Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eis Fareast Fuel PDF

Caricato da

ricchrist dela cruzDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eis Fareast Fuel PDF

Caricato da

ricchrist dela cruzCopyright:

Formati disponibili

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

1.0 EXECUTIVE SUMMARY:

1.1 Brief Company Profile:

FAR EAST FUEL CORP., herein referred as the Proponent with office address at El Camino

Rd.,Brgy. Bahay Pare, Meycauayan, Bulacan and managed by its President, Mr. Ruel S.

Mangaron and Mr. Jun S. Mangaron, VP-Marketing and PCO is currently in the business as

Environmental Service Provider and engage in the Treatment, Storage, Recycling and Disposal

of Hazardous Waste. The company is duly registered with the Securities and Exchange

Commission(SEC) under A200017520 and was issued Environmental Compliance Certificates

under ECC Ref. Code No. RO3-1103-0114.. The company was likewise issued Permit to

Operate Air Pollution Source and Control Installation and Discharge Permit by the EMB-

Regional Office III and was duly Accredited as Hazardous Waste Treater and Transporter by the

EMB under TR-R3-14-00070 respectively. FAR EAST FUEL CORP. was likewise issued by

BIR under Certificate No. 4RC0000388754 and TIN No. 210-962-171-000.

The Proponent after satisfactorily submitted all the information needed by the Environmental

Management Bureau-Department of Environment and Natural Resources with regards to the

registration of the Hazardous Waste Treatment/Storage/Disposal(TSD) was given Permit to

maintain/operate the following categories of TSD Facilities pursuant to Chapter 5.1 of DAO

2013-22:

Category B Thermal Treatment Facility for: Acid Wastes(B201-B299), Alkali Wastes(C301-

C399), Waste Organic Solvent(G703-G704),

Ink/Dyes/Pigments/Paints/Latex/Adhesives/Organic Sludge(F601-F699), Organic

Wastes(H802), Contaminated Empty Containers(J201), Immobilized Wastes(K301-K303), and

Miscellaneous Wastes(M501,M503 and M504).

Category D Recycling Facility for: Waste Oil(I101),Waste Vegetable Oil and Sludge(I102)

Tallow(I103), Oil Contaminated Materials(I104), Waste Electrical and Electronic

Equipment(M506), Waste Halogenated and Non Halogenated Organic Solvents(G703-G704).

Category E Facility for: Acid Wastes(B201-B299), Alkali Wastes(C301-C399), Busted

Fluorescent Lamps/Bulbs/CFLs(D407) and Empty Chemical Containers(J201)

Category F Facility for:Used Lead Acid Batteries(D407)

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

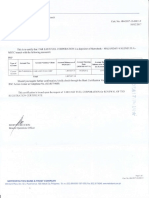

1.2 Organizational Structure:

1.3 Area and Location of the Proposed Project:

FAR EAST FUEL CORP. shall proposes to relocate its existing Hazardous Waste Oil

Treatment, Solid Hazardous and Medical Waste Treatment and Waste Tire Recycling Facility

from El Camino Rd., Brgy. Bahay Pare, Meycauayan, Bulacan to its newly acquired property

located at Brgy. Anyatam, San Ildefonso, Bulacan. The total land area of the property is more

or less 80,516 sq. m.(Pls. Refer to the attached TCTs)

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

PROJECT SITE

Barangay Antayam,

San Ildefonso,

Bulacan

HAZARDOUS MATERIAL TSD AND TIRE RECYCLING FACILITY FAR EAST FUEL CORP.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

PROJECT SITE

Barangay Antayam,

San Ildefonso,

Bulacan

HAZARDOUS MATERIAL TSD AND TIRE RECYCLING FACILITY FAR EAST FUEL CORP.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

VICINITY MAP

Barangay Antayam,

San Ildefonso,

Bulacan

HAZARDOUS MATERIAL TSD AND TIRE RECYCLING FACILITY FAR EAST FUEL CORP.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

LOCATION MAP

Barangay Antayam,

San Ildefonso,

Bulacan

HAZARDOUS MATERIAL TSD AND TIRE RECYCLING FACILITY FAR EAST FUEL CORP.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

1.4 Brief Project Description:

FAR EAST FUEL CORP. shall dismantle its existing TSD and Tire Recycling Facility at Brgy.

Bahay Pare, Meycauayan, Bulacan and transport all of these piece by piece or by bulk to the

proposed project site and newly acquired property at Brgy. Anyatam, San Ildefonso, Bulacan.

FAR EAST FUEL shall install at Brgy. Anyatam, San Ildefonso, Bulacan the following

facilities:

1. 2 sets of Waste Oil Treatment Plant with annual production capacity of 600 cubic meters

per day(Furnace1-400cu.m./day & Furnace2-200cu.m./day) of product oil;

-I101-Waste Oil Treatment @ 600 cu m./day

-I102-Waste Tallow Treatment @ 20 cu m/day

-I103 Treatment

-I104 Treatment

2. Solvent Recovery and Destruction Facility with capacity of 20 cu. m./day;

3. 2 sets Solid Hazardous and Medical Waste Treatment Facility with destruction capacity

of 1500 Tons/month;

4. Tire Recycling Facility with output production capacity of 67.50 Tons/day Tire Derived

Oil, 45.00 Tons/day Carbon Black, 22.50 Tons/day Steel Wire and 0.40 Tons/day Gasses.

5. Wastewater Treatment Facility(WTF) with a capacity of 60 cubic meters per day of

wastewater of Physico-chemical Treatment and 500 cu.meters per day for Biological

Treatment

6. Bulb Crushing Facility with capacity of 1.8 tons/day;

Treatment Capacity

Meycauayan

San Ildefonso

Plant

Description HW Class & HW (Code) Plant Treatment

Treatment

Capacity (New)

Capacity (Old)

Waste Oil 600 cu. Meters 600 cu. Meters

Treatment (I101) Waste Oil per day of per day of

Capacity product oil product oil

(B201-B299) Waste Acid

(C301-C399) Waste Alkali

(D401-D407,D499) Waste

Waste

Inorganic Chemicals, Electronic

Hazardous

Waste 1,500.00 1,500.00

Thermal

(F601-F699) Tons/Month Tons/Month

Treatment

Inks/Dyes/Pigments/Paints/Latex/

Facility

Adhesives/Organic Sludge

(G703-G704) Waste Organic

Solvent, Halogenated & Non

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Halogenated

(H801-H802) Putrescible Organic

Waste

(K301-K302) Immobilized Waste

(L401) Waste Organic Chemical

(M501-M505) Miscellaneous

Waste

(I101) Waste Oil

(J201) Contaminated Containers

With Input Capacity of 150.00 Output

Output Capacity

Tons/day Capacity

67.50 Tons/day

67.50 Tons/day

Tire Derived

Tire Derived Oil

Waste Tire Oil

Recycling 45.00 Tons/day 45.00 Tons/day

Facility Waste Tire Carbon Black Carbon Black

22.50 Tons/day 22.50 Tons/day

Steel Wire Steel Wire

0.40 Tons/day 0.40 Tons/day

Gasses Gasses

Waste Solvent (G703-G704) Waste Organic

20.00 20.00

Treatment Solvent Halogenated & Non

cu.meters/day cu.meters/day

Facility Halogenated

Waste Bulb

Lamps Crusher

(D407) Waste Organic Chemicals 1.80 Tons/day 1.80 Tons/day

Treatment

Facility

Physico-Chemical Treatment @

Wastewater

60cu.meters/day 560.00 560.00

Treatment

Biological Treatment @ 500 cu.meters/day cu.meters/day

Facility

cu.meters/day

(J201) Waste Containers

(B201-B299) Waste Acid

(C301-C399) Waste Alkali

(D401-D407,D499) Waste

Waste Inorganic Chemicals, Electronic

Contaminated Waste

500.00 500.00

Containers (F601-F699)

