Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDF

Caricato da

Mani Rathinam RajamaniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDF

Caricato da

Mani Rathinam RajamaniCopyright:

Formati disponibili

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

ACCREDITATION CRITERIA – INSPECTION BODIES

NABCB Inspection Body Accreditation Scheme

Foreword

The Government of India and the Indian Industry jointly took the initiative in 1990s to establish an

accreditation framework within the country in response to the emerging needs of the trade and industry. The

objective was to make available internationally recognized formal accreditation mechanism to the

organizations which provide conformity assessment services such as certification, inspection and testing,

who were till then largely dependent on the accreditation systems of Europe and US.

A Council with representation from the Government, Industry and other stakeholders was established and

named as the Quality Council of India. This Council was entrusted with the task of establishing the

accreditation system in India. Accordingly, the National Accreditation Board for Certification Bodies

(NABCB) was established to provide accreditation to the Inspection and Certification Bodies.

NABCB has adopted the international standard ISO/IEC 17020 as the criteria for providing accreditation

services to the Inspection Bodies to facilitate harmonization of inspection services in India and to bring them

at par with other countries. This is also to facilitate signing of Mutual Recognition / Multilateral

Arrangements with regional and international bodies.

Contents

1.0 Scope ________________________ 2

2.0 Accreditation Criteria ________________________ 2

3.0 Guidance Documents ________________________ 2

4.0 Scope of Accreditation ________________________ 2

5.0 Policy on Metrological Traceability and Calibration _______ 2

6.0 Policy on use of Testing Laboratories ________________ 4

7.0 Policy on Proficiency Testing ________________________ 4

8.0 Policy on use of NABCB Accreditation Mark ___________ 6

9.0 Policy on Subcontracting ________________________ 6

10.0 Inspection Standards ________________________ 7

11.0 Time for Inspections ________________________ 7

BCB 110 (IB) / Mar 2017 Page 1 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

1.0 Scope

This document specifies the requirements that an inspection body shall meet if it is to be recognized by the

Board as competent and reliable in the providing inspection services.

2.0 Accreditation Criteria

The Inspection Bodies seeking accreditation for Inspection in specific technical areas shall comply with the

requirements as specified in the international standard ISO/IEC 17020:2012 “Conformity assessment –

Requirements for the operation of various types of bodies performing inspection” and other requirements as

specified in this document.

The standard ISO/IEC 17020:2012 can be obtained online from ISO website ‘www.iso.org’ or its equivalent

Indian adopted standard can be procured from the Bureau of Indian Standards.

3.0 Guidance Documents for Inspection Bodies

NABCB has adopted the relevant ILAC and APLAC requirements and guidance documents as applicable to

the Inspection Bodies as part of its criteria to be read with the criteria as above.

NABCB has adopted the ILAC Policy Document “ILAC P15: Application of ISO/IEC 17020:2012 for the

Accreditation of the Inspection Bodies”. Applicant and accredited inspection bodies shall also comply with

this document. This document provides application notes to inspection bodies to comply with the

corresponding clauses of ISO/IEC 17020 and is used for assessment of inspection bodies in a harmonized

manner by the accreditation bodies world over. This document forms the basis of mutual recognition

arrangements between accreditation bodies, and is considered necessary for the consistent application of

ISO/IEC 17020. This document can be freely downloaded from ILAC website ‘www.ilac.org’ or by directly

accessing the link given below:

http://ilac.org/publications-and-resources/ilac-policy-series/

Further, NABCB has also adopted the APLAC Document “APLAC TC 006: APLAC Guidance Notes on

ISO/IEC 17020”. Applicant and accredited inspection bodies shall comply with the guidance given in this

document. This document can be freely downloaded from APLAC website ‘www.aplac.org’ or by directly

accessing the link given below:

http://www.aplac.org/publications.html

In addition, NABCB has elaborated some of the requirements of ISO 17020, based on ILAC/APLAC

application documents, which have to be complied with by all applicant and accredited inspection bodies.

4.0 Scope of Accreditation

NABCB would categorize the scope of accreditation based on the broad ‘IAF Classification of Scope

Sectors’ as indicative scope. The inspection body shall while applying for accreditation to NABCB specify

its detailed scope including the title, number and year of publication of the standards / regulations / methods

/ procedures applicable The scope of accreditation after assessment shall be issued by NABCB to reflect the

demonstrated technical competence of the inspection body.

5.0 Policy on Metrological Traceability and Calibration

Traceability is the property of a measurement result whereby the result can be related to stated references,

usually national or international standards, through a documented unbroken chain of comparisons (i.e.

calibrations), each having stated measurement uncertainties. The purpose of requiring traceability is to

BCB 110 (IB) / Mar 2017 Page 2 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

ensure that measurements are accurate representations of the specific quantity subject to measurement,

where measurement results form the basis of inspection results.

