Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Installation and Operating Instructions Synchro-Check Monitor PLL/D-100/120, PLL/D-173/240, PLL/D-380/480, DIN-rail Mounted

Caricato da

Anonymous RcxX0FcTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Installation and Operating Instructions Synchro-Check Monitor PLL/D-100/120, PLL/D-173/240, PLL/D-380/480, DIN-rail Mounted

Caricato da

Anonymous RcxX0FcCopyright:

Formati disponibili

Installation and Operating

Instructions

Synchro-check Monitor PLL/D-100/120, PLL/D-173/240,

PLL/D-380/480, DIN-rail mounted

Introduction

This unit compares the voltage, frequency and phase angle of two

supplies and operates a relay according to the synchronicity of the

supplies. If the two supplies cease to match, the relay operates to

provide a control output. The relay output can be used for alarm or

control purposes.

The unit also provides a dead bus function. If the bus supply fails, the

relay operates and the output can be used to switch in an emergency

generator. LEDs indicate power on, relay and dead bus status.

Controls on the front panel set the trip points at which the relays and

LEDs operate:

Degree of synchronicity Ux (%Volts)

Nominal voltage (Un)

Dead bus function on/off

The unit is powered from the generator supply.

These instructions contain important safety information. Please read

them thoroughly before commissioning, operating or maintenance of

the unit.

The differential trip levels help to prevent relay chatter as the

Specification monitored voltage level varies.

Parameter PLL/PLD 100/120 173/240 380/480 As the relays have changeover contacts, the relay outputs can be

Rated Vg range Un 57-69V 100-139V 220-277V inverted by wiring to the alternative terminals 15-16 or 25-26.

Overload capacity

- continuous 87V 174V 346V

- 10s max. 104V 209V 416V With Dead Bus On, if the bus voltage falls below the Udbon level, the

Minimum supply Vg Uon 35V 60V 132V relay energises and the Dead Bus LED lights. The relay can be used

Burden on supply (Max) 2 VA/1.6W 2.7 VA/1.7W 4 VA/2.2W to turn on an emergency supply in the event of bus supply failure. The

relay will de-energise again and the LED will go off when the bus

Frequency range 45-65 Hz

voltage rises above the Udboff level.

Deadbus on Udbon 25% Uon

Deadbus off Udboff 50% Uon Note; Red LED indicates fault condition, not relay status

Sync Tolerance 10-30% Volts

Relay contacts: for 2 x changeover, volt-free Installation

general switching

The unit is intended for mounting on a standard DIN rail. Hook the unit

Load capacity - a.c. 250V @ 8A, 2 kVA onto the top of the rail and press the bottom of the unit until it locks in

Load capacity - d.c. 30V 8A place. To remove the unit from the rail, lever down the black tabs at

Insulation 4 kV/1 min the bottom of the unit to release it from the rail.

6

Mech. endurance 30x10 operations The unit is intended for use in a reasonably stable ambient

Other Data: temperature within the range -20 to +55°C. Do not mount the unit

Dimensions 90 x 105 x 64 mm where there is excessive vibration or in excessive direct sunlight.

Weight (100/208/380) 291 / 335 / 332g

2 2

Maximum conductor 2 x 1.5 mm or 1 x 2.5 mm

size

Operating temperature -20 to +55 °C

Storage temperature -30 to +70 °C

Over-voltage category III

Pollution degree 2

Environmental IP40 for front panel

protection IP20 for terminals.

Standards EN 60255-6, EN 60255-27, EN 61000-6-2,

EN 61000-6-4

Insulation Class: Ensure any external circuits connected to

the relay are provided with double or reinforced insulation.

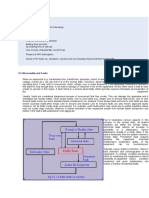

Operation

The green LED lights shows when the power supply is on.

While the two supplies match in voltage, frequency and phase to the

degree set by the %Volts control, the Sync LED lights and the relay is

energised.

If one supply varies such that they no longer match to that degree, the

Sync LED goes off and the relay de-energises.