Tons/month Tons/month

Treatment Inks/Dyes/Pigments/Paints/Latex/

Facility Adhesives/Organic Sludge

(G703-G704) Waste Organic

Solvent, Halogenated & Non

Halogenated

(H801-H802) Putrescible Organic

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Waste

(K301-K302) Immobilized Waste

(L401) Waste Organic Chemical

(M501-M505) Miscellaneous

Waste

(I101) Waste Oil

(F601-F699) Inks/ Dyes/

Waste Sludge

Pigments/ Paints/Latex/

Treatment

Adhesives/Organic Sludge

Facility 3.00 Tons/day 3.00 Tons/day

(D499) Organic Chemicals

(Solidification/

(K301-K302) Immobilized Waste

Fixation)

(D405)

Non

Hazardous

Waste

1500.00 Tons/ 1500.00 Tons/

Materials

month month

Destruction

and Recovery

Facility

1.5 Project Rationale:

The Relocation of the TSD and Tire Recycling facility of FAR EAST FUEL CORP. was

conceptualized by the Board of Directors in order to provide more space for hazardous waste

storage, treatment, recycling and disposal facility because of the limited area at the El Camino

Rd., Brgy Bahay Pare, Meycauayan plant.

The total land area of the proposed project site covers more or less 80,516 sq. m. as earlier

mentioned compared to the 16,372 sq. m. in Bahay Pare Plant.

1.6 Pre-Construction Phase:

During this phase, the incorporators decided to transfer the TSD in order to provide more space ,

control and easy management of hazardous wastes treatment, storage, recycling and disposal.

The following activities were undertaken during the pre construction stage: Project Planning;

Negotiation with the owners of the acquired property; Preparation of Project Design and Plans;

and Securing Government Permits and Clearances.

Our preconstruction timetable is 6 months.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

1.7 Construction Phase:

The following activities shall be done during this stage:

1. Site Clearing and Grading;

-Perimeter Fence Construction

-Main Road Construction and Storm Drainage

-Parking Area Construction

2. Process Building Construction;

-Guard house, Power House, and Gen Set House Construction

-Construction of 4-Bay Ware House Bldng

-Production Bldg Construction

-Construction of Row Houses

-Admin Office Construction

-Motorpool Construction

-Machine shop Construction

-Tank Farm Construction

-Settling Tank Installation

3. Dismantling, Transport, Temporary Storage of Equipment from Bahay Pare-Plant to

Anyatam Plant;

4. Process Equipment Assembly

-Waste Oil Treatment and Storage Facility(I101)

-Storage and Thermal Destruction Facility for acid wastes(B201-B299), alkali

Wastes(C301-C399), waste organic solvents(G703-G704), ink/dyes/pigments/paints

Latex/adhesives/organic sludge(H801-H802), oil contaminated materials and

containers(I101), immobilized wastes(K301-K303),miscellaneous wastes(pathogenic

and infectious wastes(M501), pharmaceutical wastes and drugs(M503).

-Waste Solvent Treatment Processing Equipment

-Bulb Crushing Processing Equipment

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

-Tire Derived Fuel Processing Equipment

- Wastewater Treatment Facility(WTF)

5. Electrical/Instrumentation Installation

6. Plumbing installation and

7. Equipment Calibration and Dry Run

1.8 Description of the existing Surrounding Environment:

The primary impact zone was drawn at 500 m radius consisting of mixed uses such as Industrial,

Agricultural Commercial and Residential uses. The Industrial locators dominates the primary

impact zone seconded by agricultural locators(mostly orchards and grazing land). The immediate

adjoining areas is characterized by the following environmental setting:

North-Residential/Brgy. Road and Agricultural Use

South-Agricultural Use

East- Piggery Farm/Agricultural Use

West- Agricultural Use

Farther from the project site and within the secondary impact zone are also mixed uses consisting

of industrial, agricultural, institutional, commercial and residential uses. The agricultural sector

dominates this area in terms of land use and it can be said that the municipality of San Ildefoso,

Bulacan is Agricultural based which is mostly dedicated to rice and vegetable production and

orchards. The Agro-industrial sector comprising of backyard and commercial poultry and farms

are also present in the locality while commercial establishments are mostly located in the built up

areas of the municipality of San Ildefonso, Bulacan. These are the primary contributor of

government revenue aside from the agricultural sector in the municipality of San Ildefonso..

1.9 Government Permits and Clearances:

FAR EAST FUEL CORP. proposed Hazardous Waste TSD and Tire Recycling Facility

Project was issued the following Government Permits and Clearances for its proposed San

Ildefonso Plant:

1. Securities and Exchange Commission(SEC);

2. Barangay Business Clearance;

3. Zoning Certification;

4. DENR-CENRO Certification;

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

5. NIA Certification;

6. DAR Certification;

7. DA Certificate of Eligibility for Reclassification of Agricultural Lands;

8. Sanggunian Bayan Resolution;

9. Business Permit;

Previous Clearance and Permits Issued to Meycauyan Plant

1. Environmental Compliance Certificate(EMB-DENR);

2. Permit To Operate APSCI(EMB-DENR);

3. Discharge Permit(EMB-DENR);

4. DENR Hazardous Waste ID No. Registration(EMB-DENR);

5. TSD Registration Certificate(EMB-CO);

6. Registry Certificate for the Importation of Recyclable Materials containing Hazardous

Substances(EMB-CO);

7. Transporter Registration Certificate(EMB-CO);

8. BIR Certificate of Registration(BIR);

9. Accreditation as Oily Waste Collector(Philippine Coast Guard);

1.10 Impact Assessment:

Impact assessment of the proposed Relocation of the TSD Facility Project was conducted on all

phase of the project ie. pre construction, construction and operational phase to determine the

degree of impact and to cushion or minimize its impact to the environment. Results of which was

positive which means that all identified adverse impacts can be mitigated and that the project

will contribute to the welfare of the people of the primary impact area. The details of the impact

assessment shall be discussed in the later section of these IEE.

1.11 Environmental Management Plan:

Environmental Management Plan was likewise crafted in order to address the identified adverse

environmental impacts of the project during construction and operational phase. The detailed

discussion shall be fully discussed in the later section.

1.12 Environmental Monitoring Program:

An Environmental Monitoring Program was likewise crafted in order to monitor efficacy of the

EMP. The details of the monitoring program shall be discussed in the later section.

1.13 Evaluation and Recommendation:

Since all the identified and predicted impacts of the project to the environment is fully addressed

and mitigated it is recommended that the proposed relocation of the existing TSD Facilty of

FAR EAST FUEL from its Brgy. Bahay Pare, Meycauayan Plant to Brgy. Anyatam, San

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Ildefonso, Bulacan be issued an Environmental Compliance Certificate (ECC) in order to comply

with PD 1586 and other Environmental Laws.

1.14 Introduction:

1.14.1 Project Background:

As earlier mentioned, the project was conceptualized because of the limited area of the Bahay

Pare TSD Facility which restricts the movement, storage and disposal of hazardous waste and

waste tires and other materials for treatment/recycling in the firms facility.

1.14.2 EIA Approach and Methodology:

The Proponent did not find hard in the preparation of the EIA Study considering its expertise in

Hazardous Waste Treatment and disposal. Before negotiating with the procurement of the lot or

investing in the proposed project, the management organized a team conducted consultation

with leaders of the impacted barangays up to the municipal level. Primary and secondary data

and concerns were likewise inputted in this document.

1.14.3 EIA Process Documentation:

All the gathered data/concerns from interviews were documented and shall be part of the EIS

study. Key issues and concerns were air pollution, odor, solid waste and water pollution

including employment.

