Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CWC-BookletF1 10

Caricato da

satnamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CWC-BookletF1 10

Caricato da

satnamCopyright:

Formati disponibili

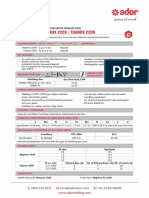

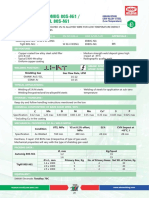

AUTOMIG 70S-G GMAW/GTAW C-Mn STEEL

COPPER COATED GMAW SOLID WIRE FOR WELDING C-Mn STEEL

CLASSIFICATION : EN ISO 14341-A AWS A/SFA 5.18

G 42 3 C G4Si1 ER 70S-G

G 46 3 M G4Si1

KEY FEATURES :

• C-Mn steel GMAW solid wire • Suitable for applications where dirt, rust or

• Uniform copper coating mill-scale is present

• Smooth wire feeding • All Position Welding capability

• Can be use with 100% CO2, Ar+CO2 • Radiographic quality weld

WELDING POSITION : DCEP

Shielding Gas Gas Flow Rate, LPM Stickout, mm

CO2 12-18 10-20

80Ar+20CO2 17-22 10-20

TYPICAL APPLICATIONS :

• Pressure vessels, LPG Cylinders • General fabrication

• Construction and mining equipment • Farm implements, Steel casings

• Pipe and Structural steel welding • High-speed robotic, automatic and

• Thin sheet metal, Auto body semi-automatic welding applications

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si S P Cu*

Specification 0.06-0.14 1.60-1.90 0.80-1.15 0.025 max 0.025 max 0.35 max

* Including Cu in the coating

MECHANICAL PROPERTIES OF ALL WELD METAL :

Shielding Gas UTS, MPa YS at 0.2% EL% CVN Impact

Condition

offset, MPa at -30°C, J

Specification As Welded 100% CO2 520 min 420 min 22 min 47 min

Specification As Welded 80Ar + 20CO2 550 min 460 min 24 min 47 min

Hardness, 3 Layer: 210 BHN max (irrespective of type of gas used) with mixed gas mechanical properties will be higher.

PARAMETERS - PACKING DATA :

Ø, mm Voltage, V Amperage, A Kg/Spool MIGPAC DRUM, Kg

0.8 17-27 80-250 15 100 / 250

1.0 18-30 100-350 15 100 / 250

1.2 20-34 120-400 15 100 / 250

1.6 24-36 150-450 15 100 / 250

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

10

Potrebbero piacerti anche

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Automig 70S-61Documento1 paginaAutomig 70S-61tarun kaushalNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- Automig FC 71 T1Documento1 paginaAutomig FC 71 T1Sushil BhansaliNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- Automig 70S A1 - Tigfil 70S A1Documento1 paginaAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNessuna valutazione finora

- Electrode Booklet F Web 93Documento1 paginaElectrode Booklet F Web 93satnamNessuna valutazione finora

- GBTDocumento1 paginaGBTRaviTeja BhamidiNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Supabase-X-Plus AdorDocumento1 paginaSupabase-X-Plus AdorJagan TnNessuna valutazione finora

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Documento1 paginaAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- Celwel - 60 (Adore Electrodes)Documento1 paginaCelwel - 60 (Adore Electrodes)Harish KandollaNessuna valutazione finora

- CWC-BookletF1 24Documento1 paginaCWC-BookletF1 24Jagannath SahuNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Data Sheet A-10: Alloy TypeDocumento3 pagineData Sheet A-10: Alloy Typemohamed AdelNessuna valutazione finora

- CSF-71T Technical Report EN - V2Documento7 pagineCSF-71T Technical Report EN - V2Miroslav ThôngNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- X Bond: Welding Electrode For Structural Welding ApplicationDocumento1 paginaX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocumento2 pagineChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNessuna valutazione finora

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocumento1 paginaAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNessuna valutazione finora

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocumento1 paginaMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNessuna valutazione finora

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNessuna valutazione finora

- Elgamatic 100Documento1 paginaElgamatic 100Milos StoisavljevicNessuna valutazione finora

- Supabase X Plus 2Documento1 paginaSupabase X Plus 2Michael FortunaNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- Technical Report (CSF-81TM)Documento5 pagineTechnical Report (CSF-81TM)matiasg.sanchezv95Nessuna valutazione finora

- Idalloy: C MN Si CR Mo V P S CuDocumento1 paginaIdalloy: C MN Si CR Mo V P S CuiocephNessuna valutazione finora

- Automig 80s G Tigfil 80s GDocumento1 paginaAutomig 80s G Tigfil 80s Gvijaysvm999Nessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Documento1 paginaAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Purus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresDocumento1 paginaPurus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresYudhveer GrewalNessuna valutazione finora

- Electrode Booklet F Web 97Documento1 paginaElectrode Booklet F Web 97satnamNessuna valutazione finora

- 29102015000000B - Boehler DCMS-IG - SWDocumento1 pagina29102015000000B - Boehler DCMS-IG - SWErdinc BayatNessuna valutazione finora

- 29102015000000B - Boehler DCMS-IG - SWDocumento1 pagina29102015000000B - Boehler DCMS-IG - SWErdinc BayatNessuna valutazione finora

- 3dprint AM P22: Material TypeDocumento1 pagina3dprint AM P22: Material TypeKara WhiteNessuna valutazione finora

- Electrode Booklet F Web 21Documento1 paginaElectrode Booklet F Web 21satnamNessuna valutazione finora

- Datasheet Sanicro 72hpDocumento2 pagineDatasheet Sanicro 72hpphillipskincaidNessuna valutazione finora