If the generator voltage falls below the Uon level, the unit ceases to

operate, the relay de-energises and the Sync LED goes off.

Ref: PLL/D APR11-REV1 Page 1 of 2

• Avoid routing wiring to this unit alongside cables and products

NC = Normally closed.

that are, or could be, a source of interference.

Contact closed when

relay de-energised. • To protect the product against incorrect operation or permanent

NO = Normally open. damage, surge transients must be controlled. It is good EMC

Contact open when practice to suppress differential surges to 2kV or less at the

relay de-energised. source. The unit has been designed to automatically recover from

typical transients, however in extreme circumstances it may be

necessary to temporarily disconnect the auxiliary supply for a

period of greater than 5 seconds to restore correct operation.

• Screened communication leads are recommended and may be

required. These and other connecting leads may require the fitting

of RF suppression components, such as ferrite absorbers, line

filters etc., if RF fields cause problems.

• It is good practice to install sensitive electronic instruments that

are performing critical functions in EMC enclosures that protect

against electrical interference causing a disturbance in function.

Caution: Risk of

Warnings: Electric Shock

Wiring

• During normal operation, voltages hazardous to life may be All connections are made to screw clamp terminals. Terminals are

present at some of the terminals of this unit. Installation and suitable for copper wires only and will accept one stranded 0.05 -

servicing should be performed only by qualified, properly 2.5mm2 (30 - 12 AWG) stranded or solid core cables. Terminal

trained personnel abiding by local regulations. Ensure all screws should be tightened to 0.5 Nm. Choice of cable should meet

supplies are de-energised before attempting connection or local regulations.

other procedures. Instrument transformers used for connection to the meter must be of

• It is recommended adjustments be made with the supplies approved type, compliant with ANSI/IEEE C57.13 / IEC 60044-1 to

de-energised, but if this is not possible, then extreme caution provide isolation from measuring inputs.

should be exercised. For UL approved installation, use National Electrical Code (NEC)

Class 1 wiring, rated at 300V / 60°C min rating.

• Terminals should not be user accessible after installation

and external installation provisions must be sufficient to

prevent hazards under fault conditions. Fusing

• This unit is not intended to function as part of a system A suitable switch or circuit breaker conforming to the relevant parts of

providing the sole means of fault protection - good IEC 60947-1 and IEC 60947-3 should be included in the building

engineering practice dictates that any critical function be installation. It should be positioned so as to be easy to operate, in

protected by at least two independent and diverse means. close proximity to the equipment, and clearly identified as the

disconnecting device.

• The unit does not have internal fuses therefore external

fuses must be used for protection and safety under fault This unit must be fitted with an external fuse in voltage supply line.

conditions. Line must be fused with a quick blow fuse 1A maximum. Choose fuse

of a type and with a breaking capacity appropriate to the supply and in

• If this equipment is used in a manner not specified by the accordance with local regulations.

manufacturer, protection provided by the equipment may be For UL approved installations:

impaired. UL listed branch circuit fuses, suitable for the installation voltage, shall

be provided and installed in accordance with national installation code

Safety – 1A fast acting AC rated at the input.

The unit was designed in accordance with BS EN 600255-6 and -27 –

Permanently connected use, Normal condition. Insulation category III, Maintenance

pollution degree 2, basic insulation for rated voltage. Measurement In normal use, little or no maintenance is needed. Where used, ensure

Category III. any CT secondary circuits are short circuited prior to carrying out

installation or maintenance of the unit. As appropriate for service

EMC Installation Requirements conditions, isolate electrical power, inspect the unit and remove any

dust or other foreign material present. Periodically check all

This unit has been designed to provide protection against EM (electro-

connections for freedom from corrosion and screw tightness,

magnetic) interference in line, in accordance with BS EN 61000-6-2

particularly if vibration is present.

and -6-4. Precautions necessary to provide proper operation of this

and adjacent equipment will be installation dependent and so the

following can only be general guidance:

All of the above information, including drawings, illustrations and graphic designs, reflects our present understanding and is to the best of our knowledge and belief correct

and reliable. Users, however, should independently evaluate the suitability of each product for the desired application. Under no circumstances does this constitute an

assurance of any particular quality or performance. Such an assurance is only provided in the context of our product specifications or explicit contractual arrangements.