1.14.4 EIA Team:

The Proponent formed an EIA Team composed of the following:

Ruel S Mangaron, Team Leader

Emilio S. Mangaron, Member

Exequiel De Vera, Member

Engr. Romeo G. Cala, Member

Engr. Mark Odullo, Member

Merlin R. De La Paz, Member

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

2.0 PROJECT DESCRIPTION:

2.1 RATIONALE

The Proposed Hazardous Waste Treatment, Storage and Disposal(TSD), Wastewater

Treatment and Tire Recycling Facility of FAR EAST FUEL was conceived in order

to cater the growing demand for Service Provider of Hazardous Waste Treater due to

the strict implementation of RA 6969 in the country. The company aims also to

augment the government effort to clean the environment from hazards caused by

toxic and hazardous waste generated by human activities and to convert waste tires

into useful resource.

2.2 NAME AND ADDRESS OF THE PROPONENT:

NAME OF PROPONENT : FAR EAST FUEL CORP.

PROJECT NAME : Proposed Hazardous Waste TSD and

Tire Recycling Facility

PROJECT LOCATION : Brgy. Anyatam., San Ildefonso,

Bulacan

CONTACT PERSON : Emilio S. Mangaron, Jr.

VP Marketing/PCO

CONTACT NO. : 0920 954 71 70

COMPANY TIN NO. : 210-962-171-000

GEOGRAPHICAL COORDINATES : N 15 06’ 00.2”

E 120 57’ 04.4”

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

2.3 TYPE AND PURPOSE OF THE PROJECT:

TYPE OF PROJECT: Proposed TSD and Used Tire Recycling Facility

PURPOSE OF THE PROJECT: The purpose of the Proponent as earlier mentioned is

to cater the growing demand of industrial operations for Service provider in the

treatment, storage and disposal of hazardous wastes under RA 6969 and wastewater

under RA 9275 and to recover tire derived fuel from waste/scrap rubber tires.

2.4 LOCATION AND AREA COVERED BY THE PROJECT:

The proposed TSD and Tire Recycling Facility of the Proponent shall be relocated at

Brgy. Anyatam, San Ildefonso, Bulacan within the 80,516 sq. m. lot described in

CLOA-T-10325, Lot No. 1897-13,103 sq. m., CLOA-T-10324, Lot No. 1712-29775

sq. m. and TCT 88182, Lot No. 1896-37,638 sq. m. . The area is considered an

Agricultural area as per Zoning Certificate issued by the Zoning Administrator of the

municipality of San Ildefonso, Bulacan but was converted into Industrial by virtue of

SB Resolution No.2015-066 dated August 26, 2015.(Pls. Refer to the attached area

utilization plan)

2.5 PROJECT PHASES:

2.5.1 Pre Construction Phase:

Activities undertaken during this stage consist of the following:

1. Project Planning

2. Negotiations with the property owner

3. Preparation of plans

4. Securing Government Permits

As earlier mentioned preconstruction time table is 6 months.

2.5.2 Construction Phase:

During this phase site clearing, grading, construction of roadways,

drainage, electrical and plumbing installation and process buildings shall

be implemented.

The activities and estimated cost during this phase is stated below:

Activities: Cost

-Hauling of materials and Process Equipment 5,250,000

-Site Clearing and Grading 7,750,000

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

-Roadways and Drainage Installation 15,250,000

-Process Building Installation 55,500,000

-Electrical and Plumbing Installation 25,500,000

-Green area development 500,000

-Installation of parking area 4,000,000

-Electro-Mechanical Installation 10,500,000

-Wastewater Treatment Facility Installation 12,000,000

Total Cost P136,250,000

2.5.3 Operational Phase

It is important to secure first all required permits from the local and

national government before operating. FAR EAST FUEL CORP. shall

adopt the acceptance criteria in which only hazardous waste under the

registered category duly approve by EMB shall be accepted.

The Flow Process of Operation of the Treatment, Storage and Disposal of Hazardous Wastes,

Wastewater Treatment and Tire Recycling Facility of the Proponent is hereunder described and

discussed as follows:

Treatment, Storage and Disposal(TSD) of Hazardous Wastes:

Used Oil Treatment Process: Production Capacity- 600 cubic meters per day(Furnace1-

400cu.m./day and Furnace2-200cu.m./day)

For the treatment of used oil(I101), I102 and I103, the process involves the following:

Used Oil Delivery- Used oil from various industrial establishment are delivered onsite either in

drums or in truck lorry by accredited transporter.

Used Oil Acceptance- The materials delivered are inspected for quality and quantity along with

Manifest and Permit to Transport. Likewise, the Proponent shall ensure

that materials are properly labelled, packed and secured during the

delivery and with the waste category allowed by EMB.

Raw Used Oil Storage- The delivered used oil are either stored in drums or in Tanks. Transfer of

oil is done thru the use of oil pump to avoid spillage or material losses

that might contaminate the soil.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Used Oil Distillation- Used oil are fed into distillation furnace wherein it is heated at more or

less 370 degrees. The furnace is fired with combination of diesel fuel and

excess gas from hydroseal gas treatment. FAR EAST FUEL CORP. shall

operate 2 units Distillation Furnace with a cap. of 32,000 liters each.

Condensing - Gas produced in the distillation process are condensed in the condenser or

heat exchanger to form a distillate oil products which are sold to customers.

While the excess gas from the heat exchange passes thru the furnace to

avoid gas emission. The proponent shall install 2 sets of condensers with

cooling system and 2 sets distillate receiving tanks. Each condenser shall

also be provided with hydroseal gas treatment device or scrubber system to

treat excess gases before it is used as fuel in the furnace to avoid gas/odour

emission.

Product Storage- Product oil distillates are stored in oil tanks thru transfer oil pumps. The

storage tanks are provided with air relief valves/vents which are connected

piping system leading into the common hydroseal gas treatment

device/scrubber.

Polishing Vacuum Reactor- Oil distillate are transferred into polishing vacuum reactor for further

treatment. The reactor contains purifying additives and clay which

treats the distillate oil for impurities of moisture and water. The

polishing vacuum reactor furnace (1unit) is provided with heating

furnace which is diesel and gas fired. The gases produced from the

heating are transferred into the 1 unit condenser. The polishing

vacuum reactor furnace has a cap. of 10,000 li.

Condensing Process- The gases produced during the heating process are liquefied thru heat

exchange in the condensing unit. The Condenser is provided with a

cooling system. The Distillate fuel oil are stored in distillate receiving

tank which is provided with hydroseal gas treatment device or scrubber

system to treat excess gases before it is used as fuel to furnace. The

distillate receiving tank has a cap. of 3,000 li.

Filtration- The oil generated from the polishing vacuum reactor passes thru filtration

Process which undergoes the following: pre-heating, cooling, pumping

pressing. The extracted or produced oil are stored in product storage or

filtered oil tank with a cap. of 10,000 li. While the spent clay from the

pressing at filter press are disposed at secured Sanitary Landfill.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

List of Equipment:

1 unit 1,000,000 li cap.raw Oil Storage Tank

2 units Distillation Furnace (1-24,000li. cap & 1-32,000 li. cap)

2 sets Furnace Distillation Condensers with Cooling System;

2 sets Distillate Receiving Tanks(1-12,000li cap & 1-10,000li cap.)

2 units Hydroseal Gas Treatment Device/Scrubber System;

1 set Polishing Vacuum Reactor;

1 unit Reactor Condenser with Cooling System;

1 unit Distillation Fuel Oil Receiving Tank;

1 unit Hydroseal Gas Treatment Device/ Scrubber System;

1 set Filtration Process consisting of pre-heater with Cooling System, Pump and Filter Press; 1

unit Filtered oil tank

2 units100,000 li. each cap. Product Storage Tanks

Solid Hazardous Waste and Medical Waste Destruction Treatment Process: Destruction

Capacity of 1,500.00 tons per month.

