Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WPS GTAW-SMAW h1

Caricato da

Jesus Gabrielw Blanco GhostbustersIzCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WPS GTAW-SMAW h1

Caricato da

Jesus Gabrielw Blanco GhostbustersIzCopyright:

Formati disponibili

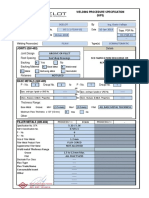

WELDING PROCEDURE SPECIFICATIONS (WPS) DATE:21-01-2009

Company Name: By:

Welding Procedure Specification No. 1-1-GTAW-SMAW-FMI Date 21/01/2009 Supporting PQR No.(s) 01

Revision No. 0

Welding Process(es) GTAW- SMAW Type(s) Manual

(Automatic,Manual,Machine, or Semi-Auto)

JOINTS (QW-402) Detalis

Joint Design Groove

Backing (Yes) Yes (No)

Backing Material (type) Weld metal for SMAW 37º + 2,5º

(Refer to both backing an retainers)

Metalico Nonfusing Metal

Nonmetalic Other

0280"

6 5/8" O.D

Sketches, Production Drawings, weld Symbols or Written Description

3/32 -1/8"

shouldshow the general arrangement of teh parts to bewelded. Where

applicale, the root spacing and teh details of weld groove may be specified. 1/8"

(At the option of the Mfgr., sketches may be attached to ilustrate joint

desing, weld layers and bead sequence, e.g., for notch toughness

procedure, for multiple process procedures, etc)

*BASE METAL (QW-403)

P No 1 Group No 1 to P-No 1 Group No. 1

OR

Specification type and grade SA-106 Gr B

to Specification type and grade SA-106 Gr B

OR

Cherm. Analysis and Mech. Prop, ------------------------

to Cherm. Analysis and Mech. Prop -----------------------

Thickness Range:

Base Metal: Groove 1/16" to 0.560" Fillet All

Other None

*FILLER METALS (QW-404) GTAW SMAW

Spec. No (SFA) 5.18 5.1

AWS No (CLASS) ER-70S-2 E-7018

F-No 6 4

A-No 1 1

Size of Filter Metals 3/32" 1/8", 3/32"

Weld Metal

Thickness Range:

Groove 0.186" Max. 0.374" Max.

Fillet All All

Electrod -Flux (class) None None

Flux trade Name None None

Consumable insert None None

Flux Not used None

Other With solid wire None

* Each base metal - filter metal combination should be recorded individualy.

Potrebbero piacerti anche

- 07.4 111 FW ML PF WPS 20mm ENGDocumento1 pagina07.4 111 FW ML PF WPS 20mm ENGViktorNessuna valutazione finora

- Poster DIN EN 1090-1 ENG Final PDFDocumento1 paginaPoster DIN EN 1090-1 ENG Final PDFlth770310Nessuna valutazione finora

- Equivalents of Carbon Steel QualitiesDocumento6 pagineEquivalents of Carbon Steel QualitiesMarcos Fuller AlbanoNessuna valutazione finora

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Documento12 paginePT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Spec Sheet - Handler 210Documento4 pagineSpec Sheet - Handler 210Hobart Welding ProductsNessuna valutazione finora

- WPS - 2Documento3 pagineWPS - 2aleventNessuna valutazione finora

- MarcoDocumento1 paginaMarcobimboNessuna valutazione finora

- Din 59410Documento8 pagineDin 59410Fitra BagusNessuna valutazione finora

- WPQR3Documento3 pagineWPQR3Dimitris NikouNessuna valutazione finora

- Test Pack Contents SQ No. Title DescriptionDocumento14 pagineTest Pack Contents SQ No. Title DescriptionThắng Trần QuangNessuna valutazione finora

- WPS 19Documento15 pagineWPS 19Avishek Gupta100% (1)

- Sample Wps Carbon Steel GTAW SMAW PDFDocumento2 pagineSample Wps Carbon Steel GTAW SMAW PDFirwanNessuna valutazione finora

- Wps Sp14 Reva PDFDocumento9 pagineWps Sp14 Reva PDFravi00098Nessuna valutazione finora

- 03 WPS CS 1Documento3 pagine03 WPS CS 1mohammadNessuna valutazione finora

- PQR For 32 MM PlateDocumento1 paginaPQR For 32 MM PlateMuhammed MubeenNessuna valutazione finora

- (First Revision) : Indian StandardDocumento8 pagine(First Revision) : Indian StandardBhanu Pratap ChoudhuryNessuna valutazione finora