- Technical Date Sheet Welding Wire: E R 7 0 S - GDocumento2 pagineTechnical Date Sheet Welding Wire: E R 7 0 S - GRahmat RiskiNessuna valutazione finora

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocumento9 pagineSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNessuna valutazione finora

- Midalloy ER80S B6 EB6Documento1 paginaMidalloy ER80S B6 EB6joel cisnerosNessuna valutazione finora

- Electrode Booklet F Web 100Documento1 paginaElectrode Booklet F Web 100satnamNessuna valutazione finora

- Railrod: Data SheetDocumento1 paginaRailrod: Data Sheetmohamed AdelNessuna valutazione finora

- Merit S-G: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNessuna valutazione finora

- Miginox 307: Classification: en Iso 14343-ADocumento1 paginaMiginox 307: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- Electrode Booklet F Web 121Documento1 paginaElectrode Booklet F Web 121satnamNessuna valutazione finora

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Documento1 paginaAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNessuna valutazione finora

- Automig FC 71T-1Documento1 paginaAutomig FC 71T-1Michael FortunaNessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Martin DuarteNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- CWC-BookletF1 59Documento1 paginaCWC-BookletF1 59satnamNessuna valutazione finora

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Documento1 paginaAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNessuna valutazione finora

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 paginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocumento1 paginaAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNessuna valutazione finora

- Tigfil Cuni: Classification: ApprovalsDocumento1 paginaTigfil Cuni: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 paginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Documento1 paginaAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNessuna valutazione finora

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADocumento1 paginaMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 36 PDFDocumento1 paginaCWC-BookletF1 36 PDFJagannath SahuNessuna valutazione finora

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Documento1 paginaAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNessuna valutazione finora

- CWC-BookletF1 38 PDFDocumento1 paginaCWC-BookletF1 38 PDFsatnamNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- Principles of Dynamics4Documento524 paginePrinciples of Dynamics4Christien MarieNessuna valutazione finora

- Iso 2503 2009 en PDFDocumento11 pagineIso 2503 2009 en PDFВикторNessuna valutazione finora

- Materials Today: Proceedings: Chirag D. Bhatt, Mukesh Nadarajan, R. Balaji, Isukapalli Rohith, Ashish SelokarDocumento7 pagineMaterials Today: Proceedings: Chirag D. Bhatt, Mukesh Nadarajan, R. Balaji, Isukapalli Rohith, Ashish SelokarRahulJNairNessuna valutazione finora

- Assignment On Wave Function and Born's Interpretation On Wave FunctionDocumento6 pagineAssignment On Wave Function and Born's Interpretation On Wave FunctionMehak MughalNessuna valutazione finora

- Chapter1 Intro ME651Documento93 pagineChapter1 Intro ME651Sahastranshu KomalangamNessuna valutazione finora

- SB 1803 R2 Operating TBO & HSI FrequencyDocumento22 pagineSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- Testing and Adjusting: Troubleshooting Problem ListDocumento101 pagineTesting and Adjusting: Troubleshooting Problem ListJose DarioNessuna valutazione finora

- 125 Series Diesel: ConvertibleDocumento2 pagine125 Series Diesel: ConvertibleLuis Alberto Serrano MesaNessuna valutazione finora

- TMA2 12 09 2021 UploadDocumento3 pagineTMA2 12 09 2021 UploadG.G. PRABHATH CHINTHAKANessuna valutazione finora

- Ecg303-M3-01 Soil Permeability and Seepage PDFDocumento20 pagineEcg303-M3-01 Soil Permeability and Seepage PDFDk AshokNessuna valutazione finora

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDocumento18 pagineDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajNessuna valutazione finora

- Notes PDFDocumento252 pagineNotes PDFclose022Nessuna valutazione finora

- Signum-Technical-Guide LO SAMPLING GUIDEDocumento30 pagineSignum-Technical-Guide LO SAMPLING GUIDEshirishkv100% (1)

- Duct Design For "Super" SupermarketDocumento47 pagineDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Chilled Water System OptimizationDocumento36 pagineChilled Water System OptimizationPramod EkNessuna valutazione finora

- ATV 250 ManualDocumento223 pagineATV 250 ManualDavid PootNessuna valutazione finora

- Centrifugal Pumps PresentationDocumento28 pagineCentrifugal Pumps Presentationprasoon_eilNessuna valutazione finora

- Helical Gears ProblemsDocumento29 pagineHelical Gears Problemsa17e100% (1)

- FlushFlo - Flush Bottom ValveDocumento2 pagineFlushFlo - Flush Bottom ValveVarun PatelNessuna valutazione finora

- Inplant Training Presentation Aniket Shinde 151Documento17 pagineInplant Training Presentation Aniket Shinde 151ajayNessuna valutazione finora

- Aerodynamic DragDocumento486 pagineAerodynamic Draggswicke gmailNessuna valutazione finora

- FGM Piston Liner Kit IndexDocumento88 pagineFGM Piston Liner Kit IndexLuis Arturo Arevalo LeonNessuna valutazione finora

- Combustion Instabilities PDFDocumento33 pagineCombustion Instabilities PDFMohamed FaragNessuna valutazione finora

- Performance Task in General Physics 1Documento3 paginePerformance Task in General Physics 1Erica JoyNessuna valutazione finora

- Correlation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001Documento21 pagineCorrelation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001lram70Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityMaulik PatelNessuna valutazione finora

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDocumento38 pagineTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanNessuna valutazione finora

- Project Name: Xflow Local Protection Water Mist System Area Reference: Main EngineDocumento5 pagineProject Name: Xflow Local Protection Water Mist System Area Reference: Main EngineAlexDorNessuna valutazione finora