Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Position: Truck Driver: Job Hazard Analysis

Caricato da

marvinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Position: Truck Driver: Job Hazard Analysis

Caricato da

marvinCopyright:

Formati disponibili

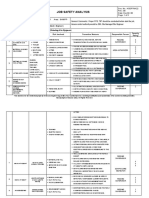

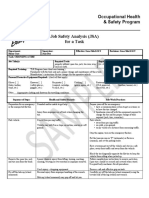

Job Hazard Analysis

Position: Truck Driver NOTE: If you do not have Safe Work Procedures that identify

Company: potential hazards, ensure you identify and address all potential

Analysis by: hazards and preventive measures. (A list of Sample Safe Work

Location: Procedures is available by contacting NSTSA www.nstsa.ca)

Date:

Job Task/Steps Potential Accidents or Hazards Preventive Measures

Training and adherence to "Hours of Service" and conducting pre-trip

Traffic accidents on roadways; adverse weather conditions; inspections. Completing necessary paperwork (log books) and sending

head on collisions; overturning vehicle trapping driver inside it to the company for evaluation. Auditing of "Driver Files" to ensure all

cabin or under truck; pedestrian traffic and other traffic on paperwork is current. Successful completion of a Driver Evaluation

roads causing secondary accidents. Improper rest and Program prior to employment. Knowledge and conforming to the

dietary habits contributing to driving habits, driving long hours Commercial Vehicle regulation. Wearing PPE such as gloves, CSA

Driving trucks w gross vehicle weight of 4500 KG or more

without breaks, hypnotic effects during periods of drowsiness approved footwear, safety glasses , reflective vests, hard hat, hearing

caused by fatigue. Inhalation of gasoline or diesel fumes and protection and respiratory protection when required and wear seatbelt

other exhaust fumes producing carbon monoxide, at all times. Ensure proper rest, compliance with "hours of service",

hydrocarbons and other toxic substances. Exposure to smoking cessation programs and wellness programs. WHMIS trained,

prolonged noise of higher amplitude than 85 decibels. proper preventive maintenance system (pre and post inspections).

Ensure 3 points of contact when entering and exiting vehicle.

Injuries to head, back, arms, hands, feet & shoulders due to Wear proper footwear and clothing. Use 3 Points of Contact when

Entering / Exiting the Vehicle

slips / trips or falls. entering or exiting the vehicle. Keep vehicle steps clean.

Traffic, slips, trips and falls causing injury; dust particles,

Training in proper inspection procedures. Wearing PPE including

Pre Trip or Post Trip Vehicle Inspections adverse weather conditions such as extreme heat or cold

proper footwear and clothing for weather conditions.

causing hypothermia or hyperthermia, frostbite or fatigue.

Improper placement of freight in trailer or warehouse.

Stack freight properly in trailer or warehouse to ensure safe access.

Overloading of jack and rupture of hydraulic hose. Damage to

Wear PPE such as safety glasses, gloves, reflective vest, CSA

freight or toppling potentially causing personal injury. Possible

approved safety boots. Have training in the use of hydraulic jacks;

injury to back, arms, legs, feet from pushing / pulling. Slips,

Loading and Unloading of trailers injury prevention with manual lifting techniques ensuring you do not

trips and falls from slippery surfaces and from not maintaining

exceed your personal lifting capability. The NSTSA has a "Proper

3 points of contact when entering and exiting vehicle. Muscle

Lifting Techniques Program", consult the NSTSA to find out more about

strain or over exertion as a result of manual lifting. Hydraulic

this program.

jacks may slip causing crushing injuries.

Improper technique causing injury to various body parts. Use PPE such as gloves & proper footwear. Be aware of weather &

Opening & Closing Trailer Doors Possible crushing injuries from unsecured load against the road conditions. (Refer to NSTSA's safe work procedure for Opening

doors. Trailer).

Refer to MSDS for Safe handling procedures for chemicals. Use PPE

Injuries to back, hands, feet and face. Other moving traffic

such as chemical resistant gloves and clothing, CSA approved

hazards with the potential to cause bodily harm or death.

Emergency Roadside Repairs footwear, glasses / goggles, high visibility vests, cones and use fire

Exposure to hazardous materials. Exposure to fire and flying

shields / extinguishers when required. (see NSTSA's Safe Work

debris.