For the treatment of hazardous wastes such as acid wastes(B201-B209); alkali wastes(C301-

C399);Waste organic solventsG703-G704); inks/dyes/pigments/paints/latex/adhesives/organic

sludge9F601-F699); Putrescible/organic wastes (H801-H802); Oil contaminated materials and

containers(I104); Immobilized wasted(K301-K303); Miscellaneous wastes as pathogenic or

infectious wastes(M501), pharmaceutical wastes and drugs(M503) the Process involves the

following:

Delivery- Hazardous solid wastes from industries and medical wastes are delivered on site in

Trucks and shall be covered with Permit To Transfer from EMB and shall conform

with the hazardous waste category approved by in the Hazardous Waste Registry

of EMB.

Hazardous Waste Acceptance Criteria- The Proponent shall likewise ensure that the accepted

hazardous waste are properly labelled and properly contained in a secured container

before acceptance.

Storage- Hazardous wastes are stored properly in secured area near the processing area to

avoid double handling.

Hazardous Solid Waste Destruction- Solid Hazardous and Medical Wastes are loaded by

batch into 2 units Thermal Processor(1-3tons and 1-5tons). The Thermal processor is

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

provided with Gas Treatment Device(Scrubber) and Cyclone Dust Collector leading

into a smoke stack. The thermal destruction temperature of the processor is more or

1,200 degrees centigrade.

Ash Storage-Ash generated at approximately 50 kg per ton are properly stored in the ash

Storage area in sacks or in carbuys or in a secured and shall be disposed finally in

Secured Sanitary Landfill after undergoing TCLP analysis.

List of Equipment/Facility:

1 set Hazardous Waste Storage Area;

2 units Stationary Thermal Processor(1-3tons and 1-5tons cap.) provided with Cyclone Dust

Collector and Chimney; and

1 set Ash Storage Area

Tire Recycling Process: Production capacity of the firm’s Tire Recycling Facility are as

follows: a.) Tire Derived Fuel(TDF)- 67.50 tons/day

b.) Carbon Black-45.00 tons/day

c.) Steel Wire-22.5 tons/day

d.) Gases-0.40 tons/day

The process flow of operation involves the following:

Delivery of Scrap Tire- Scrap tires from vulcanizing shops, junkshops, tire mfg. rejects, and

service shops are delivered to the plant site by hauler trucks. The transport shall not be covered

by Permit to Transport from EMB since rubber tire wastes are not considered Hazardous wastes

under RA 6969.

Storage- The scrap tires are stored in the storage area near the process building to avoid double

handling. The storage area shall be properly covered to avoid being thebreeding ground of

rodents, mosquitoes and other disease causing insects.

Feeding- Scrap tires are manually feed into the Thermal Processor for gasification.

Thermal Gasification- Scrap tires are feed and heated at about 370 degrees centigrade just

enough to turn the feed rubber tires into gases in the rotary type Thermal Processor pyrolytic

chamber.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Condensing- The gases produced from the thermal heating process are condensed after passing

the heat exchanger/Condensing unit. Distillate oil recovered from the condensing process are

transferred into the product storage tanks while excess gas goes to the hydroseal gas treatment

device/ scrubber system. The treated gases are then fed into the furnace as fuel blend.

Approximately 42% of tire derived oil are recovered, 33% carbon black, 22% steel wires and

3% gases are produced per batch or load of scrap tires in the rotary thermal processor. The

excess gases are re used as fuel in the in the thermal processor furnace while recovered steel

wires are sold to smelting plants.

Product Storage- Oil recovered from the condensing process are stored in product storage Tanks

with gas exhaust connected to the hydroseal gas treatment device/scrubber System.

Ash Storage- Ash produced approximately 33% of scrap tires loaded or 101.83 tons/mo. shall

be temporarily stored in the storage area in sacks or in carboys and shall be sold to prospective

buyers of carbon black or disposed finally to secured Sanitary Landfill after undergoing TCLP

analysis.

List of process equipment:

1 set Scrap tire storage area

2 units Rotary Type Thermal Processor each with built-in furnace, cyclone dust collector,

hydroseal gas treatment/scrubber system and smoke stack.

2 units condenser each provided with hydroseal gas treatment/scrubber system

1 unit 20,000 li. cap. Product Storage Tank

SOLVENT RECOVERY PROCESS:(DISSTILLATION)

Solvent Recovery Process of the Proponent involves the so called Dehydration thru Distillation

heating method. In this method contaminated liquid solvents is heated up to limiting temperature

of 87.8°C inside a thermal oil coil heating Reactor Tank. Heated liquid produces gas that flow to

the water cold condenser where it condenses and then transform into liquid solvents to be

collected on a closed vessel or receiving tank.

Recovered liquid solvent stored in the Receiving Tanks are drummed and sold to local customer

/consumer of marketable amount of value for their use as process input or cleaning agent. The

Receiving Tank is equipped with vent arrester to treat gas fumes from the Tank. While

dehydrated residuals left at the reactor are collected in storage tank and further undergo treatment

at the Wastewater Treatment Plant of the Proponent prior to disposal as effluent. While solid

waste residue contaminated with solvent are stored in drums to be charged into the Thermal

Processor for final treatment /destruction. Collected ash are placed in drums and subjected to

TCLP Analysis and then disposed finally in secured Sanitary Landfill.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

SOLVENT CONTAMINATED SOLID WASTE DESTRUCTION PROCESS:(THERMAL

DESTRUCTION)

Thermal destruction process involves charging of solvent contaminated solid waste from

industrial operations in the existing Thermal Processor by heating these at high temperature at

more or less 1,200 degrees centigrade. The heating process involves 2 stages wherein charged

solid wastes are heated initially in the first chamber and finally destroyed in the second chamber.

The Thermal Processor is equipped with Air Pollution Control Device for the abatement of air

pollutants consisting of Gas Treatment Device(Scrubber) and Cyclone Dust Collector. Ash

generated are put in drums and subjected to TCLP Analysis prior to final disposal at secured

Sanitary Landfill.

LIST OF EQUIPMENT AND SPECIFICATIONS:

LIQUID SOLVENT RECOVERY:

2 UNITS – 5 drums capacity reactor tank w/ thermal oil heating coil inside, fully

insulated.

2 UNITS – water cooled condenser 150 to 300 ft.² heating surface area.

1 SET - cooling system w/ circulating pump & spray manifold.

1 SET -500 kw thermal oil heater w/ expansion tank & circulation pump.

2 UNITS – distillate Receiver Tank.

1 UNIT - vent arrester.

SOLVENT CONTAMINATED SOLID WASTE DESTRUCTION:

2 UNITS – Thermal Processor provided with Gas Treatment Device(Scrubber) and Cyclone Dust

Collector.

CAPACITY:

Solvent recovery in 8 hrs. operation gives a total of 20 cu.meters per day capacity in

24 hrs. operation at 50% liquid solvent recovery.

Solid waste contaminated with solvent treatment at thermal processor capacity 5 tons per day

with the existing 2 units Thermal Processor of 1unit-3tons and 1unit-5tons per batch capacity.

The proposed WTF is basically a combination of physical, chemical and biological treatment. It

shall consist of the following units:

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Equalization/Neutralization Tank- Mixing and pH adjustment occurs;

Filtration Tanks-Solid particles are partially collected;

Sump Pit-Chemicals are added from chemical dosing tanks;

Primary Clarifier Tank-The flocs are separated in the primary clarifier and the sediments are

pumped into sludge drying bed while the wastewater are aerated to biodegrade the organic

content of the wastewater.

Secondary Clarifier Tank- The secondary clarifier shall further treat the remaining wastewater

from the primary clarifier. The sediments at the bottom of the tank shall be returned thru pump

into the aeration tank as input with the incoming wastewater while the excess sludge are pumped

into the sludge drying bed.

Water Chest- Effluent from the secondary clarifier tank passes the water chest wherein chlorine

treatment is employed. FAR EAST FUEL CORP. guarantees that the resulting effluent shall

comply with the DENR Standards.