Our liability for these products is set forth in our standard terms and conditions of sale.

TE connectivity (logo), TE (logo) and TE Connectivity are trademarks of the TE Connectivity Ltd. family of companies. CROMPTON is a trademark of Crompton Parkinson

Ltd. and is used by TE Connectivity Ltd. under licence. Other logos, product and company names mentioned herein may be trademarks of their respective owners.

Tyco Electronics UK Ltd.

a TE Connectivity Ltd. company

Freebournes Road, Witham, CM8 3AH

Tel: +44 (0) 1376 509509, Fax: +44 (0) 1376 509511 Page 2 of 2

www.crompton-instruments.com

www.energy.te.com

Potrebbero piacerti anche

- Adh-2000 Manual de OpracionDocumento48 pagineAdh-2000 Manual de OpracionCarlos MenaNessuna valutazione finora

- Woodward Dyna 8000 8200 8400 - Technical Manual - en - 2017 PDFDocumento18 pagineWoodward Dyna 8000 8200 8400 - Technical Manual - en - 2017 PDFangel aguilarNessuna valutazione finora

- Circuit Breaker Selections For Low Voltage Installation (With Discrimination)Documento5 pagineCircuit Breaker Selections For Low Voltage Installation (With Discrimination)sabeerNessuna valutazione finora

- Modulo Emcp II m063Documento4 pagineModulo Emcp II m063EDUANG20Nessuna valutazione finora

- JFE-380 Instruction Manual April 07 Ed1 7ZPNA2002 PDFDocumento60 pagineJFE-380 Instruction Manual April 07 Ed1 7ZPNA2002 PDFAjay Singh100% (2)

- Sm6 Gam Cubicle User ManualDocumento46 pagineSm6 Gam Cubicle User ManualRizki SulistyowatiNessuna valutazione finora

- MCS100 Check Synch RelayDocumento15 pagineMCS100 Check Synch RelayAdetunji TaiwoNessuna valutazione finora

- Partes Chiller 30hxc186ry-571 - UccDocumento18 paginePartes Chiller 30hxc186ry-571 - UccANGEL MURILLO100% (1)

- Electricity For EngineersDocumento15 pagineElectricity For Engineerslalinda100% (3)

- 3.0.1 Elektric CM 1250, ENDocumento75 pagine3.0.1 Elektric CM 1250, ENthuan100% (1)

- AC Motor ProtectionDocumento33 pagineAC Motor ProtectionLoretta KimNessuna valutazione finora

- Deutz - Emr3 CAN BUS - Specification.v11.3Documento53 pagineDeutz - Emr3 CAN BUS - Specification.v11.3Guido Giovanni Franco RodriguezNessuna valutazione finora

- Vagm 22Documento4 pagineVagm 22AONLANessuna valutazione finora

- (PDF) Basement Standard MALAYSIA - Compress PDFDocumento15 pagine(PDF) Basement Standard MALAYSIA - Compress PDFWilson LeongNessuna valutazione finora

- CAN Doku EMR2 Engl PDFDocumento28 pagineCAN Doku EMR2 Engl PDFAnonymous RcxX0FcNessuna valutazione finora

- 3rd Quater EimDocumento3 pagine3rd Quater EimJoyce Anne UmbaoNessuna valutazione finora

- ALSTOM Instntneous Voltage Relay VAGM HighRes PDFDocumento4 pagineALSTOM Instntneous Voltage Relay VAGM HighRes PDFnadhsai3Nessuna valutazione finora

- QLT H50 KD ESFDocumento133 pagineQLT H50 KD ESFPakiNessuna valutazione finora

- SG-1478L Tablero de Transferencia PDFDocumento6 pagineSG-1478L Tablero de Transferencia PDFReynaldo Mariano100% (1)