ILAC Document - ILAC P10 “ILAC Policy on Traceability of Measurement Results” available on ILAC

website ‘www.ilac.org’ forms the basis of NABCB Policy on Measurement Traceability. Traceability of

measurement results is a fundamental topic for equivalence as well as harmonization of measurement results

provided by conformity assessment bodies including inspection bodies and to ensure confidence amongst

accreditation bodies to maintain international Mutual Recognition Arrangements.

NABCB Policy on Measurement Traceability applicable to all NABCB applicant/accredited Inspection

Bodies is as follows:

i. Inspection Bodies shall be able to demonstrate that calibration of critical equipment/instruments,

whether owned by itself or others, used in inspection and hence the measurement results generated by

that equipment/instrument, relevant to the applied / accredited scope of accreditation, are traceable to the

International System of Units (SI units) in accordance with the requirements specified in ISO 17025.

When using external calibration services, traceability of measurement shall be assured by the use of

calibration services from laboratories that can demonstrate competence, measurement capability and

traceability.

ii. NABCB accepts as an evidence of traceability to national and international standards of measurements

those calibrations performed by:

a) National Metrology Institutes such as NPL-India or other CIPM (International Committee for

Weights and Measures) MRA Signatories;

b) Calibration laboratories accredited by NABL-India, an ILAC and APLAC MRA Signatory, or those

demonstrating compliance to ISO/IEC 17025, as assessed by the inspection body, if need be;

c) Calibration laboratories accredited by other ILAC MRA Signatories.

iii. Where in-house calibration of equipment is accepted, the inspection body shall ensure that the

calibration has been performed in accordance with the relevant criteria for metrological traceability in

ISO/IEC 17025, which states that traceability of measurement shall be assured by the use of calibration

services from laboratories that can demonstrate competence, measurement capability and traceability. In

such cases the inspection body has the responsibility for ensuring and demonstrating that calibrations are

performed by using a valid calibration method, by competent person(s), maintaining all conditions for

performing calibration such as traceability of master equipment as per (ii) above, environmental

conditions etc. and that calibration records are adequately maintained.

iv. Where traceability as stated above is not technically possible or reasonable or available, the inspection

body and the client and other interested parties may agree to using certified reference materials provided

by a competent supplier or using specified methods and/or consensus standards that are clearly described

and agreed by all parties.

v. Where inspection body opts to verify compliance of an external/in-house calibration laboratory to

ISO/IEC 17025 instead of using a calibration laboratory accredited as per ISO/IEC 17025, then it shall

have a documented procedure to assess an external/in-house calibration laboratory to the applicable

requirements of ISO/IEC 17025 (as described in iii above) and shall demonstrate to have assessed the

external/in-house calibration laboratory by an assessor trained in ISO/IEC 17025 and relevant

calibrations and the IB’s procedures, and shall maintain detailed records of assessing compliance of the

external calibration laboratory to ISO/IEC 17025.

BCB 110 (IB) / Mar 2017 Page 3 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

6.0 Policy on use of Testing Laboratories as part of Inspection

Inspection Bodies use the services of laboratories for testing as a part of its inspection activities. NABCB

Policy on use of laboratories for testing by the Inspection Bodies is as follows:

i. When as a part of inspection, for confirming product compliance to relevant standard, tests are required

to be carried out in a laboratory, the inspection personnel may draw sample(s) and send it to their own

laboratory or an independent external laboratory. Inspection bodies shall ensure that the laboratories to

which samples are sent for testing are either accredited or compliant to ISO/IEC 17025 for the scope of

tests being undertaken. Inspection bodies shall not use testing laboratories recommended or decided by

its clients unless they are either accredited or compliant to ISO/IEC 17025. If the inspection body opts to

verify compliance of an external testing laboratory to ISO/IEC 17025, instead of using a laboratory

accredited as per ISO/IEC 17025, then it shall have a documented procedure to assess the external

testing laboratory to the requirements of ISO/IEC 17025, shall demonstrate to have assessed the external

testing laboratory by an assessor trained in ISO/IEC 17025 and relevant testing procedures, and shall

maintain records of assessing compliance of external testing laboratories to ISO/IEC 17025. Only in the

above cases the laboratory test report as received from the laboratory may be directly attached to the

inspection report.

ii. When as a part of inspection, the inspection body is required to review test reports for the purpose of

assessing conformity to specified requirements/criteria, the testing shall have been carried out in

laboratories complying with ISO/IEC 17025 as established by the inspection body or accredited to

