Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

369 PDF

Caricato da

Grd doTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

369 PDF

Caricato da

Grd doCopyright:

Formati disponibili

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

Dynamic Programming Approach to Unit Commitment

Problem for Kuwait Power Generations

Nadine Awadah, Rawan AlShikh Ali, Shaikha AlBaijan, Ghalia Al-Qallaf, Muneerah Al-

Hassawi, and Suat Kasap

Industrial Engineering Department

College of Engineering and Technology

American University of the Middle East - AUM

Egaila, Kuwait

Suat.kasap@aum.edu.kw

Abstract

Optimization techniques are becoming essential in the field of power systems. In this paper, two Dynamic

Programming (DP) optimization methods were used to solve a large-scale problem which is known as the

unit commitment problem (UCP). A sample of ten generating units that forms one power station in

Kuwait was chosen to be tested. This paper aims to have a schedule with the least possible electricity

production cost while meeting the hourly demand in addition to other system constraints and this is what

is known as UCP. A MATLAB code was used to generate solutions for the ten-unit system. The results

showed that the conventional DP method reduced the cost by 36.1% while priority DP method reduced

the cost by 35%. Since the future NEWKUWAIT vision is introducing renewable energy resources to the

power system, solving the UCP will be the first step towards reaching the vision.

Keywords

Unit Commitment Problem, Optimization Methods, Dynamic programming, Priority Dynamic

Programming, Conventional Dynamic Programming, Unit Generation Optimization

1. Introduction

The electricity consumption worldwide is increasing with the continuous increase of the population. This huge

consumption creates threats on the power systems. Speaking locally, Kuwait’s electrical systems are under risk in

terms of electricity shortages and blackouts (Ansari, 2013). A new investment of buying more generators to supply

the current demand would be expensive. Consequently, we need to search what problems the current grid is facing

and how these problems can be solved. When studying an electrical grid, the first component is the generator. The

most studied problem related to generators is the unit commitment problem (UCP) (Hobbs, Rothkopf, O'eill, &

Chao, 2002). Therefore, the problem addressed in this paper is the UCP which is the scheduling of generators to

produce enough electricity to meet the increasing power demands with the least possible production operating cost.

The current system will be modeled and solved by knowing the inputs and the costs of the generation, and by adding

the amount of consumption over time to balance the input and output. There are many techniques that can be used to

solve the UCP. One of the disadvantages of the methods of solution is that the optimum solution is not guaranteed

100 percent; however, the optimality percentage varies from one method to the other (Tung, Bhadoria, Kaur,

Bhadauria & Pg, 2012). Dynamic programming (DP) approach was considered in this paper. The advantage behind

using DP is the easy implementation of the problem. DP includes various features that deal with controlling the size

of the problem effectively (Alshareef & Saber, 2012). It was proven to be a successful technique in solving a

medium size power plant. Solving unit commitment problem is an important issue which is targeted by most

electrical companies and ministries. Solving such problem will help in reducing the total operating cost, as well as

the emissions that are given off by fuel combustion (Taha, 2010). The main objectives of this paper are to formulate

and optimize the problem, create a 24 hour schedule for ten generators that are located in Sabiya- Kuwait power

system, and finally specifying when to turn them on/off to reduce the generating cost while meeting the daily

demand and the operational constraints. Reaching the objectives will show the impact of this paper towards

engineering solution economically in Kuwait as well as meet future environmental needs.

© IEOM Society International 1939

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

2. Background of the Problem

The unit commitment schedule can be daily, weekly or monthly prepared to optimize the amount of electricity

generated with least cost possible (Sivanagaraju & Sreenivasan, 2010). Therefore, the problem is to generate daily

electricity schedules and introduce them to Kuwait for the first time that will help in reaching the future

NEWKUWAIT vision.