Wastewater Treatment Capacity

Physico-Chemical Treatment: 60.00 cubic meters per day

Biological Treatment: 500.00 cubic meters per day

Total: 560.00 cubic meters per day

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Summary of Treatment Capacity

Meycauayan

San Ildefonso

Plant

Description HW Class & HW (Code) Plant Treatment

Treatment

Capacity (New)

Capacity (Old)

600 cu. Meters 600 cu. Meters

Waste Oil

(I101) Waste Oil per day of per day of

Treatment Capacity

product oil product oil

(B201-B299) Waste Acid

(C301-C399) Waste Alkali

(D401-D407,D499) Waste

Inorganic Chemicals, Electronic

Waste

(F601-F699)

Inks/Dyes/Pigments/Paints/Latex/

Adhesives/Organic Sludge

Waste Hazardous (G703-G704) Waste Organic

1,500.00 1,500.00

Thermal Treatment Solvent, Halogenated & Non

Tons/Month Tons/Month

Facility Halogenated

(H801-H802) Putrescible Organic

Waste

(K301-K302) Immobilized Waste

(L401) Waste Organic Chemical

(M501-M505) Miscellaneous

Waste

(I101) Waste Oil

(J201) Contaminated Containers

With Input Capacity of 150.00 Output

Output Capacity

Tons/day Capacity

67.50 Tons/day

67.50 Tons/day

Tire Derived

Tire Derived Oil

Oil

Waste Tire

45.00 Tons/day 45.00 Tons/day

Recycling Facility

Waste Tire Carbon Black Carbon Black

22.50 Tons/day 22.50 Tons/day

Steel Wire Steel Wire

0.40 Tons/day 0.40 Tons/day

Gasses Gasses

(G703-G704) Waste Organic

Waste Solvent 20.00 20.00

Solvent Halogenated & Non

Treatment Facility cu.meters/day cu.meters/day

Halogenated

Waste Bulb Lamps

(D407) Waste Organic Chemicals 1.80 Tons/day 1.80 Tons/day

Crusher Treatment

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Facility

Physico-Chemical Treatment @

Wastewater 60cu.meters/day 560.00 560.00

Treatment Facility Biological Treatment @ 500 cu.meters/day cu.meters/day

cu.meters/day

(J201) Waste Containers

(B201-B299) Waste Acid

(C301-C399) Waste Alkali

(D401-D407,D499) Waste

Inorganic Chemicals, Electronic

Waste

(F601-F699)

Inks/Dyes/Pigments/Paints/Latex/

Waste

Adhesives/Organic Sludge

Contaminated 500.00 500.00

(G703-G704) Waste Organic

Containers Tons/month Tons/month

Solvent, Halogenated & Non

Treatment Facility

Halogenated

(H801-H802) Putrescible Organic

Waste

(K301-K302) Immobilized Waste

(L401) Waste Organic Chemical

(M501-M505) Miscellaneous

Waste

(I101) Waste Oil

(F601-F699) Inks/ Dyes/

Waste Sludge Pigments/ Paints/Latex/

Treatment Facility Adhesives/Organic Sludge

3.00 Tons/day 3.00 Tons/day

(Solidification/ (D499) Organic Chemicals

Fixation) (K301-K302) Immobilized Waste

(D405)

Non Hazardous

Waste Materials 1500.00 Tons/ 1500.00 Tons/

Destruction and month month

Recovery Facility

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

3.0 ABANDONMENT PLAN OF THE PROPONENT

The proponent shall in any event clean up the area from any harmful waste should it decide to

cease its operation. The plan shall include inventory of waste materials, stocks, and solid waste

and facilities of the plant site before the closure. Assessment of the electro-mechanical

equipment and other facilities shall be done before decision can be made whether it can be sold

as is or as scrap. The remaining inventory of used oil and oil products shall be sold to

prospective clients while suspected contaminated area within the project site shall be subjected

to clean up. The proponent is committed to implement measures to decontaminate the identified

area from toxic and hazardous substances.

4.0 CONTINGENCY MEASURES

The management will sponsor safety trainings and seminars to all employees and will conduct

emergency drills to prepare all employees from any eventuality. All the employees shall be

familiarized with the proper handling of hazardous materials and products and shall be oriented

on Material Safety Data Sheet to inform them of health and environment hazards and emergency

response of the materials during the training/seminar. Trucks and Tank Lorry Drivers and

Personnel involve in the transport of hazardous waste shall be the priority of the said training and

orientation seminar of EMB to comply with the Transport Registration requirements of

hazardous wastes. The appointed Pollution Control Officer of the Proponent shall implement and

prepare report on this activity to the proper authority and shall be oriented thru DENR-EMB

sponsored seminars and workshops with environmental laws, rules, and regulations.

5.0 DESCRIPTION OF THE EXISTING ENVIRONMENT:

5.1 DESCRIPTION OF THE PRIMARY IMPACT AREA:

The primary impact area of the project which was delineated at 500 m. radius comprise mostly of

mixed industrial, agricultural, commercial, institutional, and residential uses. The agricultural

sector dominates the surrounding areas or primary impact area which comprises of rice field,

orchards and Livestock(poultry and piggery).

Description of the immediate/primary impact area of the project site:

North – Residential/Brgy. Road/Agricultural use

East – Piggery Farm/Agricultural use

West – Agricultural use

South – Agricultural use

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

5.2 BASELINE ENVIRONMENT CONDITIONS:

The existing environmental conditions of the primary impact zone was already described and

discussed. In this chapter the secondary impact zone will be described and relevant data were

gathered and obtained from various sources such as DENR and LGU-Bulacan. Ocular inspection

was likewise conducted by the staff of the LGU thru its Barangay Officials, Sanitary Inspectors

and Zoning Administrator before granting and approving their Clearances and Permits.

5.2.1 SOCIO ECONOMIC PROFILE OF SAN ILDEFONSO, BULACAN

San Ildefonso

Seal

Map of Bulacan showing the location of San Ildefonso

Coordinates: 15°4′44″N 120°56′31″E

Coordinates: 15°4′44″N 120°56′31″E

Country Philippines

Region Central Luzon (Region III)

Province Bulacan

District 3rd District

Founded 1885

Barangays 36

Area

• Total 128.71 km2 (49.70 sq mi)

Population (2010)

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

• Total 95,000

• Density 740/km2 (1,900/sq mi)

Time zone PST (UTC+8)

ZIP code 3010

Dialing code 44

Income class 1st class

San Ildefonso is a municipality in the province of Bulacan, Philippines. According to the 2010

census, it has a population of 95,000 inhabitants.

With the continuous expansion of Metro Manila, the municipality is now part of Manila's built

up area which makes San Ildefonso it's northernmost part.

July 23, 2013, an entertainment and supermarket complex was opened where the old public

market used to stand. This made San Ildefonso the "Biglangbukas, Ubosagad" of Bulacan.

History

Long before the arrival of the Spaniards in the Philippines, the town of San Ildefonso was known

as Bulak. The early inhabitants called this town as such because of the abundant "kapok" trees

(Bulak in vernacular) growing on the hill where the town proper is now situated.

Bulak was then a barrio of San Rafael. There were very few inhabitants numbering only about

3,000. The early inhabitants were people from neighboring towns and provinces that preferred to

settle in this place because of the good prospect of agriculture.

When the Spaniards came, the name Bulak was changed to Hacienda San Juan de Dios because

her 15,500 hectares of grazing and farming grounds were claimed by the friars. The people were

told to pay tribute. Proceeds from the rentals were used to finance the operation of the San Juan

de Dios Hospital in Manila. The Spanish friars though antagonistic towards the Filipinos, could

not help admiring the beauty of the numerous natural scenarios God bestowed on the town.

Because of their admiration, they changed the name Hacienda de San Juan de Dios to a more

fitting one Hacienda Buenavista, a Spanish word which means beautiful scenery.

As the population grew, a chapel was constructed under the parochial jurisdiction of San Rafael.