Procedures for "Changing Tires" and procedure for "Wheels")

NSTSA Safety Manual and Resource Guide Page 1 of 2

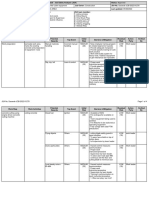

Job Hazard Analysis

Position: Truck Driver NOTE: If you do not have Safe Work Procedures that identify

Company: potential hazards, ensure you identify and address all potential

Analysis by: hazards and preventive measures. (A list of Sample Safe Work

Location: Procedures is available by contacting NSTSA www.nstsa.ca)

Date:

Job Task/Steps Potential Accidents or Hazards Preventive Measures

Maintain 3 points of contact when entering and exiting vehicle; use PPE

Slips, trips, eye injuries, pinched fingers, back injuries, injuries such as gloves, CSA approved footwear, safety glasses, high visibility

Coupling & Uncoupling Tractors / Trailers & Raising and

caused by improper coupling and crushing injuries causing vests, hard hat. Ensure the brakes are engaged until the process is

lowering of landing gear

death. complete. Use proper procedures for raising and lowering of landing

gear.

Exposure to hazardous substances causing burns, inhalation Training in TDG every 3 years. Proper placarding for the trailer.

Transporting Dangerous Goods injury, decrease level of consciousness, death, toxic exposure Ensuring all paperwork is complete. Extra caution when

injuries and explosions. loading/unloading will reduce likelihood of exposure to chemicals.

Possible hypothermia and hyperthermia, dehydration, fatigue, Appropriate clothing shoul,d be worn for cold and hot temperatures.

Working in extreme temperatures - Hot / Cold

loss of judgment and sunburn. Ensure rest breaks (i.e every 4 hours).

Use First Aid Kit in the truck for medical problems. Ensure regular

contact with dispatcher on a regular basis by using phone or satellite.

Not receiving medical attention if required; physical violence

Working Alone Training on health and safety and "working alone" safe work

from intruder/customer or strangers.

procedures and company policy. (Refer to NSTSA's safe work

procedure for "Working Alone".)

Use PPE such as safety glasses, CSA approved footwear & containers,

Fire, explosion, spillage of toxic substances, slips and falls,

Refueling - Portable Containers gloves, fire extinguisher & reflective vest. Have the MSDS sheet

inhalation of toxic substances

available. Ensure there is adequate ventilation.

Valid fall restraint and PPE. CSA approved footwear, hard hat, maintain

3 point contact. If there is no fall protection, develop a "safe work

Snow & Ice Removal Slips, trips, falls and falls from height and physical exertion.

procedure" with the Occupational Health and Safety Committee and

ensure training is provided for this procedure.

Shifting of the load, slips, trips, falling from height and Position tarp with boom truck, follow load securement legislation

Tarping and Strapping

physical exertion. (www.fmcsa.dot.gov.) and follow proper procedures.

Approved By;____________________________________________ Date: ______________________ NOTE: This JSA is reviewed yearly

NSTSA Safety Manual and Resource Guide Page 2 of 2

Potrebbero piacerti anche

- Skid Steer (Generic) : Job Safety AnalysisDocumento2 pagineSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNessuna valutazione finora

- Robert Sylvester Kelly (Born January 8, 1967) Is An American Singer, Songwriter, Musician, RecordDocumento3 pagineRobert Sylvester Kelly (Born January 8, 1967) Is An American Singer, Songwriter, Musician, Recordmarvin100% (1)

- Jsa ExcavatorDocumento1 paginaJsa Excavatorbladeliger220% (1)

- TiremanDocumento6 pagineTiremanKent Charles Monreal NotarioNessuna valutazione finora

- Jsa Grinding Welding Gas CuttingDocumento3 pagineJsa Grinding Welding Gas CuttingRyanNessuna valutazione finora

- JSA-Hydraulic Press Testing For PilesDocumento6 pagineJSA-Hydraulic Press Testing For PilesUMUTNessuna valutazione finora

- DOT New Entrant Safety Audit GuidebookDocumento32 pagineDOT New Entrant Safety Audit GuidebookUnity Brothers100% (1)

- Safe Systems of WorkDocumento19 pagineSafe Systems of Workmarvin100% (1)

- 0006 - 004 Near Miss Reporting Form PDFDocumento1 pagina0006 - 004 Near Miss Reporting Form PDFArshad MahmoodNessuna valutazione finora

- JSA-for Lifting Activity by Crane. (11-01-2016)Documento3 pagineJSA-for Lifting Activity by Crane. (11-01-2016)Mohammed Minhaj100% (2)

- Truck Driver SOPDocumento3 pagineTruck Driver SOPAldi Rinaldi Rahmat60% (5)