The directly related facility to the paper is the ministry of the electricity and water (MEW) and specifically the

National Control Center (NCC) as it manages electricity and water production to fulfill Kuwait’s daily demand. It

was found that the generating units in all power stations are committed to be online 24/7 as it is easier to keep up

with the hourly changing electricity demand. Consequently, extremely high costs are spent on excess electricity that

is higher than the required demand in some hours throughout the day.

Throughout the years the electricity consumption in Kuwait has been increasing tremendously. Figure 1 illustrates

the development of power stations installed capacity from 1965 up until 2015. It proves that the consumption is

increasing enormously which led the country to add more generating units to satisfy the needs.

Figure 1: Development of power station installed capacity through 1965 to 2015

Figure 2 supports the information by showing the clear increase in the maximum consumption of electricity during

1996-2016 with the average increase of 4.8% per year. To keep up with this rapid increase, the government is

increasing the number of units and their capacities each year which is very costly (Statistics Dept. & Information

Center, 2015). When comparing figure 1 and 2, it is easily noticed that the total capacity installed by the ministry of

electricity exceeds the demand needed. From here arises the importance of optimizing the generators’ behavior to

decrease the extra production and therefore the total cost. Kuwait’s electrical grid consists of 8 power stations

distributed throughout the country. The power stations are composed of different units, stream turbines, gas turbines

and combined cycles with a total number of 90 units. The 8 power stations are in Shuwaikh, Shuaiba North, Shuaiba

South, Doha East, Doha West, Al-Zour South, Al-Zour North, and Sabiya. To keep up with the increasing demand,

the ministry kept increasing the capacity and the number of stations each year. The new introduced Unit

Commitment schedule will limit the increase in generating units and reduce operation costs as well.

Figure 2: Maximum electricity consumption during (1996-2016)

© IEOM Society International 1940

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

3. Dynamic Programming Approach

Dynamic programming (DP), also known as dynamic optimization, is a method used to solve complex problems by

breaking it into steps (stages). The searching process could be either in a forward direction or backward direction,

meaning that the search for a solution can start at the very beginning of the system or at the very end of the system

(Sen & Kothari, 1998). A study by Thakur and Titare, (2016) shows the mechanism of dynamic approach step by

step. The first step is to consider two units randomly. Then, the output of the two units should be found as discrete

load levels and the best combination for all levels of those units. After that, construct a cost curve for the two units

and add an additional unit. Finally, calculate the cost curve for the three. This process of adding units will keep

repeating until all units are taken into consideration.

3.1 Conventional Dynamic Programming

The conventional dynamic programming obtains the optimum (close to the best) solution but it requires huge

memory and consumes a lot of time to get the desired solution (Moores, 1988). The total number of paths tested

depends on the number of processed units and the time horizon. Since a sample of 10 units will be processes for 24

hours, paths can be calculated according to Singhal and Sharma (2011) as follows where i represents number of

generating units and t is the hours needed to create the schedule:

combinations computed: (2𝑖 − 1) t = (210 − 1) 24 = 1.72589 1072 combinations

Since the number of paths or combinations is high, another alternative method was considered to find schedules in

much less time, which is the Priority Dynamic Programming.

3.2 Priority Dynamic Programming

This method is also called sequential dynamic programming since it works step by step to the final solution. This

technique starts with the first unit and compares it to the next one in a strict method, and then it prioritizes the best

one and continues until reaching the best schedule hourly (Singhal & Sharma, 2011). The main advantage behind

using priority dynamic programing is that it reduces the dimensionality of the problem (number of paths used), as

well it produces a schedule for the units at given certain time (Snyder, Powell, & Rayburn, 1987).The expected

number of paths for the same previous sample size is “ i ” combinations hourly. As a result, only 240 combinations

are tested for 10 units. Finally, this method is tested as a second scenario and the least-cost method is chosen. By

that, it is guaranteed that the design is good.