ISO/IEC 17025. The tests for which results are to be reviewed shall either be covered under

accreditation in accordance with ISO/IEC 17025 or the compliance of the laboratory performing the

tests shall have been verified by the inspection body for compliance to applicable requirements of

ISO/IEC 17025 for the tests under consideration.

iii. When as a part of inspection, the inspection personnel witness testing at client’s or vendor’s laboratory

at the site, the inspection bodies shall ensure that these laboratories demonstrate compliance to relevant

requirements as specified in Clauses 6.1, 6.2 and 7.1 of ISO/IEC 17020:2012. The inspection bodies

shall ensure that client’s or vendor’s personnel performing such tests are competent and use standard /

validated test methods. The inspection body shall also ensure that the inspection personnel conducting

the test witness shall also be knowledgeable about the above requirements to be able to assess the same.

7.0 Policy on Proficiency Testing (PT)

Proficiency Testing (PT) is typically associated with laboratory accreditation and is defined as a process for

checking actual laboratory testing performance, usually by means of inter-laboratory test data comparisons.

For many tests and calibrations, results from proficiency testing are very good indicators of competence.

However in some instances proficiency testing may be relevant to inspection bodies. Proficiency testing

serves to supplement existing procedures adopted by inspection bodies to assure the quality and evaluation

of performance of the activities for which they are accredited or seek accreditation.

ILAC Document “ILAC P9: ILAC Policy for Participation in Proficiency Testing Activities” available on

ILAC website ‘www.ilac.org’ forms the basis of NABCB Policy on Proficiency Testing by Inspection

Bodies. APLAC Requirement Document “APLAC MR 001: Procedures for Establishing and Maintaining

the APLAC Mutual Recognition Agreement among Accreditation Bodies” under clause 3.3.2 states:

- Proficiency testing activities are also applicable to certain types of inspection. An applicant accreditation

body to the APLAC MRA for inspection shall have a documented policy on proficiency testing, and

encourage its accredited inspection bodies to participate where relevant proficiency testing activities are

available.

BCB 110 (IB) / Mar 2017 Page 4 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

NABCB encourages its applicant/accredited inspection bodies to participate in appropriate PT activities,

where available and/or relevant. It shall be the responsibility of inspection bodies to check the availability of

appropriate PT programs which best match their day-to-day work and to select the programs in which to

participate as per their scope of accreditation. NABCB will provide information, as may be available, to its

applicant/accredited inspection bodies on PT programs organized by APLAC or other ILAC recognized

regions or by ILAC MRA Signatories and their accredited PT Providers.

In considering the application of proficiency testing to inspection bodies, the specialized nature of many

inspections and the small number of inspection bodies practicing in any one area may make reliance upon

externally sourced proficiency testing challenging. Accordingly, “Proficiency Testing” should at least

involve internally conducted technical witnessing of inspectors and other activities that assure the quality of

inspection activities.

The quality of inspection activities may be established by the inspection bodies in a number of ways which

include, but are not limited to:

a) Comparison of findings

Several inspectors (drawn from one or several inspection bodies) may inspect an item (either concurrently

or over a time interval such that the stability of the inspected item is assured) and the findings are then

compared. Comparisons may be numerical or qualitative and a statistical analysis of outcomes may

highlight whether the findings from each inspector are satisfactory. Comparison is against the consensus

of the group.

b) Measurement audits

An object of inspection with known reference values or qualities may be used in a manner similar to that

described in a) above. The extent of variance between the reported results from the inspector and the

reference value / quality may be used as a performance evaluation tool.

c) Technical witnessing

An inspector may observe another inspector in the course of an inspection, to confirm the coverage and

application of judgment. This technique is frequently used as a measure of the effectiveness of training.

IAF/ILAC A4 requires that the monitoring of performance of inspections should include on-site

witnessing of inspections by technically competent personnel and cover a representative sample of

inspections.

d) Review of inspection reports, records and supporting materials

In some cases the reports & records of inspection will be sufficient to establish whether the inspection was

conducted properly and it is therefore possible for a high degree of assurance to be established through

review of a comprehensive set of records. An example could include structural and condition inspections

where these are supported by extensive photographic records, original observations, notes, drawings etc.

The above activities are able to discriminate between varying levels of performance on the part of the

inspector, across the diverse dimensions of the service delivery. They, however, serve as examples and

inspection bodies should draw upon them as appropriate to their industry, the environment, the processes of

service delivery and the inspection task.