- Pas TDocumento2 paginePas TAbdul KurniadiNessuna valutazione finora

- Installation Instructions: Protector Trip Relays DIN Rail & Wall Mounted 250 Series Paralleling & Reverse PowerDocumento8 pagineInstallation Instructions: Protector Trip Relays DIN Rail & Wall Mounted 250 Series Paralleling & Reverse PowerAnonymous RcxX0FcNessuna valutazione finora

- Electronic Potentiometer EPQ96-2 Data SheetDocumento4 pagineElectronic Potentiometer EPQ96-2 Data SheetLUATNessuna valutazione finora

- Installation Instructions: 256 Series Paralleling & Reverse Power Protector Trip RelayDocumento2 pagineInstallation Instructions: 256 Series Paralleling & Reverse Power Protector Trip RelaySreekanth SunkeNessuna valutazione finora

- LMR-111D Data Sheet 4921240214 UKDocumento4 pagineLMR-111D Data Sheet 4921240214 UKCristian Camilo Arias RodriguezNessuna valutazione finora

- Installation Instructions: Protector Trip Relays DIN Rail & Wall Mounted 250 Series Paralleling & Reverse PowerDocumento8 pagineInstallation Instructions: Protector Trip Relays DIN Rail & Wall Mounted 250 Series Paralleling & Reverse PowerBogrek RNessuna valutazione finora

- VDG13Documento5 pagineVDG13saravana symmetricalNessuna valutazione finora

- RMF-112D, Installation Instructions 4189340238 UKDocumento5 pagineRMF-112D, Installation Instructions 4189340238 UKFrancisco J. Rodriguez PermuyNessuna valutazione finora

- PTC Thermistor Relay Series - PD-225Documento3 paginePTC Thermistor Relay Series - PD-225dhir.221016Nessuna valutazione finora

- Manual Phoenix Inverter 250va 375va Rev 01 enDocumento10 pagineManual Phoenix Inverter 250va 375va Rev 01 enViktor BurkertNessuna valutazione finora

- Overload Relay - RMP111DDocumento2 pagineOverload Relay - RMP111DGaeSan EngenhariaNessuna valutazione finora

- Manuel D'utilisation Convertisseur Phoenix Victron 250VA-375VA-En - NL - FR - DE - ESDocumento42 pagineManuel D'utilisation Convertisseur Phoenix Victron 250VA-375VA-En - NL - FR - DE - ESJean Pierre KANYINDANessuna valutazione finora

- KEV114x: Single-Phase Ac Voltage GuardDocumento2 pagineKEV114x: Single-Phase Ac Voltage GuardRN NNessuna valutazione finora

- VTT11 12Documento5 pagineVTT11 12AONLANessuna valutazione finora

- PreventaDocumento4 paginePreventatinicm02Nessuna valutazione finora

- Instructions 133702Documento2 pagineInstructions 133702NNessuna valutazione finora

- 63A Series Transfer Switch User ManualDocumento1 pagina63A Series Transfer Switch User ManualOgie SeptiawanNessuna valutazione finora

- Esm 906-910Documento5 pagineEsm 906-910Pascal cNessuna valutazione finora

- PWM OC10A Rev0808Documento5 paginePWM OC10A Rev0808Patrizia Cudina100% (1)

- Fisher 4200 Electronic Position TransmittersDocumento8 pagineFisher 4200 Electronic Position TransmittersAndrey levashovNessuna valutazione finora

- Data Sheet: Overload Relays, RMP-111D ANSI Code 32Documento7 pagineData Sheet: Overload Relays, RMP-111D ANSI Code 32LUATNessuna valutazione finora

- Automatic Voltage Regulating Relay EE 301-M: Instruction ManualDocumento22 pagineAutomatic Voltage Regulating Relay EE 301-M: Instruction ManualnarendragahlotNessuna valutazione finora

- Loss of Mains Relay Type LMR-122D: Installation and Start Up InstructionsDocumento4 pagineLoss of Mains Relay Type LMR-122D: Installation and Start Up InstructionsLUATNessuna valutazione finora