- JSA-017 Lifting With ForkliftDocumento3 pagineJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 021 Crane Operator ChecklistDocumento1 pagina021 Crane Operator ChecklistJunard Lu HapNessuna valutazione finora

- Crane Inspection ChecklistDocumento1 paginaCrane Inspection Checklistrig4Nessuna valutazione finora

- JSA of Drill Machine UseDocumento1 paginaJSA of Drill Machine UseSumair Khalid100% (1)

- JSA-020-Safety Watch-Hot WorkDocumento2 pagineJSA-020-Safety Watch-Hot WorkNishad MuhammedNessuna valutazione finora

- Jsa Working at Height (Maintenance & Cleaning)Documento2 pagineJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Bar Cutting MachineDocumento1 paginaBar Cutting Machinesaurav roy100% (1)

- Risk Assessment (Snake Bites, Scorpion Sting, Reptiles Bites)Documento3 pagineRisk Assessment (Snake Bites, Scorpion Sting, Reptiles Bites)Raza Muhammad SoomroNessuna valutazione finora

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Documento7 pagineHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Documento3 pagineSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNessuna valutazione finora

- Concrete Cutting JsaDocumento4 pagineConcrete Cutting JsaMohammad Irfan Kiki IsmailNessuna valutazione finora

- Risk Assessment - Lifting OperationsDocumento3 pagineRisk Assessment - Lifting Operationsdnmule100% (2)

- Jsa For Fuel Pump Operation - Spill Clean-UpDocumento1 paginaJsa For Fuel Pump Operation - Spill Clean-Upwahyu nugrohoNessuna valutazione finora

- Lifting Hoisting Hazard HuntDocumento1 paginaLifting Hoisting Hazard Hunt曹庆园100% (1)

- 011 - JSA (Tower Crane)Documento9 pagine011 - JSA (Tower Crane)satti80% (5)

- Critical Lift Plan - ChecklistDocumento4 pagineCritical Lift Plan - ChecklistDelia HarsanNessuna valutazione finora

- Form 092 Excavator Safety Checklist 1Documento2 pagineForm 092 Excavator Safety Checklist 1TANWIR AHEMADNessuna valutazione finora

- JSA FOR Vehicle OperationDocumento3 pagineJSA FOR Vehicle Operationanko heroNessuna valutazione finora

- 19-F13 Vehicle Mounted Crane Inspection ChecklistDocumento2 pagine19-F13 Vehicle Mounted Crane Inspection ChecklistSn Ahsan100% (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Documento16 pagineJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Jsa For Lifting Crane 016Documento6 pagineJsa For Lifting Crane 016kiran kumar100% (1)

- Federal Motor Carrier Safety Regulations PDFDocumento2 pagineFederal Motor Carrier Safety Regulations PDFLarenzo0% (3)

- JSA Sample 1 Changing A TireDocumento3 pagineJSA Sample 1 Changing A Tiree smith100% (1)

- Overhead Crane CLPDocumento5 pagineOverhead Crane CLPmarvin100% (1)

- Target Construction Sa WLL: FlagmanDocumento11 pagineTarget Construction Sa WLL: FlagmanSanthoshNessuna valutazione finora

- Commerical Vechicle Operators Safety ManualDocumento297 pagineCommerical Vechicle Operators Safety ManualIslam ActrosNessuna valutazione finora

- JSA For Bobcat OperationDocumento2 pagineJSA For Bobcat Operationwahyu nugrohoNessuna valutazione finora

- Critical Lift Plan For Overhead Cranes: (Net Load)Documento6 pagineCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNessuna valutazione finora

- 168977Documento2 pagine168977meda590Nessuna valutazione finora

- 14.lifting Operations & Lifting EquipmentDocumento28 pagine14.lifting Operations & Lifting EquipmentbabadapbadapNessuna valutazione finora

- 7.electrical LOTO Check List InspectionDocumento1 pagina7.electrical LOTO Check List Inspectionfitri widyaNessuna valutazione finora

- JSA For Scissor Lift, Rev-6Documento2 pagineJSA For Scissor Lift, Rev-6Mahamudul HasanNessuna valutazione finora

- JSA FORMAT For Materials LoadingDocumento2 pagineJSA FORMAT For Materials LoadingVikky KumarNessuna valutazione finora

- Truck BookDocumento48 pagineTruck BookJane SmihtNessuna valutazione finora

- 112 D HSE Bulletin Safe Working at HeightDocumento1 pagina112 D HSE Bulletin Safe Working at HeightOws AnishNessuna valutazione finora