Inspection bodies should identify their approach to assuring the quality of inspection services, by including a

statement, policy or procedure in their management system. An applicant/accredited inspection body should

have a plan on their intended participation in relevant proficiency testing activities, as applicable, to cover

the major technical areas included in its scope of accreditation.

BCB 110 (IB) / Mar 2017 Page 5 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

8.0 Policy on use of NABCB Accreditation Mark

NABCB strongly encourages its accredited inspection bodies to use NABCB Accreditation Mark on their

inspection reports/certificates to promote accreditation granted to their inspection services. It is each

inspection body’s responsibility to ensure that it describes its NABCB Accreditation Status in a manner that

does not imply that accreditation is held in areas that are outside the scope of accreditation, for its other

activities and branch offices facilities that are not included in the accreditation or for products or services

that NABCB accreditation does not cover.

ILAC Document “ILAC P8: ILAC Mutual Recognition Arrangement (Arrangement) - Supplementary

Requirements and Guidelines for the Use of Accreditation Symbols and for Claims of Accreditation Status

by Accredited Laboratories and Inspection Bodies” available on ILAC website ‘www.ilac.org’ forms the

basis of NABCB Policy on Use of NABCB Accreditation Mark by Inspection Bodies. The detailed

conditions on use of NABCB Accreditation Mark are prescribed in NABCB document BCB 202.

While the use of “NABCB Accreditation Mark” on inspection reports / certificates is not mandatory, only

inspection reports/certificates bearing the “NABCB Accreditation Mark” (or that otherwise make reference

to accredited status by a specific, recognized accreditation body) can benefit from the acceptance established

through mutual recognition agreements/arrangements amongst accreditation bodies globally.

Inspection reports/certificates issued by NABCB accredited inspection bodies for the scope and locations

covered under NABCB accreditation, irrespective of whether NABCB Accreditation Mark is used or not on

such reports/certificates issued, shall be deemed to be covered under accreditation and shall be subject to

assessment during routine NABCB Surveillances and/or Reassessments of accredited inspection bodies.

NABCB Fee based on per inspection report/certificate or on % of inspection contract value as announced

annually in the NABCB Fee Structure shall be applicable on all inspection reports/certificates issued by

NABCB accredited inspection bodies for the scope and locations covered under NABCB accreditation, with

or without NABCB Accreditation Mark. It is the responsibility and obligation of NABCB accredited

inspection bodies to declare quarterly (every 3 months) the number of such reports/certificates issued or

inspection contracts signed / executed and related information, correctly to NABCB.

9.0 Policy on Subcontracting

NABCB shall not grant accreditation to inspection bodies for the scope for which it does not have the

competence, resources etc. and for which it intends to subcontract entire inspection activity on permanent

basis.

When an inspection body subcontracts inspection activities for allowable reasons as given in ISO/IEC

17020:2012 other than on a permanent basis, it should select a subcontractor inspection body which meets at

least the same independence criteria (Type A, B or C) as itself. It shall ensure that the subcontractor

inspection body complies with ISO/IEC 17020 as established by the inspection body or accredited to

ISO/IEC 17020.

Assigning inspection work to branch offices within the organization structure of the main office and

operating under the same quality system is not considered as subcontracting. However, operation of these

branch offices shall be assessed by NABCB, if they are to be included in the scope of accreditation. The

inspection body shall also be required to demonstrate that it can exercise effective supervision over the

inspections performed by these branch offices.

BCB 110 (IB) / Mar 2017 Page 6 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

10.0 Inspection Standards

It would be the responsibility of the Inspection body to demonstrate that inspections are carried out in

accordance with internationally / nationally acceptable standards. Standards developed by the customer or

the inspection body itself, if used, shall be appropriate, fully documented and validated and should be clearly

specified in the inspection contract.

11.0 Time for Inspections undertaken by the Inspection Body

The inspection body shall have a system for ensuring required time is spent by the inspection personnel for

carrying out inspections and for monitoring the time spent on inspections. The documented system shall be

assessed for adequacy by the NABCB AT as part of documentation review and if required, during the onsite

assessment as part of implementation verification.

