Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Intertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas Carriers

Caricato da

mouloud miloudTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Intertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas Carriers

Caricato da

mouloud miloudCopyright:

Formati disponibili

INTERTANKO

GAS AND MARINE SEMINAR

Blending/Commingling of LPG Cargoes On Board

Gas Carriers.

Mr Stefanos Karakelles

Senior Manager Gas(LPG)

Leading the way; making a difference

LPG Blending and SOLAS Regulation VI 5-2

• At its 90th session in 2012, the IMO Maritime Safety

Committee adopted SOLAS Regulation VI 5-2.

• SOLAS Regulation VI 5-2 consists of 4 paragraphs and is

the result of lengthy deliberations at IMO beginning in

2005 and finally concluding in 2011 when MSC 89

approved the draft of SOLAS Regulation VI 5-2 and

authorized its circulation for subsequent approval at MSC

90

• The paragraph which is of importance with regards to LPG

blending is para .1:

Leading the way; making a difference

LPG Blending and SOLAS Regulation VI 5-2

.1 The physical blending of bulk liquid cargoes during sea

voyages is prohibited. Physical blending refers to the

process whereby the ship's cargo pumps and pipelines are

used to internally circulate two or more different cargoes

with the intent to achieve a cargo with a new product

designation. This prohibition does not preclude the master

from undertaking cargo transfers for the safety of the ship

or protection of the marine environment.

Leading the way; making a difference

LPG Blending and SOLAS Regulation VI 5-2

This Paragraph makes it clear that LPG Blending

during sea voyages is prohibited. Although IMO

decided that LPG blending cannot be performed

during sea voyages, it felt that it was beyond its

remit to specify if LPG blending should be allowed

within port limits.

It has therefore been left to each port state/port

authority to define the respective port location,

limits and circumstances under which blending may

be undertaken in each port.

Leading the way; making a difference

Reasons for Blending

LPG Blending is being performed on board gas carriers for

one of the following reasons.

• The reception facility might not have the tank space

required for blending.

• The reception facility might not have the

equipment/expertise needed for LPG blending.

• Blending might be interfering with shore facility’

loading/discharging schedule.

Leading the way; making a difference

Reasons for Blending

• Importing Butane in countries where the ambient

temperature drops below – 5C.

• The avoidance or reduction of tax (either import or

manufacturing tax).

• Quicker turnaround of the cargo being imported, as the

LPG mix would be directly fed to bottling plants, without

delay.

Leading the way; making a difference

Propane to Butane or Butane to Propane?

Propane to Butane

When propane is introduced to a butane tank, there will be

rapid rise in tank pressure as the cooler propane tends to

produce a large quantity of flash gas. If the propane is not

introduced in a controlled manner, the vessel’s cargo

compressors may not be able to cope up with the rise in tank

pressures. Also the temperature gradient needs to be

monitored, as temperature will tend to fall with introduction

of propane. The risk of thermal stresses / shock should be

considered during the blending process.

Leading the way; making a difference

Propane to Butane or Butane to Propane?

Butane to Propane

When butane is introduced in a propane tank, the rise in

tank pressure may not be immediate, but will tend to rise

after a time lag. This can take place once the vessel proceeds

to sea. Hence introducing of butane into a propane tank has

higher associated risks, as the rise in tank pressure may not

be apparent. It will tend to rise suddenly and could lead to

uncontrolled venting if not monitored carefully. The heavier

butane will also tend to stay in the bottom so the need for

circulating the cargo arises.

Leading the way; making a difference

Ways of Blending

1. Blending during Loading

2. Blending while at safe anchorage or at layby

berth

3. Blending during Discharging

Leading the way; making a difference

Blending in Various Ship Types

• On board Fully Pressurized vessels:

Is not a concern. Vessels are designed to withstand the pressure of all cargoes they are

carrying even if the cargo reaches ambient temperature.