- Driving On SiteDocumento15 pagineDriving On SitejhoniNessuna valutazione finora

- Hse Sop-07 Monitoring and ControlDocumento6 pagineHse Sop-07 Monitoring and ControlmarvinNessuna valutazione finora

- 7.L015-OHSE Height Work Permit FormatDocumento2 pagine7.L015-OHSE Height Work Permit Formathafis100% (2)

- Hydro Jetting and Sludge RemovalDocumento18 pagineHydro Jetting and Sludge Removalmarvin100% (1)

- Loading Driving DumptruckDocumento1 paginaLoading Driving Dumptruckderi purnamaNessuna valutazione finora

- Subject: Work at Height: Unit: Maihar Cement WorksDocumento3 pagineSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Ryder Driver Safety Manual PDFDocumento47 pagineRyder Driver Safety Manual PDFki LastimosaNessuna valutazione finora

- Risk Assessment - Loading of CBS Hopper Using Pay-LoaderDocumento2 pagineRisk Assessment - Loading of CBS Hopper Using Pay-LoaderAbasiemekaNessuna valutazione finora

- JSA Loading UnloadingDocumento2 pagineJSA Loading Unloadingadnan amal yusfar100% (1)

- Crane Assembly and Dismantling and ModificationDocumento1 paginaCrane Assembly and Dismantling and Modificationsrinibas mohapatraNessuna valutazione finora

- SWP Coshh v5.02 Dec 2015Documento8 pagineSWP Coshh v5.02 Dec 2015marvinNessuna valutazione finora

- Service Truck Driver SOPDocumento3 pagineService Truck Driver SOPVenkadesh PeriathambiNessuna valutazione finora

- Review of Related LiteratureDocumento22 pagineReview of Related Literatureelizabeth monasterio100% (1)

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Documento2 pagineRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Jsa forOperatingAForkliftDocumento2 pagineJsa forOperatingAForkliftsupahing supahingNessuna valutazione finora

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 pagineKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNessuna valutazione finora

- Anchor Bolt Setting - Rev 01Documento26 pagineAnchor Bolt Setting - Rev 01Geherson AbustanNessuna valutazione finora

- Sogetrap JSA Lifting Cabin by ForkliftDocumento2 pagineSogetrap JSA Lifting Cabin by ForkliftTSP HSENessuna valutazione finora

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocumento1 paginaHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- JSA - Installation of U G PipingDocumento11 pagineJSA - Installation of U G PipingOws Anish100% (1)

- 02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPDocumento8 pagine02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPB&R HSE BALCO SEP SiteNessuna valutazione finora

- Driver and Vehicle SafetyDocumento7 pagineDriver and Vehicle SafetyyahiyaNessuna valutazione finora

- Jsa-001 Manual Handling & Heavy LiftingDocumento2 pagineJsa-001 Manual Handling & Heavy LiftingDamien MonizeNessuna valutazione finora

- 04 Jsa For Camp Constn & Associated FacilitysDocumento5 pagine04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- 10 - Cherry Picker Inspection ChecklistDocumento1 pagina10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Position: Mechanic / Technician / Shop Personnel: Job Hazazrd AnalysisDocumento3 paginePosition: Mechanic / Technician / Shop Personnel: Job Hazazrd AnalysisKimmy LyonsNessuna valutazione finora

- Vimar FG15-FG35, FD15-FD35 Operator ManualDocumento152 pagineVimar FG15-FG35, FD15-FD35 Operator ManualHolly DrinovzNessuna valutazione finora

- Early 1960s: Drag Racing Influences: Ford ThunderboltDocumento3 pagineEarly 1960s: Drag Racing Influences: Ford ThunderboltmarvinNessuna valutazione finora

- Australia: Holden HG MonaroDocumento2 pagineAustralia: Holden HG MonaromarvinNessuna valutazione finora

- HistoryDocumento2 pagineHistorymarvinNessuna valutazione finora

- Influence: MarriageDocumento11 pagineInfluence: MarriagemarvinNessuna valutazione finora

- Muscle CarDocumento3 pagineMuscle CarmarvinNessuna valutazione finora

- Greates Hits of R KellyDocumento3 pagineGreates Hits of R KellymarvinNessuna valutazione finora

- JSA Concrete Lifting FoundationDocumento3 pagineJSA Concrete Lifting Foundationmarvin100% (1)