- Pre Production ProcedureDocumento1 paginaPre Production ProcedureNguyen Quoc TriNessuna valutazione finora

- WPS PQR 12 PDFDocumento9 pagineWPS PQR 12 PDFVinay YadavNessuna valutazione finora

- Alishar SP 2Documento84 pagineAlishar SP 2Alam MD SazidNessuna valutazione finora

- WPS-PQR ListDocumento1 paginaWPS-PQR ListSandra SandersNessuna valutazione finora

- VIPER XTREM + Threaded Stud ZN 8.8 HDG 8.8 M16-28 09 2022Documento8 pagineVIPER XTREM + Threaded Stud ZN 8.8 HDG 8.8 M16-28 09 2022borceNessuna valutazione finora

- Wps For Aluminium WeldingDocumento8 pagineWps For Aluminium WeldingMohammed MusaNessuna valutazione finora

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocumento5 pagineQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Nessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw SawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNessuna valutazione finora

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocumento19 pagineJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNessuna valutazione finora

- Welding Procedure Specification According To EN ISO 15609, 2004Documento2 pagineWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNessuna valutazione finora

- Hardness Test Report: Test Details Machine DetailsDocumento1 paginaHardness Test Report: Test Details Machine DetailsESHWAR CHARYNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Documento2 pagineSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNessuna valutazione finora

- Supercito (E 42 5 B 32 h5)Documento1 paginaSupercito (E 42 5 B 32 h5)brunizzaNessuna valutazione finora

- Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeDocumento0 pagineDin 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeAdrian MarinNessuna valutazione finora

- OC-1-1-FCAW-1 Rev 0 PDFDocumento4 pagineOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocumento7 pagineCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248Nessuna valutazione finora

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Documento21 pagineTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocumento9 pagine2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNessuna valutazione finora

- Evaluation of 8090 and Weldalite-049 Aluminum-Lithium AlloysDocumento39 pagineEvaluation of 8090 and Weldalite-049 Aluminum-Lithium Alloysskylancer-3441Nessuna valutazione finora

- TopCoreBelco 101 FCDocumento9 pagineTopCoreBelco 101 FCCesar ArellanoNessuna valutazione finora

- PQR - PipeDocumento3 paginePQR - PipeAdvanced Quality Centre AQC100% (1)

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Documento2 paginePreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNessuna valutazione finora

- WPS BhelDocumento2 pagineWPS BhelpradhankruhsnaNessuna valutazione finora

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Documento1 paginaTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16Nessuna valutazione finora

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Documento1 paginaDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNessuna valutazione finora

- Welding Rod For c5 & f5 - Er 80s-b6Documento1 paginaWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNessuna valutazione finora

- Guidance To Prepare Wps PQR For WeldingDocumento1 paginaGuidance To Prepare Wps PQR For WeldingHamid MansouriNessuna valutazione finora

- ASTM A36 DatasheetDocumento4 pagineASTM A36 DatasheetRene D. ArrietaNessuna valutazione finora

- WPQ Ejcom Nr476Documento13 pagineWPQ Ejcom Nr476Touil HoussemNessuna valutazione finora

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocumento1 paginaPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNessuna valutazione finora

- Wps Mma PipeDocumento2 pagineWps Mma PipeDimitris NikouNessuna valutazione finora

- Mig Handbook (Despark)Documento19 pagineMig Handbook (Despark)Izad Bin IdrisNessuna valutazione finora

- WPS - 004Documento12 pagineWPS - 004MAT-LIONNessuna valutazione finora

- PDF Iso 3834 Checklist 1 CompressDocumento12 paginePDF Iso 3834 Checklist 1 CompressViệt VũNessuna valutazione finora

- Manual Bios Intel Dp35dpDocumento32 pagineManual Bios Intel Dp35dpMarcelo CheloNessuna valutazione finora

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDocumento13 pagineFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuNessuna valutazione finora

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocumento12 pagineDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNessuna valutazione finora

- Revised Wps For Gtaw - Xls Dated 25.01.2017Documento2 pagineRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathNessuna valutazione finora

- Ds Universal Wps Migmag enDocumento6 pagineDs Universal Wps Migmag enMarija IvanovskaNessuna valutazione finora

- PQR Format PDFDocumento2 paginePQR Format PDFHarshit Adwani100% (2)

- En 15085-2020-What Has ChangedDocumento2 pagineEn 15085-2020-What Has ChangedBoran YelkenciogluNessuna valutazione finora