- Fisher 4200 Transmitter BulletinDocumento12 pagineFisher 4200 Transmitter BulletinAmirouche BenlakehalNessuna valutazione finora

- RMP 121d Data SheetDocumento7 pagineRMP 121d Data Sheetmitchell morenoNessuna valutazione finora

- Type VTT 11, 12: Definite Time Delay RelayDocumento6 pagineType VTT 11, 12: Definite Time Delay RelayArun KumarNessuna valutazione finora

- Voltage Monitoring Types SWDocumento12 pagineVoltage Monitoring Types SWMardian Syah BejjoNessuna valutazione finora

- T2500-Datasheet 4Documento2 pagineT2500-Datasheet 4Rodni EmslieNessuna valutazione finora

- RMV-142D Data Sheet 4921240128 UKDocumento8 pagineRMV-142D Data Sheet 4921240128 UKAlexNessuna valutazione finora

- Manual MT-SX48 - EN - 170216Documento65 pagineManual MT-SX48 - EN - 170216MiguedxtrNessuna valutazione finora

- Cummins Gtec Ats Panel SpecificationDocumento6 pagineCummins Gtec Ats Panel SpecificationMohammed SalahNessuna valutazione finora

- Dead Band LOAD CONNECTIONSDocumento4 pagineDead Band LOAD CONNECTIONSAjay Kumar GiriNessuna valutazione finora

- Instruction Manual for EVA Voltage RegulatorDocumento8 pagineInstruction Manual for EVA Voltage RegulatorDaniel PricopNessuna valutazione finora

- RMC 131d Data Sheet 4921240104 UkDocumento8 pagineRMC 131d Data Sheet 4921240104 UkAilton NevesNessuna valutazione finora

- Short Circuit and Overcurrent Relay Type RMC-122D: Installation and Start Up InstructionsDocumento4 pagineShort Circuit and Overcurrent Relay Type RMC-122D: Installation and Start Up Instructionsnj4ypp8g86Nessuna valutazione finora

- 3RV16 Voltage Transformer Circuit-Breaker: Function OverviewDocumento2 pagine3RV16 Voltage Transformer Circuit-Breaker: Function OverviewVictor Manuel BonettoNessuna valutazione finora

- Users Manual Phenix Technologies Inc.: PPD September 19, 2007Documento31 pagineUsers Manual Phenix Technologies Inc.: PPD September 19, 2007Augusto SiuNessuna valutazione finora

- Vapm 31Documento4 pagineVapm 31AONLANessuna valutazione finora

- 4CAE000328 A en High Burden Tripping RelayDocumento11 pagine4CAE000328 A en High Burden Tripping RelayDave ChaudhuryNessuna valutazione finora

- Fisher 4200 Transmitters Product BulletinDocumento12 pagineFisher 4200 Transmitters Product BulletinShahnawaz SalimNessuna valutazione finora

- Man 1200S24Documento14 pagineMan 1200S24RameshNessuna valutazione finora

- Zenith ZTS Series Automatic Transfer Switches: Neutral SwitchingDocumento1 paginaZenith ZTS Series Automatic Transfer Switches: Neutral SwitchingmadhivananspNessuna valutazione finora

- RMF-112D Data Sheet 4921240223 UKDocumento8 pagineRMF-112D Data Sheet 4921240223 UKAlexNessuna valutazione finora

- Safezone 3D InstallationDocumento5 pagineSafezone 3D InstallationChien liang LiuNessuna valutazione finora

- ADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualDocumento6 pagineADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualMahendraLiyanage0% (1)

- TD Altern-Pm - GB 09.02 01Documento2 pagineTD Altern-Pm - GB 09.02 01Worapol KaewyingNessuna valutazione finora

- EN-RAC-04 - Power Substation MaintenanceDocumento30 pagineEN-RAC-04 - Power Substation Maintenancemd_khudNessuna valutazione finora