• On board Semi-refrigerated vessels:

Is not considered a major safety issue, although the relief valve settings can vary (MARVS

Setting: 5~8.0 Bar) and the pressure of the resultant mix could exceed the MARVS setting.

• On board a Fully refrigerated vessels:

Can cause major concerns as these ships cannot carry the cargo at ambient temperatures.

The cargo carried, is cooled below its boiling point. (MARVS Setting: 0.45 Bar)

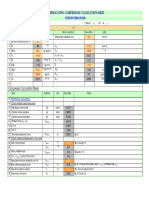

PRODUCT Chemical Symbol Atmospheric Boiling Point Vapour Pressure at 37.8ºC

(Bars Absolute)

PROPANE C3H8 -42.3 12.9

n-BUTANE C4H10 -0.5 3.6

i-BUTANE C4H10 -11.7 4.9

SHIP TYPE FULLY REF SEMI PRESS FULLY PRESS

MARVS BarG 0.45-0.50 5-8 17

Leading the way; making a difference

Hazards associated with Blending

1. Generation of flash gas

2. Loss of power

3. Miscommunication with shore

4. Cargo roll-over due to density inversion.

Leading the way; making a difference

Hazards associated with Blending

5. Stability and stress issues

6. Accuracy and sloshing issues

7. Thermal stress

Leading the way; making a difference

HUMAN FACTOR

Biggest Hazard also the Biggest Safeguard

Crew experience is a hazard common to each way

of blending.

On the other hand Crew experience can prove to be

the most important safety buffer when conducting

blending.

It has become common in the industry for

instructions on LPG blending to be issued without

taking into account whether those on board have

any previous experience of such operations.

Leading the way; making a difference

General Guidance

1. Carry out risk assessment of the operation.

2. Plan the operation and brief all personnel involved.

3. Specify the tank pressure at which the operation must be

halted.

4. Consider the mechanical and technical limitations of vessel’s

equipment.

5. Evaluate and monitor stability and stress conditions affecting

the vessel during every stage of the blending operation.

6. Ensure sufficient ullage is available in the tanks.

7. Monitor the hourly trend of change in tank pressure and tank

temperature. In case of an upward trend, reduce rate of

blending in order to stabilize pressure.

8. No other operations to be carried out during LPG blending.

Leading the way; making a difference

Commercial Implications for Owners

• Cargo calculations and Deadfreight

• Bunkers used for Blending

• Time used for Blending

• Tanks’ condition upon completion of discharge

Leading the way; making a difference

Commercial Implications for Owners

• Cargo calculations and Deadfreight.

After the blending operation, the density of the mixture will

not be a mathematical average of the two cargoes because

the molecular composition of the mixture will be different.

This can lead in cargo shortage claims. A prudent Owner

should get indemnification from Charterers in this regard.

The quantity the vessel would have been able to load in case

mixing was not required must be taken into account by the

Chartering department when calculating the freight rate. A

relevant deadfreight letter of protest and a statement should

be prepared by master.

Leading the way; making a difference

Commercial Implications for Owners

• Bunkers/Time used for Blending

Time Charter

Clearly communicate to Time Charterers that all costs for the blending

operation will be for their account and get their written agreement to

avoid future disputes. Clearly communicate an estimate of the time and

bunkers required.

Spot Charters

If a spot chartered vessel is requested to perform blending operations, in

absence of a blending clause in the fixture, an addendum to the charter

should be agreed identifying clearly that the owner will be compensated

for time lost (at the demurrage rate) and for additional bunkers

consumed. Clearly communicate an estimate of the time and bunkers

required.

Leading the way; making a difference

Commercial Implications for Owners

• Tanks condition upon completion of discharge

Due consideration should be given to the condition

of the tanks upon completion of discharge as LPG

mix heel might not be suitable for the vessel’s next

employment. For example, if the next cargo is a full

propane cargo, certain terminals require the vessel

to arrive fully ref in order to be allowed to load. This

would mean that the owner will be facing a cost in

order to arrive at that condition and should

consider if this cost should be passed to Charterers.