4. Formulation of the Problem

Since our problem is optimization, the variables along with the objective function and constraints must be decided at

the beginning in order to make sure that the problem is ready to be optimized (Salam, 2007). The objective function

is minimizing the operating costs by reducing fuel costs, units starting up costs as well as shutting down costs

(Wood & Wollenberg, 1996). The objective function can be represented in equation (1): where TPC is the total

production cost, FC is the fuel cost, SUC is the startup cost and SDC is the total shut down cost

𝑖 𝑃 =𝐹 + + (1)

- The Fuel cost (FC): Fuel consumption increases in a quadratic (non-linear) form depending on the amount

of power produced. 𝐹 𝑖 is the fuel cost of unit i, Pit is the amount of power (MW) generated form unit i at time t and

the coefficients a, b and c are cost coefficients for generator I in equation (2).

𝐹 𝑖 (𝑃𝑖 ) = 𝑖 + 𝑖𝑃𝑖 + 𝑖(𝑃𝑖 )2 (2)

- Start-up cost (SUC): is the cost of turning on the offline units (Dhifaoui, Guesmi, & Abdallah, 2014). The

units must be online for a minimum time before it can be turned off (minimum up time). How to calculate it is seen

in equation (3).

= 𝑖 × ℎ 𝑖 ( / )

𝑖 × 𝑖

𝑖 (3)

- Shutdown cost (SDC): is the cost of turning off the online units. The minimum time required for the unit

to stay online before it is switched off (minimum up time) should be considered as well.

𝑺 𝑖 𝑖 × 𝑖 (4)

Two different types of variables are considered in the unit commitment problem: binary and continuous. The binary

variable is the status of the unit and it can either be 0 (off) or 1 (on). The continuous variable is the amount of power

produced at a certain time (Yang, 2007. Both variables can be expressed as follows:

- 𝑖: ℎ 𝑖 𝑖 𝑖 .

- 𝑃𝑖 : ℎ 𝑖 𝑊 𝑖 𝑖 𝑖 .

© IEOM Society International 1941

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

To solve the unit commitment problem, many constraints should be considered such as:

Load/Generation Balance: It is the total demand of electricity (D) when equal to the total generators’ electricity

production. Equation (5) satisfies the generation balance constraint.

(5)

- Spinning Reserve: is defined as the extra capacity of all units in power generators that can be generated to

meet the demand and keep frequency from dropping in case of emergencies as shown in equation (6).

( 𝑃𝑖 (6)

- Ramp rate: Ramp rate is the increase or decrease in the output over time (electricity generated). It

provides the power system with flexibility by ramping up and down the output, given the needed demand. (Datta,

2013)

- Minimum up time and Minimum down time: means that whenever a unit is online, it cannot be turned

off and whenever a unit is offline it cannot be started immediately until a certain time has passed.

If the minimum up time constraint is violated, the unit stays online for the next time-period shown in equation (7).

𝑖 =1(𝑖 𝑖 ) 𝑖, < , 𝑖

ℎ 𝑖, +1 = 1 ( 𝑖 ) (7)

If the minimum down time constraint is violated, the unit stays offline for next time-period as shown in equation (8).

𝑖 𝑖 =0( 𝑖 ) 𝑖, < , 𝑖

ℎ , 𝑖, +1 = 1 ( 𝑖 ) (8)

5. Results and Discussion

The results of the conventional dynamic programing are illustrated and tested using a prewritten MATLAB code. To

solve the problem and form an hourly schedule, the first step was to collect the data required for the ten generators.

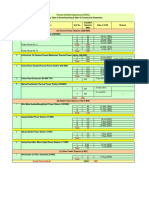

Table 1 shows the data collected related to the ten generating units which include the maximum/minimum

production limits in megawatts, the cold/hot startup status with their corresponding costs in Kuwaiti Dinar, and the

online/offline states in hours. Each generator has its own cost coefficients which are a, b, and c.