In 1809, Father Juan dela Rosa was named the first Filipino priest of the town. He held such

position up to 1911. He was responsible for changing the Bulak to San Ildefonso in honor of

Alfonso XII, then the King of Spain and San Ildefonso, its Patron Saint. By the time it was given

this name, a tribunal was created finally making it a town in 1877. Between the periods 1905-

1906, San Ildefonso was merged with San Miguel due to its low income and inability to finance

its expenditures in operating the local government.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

As year went by, more and more people were induced to live in the town. The growth of

population promoted the increase of income. The town became capable of meeting its expenses

so it consequently ceased being a barrio of San Miguel and became once again an independent

town.

Barangays

San Ildefonso is politically subdivided into 36 barangays (5 urban, 31 rural).

Umpucan

Akle

Alagao

Anyatam

Bagong Barrio

Basuit

BubulongMunti

BubulongMalaki

BuholnaMangga

Bulusukan

Calasag

Calawitan

Casalat

Gabihan

Garlang

Lapnit

Maasim

Makapilapil

Malipampang

MataasnaParang

Matimbubong

NabaongGarlang

Palapala

Pasong Bangkal

Pinaod

Poblacion

PulongTamo

San Juan

Santa Catalina Bata

Santa Catalina

Matanda

SapangDayap

SapangPutik

SapangPutol

Sumandig

Telapatio

Upig

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Demographics

Population census of San Ildefonso

Year Pop. ±% p.a.

1990 59,598 —

1995 69,319 +2.87%

2000 79,956 +3.11%

2007 93,438 +2.17%

2010 95,000 +0.61%

Source: National Statistics Office

Commerce and industry

Major industries: Cement, Pyrotechnics, Feed Mills, Food/Food Processing, Garments,

Hat Making, Wood Crafts, High-Yield Crops, Marble/Marble Processing, Metalcraft,

Major products: Bakeries and Sweet Preserves, Chicharon, Poultry and Livestock, Rice,

High Value Crops, Marbles, Vegetables, Fruits

Education

Bulacan Agricultural State College, Liceo De Buenavista, Saint Paul School of San Ildefonso,

Saint John School, Motessori De San Ildefonso, Goldenville School of Montessori.

5.2.2 SURFACE WATER BODY

The surface water body that can be found is the Anyatam Creek which drains to San Ildefonso

River. The creek is located east of the project site. The agricultural sector of Brgy. Anyatam uses

the creek as the discharge point of agricultural, residential, commercial, and industrial effluents

in the area. This creek is tributary to San Ildefonso River which is part of Manila Bay Watershed.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

5.2.3 NOISE QUALITY

The noise quality of the project area is still within the ambient noise quality standard of the

DENR. A Noise is any unwanted sound and is usually measures in decibels (dBA). Shown

hereunder is Environmental Quality Standards for Noise in General Area:

Category of Area Daytime (dBA) Morning and Evening Nighttime (dBA)

(dBA)

AA 50 45 40

A 55 50 45

B 65 60 55

C 70 65 60

D 75 70 65

AA- A section or contagious area which requires quietness such as area within 100 m. from

school sites, nursery schools, hospitals, and special home for the aged.

A – A section or contagious area which is primarily used for residential purposes.

B – A section or contagious area which is primarily a commercial area.

C – A section or contagious area primarily reserved as a light industrial area.

D – A section or contagious area primarily reserved as a heavy industrial area.

Division of 24-hr. Period

Morning – 5:00 AM TO 9:00 PM

Daytime – 9:00 AM TO 6:00 PM

Evening – 6:00 PM TO 10:00 PM

Nighttime – 10:00 PM TO 5:00 AM

5.2.3 GEOGRAPHY AND LAND RESOURCES:

The province of Bulacan has a total land area of 262, 500 has or 14% of the entire land area of

the entire region or the Central Luzon. The municipality of Dona Remedios Trinidad has the

biggest land area with 93,928 has. Bulacan is accessible from the National Capital Region or

Metro Manila through two major road networks which are the North Luzon Expressway (NLEX)

and MacArthur Highway. The province is within the development area being close to Metro

Manila and the fastest growing area in the region because it is located within the W-Growth

Corregidor and within the Super Region designated by the government. It is bounded on the

north by the province of Nueva Ecija, on the east by Aurora and Quezon, on the west by

Pampanga on the southeast by Rizal, and on the southwest by Manila Bay.

The existing land uses of Bulacan are composed of six major categories and the largest user of

Bulacan’s land resources is the agricultural sector particularly those involving the cultivation of

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

lands for production purposes. Covering a land area of 96,547 hectares or close to 37 percent of

the total land area of the province, the agricultural lands almost cover the western half of

Bulacan, thus practically dividing the province into two equal parts with the western portion of

the province specifically east of the municipality of San Miguel and down to the boundaries

between the city of San Jose Del Monte and municipality of Sta. Maria.

These lands are mostly devoted to the cultivation of palay, both irrigated and rain fed. Irrigated

palay areas are concentrated in the western portion of the agricultural lands. With irrigation

water provided by the National Irrigation Administration (NIA) from Angat River, farmers have

the luxury of having two to three cropping per year barring the negative impacts of storms and

typhoons. In some areas where infrastructure of NIA is yet to be extended, communal irrigation

systems have been put in place by the government.

On the eastern part of the agricultural lands are the rain fed areas, which are also being used for

palay production during rainy season. For the rest of the year, these lands are either used for

vegetable farming or for corn production. The other forms of agricultural activities in the

province, which also takes up a relatively large amount of land, are the fishpond areas. Found on

southwest part of the province, fishpond areas take up about 16,968 hectares or a little over 6

percent of the province of Bulacan.

In 1995, the Bureau of Fisheries and Aquatic Resources (BFAR) came up with a Resource and

Ecological Assessment of the Manila Bay area and this includes the coastal areas of Bulacan.

According to the report, the coastal areas of Bulacan have the largest aqua-cultural activities in

the entire stretch of Manila Bay area and this is the reason why Bulacan is considered as one of

the major producers of aqua-cultured fish varieties like bangus and prawns. In fact, from the

municipality of Meycauayan up to Hagonoy, one of the major economic activities centered on

aqua-culture which are often run by corporations or big time businessmen. The study also noted

some structures that are illegal or unregistered. Actual visit in the area indicate that there are

some fishponds, which encroached on waterways and/or constructed more than what is provided

for in the lease agreement.

On the eastern portion of the agricultural areas is a long band of the kinds that connects the

northern and southern areas of the province. Covered mostly with grasses and shrubs, these lands

have a total land area of close to sixty thousand has. Or 22% of the total provincial land area,

apparently the third largest land use category in the province. There may be spots or isolated

cases wherein agricultural activities can be observed but in general, these areas are characterized

with rolling and quite steep topography that constraints the practice of land cultivation.

Further eastward is also a long band but much wider than the grassland areas. This particular

feature of the provincial land use structure represents the forested part of Bulacan. With a total

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

land area of 75,731 has. or 28% of the provincial total, these areas are mostly covered with

residual or secondary growth forests.

In the DENR’s Land Classification Map, the forested areas consist of two major watersheds,

namely the Angat Watershed Metro Water District which is covered under Proclamation No. 391

issued on April 30, 1968 and the Dona Remedios Trinidad-General Tinio Watershed Forest

Reserve set aside for watershed protection under Proclamation No. 230 of March 26, 1988. The

Angat Watershed is considered as one of the most important watershed in the country today. For

one, it is a main source of potable water as it provides the bulk of water supply to Metro Manila

residents and second, it also helps generate power for the Luzon grid. Based on the identified

land management, there are 8 identified land use types with the view of optimizing land

production and the protection of the environment. These are:

1. Agro-forestry

2. Protection forest

3. Production forest

4. Rain fed mixed farming

5. Urban expansion areas

6. Diversified crops

7. Irrigated rice paddy, and

8. Aqua-culture

5.2.5 METEOROLOGY

The baseline information on the climatology of Bulacan is derived from Cabanatuan, Nueva

Ecija which is the nearest synoptic station of PAG-ASA north of the province. The present study

nonetheless provides additional Climatological Normals from Science Garden in Quezon City

and from Port Area in Manila as the basis for describing the climate in Bulacan. There are no

Climatological distinctions between places separated only by tens of kilometer distance.