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocumento2 pagineWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Eaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsDocumento379 pagineEaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsMAURIZIO MARININessuna valutazione finora

- Case StudyDocumento6 pagineCase Studyzaid bin shafiNessuna valutazione finora

- Chapter 2 Approaches To Software DesignDocumento25 pagineChapter 2 Approaches To Software DesigntarunkakkarNessuna valutazione finora

- Reflection and ShearDocumento7 pagineReflection and ShearsamNessuna valutazione finora

- Curved Path of Electron A B: ST Mary's College 1Documento5 pagineCurved Path of Electron A B: ST Mary's College 1elsie limNessuna valutazione finora

- Firetroll User Interface Manual Ns550f-01-Instruction-manualDocumento16 pagineFiretroll User Interface Manual Ns550f-01-Instruction-manualMike CerreroNessuna valutazione finora

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Documento4 pagineLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloNessuna valutazione finora

- FG200308-malfatti Circles PDFDocumento11 pagineFG200308-malfatti Circles PDFMario DalcínNessuna valutazione finora

- Practical 3 CGR PDFDocumento4 paginePractical 3 CGR PDFKalpesh PiloreNessuna valutazione finora

- Intro 4 - Substantive Concepts: Description Remarks and Examples References Also SeeDocumento19 pagineIntro 4 - Substantive Concepts: Description Remarks and Examples References Also SeeAntonella PetrilloNessuna valutazione finora

- 3M Fire Barrier, Fire Protection & Fire Stopping ProductsDocumento3 pagine3M Fire Barrier, Fire Protection & Fire Stopping ProductsOtto BorgesNessuna valutazione finora

- Chapter6b-Combinational Logic Design PracticesDocumento38 pagineChapter6b-Combinational Logic Design PracticesZulkarnineNessuna valutazione finora

- A Generic Circular BufferDocumento3 pagineA Generic Circular BufferSatish KumarNessuna valutazione finora

- TELEMETRY TEMPERATURE MONITOR (Project)Documento34 pagineTELEMETRY TEMPERATURE MONITOR (Project)Judpraise AkumsNessuna valutazione finora

- 19 - K.van Helden - Towards Iso 17089-1Documento58 pagine19 - K.van Helden - Towards Iso 17089-1Bar AvaitNessuna valutazione finora

- 3D-ICONS Guidelines PDFDocumento53 pagine3D-ICONS Guidelines PDFAna Paula Ribeiro de AraujoNessuna valutazione finora

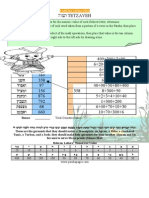

- Tetzaveh Parsha GematriaDocumento1 paginaTetzaveh Parsha GematriaRabbi Benyomin HoffmanNessuna valutazione finora

- Data Structure and AlgorithmDocumento12 pagineData Structure and Algorithmleah pileoNessuna valutazione finora

- 1 Priority KeywordDocumento8 pagine1 Priority KeywordKavithaNessuna valutazione finora

- BS DanielDocumento6 pagineBS Danielsandy30694Nessuna valutazione finora

- August 19-23 Lesson PlanDocumento1 paginaAugust 19-23 Lesson Planapi-282162606Nessuna valutazione finora

- BQ 76 PL 102Documento23 pagineBQ 76 PL 102AlexNessuna valutazione finora

- Potassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForDocumento4 paginePotassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForhydrogenperoksideNessuna valutazione finora

- LISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesDocumento10 pagineLISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesJavier DavidNessuna valutazione finora

- Chapter # 1 ChemDocumento3 pagineChapter # 1 ChemRana Hassan TariqNessuna valutazione finora

- Ball BearingsDocumento31 pagineBall Bearingsnike_y2kNessuna valutazione finora

- Shape and Volume: A Presentation On AcousticsDocumento35 pagineShape and Volume: A Presentation On AcousticsSiddharth BhandariNessuna valutazione finora

- CS405PC JP Unit-3Documento44 pagineCS405PC JP Unit-3MEGHANA 3Nessuna valutazione finora

- Upstream Process Engineering Course: 5. Produced WaterDocumento27 pagineUpstream Process Engineering Course: 5. Produced WaterMohamed SelimNessuna valutazione finora

- State-Of-The-Art of Battery State-Of-Charge DeterminationDocumento19 pagineState-Of-The-Art of Battery State-Of-Charge Determinationyasvanthkumar sNessuna valutazione finora