Leading the way; making a difference

Port of Gotheburg, Sweden: Photo: Johan Gahnström

Thank you

Stefanos Karakelles

INTERTANKO Senior Manager,Gas (Secondee) London office: St Clare House, 30-33 Minories, London EC3N 1DD, UK

T: +44 (0)20 7977 7037 (Dir) T: +44 20 7977 7010 (S/B) M: + 44 (0)7885897522 M(2): +30 69 55 666 423

E: Stefanos.Karakelles@intertanko.com

Leading the way; making a difference

Potrebbero piacerti anche

- LNG Risk Based Safety: Modeling and Consequence AnalysisDa EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNessuna valutazione finora

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryDa EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNessuna valutazione finora

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Isobutane Butane Fractionator PDFDocumento7 pagineIsobutane Butane Fractionator PDFhoustonmathNessuna valutazione finora

- Fractionation SystemsDocumento8 pagineFractionation SystemsKha Damayantirika Tsf 'reall'Nessuna valutazione finora

- Marine Pollution ConventionsDocumento4 pagineMarine Pollution Conventionssusnata236Nessuna valutazione finora

- U-type open-loop scrubber system layout, screens and alarm listsDocumento21 pagineU-type open-loop scrubber system layout, screens and alarm listshein chanNessuna valutazione finora

- Replace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsDocumento11 pagineReplace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsAmji ShahNessuna valutazione finora

- Design III Cargo Handling CalculationDocumento12 pagineDesign III Cargo Handling CalculationSean GyarinoNessuna valutazione finora

- Marine Vapour ControlDocumento3 pagineMarine Vapour Controlgatzbu81100% (1)

- Blending Parameters by NeniDocumento8 pagineBlending Parameters by NeniAjinkya PatilNessuna valutazione finora

- Appendix E Preliminary Hazard AnalysisDocumento66 pagineAppendix E Preliminary Hazard Analysissusa2536Nessuna valutazione finora

- Adnan Ezzarhouni GTTChina (Revised Version)Documento17 pagineAdnan Ezzarhouni GTTChina (Revised Version)ClemenNessuna valutazione finora

- Methanol ProposalDocumento7 pagineMethanol Proposalapi-292477726Nessuna valutazione finora

- Short History Og LNG VesselDocumento32 pagineShort History Og LNG VesseljwsommermannNessuna valutazione finora

- Estimate BOR in LNG Type C TankDocumento14 pagineEstimate BOR in LNG Type C TankNgoVietCuongNessuna valutazione finora

- A O R N G B: N Verview of Enewable Atural AS From IogasDocumento55 pagineA O R N G B: N Verview of Enewable Atural AS From IogasBagas YuhuNessuna valutazione finora

- Shell N2 CalculationDocumento6 pagineShell N2 Calculationmacea1Nessuna valutazione finora

- Tier III EGR For Large 2-Stroke MAN B&W Diesel EnginesDocumento6 pagineTier III EGR For Large 2-Stroke MAN B&W Diesel EnginesWon-young Seo100% (1)

- LNG Fundamentals Presentation 2019Documento26 pagineLNG Fundamentals Presentation 2019endosporaNessuna valutazione finora

- Recycling Co2: From Sun To GasDocumento15 pagineRecycling Co2: From Sun To GasAnonymous YOeo7EIVurNessuna valutazione finora

- AICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiDocumento16 pagineAICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiSrbislav GenicNessuna valutazione finora

- Hydrogen and AmmoniaDocumento74 pagineHydrogen and AmmoniaFreyrVoNessuna valutazione finora

- Validation of Openfoam For Heavy Gas Dispersion ApplicationsDocumento14 pagineValidation of Openfoam For Heavy Gas Dispersion ApplicationsAndrzej BąkałaNessuna valutazione finora