5.2.5.1 The Port of Manila Synoptic Station

Based on the Climatological Normals of a synoptic station in Port Area, Manila the climate of

Bulacan can be described under Type I of the Modified Corona’s Classification. This type of

climate is characterized by two pronounced seasons. A much defined rainy season occurs in the

months of November to April.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

The major air stream passing over the region are the southwest and northeast monsoon, which

are driven by differential heating between continents and ocean. The southwest monsoon is a

warm and moist air mass coming from the Indian Ocean which passes thru the area with a

southwesterly direction from June to October while the northeast monsoon usually brings cold

dry air in the months of December to February.

Another major air stream is the easterly (also called the trade winds) which dominate during the

transition period between the monsoons. Disturbances in these air masses (called easterly waves)

also bring considerate amount of rains during the transition months.

5.2.5.2 Tropical Cyclones

In the Philippines, the ave. cyclone passage is about 20 per year. In Manila, the ave. frequency of

cyclone passage is five in three years. These cyclones have greater frequencies in the months of

July, October, and November.

5.2.5.3 Rainfall

The atmospheric system which contributes to the annual rainfall in the country is the monsoons,

tropical cyclones, the oscillation of the Inter Tropical Convergence Zone (ITCZ), and the

easterly waves. Tropical cyclones which are most frequent in June to September bring very

intense rainfall over the area while the disturbances in the easterly cause some rainfall during

transition between the monsoon periods. The ITCZ contributes to the rainfall during the month

of June to July.

The wettest period occurs during the months of June to September with mean monthly rainfall

values ranging from 283.9 mm to 476.3 mm. August is the rainiest month while the driest month

is February. The driest period occurs to January to March with mean monthly rainfall values of

7.3 mm to 21.4mm.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

5.2.5.4 Temperature and Humidity

The mean annual temperature in the area is 27.6 degrees to 29.5 degrees Celsius. The coldest

months are December and February with mean daily temperature ranging from 25.8 degrees to

26.3 degrees Celsius. The warmest months are April to June with values ranging from 28.7

degrees to 29.5 degrees Celsius.

The mean annual relative humidity at the province is 74%. It is highest in August with an ave. of

83% and the lowest in April with 64%. The relative humidity in the area is controlled by the

available moisture from evaporation of rainfall and by the variations in air temperature.

5.2.5.5 Surface Winds

The annual frequency distribution of surface winds is distributed in 8 compass directions except

in the northwest. A large percentage of the wind directions are mainly westerly and easterly. This

shows the effect of land sea breeze is very strong.

5.2.5.6 Frequency of Rainy Days and Thunderstorms

The annual average number of rainy days is 143. Data on mean monthly number of rainy days

show that the month July to September have the greatest frequency of rainy days with values

ranging from 20-22 day a month. The mean annual numbers of days during the thunderstorms is

14. The mean monthly thunderstorm days are 5 in June, 4 in September, 3 in May, 1 each

summer month due to thermal convection.

5.2.5.7 The Cabanatuan Synoptic Station

The Climatological Normals taken over a period of 34 years from 1961 to 1995 in Cabanatuan,

Nueva Ecija is consistent with that taken from Port Area, Manila. This station categorizes the

provinces to fall under Type I climate of Modified Corona’s Classification. Tropical cyclones are

expected to pass over or near the province 5 times a year.

From the month of June to September, there is heavy rainfall coinciding with the southwest

monsoon. However, during the months of October to November, the relatively high rainfall can

be traced from passage of tropical cyclones. Tropical cyclones are known to pass over the central

part of Luzon in the later part of the year as the coldest part in the northern hemisphere

strengthens. August proves to be the wettest month at 378.9mm of rainfall while February is the

driest month with only 3.4 mm of rain.

Days with thunderstorms also fall within the rainy months of June to September as local heating

becomes more pronounced. Normally, the prevailing southwest flow also induces vertical cloud

development that is responsible for thunderstorms.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Consistent with these local disturbances is the frequency of lightning.

The average wind direction throughout the year in northeasterly with a speed of 2 m/s. The

characteristic surface wind surface direction from May to September is southerly instead of south

westerly. This may be due to the fact that the Cabanatuan, like majority of the province of

Bulacan, is located further inland and away from the large bodies of water. In addition, the

topography affected by Zambales Mountain Range may have a funneling effect on the wind.

The max. and min. ranges from 38.7 degrees Celsius to 22.3 degrees Celsius, respectively. On

the average, relative humidity is 77%.

5.2.5.8 The Science Garden Synoptic Station

Consistent with the synoptic in Cabanatuan, the annual average wind can be noted to

northeasterly from the months of November to February and then southwesterly from the months

of June to September which is more pronounced than that of Cabanatuan. This may be due to the

fact that there is no local topography to hinder the southwest flow as it reaches Manila.

Similar to the Port Area, Manila and Cabanatuan stations, August proves to be the wettest month

with 517.1 mm of rainfall and February as the driest with only 7.4 mm of rainfall.

5.2.6 AIR QUALITY:

The air quality of the San Ildefonso, Bulacan is generally fair and typical to rural but developing

areas in Bulacan. However air quality deterioration is increasing due to population increase and

increase in mobile sources emission plying the busy National Highway . The air pollutants come

mostly from mobile sources in the area and light industrial activities such as ricemill and

limestone crushing and pulverizing which is common in the area. Other source of air pollution

comes from agricultural waste open burning, unpaved roads, and other area sources.

5.2.7 WATER RESOURCES

Based on previous studies, it was revealed that the static water level of private and communal

deep wells has not significantly lowered. This was attributed to the recharge to ground water,

which compensates to the extraction at the nearby watershed reservation areas of Angat Dam.

NWRC estimates that the ground water storage in the Angat River Basin is approx. 4,100 million

cu. m. while the estimated safe yield is 180 million cu. m. per year (NWRC, 1983).

The Angat Reservoir (Angat Multipurpose Dam) yields an ave. of 58 cum/s of water. The 1967

water sharing agreement among MWSS, NPC, and NIA allocate 22 cum/s to MWSS and 36

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

cum/s to NIA. The NPC, in principle utilizes water drawn by MWSS and NIA for its power

generation (ADB, 1995). Historically, water that is not needed by NIA from its allocation has

been available to MWSS. Currently, MWSS draws 32 cum/s for urban water supply in Metro

Manila (ADB, 1995). Water is drawn from the Ipo Dam that is located downstream of the Angat

Multipurpose Dam. On the other hand, the irrigation water requirement of NIA is drawn from a

site farther downstream of the Angat River ie. At the Angat Diversion Dam in San Rafael,

Bulacan.

The water supply demand in Bulacan is supplied by the local water district coming mostly from

ground water sources. The major sources of domestic water supply in the area are shallow wells

which are available at about 20 meters below ground surface (mbgs) and deep wells which are

about 30 mgbs. While difficult areas in the eastern planks such as DRT had water available that

reaches sub strata thru fissures, crack, and crevices. The earliest attempt to tap water resources of

the province materialized in 1979 when La Mesa Dam was build in Novaliches River to provide

potable water supply to Manila and the surrounding suburban areas.

The Ipo River is the site of another dam which supplements the water provided for by the La

Mesa Dam.