BCB 110 (IB) / Mar 2017 Page 7 of 8

NATIONAL ACCREDITATION BOARD FOR CERTIFICATION BODIES (NABCB)

Quality Council of India (QCI), 2nd Floor, Institution of Engineers Building, Bahadur Shah Zafar Marg, New Delhi – 110002

Phone: +91-11-2337 8056 / 57; Fax: +91-11-2337 8678; Web: www.qcin.org; E-mail: nabcb@qcin.org

Amendment Record

Date Auth. by Description of Amendment

Jan 2013 Director To incorporate ISO/IEC 17020:2012 as the accreditation criteria and

to align with ILAC & APLAC requirements

Mar 2017 CEO To incorporate ILAC P 15, to add more details to some requirements

and to align with other changes

BCB 110 (IB) / Mar 2017 Page 8 of 8

Potrebbero piacerti anche

- Global: Personnel Certification SchemeDocumento36 pagineGlobal: Personnel Certification SchemeJadson FerreiraNessuna valutazione finora

- General Information Brochure: National Accreditation Board For Testing and Calibration Laboratories (NABL)Documento44 pagineGeneral Information Brochure: National Accreditation Board For Testing and Calibration Laboratories (NABL)Arun KumarNessuna valutazione finora

- QS2 PDFDocumento7 pagineQS2 PDFtomcanNessuna valutazione finora

- Certification Body Requirements: Section 7Documento20 pagineCertification Body Requirements: Section 7Nagasimha A RNessuna valutazione finora

- Nandtb 07 Qualifications Requirements For NDT PersonnelDocumento4 pagineNandtb 07 Qualifications Requirements For NDT PersonnelMuthumonickamNessuna valutazione finora

- QS2Documento7 pagineQS2tomcanNessuna valutazione finora

- Quality Aspects: Personal QualificationDocumento3 pagineQuality Aspects: Personal QualificationShahazad ShaikNessuna valutazione finora

- IRIS Rev Vs IS022163 Correlation Matrix 1Documento6 pagineIRIS Rev Vs IS022163 Correlation Matrix 1Centre For Total Quality ManagementNessuna valutazione finora

- BS en 16122-2012 (2015)Documento44 pagineBS en 16122-2012 (2015)civillab82Nessuna valutazione finora

- Certification Services DivisionDocumento12 pagineCertification Services Divisiontomcan100% (1)

- PSL57WIRDocumento4 paginePSL57WIRmusaismail8863Nessuna valutazione finora

- ASNT L3 ApplicationDocumento12 pagineASNT L3 ApplicationErick PachasNessuna valutazione finora

- Pcn/Gen Appendix F3.1 Issue 2 Rev ADocumento13 paginePcn/Gen Appendix F3.1 Issue 2 Rev AaboutdestinyNessuna valutazione finora

- IAEA Radiological Crime Scene ManagementDocumento107 pagineIAEA Radiological Crime Scene ManagementdonaNessuna valutazione finora

- Near Surface Disposal Facilities For Radioactive WastDocumento124 pagineNear Surface Disposal Facilities For Radioactive WastcaflosNessuna valutazione finora

- Procedure - DraftDocumento9 pagineProcedure - Draftbadar13Nessuna valutazione finora

- JP For RadiographyDocumento7 pagineJP For Radiographytaparia_piyushNessuna valutazione finora

- Atmeeya SwastathaDocumento121 pagineAtmeeya SwastathaDharma TejaNessuna valutazione finora

- Daivika SwastataDocumento41 pagineDaivika SwastataBible Mission KarimnagarNessuna valutazione finora

- EN 473/ISO 9712 Level 3 Information Package: Wens Quality Assurance PVT LTDDocumento12 pagineEN 473/ISO 9712 Level 3 Information Package: Wens Quality Assurance PVT LTDkoib789Nessuna valutazione finora

- Bhel UtDocumento14 pagineBhel UtAnonymous 6k4VeeRNessuna valutazione finora

- ISO 9712:2012 International Standard Non Destructive Testing - Qualification and Certification of NDT PersonnelDocumento1 paginaISO 9712:2012 International Standard Non Destructive Testing - Qualification and Certification of NDT PersonnelClayton CalvertNessuna valutazione finora

- ISO 23278 (2006) - Magnetic Particle Testing of Weld - Acceptance LevelsDocumento8 pagineISO 23278 (2006) - Magnetic Particle Testing of Weld - Acceptance Levels_PiperCub_Nessuna valutazione finora

- UntitledDocumento105 pagineUntitledUlises Almeida CruzNessuna valutazione finora

- General Requirements For Qualification and PCN Certification of Guided Wave Testing PersonnelDocumento17 pagineGeneral Requirements For Qualification and PCN Certification of Guided Wave Testing Personnelmjranjbarn0% (1)

- ICNDT Guidelines July 2012Documento30 pagineICNDT Guidelines July 2012Asadah Surya DharmaNessuna valutazione finora

- PCNGENC1Documento23 paginePCNGENC1Pubg addictedNessuna valutazione finora

- Ultrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar JhaDocumento43 pagineUltrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar Jhajohn power100% (1)

- Ein II TFT Manual020306print-1Documento31 pagineEin II TFT Manual020306print-1Arthanari Vaidyanathan0% (1)