Table 1: Data for 10-unit system

Parameter Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Unit 6 Unit 7 Unit 8 Unit 9 Unit 10

1 Pmin (MW) 100 130 130 30 30 10 10 80 100 100

2 Pmax (MW) 220 300 300 62 62 41 41 215 250 250

3 Cold start cost ($) 100 8000 8000 100 100 100 100 6500 100 100

4 Min up (hr) 1 5 5 1 1 1 1 4 1 1

5 Min down (hr) 1 6 6 1 1 1 1 5 1 1

6 Initial Status (hr) -1 7 7 -1 -1 -1 -1 -3 -1 -1

7 Hot start cost ($) 50 4000 4000 50 50 50 50 3000 50 50

8 Cold start Hours (hr) 0 5 5 0 0 0 0 3 0 0

9 a (kd/hr) 3242.255 1877.95 1877.95 3299.22 3299.22 3299.22 3299.22 3305.165 3299.22 3299.22

10 b (kd/MW) 48.087 36.043 36.043 51.269 51.269 51.269 51.269 27.675 51.269 51.269

11 c (kd/MW^2) 0.03326 0.02592 0.02592 0.27143 0.27143 0.27143 0.27143 0.10974 0.27143 0.27143

To satisfy the demand, table 2 illustrates the demands in megawatts with their corresponding hours. The hourly

demand was in July 15, 2015 as it is the peak month in consuming electricity in Kuwait (Statistics Dept. &

Information Center, 2015). As mentioned before, the demand is satisfied by Sabiya power station but the problem

occurs in the excess electricity wasted and extra money spent, therefore, optimization is required.

Table 2: hourly demand relative to 10-units

Hour 1 2 3 4 5 6 7 8 9 10 11 12

Demand 1221 1212 1199 1191 1187 1170 1201 1250 1276 1320 1370 1430

Hour 13 14 15 16 17 18 19 20 21 22 23 24

Demand 1567 1591 1574 1546 1496 1468 1432 1389 1343 1307 1291 1258

© IEOM Society International 1942

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

Figure 3: Hourly demand

As noticed from Figure 3, the demand is varying during the day with a peak in hours 13, 14 and 15 so it is predicted

in these hours to have all the generating units on (or most of them).

5.1 Baseline Results

Before generating the solutions and alternatives for the problem, the current situation in Kuwait should be tested as a

baseline to compare further results and check whether the system has improved or not. Kuwait’s ministry of

electricity and water doesn’t turn off the generating units at all. To calculate the baseline all of the units should be on

for the whole time interval (24 hours). The calculated baseline cost was $ 3,642,310 (1,100,489 KWD).

5.2 Conventional Dynamic Programing Results

The first alternative solution used in this paper was the conventional dynamic programming method. After inserting

the data and the equations of the UCP, a MATLAB code was used to test the program and give the results. Table 3

shows the generated hourly schedule of the ten generating units using this method. It shows that unit 1 must stay

online for 24 hours without shutting it down in order to meet the demand. On the other hand, unit 6 must be turned

on in hours 13:00, 14:00 and 15:00 only. This table took 946 seconds which is approximately 15.7 minutes to be

constructed by the MATLAB software. The results also show that the total production cost of the generated schedule

during the 24 hours is $2,326,723 (702,947 KWD) which is much less in comparison with the baseline cost of the

current state ($3,642,310 (1,100,489 KWD)).

Table 3: Unit commitment schedule for conventional DP

Hours

Units 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Unit 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 4 1 1 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 0 0 0 0

Unit 5 1 1 1 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 0 0 0

Unit 6 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 0 0 0 0 0 0 0 0 0

Unit 7 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 0 0 0 0 0 0 0 0

Unit 8 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 9 1 1 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 10 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Table 4 demonstrates the production cost of the total online generators for each hour. Adding all these costs will

give us the total production cost for the 24 hours. This table was made to compare the total production cost of the

scheduled units using both the conventional DP and priority DP methods.