- RM 5Documento4 pagineRM 5tonnytoonsNessuna valutazione finora

- T2500Documento2 pagineT2500kylegazeNessuna valutazione finora

- O&m SPVDocumento9 pagineO&m SPVsingla.nishant1245Nessuna valutazione finora

- VT Guard Pro / VT Guard Pro-D: Solution For Ferroresonance EliminationDocumento10 pagineVT Guard Pro / VT Guard Pro-D: Solution For Ferroresonance EliminationRamesh KumarNessuna valutazione finora

- Prototyping PresentationDocumento19 paginePrototyping PresentationmukulNessuna valutazione finora

- THYRISTOR POWER CONTROLLERS FOR TEMPERATURE REGULATIONDocumento2 pagineTHYRISTOR POWER CONTROLLERS FOR TEMPERATURE REGULATIONShriram Mohan KhandekarNessuna valutazione finora

- DKG-117 Synchroscope and Check Synch RelayDocumento12 pagineDKG-117 Synchroscope and Check Synch RelaySaid TouhamiNessuna valutazione finora

- Minicas: Minicas Ii - Technical Data: DescriptionDocumento6 pagineMinicas: Minicas Ii - Technical Data: DescriptionAnonymous RcxX0FcNessuna valutazione finora

- H-T50 Installation ManualDocumento24 pagineH-T50 Installation ManualAnonymous RcxX0FcNessuna valutazione finora

- Technical Specification: DescriptionDocumento2 pagineTechnical Specification: DescriptionAnonymous RcxX0FcNessuna valutazione finora

- Technical SpecificationDocumento10 pagineTechnical SpecificationAnonymous RcxX0FcNessuna valutazione finora

- Ignition SwitchDocumento1 paginaIgnition SwitchAnonymous RcxX0FcNessuna valutazione finora

- Installation and Operating Instructions Gen-Key: Energy DivisionDocumento22 pagineInstallation and Operating Instructions Gen-Key: Energy DivisionAnonymous RcxX0FcNessuna valutazione finora

- Installation and Operating Instructions R.O.C.O.F Protection RelayDocumento24 pagineInstallation and Operating Instructions R.O.C.O.F Protection RelayBilal ŞimşekNessuna valutazione finora

- SPR System Protection, Control and Measurement Relay: OperationDocumento5 pagineSPR System Protection, Control and Measurement Relay: OperationAnonymous RcxX0FcNessuna valutazione finora

- Installation Instructions: Protector Trip Relays Panel Mounted 262 Series Current, Voltage & FrequencyDocumento2 pagineInstallation Instructions: Protector Trip Relays Panel Mounted 262 Series Current, Voltage & FrequencyAnonymous RcxX0FcNessuna valutazione finora

- Commutatori motorizzati e motori elettriciDocumento4 pagineCommutatori motorizzati e motori elettriciAnonymous RcxX0FcNessuna valutazione finora

- Gen SoftDocumento1 paginaGen SoftAhmed Sherif CupoNessuna valutazione finora

- Installation and Operating Instructions KEY-START Series: Energy DivisionDocumento20 pagineInstallation and Operating Instructions KEY-START Series: Energy DivisionAnonymous RcxX0FcNessuna valutazione finora

- Cutout HT50 PDFDocumento1 paginaCutout HT50 PDFAnonymous RcxX0FcNessuna valutazione finora

- Power Supply Systems Spds Type 2: Dehnguard® Modular Dgmtns275Documento2 paginePower Supply Systems Spds Type 2: Dehnguard® Modular Dgmtns275Anonymous RcxX0FcNessuna valutazione finora

- BP 305 Range Product Information en A2017Documento2 pagineBP 305 Range Product Information en A2017Anonymous RcxX0FcNessuna valutazione finora

- Axsp3p01 1Documento2 pagineAxsp3p01 1Anonymous g5beXbnOpTNessuna valutazione finora

- Overview Air en PDFDocumento17 pagineOverview Air en PDFAnonymous RcxX0FcNessuna valutazione finora