- PCN Qualification and Certification of NDT Personnel For The Aerospace Multi-SectorDocumento29 paginePCN Qualification and Certification of NDT Personnel For The Aerospace Multi-SectorFaisal IbrahimNessuna valutazione finora

- Guidelines For The Preparation and Grading of NDTDocumento4 pagineGuidelines For The Preparation and Grading of NDTL...nNessuna valutazione finora

- Conduct of PCN Examinations: NDTS India (P) LimitedDocumento11 pagineConduct of PCN Examinations: NDTS India (P) LimitedVasanth Praveen KumarNessuna valutazione finora

- CA-500 Series Instructions For Use Sysmex Corporation Kobe, Japan. Automated Blood Coagulation AnalyzerDocumento258 pagineCA-500 Series Instructions For Use Sysmex Corporation Kobe, Japan. Automated Blood Coagulation AnalyzerDemetrio De leonNessuna valutazione finora

- NDT Overview M1 Part2Documento55 pagineNDT Overview M1 Part2Leon Heart FC100% (1)

- PCN GenDocumento27 paginePCN GenMohammed ShamilNessuna valutazione finora

- Procedure For Management Review: Punyam Manufacturing INCDocumento3 pagineProcedure For Management Review: Punyam Manufacturing INCSoumitra HalderNessuna valutazione finora

- ASNT-L3 ApplicationDocumento15 pagineASNT-L3 Applicationvignesh seeniraj100% (1)

- QC - 08 PTCDocumento5 pagineQC - 08 PTCmahendraNessuna valutazione finora

- Chapter 3 Quality System StandardsDocumento129 pagineChapter 3 Quality System StandardsSanjay AdhikariNessuna valutazione finora

- Calibration NDTDocumento11 pagineCalibration NDTAnbalagan RenuNessuna valutazione finora

- Ansa India Information Package Level 3Documento8 pagineAnsa India Information Package Level 3manoj kumar sarojNessuna valutazione finora

- NPS-SOP-CNDT-001 Rev 0 Written Practice - Temp UpdatesDocumento12 pagineNPS-SOP-CNDT-001 Rev 0 Written Practice - Temp UpdatesYusuf bagewadiNessuna valutazione finora

- Operation Manual: Model No. PHT 1800Documento22 pagineOperation Manual: Model No. PHT 1800Mamani William100% (1)

- PCN OutlineDocumento26 paginePCN Outlinekendall0609Nessuna valutazione finora

- Procedure For Document and Record ControlDocumento4 pagineProcedure For Document and Record ControlAhmad NawazNessuna valutazione finora

- Visual Examination ProcedureDocumento23 pagineVisual Examination ProcedureEdAlmNessuna valutazione finora

- Quality Control ManualDocumento15 pagineQuality Control ManualJBStringerNessuna valutazione finora

- Itp AsntDocumento33 pagineItp AsntSYED FADZIL SYED MOHAMED100% (1)

- The Implementation of The New Standard EN ISO 18563 For Ultrasonic Phased-Array Systems at The ManufacturerDocumento7 pagineThe Implementation of The New Standard EN ISO 18563 For Ultrasonic Phased-Array Systems at The ManufacturershaxahNessuna valutazione finora

- G 2408 Accreditation Criteria For Inspection of Food Inspection BodiesDocumento7 pagineG 2408 Accreditation Criteria For Inspection of Food Inspection Bodiessafeer ahmadNessuna valutazione finora

- AEP1143Documento30 pagineAEP1143GokulPrasadNessuna valutazione finora

- Ea 4 15 G Rev01 May 2015 Rev PDFDocumento24 pagineEa 4 15 G Rev01 May 2015 Rev PDFandrej_voloscuk13100% (1)

- Ajin BabuDocumento4 pagineAjin BabuJithuJohnNessuna valutazione finora

- Radiation Safety Program 2Documento16 pagineRadiation Safety Program 2Ahmed shabanNessuna valutazione finora

- Bio DataDocumento5 pagineBio DataArun KumarNessuna valutazione finora

- BV Iso 9001 CertificationDocumento2 pagineBV Iso 9001 CertificationHarthwell CapistranoNessuna valutazione finora

- NATA 17025 Checklist With Interpretive Comments PDFDocumento8 pagineNATA 17025 Checklist With Interpretive Comments PDFzilangamba_s4535Nessuna valutazione finora

- NABL 100-21-Jul-2016Documento46 pagineNABL 100-21-Jul-2016sahaNessuna valutazione finora