- D1560Documento7 pagineD1560Aleksei AvilaNessuna valutazione finora

- Calculation of maximum inbreathing and outbreathing flow ratesDocumento2 pagineCalculation of maximum inbreathing and outbreathing flow ratesFendy ShirahNessuna valutazione finora

- Design Study of LNG ShipDocumento21 pagineDesign Study of LNG ShipssnisharNessuna valutazione finora

- Fire Engulfment of LPG Storage TanksDocumento20 pagineFire Engulfment of LPG Storage TanksKhan Lala100% (1)

- Amends To SDs 2011Documento214 pagineAmends To SDs 2011duaankushNessuna valutazione finora

- IFIA Test Question Book English - August 2010Documento84 pagineIFIA Test Question Book English - August 2010Maksim Lemon Rutovic100% (2)

- 27snii15 Week27 2015Documento151 pagine27snii15 Week27 2015Kunal SinghNessuna valutazione finora

- Suez Canal TonnageDocumento6 pagineSuez Canal TonnageBen KleinNessuna valutazione finora

- Small-Scale LNG DistributionDocumento31 pagineSmall-Scale LNG DistributionRichard RichardNessuna valutazione finora

- Enhanced Gravity OWS Sizing SpreadsheetDocumento1 paginaEnhanced Gravity OWS Sizing Spreadsheetdeion29Nessuna valutazione finora

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocumento5 pagineGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Small-Scale LNG Production System Using Ammonia AbsorptionDocumento13 pagineSmall-Scale LNG Production System Using Ammonia Absorptionkaspersky2009Nessuna valutazione finora

- MEG Properties and UsesDocumento3 pagineMEG Properties and UsesLakshman NaikNessuna valutazione finora

- 6580 - 67 - r0 - OWT Open DrainDocumento10 pagine6580 - 67 - r0 - OWT Open DrainMohammad MohseniNessuna valutazione finora

- LNG ShipDocumento4 pagineLNG ShipAkademiks29Nessuna valutazione finora

- Bureau Veritas Issues FSU, FSRU Conversion GuidelinesDocumento1 paginaBureau Veritas Issues FSU, FSRU Conversion GuidelinesamirlngNessuna valutazione finora

- Gas ship measurement guidelinesDocumento40 pagineGas ship measurement guidelinesHenry MaedaNessuna valutazione finora

- Kuwait Crude AssayDocumento5 pagineKuwait Crude Assaysparsh dateyNessuna valutazione finora

- Anhydrous Ammonia Code of Practice December 06Documento76 pagineAnhydrous Ammonia Code of Practice December 06M SharadNessuna valutazione finora

- LNG Conversion Cost Estimation PDFDocumento4 pagineLNG Conversion Cost Estimation PDF123habib123fikriNessuna valutazione finora

- LPG Co-MinglingDocumento17 pagineLPG Co-MinglingderhgawenrahulNessuna valutazione finora

- Leaders On The Future of LNG and GasDocumento20 pagineLeaders On The Future of LNG and GasShekhrendu BhardwajNessuna valutazione finora

- Gas Hydrate Tutorial: Crystal Structures and PropertiesDocumento134 pagineGas Hydrate Tutorial: Crystal Structures and PropertiesGinoNessuna valutazione finora

- ISO TC 197 Hydrogen Standards UpdateDocumento14 pagineISO TC 197 Hydrogen Standards Updatejkhgvdj mnhsnjkhgNessuna valutazione finora

- 5NRJHL Saipem FY2020 Results JMEEBODocumento42 pagine5NRJHL Saipem FY2020 Results JMEEBOsudhakarrrrrrNessuna valutazione finora

- Data Sheet LNG Loading ArmDocumento2 pagineData Sheet LNG Loading ArmlguardiaNessuna valutazione finora

- GTDMR3Documento159 pagineGTDMR3Wilson KooNessuna valutazione finora

- BOIL OFF GAS ANALYSISDocumento8 pagineBOIL OFF GAS ANALYSISJetul PatelNessuna valutazione finora

