocumento3 pagineCinnamyljennyihateNessuna valutazione finora

- Qualitative Analysis Guide AlevelDocumento29 pagineQualitative Analysis Guide Aleveljames kitigandaNessuna valutazione finora

- Acids, Bases and Chemical Bonding Challenging QuestionsDocumento6 pagineAcids, Bases and Chemical Bonding Challenging Questionschong5650% (2)

- Austin Marr - Lab 2 Flame Test InquiryDocumento3 pagineAustin Marr - Lab 2 Flame Test Inquiryapi-427302061Nessuna valutazione finora

- Student Exploration: IsotopesDocumento11 pagineStudent Exploration: IsotopesDaniella Rivera41% (17)

- Chemistry CHP Ter 8Documento21 pagineChemistry CHP Ter 8IZIKNessuna valutazione finora

- Dissimilar Metal Welds: Inconel To Carbon Steel: Steven KnappDocumento27 pagineDissimilar Metal Welds: Inconel To Carbon Steel: Steven KnappRebecca KelleyNessuna valutazione finora

- IGCSE Chem LoresDocumento16 pagineIGCSE Chem LoresApples ATGSNessuna valutazione finora

- 316 Tech DataDocumento1 pagina316 Tech Datatris khanNessuna valutazione finora

- Valve Material EquivalentsDocumento3 pagineValve Material EquivalentstungxuanbrNessuna valutazione finora

- Revision & High-Level Exercises in Chemistry, Egyptian Curriculum, 1 Sec, For Chemistry Teacher Andrew Medhat 2023-2024Documento70 pagineRevision & High-Level Exercises in Chemistry, Egyptian Curriculum, 1 Sec, For Chemistry Teacher Andrew Medhat 2023-2024yassin.study2008Nessuna valutazione finora

- Equipment Type: Stainless Steel 316 (SS 316)Documento3 pagineEquipment Type: Stainless Steel 316 (SS 316)eze josephNessuna valutazione finora

- Company Profile InductionDocumento11 pagineCompany Profile InductionGuptaVipinNessuna valutazione finora

- Incompatible Chemical Storage ChecklistDocumento2 pagineIncompatible Chemical Storage ChecklistKukuh WidodoNessuna valutazione finora

- Cherry Bomb Lip Tint in OilDocumento2 pagineCherry Bomb Lip Tint in Oilazarine wahanaNessuna valutazione finora

- 1 PPMDocumento3 pagine1 PPMpepayatomat100% (1)

- Product Information Flyer: CIMTECH® 285Documento2 pagineProduct Information Flyer: CIMTECH® 285sobheysaidNessuna valutazione finora

- Prueba de PreeceDocumento18 paginePrueba de PreeceSebastián AlmagroNessuna valutazione finora

- 4.4 IGCSE Chemistry Topic 4 Electrochemistry Electroplating Set 1 QP Ms PreviewDocumento4 pagine4.4 IGCSE Chemistry Topic 4 Electrochemistry Electroplating Set 1 QP Ms PreviewAbdul RasheedNessuna valutazione finora

- Corrosion and Compatibility Considerations of Liquid Metals For Fusion Reactor ApplicationDocumento12 pagineCorrosion and Compatibility Considerations of Liquid Metals For Fusion Reactor ApplicationMax SmithNessuna valutazione finora

- Amali Wajib Kimia Tingkatan 4Documento18 pagineAmali Wajib Kimia Tingkatan 4NUR FARRAH NAJIHAH BINTI AMIR KPM-GuruNessuna valutazione finora

- Metalworking Handbook Principles and Procedures 1976Documento473 pagineMetalworking Handbook Principles and Procedures 1976Rob FurnaldNessuna valutazione finora

- Activating DMI 65 Step by Step ProcedureDocumento3 pagineActivating DMI 65 Step by Step Procedureashry09Nessuna valutazione finora