5.2.8 SOCIO ECONOMIC PROFILE OF BULACAN:

Bulacan is subdivided into 4 districts. It has 24 municipalities and 248 barangays. First district

has Malolos, Hagonoy, Bulacan, Pulilan, Paombong, and Calumpit. Second district has Balagtas,

Guiguinto, Plaridel, Pandi, Bustos, and Bocaue while the third is composed of San Miguel, Sa

Ildefonso, San Rafael, Norzagaray, Angat, and Dona Remedios Trinidad. Fourth district

composes of Marilao, Meycauayan, Obando, San Jose Del Monte, and Sta. Maria. Bulacan has a

total land area of 262,500 has. or approx. 14% of the total land area of the region. Of the 24

municipalities, Dona Remedios Trinidad is considered to be the biggest municipality with a total

land area of about 93,298 has or about 38% of the total province area.

The 1995 census of population conducted by the NSO placed the population of central Luzon at

6,932,570. This is about 12% higher than the total population for the region in 1990 census. The

province of Bulacan is pegged to have the largest population while Bataan has the lowest

population count as of 1995. Bulacan also holds the distinction of being the fastest growing

province. During 1990-1995 periods, Bulacan’s population grew by 3.46% per year

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

6.0 IMPACT ASSESSMENT AND MITIGATING MEASURES:

In this section adverse impact was identified and assessed so that appropriate measures were

implemented by the proponent. In this study impact assessment is discussed including

environmental management measures for every phase of the proposed Hazardous Waste TSD

and Tire Recycling Facility Project of the Proponent.

6.1 IMPACT ASSESSMENT CONSTRUCTION PHASE:

6.1.1 Matrix of Impacts during Construction Phase

Activities Impact Identification Impact Assessment Remarks

1. Site

Development Noise/Dust / Solid S ST R MI

-Clearing and Waste

Grubbing

-Perimeter

Fence

Installation

-Roadways

and Storm

Drainage

Construction

-Electrical

Post Erection

-Elevated

Water Tank

and Deep

Well

Installation

2. Process

Building Dust/Noise / Solid S ST R MI

Installation Waste

3. Process

Equipment Solid Waste S ST R MI

and ancillary

equipment

installation

4. Electrical and

Plumbing Solid waste / Noise S ST R MI

Installation

5. WTF Solid Waste S ST R MI

Installation

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

Legend:

S – Significance Impact

ST – Short Term

R – Reversible

MI – Minimal Impact

6.2 IMPACT ASSESSMENT OPERATIONAL PHASE:

The operation of the proposed project of the Proponent is expected and assessed to cause

minimal effect to the environment because adequate mitigating measures to control the discharge

of air, water, and solid pollutants shall be implemented. The environmental records of the TSD

and Tire Recycling operation of the Proponent would manifest that the firm’s emission and

disposal method had complied with government standards and environmental laws.

Adverse impact to the environment was identified and assessed during the operational phase and

shall consist of the ff:

1. Noise

2. Air Pollution

3. Wastewater from the operation

4. Solid wastes and

5. Odor pollution

All of the above mentioned identified impacts shall be properly mitigated and addressed to

caution its impact to the surrounding environment during this phase.

Assessment showed that the project appeared to be beneficial to the impact area and had

mitigated and minimized its adverse effect to its surrounding environment. It shall also provide

benefits to the LGU benefit tax payments and shall provide employment opportunity to local

residents. The project shall also be in consonance with government countryside development

program and shall in one way or another save dollars from oil importation and likewise help

government effort to clean the environment from hazardous wastes.

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

6.2.1 Matrix of Impacts during Operational Phase

a. Oil Treatment Process:

Activities Impact Impact Assessment Remarks

Identification

1. Delivery of raw Air pollution S LT R MI

materials Noise S LT R MI

Water pollution S LT R MI

2. Raw used oil Water pollution S LT R MI

storage Noise S LT R MI

Solid waste S LT R MI

Odour pollution S LT R MI

Spillage S LT R MI

3. Raw used oil Air pollution S LT R MI

Distillation

4. Condensing Air Pollution S LT R MI

Water pollution S LT R MI

5. Polishing Air pollution S LT R MI

Vacuum

Reactor

6. Condensing Air Pollution S LT R MI

Water pollution S LT R MI

7. Filtration Solid waste S LT R MI

8. Product Air Pollution S LT R MI

Oil Storage Spillage S LT R MI

b. Hazardous Solid and Hospital Waste Thermal Treatment Process:

Activities Impact Impact Assessment Remarks

Identification

1. Delivery Air pollution S LT R MI

Noise S LT R MI

Odor Nuisance S LT R MI

2. Storage Air pollution S LT R MI

Odor Nuisance S LT R MI

3. Thermal Air pollution S LT R MI

Destruction Solid Wastes S LT R MI

4. Ash Storage Air pollution S LT R MI

Solid Wastes S LT R MI

Nuisance S LT R MI

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

c. Tire Recycling Process:

Activities Impact Impact Assessment Remarks

Identification

1. Delivery Air pollution S LT R MI

Noise S LT R MI

2. Air pollution Solid Wastes S LT R MI

Vermin and Pests S LT R MI

3. Thermal Air pollution S LT R MI

Gasification Solid Wastes S LT R MI

4. Condensing Air pollution S LT R MI

Water pollution S LT R MI

5. Product Air pollution S LT R MI

Storage Spillage S LT R MI

6. Ash storage Air pollution S LT R MI

Solid wastes S LT R MI

Nuisance S LT R MI

d. Solvent Recovery Process

Activities Impact Impact Assessment Remarks

Identification

1. Delivery Air pollution S LT R MI

Noise S LT R MI

Odor Nuisance S LT R MI

2. Storage Air pollution S LT R MI

Odor Nuisance S LT R MI

3. Distilling Air pollution S LT R MI

Solid Wastes S LT R MI

4. Condensing Air pollution S LT R MI

5. Solvent Solid Wastes S LT R MI

Recovery

Nuisance S LT R MI

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

e. Bulb Crushing Process

Activities Impact Impact Assessment Remarks

Identification

1. Delivery Air pollution S LT R MI

Noise S LT R MI

Odor Nuisance S LT R MI

2. Storage Hazard S LT R MI

3. Bulb Crushing Hazardous waste S LT R MI

Air Pollution

Solid Wastes S LT R MI

4.Storage Hazardous waste S LT R MI

6.2.2 Mitigating Measures

Delivery of Plant Inputs:

The following measures shall be undertaken to prevent negative impacts during hauling/transport

of plant inputs such as hazardous wastes(liquid and solid) and scrap tires.

1. Preventive maintenance of vehicle used in hauling/transport.

2. Training of personnel in handling proper transport and handling of hazardous wastes and

other safety requirements to prevent accidental spillages and contingency measures

during hazardous waste spills;

3. Provide adequate and properly sealed, secured and strong containers with proper labels

on transported hazardous wastes covered by Transport Manifest and Permit To Transport;

and

4. Provide adequate facility for emergency response such as spill booms, dispersants,

adsorbent pads, fire extinguishers and safety gadgets to haulers.

Hazardous Waste Treatment Operations:

Air Pollution:

Air pollutants from the furnace are released from fuel combustion that took place in the furnace

which produces gas emissions. The pollutants consists of primary and regulated pollutants such

as Particulate Matters(PM), Sulphur Dioxide(SO2), Nitrogen Dioxide(NO2). Carbon Dioxide

are likewise emitted during the fuel combustion process which has high Global Warming

Potencial. To mitigate harmful emission to health and environment and to ensure that the stack

emission shall comply with government standards, FAR EAST FUEL CORP. shall install

Scrubber System and shall utilize green and clean fuel such as Industrial Diesel Oil(IDO)which

Environmental Impact Statement (EIS)

Hazardous Waste Treatment Storage and Disposal, Wastewater Treatment and Tire Recycling Facility

Barangay Anyatam, San Ildefonso, Bulacan FAR EAST FUEL CORPORATION

has low sulphur content approximately .3% combined with excess gases from the condensing

process. Likewise, vents from product storage shall be provided with exhaust pipes connected to

the scrubber system to ensure that all gases passes thru scrubber and are utilized and burned as