- Frequently Asked Questions (FAQs) CII - Carbon Intensity Indicator - DNVDocumento4 pagineFrequently Asked Questions (FAQs) CII - Carbon Intensity Indicator - DNVanand raoNessuna valutazione finora

- LNG Physics Refrigeration CyclesDocumento25 pagineLNG Physics Refrigeration CyclesRodrigo AbdoNessuna valutazione finora

- Engine Heat Rejection CalcsDocumento2 pagineEngine Heat Rejection CalcsSumanth ReddyNessuna valutazione finora

- Ecole Sigtto QuestionareDocumento18 pagineEcole Sigtto QuestionareImmorthalNessuna valutazione finora

- LNG Tech 2Documento28 pagineLNG Tech 2genergia50% (2)

- Challenges During Operation and Shutdown of Waxy Crude PipelinesDocumento13 pagineChallenges During Operation and Shutdown of Waxy Crude PipelinesJesseNessuna valutazione finora

- Ocimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014Documento2 pagineOcimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014xingangNessuna valutazione finora

- Methanol As Marine Fuel: Environmental Benefits, Technology Readiness, and Economic FeasibilityDocumento52 pagineMethanol As Marine Fuel: Environmental Benefits, Technology Readiness, and Economic FeasibilityMiriam PedersenNessuna valutazione finora

- China's Maritime Silk Road Initiative and South Asia A Political Economic Analysis of Its Purposes, Perils, and Promise by Jean-Marc F. BlanchardDocumento249 pagineChina's Maritime Silk Road Initiative and South Asia A Political Economic Analysis of Its Purposes, Perils, and Promise by Jean-Marc F. Blanchardmouloud miloudNessuna valutazione finora

- Major Accidents On ShipsDocumento61 pagineMajor Accidents On ShipsGonçalo Cruzeiro100% (1)

- China's Maritime Silk Road Initiative and South Asia A Political Economic Analysis of Its Purposes, Perils, and Promise by Jean-Marc F. BlanchardDocumento249 pagineChina's Maritime Silk Road Initiative and South Asia A Political Economic Analysis of Its Purposes, Perils, and Promise by Jean-Marc F. Blanchardmouloud miloudNessuna valutazione finora

- Uk P and I - Risk - Awareness - Tanker - March - 2020 - WEB PDFDocumento36 pagineUk P and I - Risk - Awareness - Tanker - March - 2020 - WEB PDFmouloud miloudNessuna valutazione finora

- Chapter 3 - Collision Avoidance: Relative MotionDocumento88 pagineChapter 3 - Collision Avoidance: Relative Motionmouloud miloud100% (1)

- WHO Guidelines On Medical Examinations of Seafarers PDFDocumento70 pagineWHO Guidelines On Medical Examinations of Seafarers PDFiomerkoNessuna valutazione finora

- LR - What Do You Need To Know About LNG As A Marine Fuel - June 2012 PDFDocumento44 pagineLR - What Do You Need To Know About LNG As A Marine Fuel - June 2012 PDFmouloud miloudNessuna valutazione finora

- Watchstanding Guide For The Merchant Officer PDFDocumento124 pagineWatchstanding Guide For The Merchant Officer PDFmouloud miloudNessuna valutazione finora

- Maritime Safety GuideDocumento109 pagineMaritime Safety GuideBillyjeTadlas100% (2)

- GMDSS Maritime Radio OperatorDocumento150 pagineGMDSS Maritime Radio OperatorJag GonzalezNessuna valutazione finora

- MGN 324 (M+F) Amendment 1: Navigation: Watchkeeping Safety - Use of VHF Radio and AISDocumento8 pagineMGN 324 (M+F) Amendment 1: Navigation: Watchkeeping Safety - Use of VHF Radio and AISmouloud miloudNessuna valutazione finora

- Shipboard Operations PDFDocumento157 pagineShipboard Operations PDFmouloud miloud67% (3)

- Medical Handbook For SeafarersDocumento213 pagineMedical Handbook For SeafarersmuscalualinaNessuna valutazione finora