Table 4: Fuel cost for each hour

Hours 1 2 3 4 5 6 7 8 9 10 11 12

P-Cost 92234 90607 88936 8545 85212 84198 86057 89104 90858 94024 983047 105308

Hours 13 14 15 16 17 18 19 20 21 22 23 24

P-Cost 86070 127732 125284 121291 114138 110248 105559 1000419 95806 93064 91911 89631

Consequently, Figure 4 shows the total amount of online units in each hour during the 24 hours when using

conventional dynamic programming method (Snyder, Powell & Rayburn, 1987).

© IEOM Society International 1943

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

Figure 4: Conventional DP units scheduled

5.3 Priority Dynamic Programming Results

In the second alternative scenario, priority dynamic programming was used where the incremental heat rate of the

generators is required. When defining the incremental heat rate, it is the total hourly change in the heat rate. The heat

rate in a certain hour is the amount of fuel needed to produce I MW of electricity. Therefore, as the incremental heat

rate increase, the unit will have least priority to be online (Bello, Akorede, Pouresmaeil, Ibrahim, & Ai, 2016).

Prioritization of the generators is based on the incremental heat rate of each. The following Table 5 declares the heat

rates used to get the results. The importance of this rate is that it is needed to be inserted as data to run the priority

method on MATLAB. (Alsaffar & El-Sayed, 2014)

Table 5: Incremental heat rate for 10-units

Units 1 2 3 4 5 6 7 8 9 10

Incremental Heat

22 23 21 26 29 31 35 25 20 21

Rate (BTU/KwH)

Accordingly, Table 6 shows the required state of each unit for 24 hours. It is clearly noticed that more units are

staying online for longer duration when comparing it to conventional DP method which satisfies the working

process of Priority method.

Table 6: Schedule 10-units using priority DP

Hours

Units 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Unit 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 5 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 6 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 0 0 0

Unit 7 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 0 0 0 0 0 0 0 0 0

Unit 8 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 9 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Unit 10 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

The detailed production cost of each hour was listed in Table 7. When comparing the table of total production cost

we got from the priority method, it is clearly noticed that the conventional method gives lower production cost

compared to the priority method.

Table 7: Hourly production cost using priority DP

Hours 1 2 3 4 5 6 7 8 9 10 11 12

P-Cost 92234 90607 81680 77709 77170 74974 78995 8380 86643 92040 98137 105408

Hours 13 14 15 16 17 18 19 20 21 22 23 24

P-Cost 124499 127732 125284 121291 114138 110248 105559 1000419 94751 90391 88424 84587

Furthermore, Figure 5 shows the overall sequence and amount of online units hourly. As a result, the total

production cost resulted when applying priority dynamic programming is $ 2,338,674 (706,588 KWD) and it took

© IEOM Society International 1944

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

an average of 1.45 seconds to generate the schedule which is much less than the conventional method. The detailed

production cost of each hour was listed in Table 7.

Figure 5: Schedule using Priority DP method

After testing the system and comparing the results, it was found that the best method to implement for scheduling

the problem is the Conventional Dynamic Programming, since it can generate a final hourly schedule with the least

possible cost compared to the baseline cost. On the other hand, this method took much longer time than the priority

dynamic programming method when testing the system. This might cause some inconvenience, but since the main

focus was to minimize the total cost, the time is not a big issue if there was no big time variation between the two

methods. Comparing the three scenarios together, we can get the following results:

Table 8: Comparison between results

Total production cost % of reduction

Scenario Time elapsed (sec)

($) compared to baseline

Baseline 3,642,310 - -

Conventional DP 2,326,723 36.10% 946

Priority DP 2,338,674 35.70% 1.45

As noticed from Table 8, conventional method reduces the operating cost of the generations by 36.1% which is a

very high percentage. Putting into consideration that when the problem is solved as large scale problem (the whole

power system), the cost reduction would be critical. The disadvantage of the conventional DP method is that it might

consume a huge amount of time to solve such a large problem (Souroudi, 2017). For instance, 12 units were solved

using conventional DP in it took more than 45 minutes to get the final schedule. In this case, the other alternative

solution can be considered since the number of combinations is low. It would generate schedules fast but with higher

costs than the conventional. Since the ministry of electricity and water at the current time do not pay attention that

much on the costs, they might go to the priority method. However, with the continuous increase in the fuel costs,

they might go to the conventional method regardless time elapsed. Finally, both methods are applicable and

depending on the need of the customer (Matousek & Gärtner, 2007).