- Career of R KellyDocumento4 pagineCareer of R KellymarvinNessuna valutazione finora

- Industry and InfleunceDocumento5 pagineIndustry and InfleuncemarvinNessuna valutazione finora

- Priority Areas For NIDADocumento40 paginePriority Areas For NIDAmarvinNessuna valutazione finora

- SWP Working Safely at Height Version 2.01Documento7 pagineSWP Working Safely at Height Version 2.01marvinNessuna valutazione finora

- 03 Washing Floors With An Auto-scrubber-JOB PROCEDUREDocumento2 pagine03 Washing Floors With An Auto-scrubber-JOB PROCEDUREmarvinNessuna valutazione finora

- HOS Dials in The Driver App - Samsara SupportDocumento3 pagineHOS Dials in The Driver App - Samsara SupportMaryNessuna valutazione finora

- Monday WWETT Show Daily ProgramDocumento111 pagineMonday WWETT Show Daily ProgramWWETT ShowNessuna valutazione finora

- DPDHL 2017 Annual ReportDocumento172 pagineDPDHL 2017 Annual ReportrajabNessuna valutazione finora

- Omnitracs HOS Driver OverviewDocumento35 pagineOmnitracs HOS Driver OverviewBradNessuna valutazione finora

- Reservation Confirmation: Trip TypeDocumento2 pagineReservation Confirmation: Trip Typecelfo72Nessuna valutazione finora

- Sms Appendixa Violationslist 2Documento52 pagineSms Appendixa Violationslist 2Doricius ScottNessuna valutazione finora

- American Trucking Assns., Inc. v. United States, 344 U.S. 298 (1953)Documento25 pagineAmerican Trucking Assns., Inc. v. United States, 344 U.S. 298 (1953)Scribd Government DocsNessuna valutazione finora

- 6.1 TOI OTM Fleet Management Functional Overview - Session 4Documento70 pagine6.1 TOI OTM Fleet Management Functional Overview - Session 4anishokm2992Nessuna valutazione finora

- Garmin Elog™: Owner's ManualDocumento14 pagineGarmin Elog™: Owner's ManualasinghanandNessuna valutazione finora

- Oil Well Service Vehicle Cycle Exemption Permit ApplicationDocumento16 pagineOil Well Service Vehicle Cycle Exemption Permit Applicationmemet119Nessuna valutazione finora

- Puco Motor Carrier Safety Rules HandbookDocumento71 paginePuco Motor Carrier Safety Rules HandbookRandy AultNessuna valutazione finora

- Omnitracs IVG Driver OverviewDocumento56 pagineOmnitracs IVG Driver OverviewBradNessuna valutazione finora

- Robert Heath Drivers HandbookDocumento56 pagineRobert Heath Drivers HandbookBrandon AvenNessuna valutazione finora

- Truck DriverDocumento3 pagineTruck Driverapi-78455311Nessuna valutazione finora

- Supply Chain Challenges - Textile World PDFDocumento11 pagineSupply Chain Challenges - Textile World PDFOneLove EthiopiaNessuna valutazione finora

- Amtrak ComplaintDocumento112 pagineAmtrak ComplaintKevin AccettullaNessuna valutazione finora

- Blue Tree ELD User GuideDocumento56 pagineBlue Tree ELD User GuideMiguel MartinNessuna valutazione finora

- Department of Labor: MADDEN JAMES V MIDWEST TRANSPORT 2006STA00042 (SEP 27 2007) 144204 CADEC SDDocumento11 pagineDepartment of Labor: MADDEN JAMES V MIDWEST TRANSPORT 2006STA00042 (SEP 27 2007) 144204 CADEC SDUSA_DepartmentOfLaborNessuna valutazione finora

- Sample Truck ProgramDocumento78 pagineSample Truck ProgramPriSna SiGokill AjadhaNessuna valutazione finora

- 6.1 TOI OTM Fleet Management Functional Overview - Session 1Documento60 pagine6.1 TOI OTM Fleet Management Functional Overview - Session 1anishokm2992100% (1)

- FMCSA HOS For DummiesDocumento8 pagineFMCSA HOS For DummiesPeter LapsanskyNessuna valutazione finora

- Motor Carrier: Oregon Department of Transportation Motor Carrier Transportation DivisionDocumento19 pagineMotor Carrier: Oregon Department of Transportation Motor Carrier Transportation Divisionpatmos666Nessuna valutazione finora

- ELD Technical FAQsDocumento19 pagineELD Technical FAQsbrs165Nessuna valutazione finora