- Datasheet EAM114Documento3 pagineDatasheet EAM114RobiNessuna valutazione finora

- Ignition SwitchDocumento1 paginaIgnition SwitchAnonymous RcxX0FcNessuna valutazione finora

- Overview Air en PDFDocumento17 pagineOverview Air en PDFAnonymous RcxX0FcNessuna valutazione finora

- BP 305 Range Product Information en A2017Documento2 pagineBP 305 Range Product Information en A2017Anonymous RcxX0FcNessuna valutazione finora

- Battery Charger Range Technical Documentation en c2017 PDFDocumento24 pagineBattery Charger Range Technical Documentation en c2017 PDFAnonymous RcxX0FcNessuna valutazione finora

- Voltage Regulator DECS-100 ManuelDocumento81 pagineVoltage Regulator DECS-100 Manuelctsak100% (1)

- Inrush Current Reduction Module: ICRM-7, ICRM-15Documento4 pagineInrush Current Reduction Module: ICRM-7, ICRM-15Anonymous g5beXbnOpTNessuna valutazione finora

- DECS100 Product BulletinDocumento8 pagineDECS100 Product BulletinAnonymous g5beXbnOpTNessuna valutazione finora

- Busbar Systems: Rittal Offers An Exceptional Range of Solutions For The Key Application Area of Low-Voltage DistributionDocumento44 pagineBusbar Systems: Rittal Offers An Exceptional Range of Solutions For The Key Application Area of Low-Voltage Distributionpcchandra25Nessuna valutazione finora

- Example Infrared Inspection ReportDocumento18 pagineExample Infrared Inspection ReportRoland LimNessuna valutazione finora

- Catalog Numbers (AMPS)Documento2 pagineCatalog Numbers (AMPS)api-289140720Nessuna valutazione finora

- Cargador GNB FLX 200Documento30 pagineCargador GNB FLX 200José Avelar0% (1)

- Offshore-Onshore Institute of Technology, Inc.: Pre-Test Electrical Installation and Maintenance NC IIDocumento7 pagineOffshore-Onshore Institute of Technology, Inc.: Pre-Test Electrical Installation and Maintenance NC IIOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCNessuna valutazione finora

- ELE006 - EN FB Mantles Op Ins PDFDocumento24 pagineELE006 - EN FB Mantles Op Ins PDFdesi AdelinaNessuna valutazione finora

- ADR833En112 PDFDocumento6 pagineADR833En112 PDFJoseph BoshehNessuna valutazione finora

- Striker 4: Instruction ManualDocumento7 pagineStriker 4: Instruction ManualFredy Andres ValenciaNessuna valutazione finora

- Instruction Manual TDA-7560R MLDocumento2 pagineInstruction Manual TDA-7560R MLvanmiloNessuna valutazione finora

- Presentation ElectricalDocumento29 paginePresentation ElectricalSazid RajaNessuna valutazione finora

- Main Control Board User ManualDocumento15 pagineMain Control Board User Manualmohammedalathwary100% (1)

- 1100 Booster Pump Packages Owners ManualDocumento24 pagine1100 Booster Pump Packages Owners ManualErich Thomas TulusNessuna valutazione finora

- Fuse Protection FundamentalsDocumento10 pagineFuse Protection FundamentalsDeborah RochaNessuna valutazione finora

- Introduction To Electrical Principles: Unit 202: Electrical Principles and Processes For Building Services EngineeringDocumento68 pagineIntroduction To Electrical Principles: Unit 202: Electrical Principles and Processes For Building Services EngineeringSofea IzyanNessuna valutazione finora

- PD Pilot DevicesDocumento241 paginePD Pilot DevicesaguilavmNessuna valutazione finora

- PDFDocumento15 paginePDFNilesh KhareNessuna valutazione finora

- General Purpose US FusesDocumento69 pagineGeneral Purpose US FusesEliasNessuna valutazione finora

- ILTS001A - Solid State DC Injection Brake PDFDocumento27 pagineILTS001A - Solid State DC Injection Brake PDFFrancisNessuna valutazione finora