- Nabl 100Documento46 pagineNabl 100Mayur JadhavNessuna valutazione finora

- Accreditation Requirements of Certification Bodies For ProductsDocumento12 pagineAccreditation Requirements of Certification Bodies For ProductssolasmarineNessuna valutazione finora

- TL 9000 Quality Management System Measurements Handbook NPR ExamplesDocumento7 pagineTL 9000 Quality Management System Measurements Handbook NPR ExamplesMani Rathinam RajamaniNessuna valutazione finora

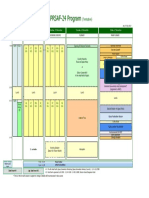

- ProgramDocumento1 paginaProgramMani Rathinam RajamaniNessuna valutazione finora

- Catalog For Bearing DesignDocumento70 pagineCatalog For Bearing DesignHameer ReddyNessuna valutazione finora

- M.SC Result 2017Documento1 paginaM.SC Result 2017Mani Rathinam RajamaniNessuna valutazione finora

- Computer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapDocumento6 pagineComputer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapMani Rathinam RajamaniNessuna valutazione finora

- D. All of The AboveDocumento3 pagineD. All of The AboveramarajanenggNessuna valutazione finora

- Payment Acknowledgment - 180604092233Documento1 paginaPayment Acknowledgment - 180604092233Mani Rathinam RajamaniNessuna valutazione finora

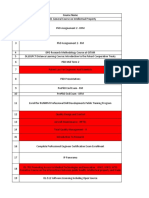

- Learning Plan Dec 2017-Apr 2018Documento5 pagineLearning Plan Dec 2017-Apr 2018Mani Rathinam RajamaniNessuna valutazione finora

- VSM TemplateDocumento7 pagineVSM TemplateMani Rathinam RajamaniNessuna valutazione finora

- Product, Process, and Problem Analysis Quality SystemDocumento25 pagineProduct, Process, and Problem Analysis Quality SystemMani Rathinam RajamaniNessuna valutazione finora

- List of Certifications DiscontinuedDocumento30 pagineList of Certifications DiscontinuedMani Rathinam RajamaniNessuna valutazione finora

- AS9100 Certification StatusDocumento192 pagineAS9100 Certification StatusMani Rathinam RajamaniNessuna valutazione finora

- LSS Mani Rathinam RajamaniDocumento2 pagineLSS Mani Rathinam RajamaniMani Rathinam RajamaniNessuna valutazione finora

- Join The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Documento1 paginaJoin The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Mani Rathinam RajamaniNessuna valutazione finora

- Leave PlanDocumento2 pagineLeave PlanMani Rathinam RajamaniNessuna valutazione finora

- 3x5 Why Worksheet For SuppliersDocumento1 pagina3x5 Why Worksheet For SuppliersMani Rathinam RajamaniNessuna valutazione finora

- Flight 1 Mon, Mar 4: Cathay PacificDocumento6 pagineFlight 1 Mon, Mar 4: Cathay PacificMani Rathinam RajamaniNessuna valutazione finora

- Letter of ParticipationDocumento1 paginaLetter of ParticipationMani Rathinam RajamaniNessuna valutazione finora

- Month Wise NC TrendDocumento2 pagineMonth Wise NC TrendMani Rathinam RajamaniNessuna valutazione finora

- Standards Made Available Free of Cost To Combat COVID-19Documento4 pagineStandards Made Available Free of Cost To Combat COVID-19Mani Rathinam RajamaniNessuna valutazione finora

- Fod Compliance & Findings - Bay 1Documento2 pagineFod Compliance & Findings - Bay 1Mani Rathinam RajamaniNessuna valutazione finora

- Minitab Print Window PDFDocumento1 paginaMinitab Print Window PDFMani Rathinam RajamaniNessuna valutazione finora

- Matecconf Imanee2018 08013Documento6 pagineMatecconf Imanee2018 08013Mani Rathinam RajamaniNessuna valutazione finora

- BCB 201 (IB) - Mar 2019 PDFDocumento38 pagineBCB 201 (IB) - Mar 2019 PDFMani Rathinam RajamaniNessuna valutazione finora

- 09 - Chapter 3Documento11 pagine09 - Chapter 3Mani Rathinam RajamaniNessuna valutazione finora

- Mani Rathinam Rajamani: Certificate of CompletionDocumento1 paginaMani Rathinam Rajamani: Certificate of CompletionMani Rathinam RajamaniNessuna valutazione finora

- BCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFDocumento10 pagineBCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFMani Rathinam RajamaniNessuna valutazione finora

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocumento8 pagineBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniNessuna valutazione finora

- Mani Rathinam Rajamani: Certificate of CompletionDocumento1 paginaMani Rathinam Rajamani: Certificate of CompletionMani Rathinam RajamaniNessuna valutazione finora