- Fire Safety Risk Assessment 2006 Factories and WarehousesDocumento148 pagineFire Safety Risk Assessment 2006 Factories and Warehouses3582100% (1)

- Medical Handbook For SeafarersDocumento213 pagineMedical Handbook For SeafarersmuscalualinaNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Echo Sounder Presentation1Documento92 pagineEcho Sounder Presentation1mouloud miloudNessuna valutazione finora

- Liquefied Gas Carrier Safety Manual SEO SummaryDocumento219 pagineLiquefied Gas Carrier Safety Manual SEO Summarymouloud miloudNessuna valutazione finora

- Lunchbox Session Actuators PDFDocumento20 pagineLunchbox Session Actuators PDFmouloud miloudNessuna valutazione finora

- Energy Efficiency Clauses in Charter Party Agreements - GA Psarros 2017Documento198 pagineEnergy Efficiency Clauses in Charter Party Agreements - GA Psarros 2017mouloud miloudNessuna valutazione finora

- Radar Workbook 2013Documento88 pagineRadar Workbook 2013sergiuserbanNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Maritime Law PDFDocumento638 pagineMaritime Law PDFmouloud miloud100% (4)

- Guidelines For Hazardous Area and Equipment of Electrical Installations On Board ChemicalOil Tankers, 2010Documento38 pagineGuidelines For Hazardous Area and Equipment of Electrical Installations On Board ChemicalOil Tankers, 2010Javier Perez HuertaNessuna valutazione finora

- Maritime Law PDFDocumento638 pagineMaritime Law PDFmouloud miloud100% (4)

- INTERTANKO Outbreak Management Plan COVID-19 PDFDocumento16 pagineINTERTANKO Outbreak Management Plan COVID-19 PDFmouloud miloudNessuna valutazione finora

- FGCE TTP GuideDocumento230 pagineFGCE TTP Guidemouloud miloudNessuna valutazione finora

- INTERTANKO Outbreak Management Plan COVID-19 PDFDocumento16 pagineINTERTANKO Outbreak Management Plan COVID-19 PDFmouloud miloudNessuna valutazione finora

- Guide For Measures To Cope With Degraded Marine Heavy (1996) PDFDocumento90 pagineGuide For Measures To Cope With Degraded Marine Heavy (1996) PDFmouloud miloudNessuna valutazione finora

- Coronavirus (Covid 19) Managing Ship and Seafarer Certificates During The PandemicDocumento21 pagineCoronavirus (Covid 19) Managing Ship and Seafarer Certificates During The PandemicDaniel Alberto HernándezNessuna valutazione finora

- OSPF Flashcards by Frederick Karban - BrainscapeDocumento51 pagineOSPF Flashcards by Frederick Karban - BrainscapeLIBERTY GAMIRANessuna valutazione finora

- Climate Solutions HandbookDocumento44 pagineClimate Solutions HandbookMARIVEL BASANessuna valutazione finora

- Darksoft'S Neogeo Multi Mvs / AesDocumento9 pagineDarksoft'S Neogeo Multi Mvs / AesCarlos Martínez GómezNessuna valutazione finora

- Master Governance Plan SummaryDocumento21 pagineMaster Governance Plan SummaryMichelle SaverNessuna valutazione finora

- Desmi Cargo Pumps CatalogDocumento8 pagineDesmi Cargo Pumps CatalogEmmanuel ToretaNessuna valutazione finora

- Domain Driven DesignDocumento9 pagineDomain Driven DesignZubair SanjraniNessuna valutazione finora

- Manu ResumeDocumento2 pagineManu ResumeManu sNessuna valutazione finora

- Dayalbagh Educational Institute: 1. Student Identity DetailsDocumento1 paginaDayalbagh Educational Institute: 1. Student Identity DetailsSwapnil RajputNessuna valutazione finora

- Cryptography CS 555: Topic 16: Key Management and The Need For Public Key CryptographyDocumento21 pagineCryptography CS 555: Topic 16: Key Management and The Need For Public Key Cryptographycrazz1Nessuna valutazione finora

- Bourbon Helios 3230 T DWT Dp2Documento2 pagineBourbon Helios 3230 T DWT Dp2Fikri KurniaNessuna valutazione finora

- Ju 120722120619 0Documento136 pagineJu 120722120619 0smilingeyes_nicNessuna valutazione finora

- NASA: 70842main FS-1998-09-34-LaRCDocumento2 pagineNASA: 70842main FS-1998-09-34-LaRCNASAdocumentsNessuna valutazione finora

- Canon 70 200 F4 Is Repair en PDFDocumento10 pagineCanon 70 200 F4 Is Repair en PDFfastbuuuuNessuna valutazione finora

- Epas11 Diagnostic Test: MULTIPLE CHOICE. DirectionsDocumento4 pagineEpas11 Diagnostic Test: MULTIPLE CHOICE. DirectionsAbanganPorferioNessuna valutazione finora

- Catalog Roxroth PDFDocumento115 pagineCatalog Roxroth PDFSidnei SilvaNessuna valutazione finora

- TC227 Shot Peening WD26910-1 060901Documento13 pagineTC227 Shot Peening WD26910-1 060901Bahadır Uysal100% (1)

- MT131 TMA 1st 2023-2024Documento6 pagineMT131 TMA 1st 2023-2024kareem978Nessuna valutazione finora

- Summative Test 7Documento9 pagineSummative Test 7Gel Obenza BunedNessuna valutazione finora

- New Ansaldo Energia Gas Turbine Passes Rigorous Testing - Power Engineering InternationalDocumento1 paginaNew Ansaldo Energia Gas Turbine Passes Rigorous Testing - Power Engineering Internationalajrivera1Nessuna valutazione finora

- ICT Prototype - PDF 022727Documento50 pagineICT Prototype - PDF 022727Nabukeera MugaggaNessuna valutazione finora

- Magenetic Chip Collector New 2Documento27 pagineMagenetic Chip Collector New 2Hemasundar Reddy JolluNessuna valutazione finora

- Elkefi Et Al 2022 Impact of Health Informatics On Patients Perception of Health Care Services Trends Over Time ofDocumento6 pagineElkefi Et Al 2022 Impact of Health Informatics On Patients Perception of Health Care Services Trends Over Time ofeva kacanjaNessuna valutazione finora

- Common Application Form I Part A For Establishment: Government of Andhra Pradesh Department of IndustriesDocumento3 pagineCommon Application Form I Part A For Establishment: Government of Andhra Pradesh Department of IndustriesLatha YerurNessuna valutazione finora

- Wu - Terms and ConditionsDocumento14 pagineWu - Terms and ConditionsMaria DharyasaNessuna valutazione finora

- Brainstorm and Idea Prioritization - IBMDocumento1 paginaBrainstorm and Idea Prioritization - IBM4022 - MANIKANDAN D - CSENessuna valutazione finora

- Universiti Teknologi Mara Final Examination: Confidential BM/APR 2009/MGT345/375Documento7 pagineUniversiti Teknologi Mara Final Examination: Confidential BM/APR 2009/MGT345/375legasijambang 83Nessuna valutazione finora

- Karadio 32 Oled Vs1053Documento1 paginaKaradio 32 Oled Vs1053Andy DanteNessuna valutazione finora

- Research Methodology - Unit - 3 - NotesDocumento10 pagineResearch Methodology - Unit - 3 - Notessatya prakashNessuna valutazione finora

- Sound Reinforcement Equipment Rack LayoutDocumento1 paginaSound Reinforcement Equipment Rack LayoutJeghiNessuna valutazione finora

- BUILDING TECH 1 Lect 3 MASONRYDocumento42 pagineBUILDING TECH 1 Lect 3 MASONRYElyzaGutierrezCabacesNessuna valutazione finora