- JD Lead Asset Integrity Engineer - R02 - WoDocumento3 pagineJD Lead Asset Integrity Engineer - R02 - WoInalegwu23Nessuna valutazione finora

- CX-9 Workshop ManualDocumento1.989 pagineCX-9 Workshop ManualRichard James100% (1)

- Contoh ItpDocumento3 pagineContoh Itphafiz elektroNessuna valutazione finora

- Wind Inspection and Testing ChecklistsDocumento11 pagineWind Inspection and Testing Checklistsengrrahman3135Nessuna valutazione finora

- How To Test Circuit Board With MultimeterDocumento9 pagineHow To Test Circuit Board With MultimeterjackNessuna valutazione finora

- Part II (B) - FMA 1967 & Amp Regulations - PPT Compatibility ModeDocumento40 paginePart II (B) - FMA 1967 & Amp Regulations - PPT Compatibility ModeMohd Farihan Bin JamaludinNessuna valutazione finora

- Work Study (Case Study) PresentationDocumento36 pagineWork Study (Case Study) PresentationMeet JaiswalNessuna valutazione finora

- Brochure - B2B - Trading - Globexia ProfileDocumento42 pagineBrochure - B2B - Trading - Globexia ProfileGaurav GoyalNessuna valutazione finora

- MHD56162ed2Manipulator Arm Parts Operation Maintenance ManualDocumento36 pagineMHD56162ed2Manipulator Arm Parts Operation Maintenance ManualhamzagiNessuna valutazione finora

- 8.4 Health, Safety and EnvironmentDocumento14 pagine8.4 Health, Safety and EnvironmentAlaa AttalahNessuna valutazione finora

- Construction Standard: IPS-C-ME-130Documento11 pagineConstruction Standard: IPS-C-ME-130RezaNessuna valutazione finora

- Armylor: Ptfe / Pfa Lined Pipes and Fittings ANSI B16.5Documento36 pagineArmylor: Ptfe / Pfa Lined Pipes and Fittings ANSI B16.5branimir jankovicNessuna valutazione finora

- Property & Supply Unit FlowDocumento8 pagineProperty & Supply Unit FlowEmmanuel EndrigaNessuna valutazione finora

- Lift Escalator and Passenger Conveyor Regulations PDFDocumento8 pagineLift Escalator and Passenger Conveyor Regulations PDFANKUSHNessuna valutazione finora

- Is 15537 2004Documento14 pagineIs 15537 2004Muhammad ImranNessuna valutazione finora

- SAP QM Introduction DeckDocumento22 pagineSAP QM Introduction DeckVikash RanjanNessuna valutazione finora

- Quality ControlDocumento7 pagineQuality ControlBhumika BhattNessuna valutazione finora

- Usman CV Qaqc 1Documento2 pagineUsman CV Qaqc 1Digital InfoNessuna valutazione finora

- Carriage of GeneralBreak Bulk Cargo On Container Vessels WEBDocumento6 pagineCarriage of GeneralBreak Bulk Cargo On Container Vessels WEBEmmaNessuna valutazione finora

- Doku Trogschn EDocumento13 pagineDoku Trogschn ELLNessuna valutazione finora

- Anson Flowline EquipmentDocumento23 pagineAnson Flowline Equipmentralph100% (1)

- Nouveau Document Microsoft Office WordDocumento16 pagineNouveau Document Microsoft Office WordbounegabNessuna valutazione finora

- S 700v2020 05 Supplementary Specs To API671 Special Purpose CouplingsDocumento13 pagineS 700v2020 05 Supplementary Specs To API671 Special Purpose CouplingsOsas AsemotaNessuna valutazione finora

- LNG Terminals - Integrity Mo..Documento2 pagineLNG Terminals - Integrity Mo..Khaled HosnyNessuna valutazione finora

- Control Plan FmeaDocumento105 pagineControl Plan FmeaOSITORONessuna valutazione finora

- 2p42611 Iron Usage and Maintenance Guide 11 WebDocumento84 pagine2p42611 Iron Usage and Maintenance Guide 11 WebSamuel MagañaNessuna valutazione finora

- Mil DTL 53022eDocumento21 pagineMil DTL 53022etamil ksNessuna valutazione finora

- European Standard Norme Européenne Europäische NormDocumento19 pagineEuropean Standard Norme Européenne Europäische NormMariusNessuna valutazione finora

- CateDocumento54 pagineCateDeepakNessuna valutazione finora

- Winch Operation Lift PLan v0Documento14 pagineWinch Operation Lift PLan v0Raza Aidan100% (1)