6. Conclusion

The aim of this paper is to apply optimization methods to a real-life problem which is the power system in this case.

The focus was based on optimizing the generators by reducing the total production cost. Different methods were

explained with their advantages and disadvantages; the discussion part of the paper included both theoretical and

numerical considerations to optimize the problem. The results were translated into tables and graphs to compare the

applied methods and reach the optimum solution. These tables and graphs were then explained in detail in the

discussion section where economic goals were satisfied through minimizing the total production operating cost.

Dynamic programming was proven to be an efficient way to solve the unit commitment problem and such a method

will make a huge difference when implementing it in Gulf Cooperation Council countries in general and in Kuwait

in specific. It was verified that solving the unit commitment problem is an effective, innovative and creative way in

the power systems field and this paper is concluded to be successful and is able to be implemented.

© IEOM Society International 1945

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

References

Alsaffar, M. A., and El-Sayed, M. A., Emission constrained unit commitment of Kuwait power generation system

using genetic algorithm. Journal of Engineering Research, Vol.2, no.2, pp. 101 – 121, 2014.

Alshareef, A., and Saber, A., An Application of Particle Swarm Optimization (PSO) to Dynamic Unit Commitment

Problem for the Western Area. Journal of King Abdulaziz University: Engineering Sciences, Vol. 23, no.1,

pp. 21-37, 2012.

Ansari, M. J., Kuwait Utilities Sector, technical report by Capital Standards (CSR). Available:

http://www.infomercatiesteri.it/public/images/paesi/107/files/Kuwait%20Utilities%20Sector%20Report_pd

f%206_13.pdf, March 11, 2018.

Bello, S., Akorede, M., Pouresmaeil, E., and Ibrahim, O., Unit commitment optimisation of hydro-thermal power

systems in the day-ahead electricity market, Cogent Engineering, Vol.3, no.1, p.1251009, 2016.

Datta, D., Unit commitment problem with ramp rate constraint using a binary-real-coded genetic algorithm, Applied

Soft Computing, Vol.13, no.9, pp.3873-3883, 2013.

Dhifaoui, C., Guesmi, T., and Abdallah, H., Application of multi-objective PSO algorithm for Economic Dispatch

(ED) through Unit Commitment Problems (UCP). In Sciences and Techniques of Automatic Control and

Computer Engineering (STA), 2014 15th International Conference on, pp. 704-710, Hammamet, Tunisia,

2014.

Hobbs, B., Rothkopf, M., O'eill, R., and Chao, H., The next generation of electric power unit commitment models,

Kluwer Academic Publishers, New York, 2002.

Matousek, J., and Gärtner, B., Understanding and using linear programming, Springer Science & Business Media,

2007.

Moores, B., Dynamic Programming versus Conventional Optimization: Response, Journal of the Operational

Research Society, Vol.39, no.3, pp.322-322, 1988.

Salam, S., Unit Commitment Solution Methods, International Jornal of Energy and Power Engineering, Vol. 1,

no.11, 2007.

Sen, S., and Kothari, D. P., Optimal thermal generating unit commitment: a review, International Journal of

Electrical Power & Energy Systems, Vol. 20, no.7, pp. 443-451, 1998.

Sivanagaraju, S., and Sreenivasan, G., Power System Operation and Control, Dorling Kindersley, Chennai/ India,

2010.

Singhal, P., and Sharma, R., Dynamic programming approach for large scale unit commitment problem, In

Communication Systems and Network Technologies (CSNT), 2011 International Conference, pp. 714-717,

Katra, JaIndia, 2011.

Snyder, W., Powell, H., and Rayburn, J., Dynamic programming approach to unit commitment, IEEE Transactions

on Power Systems, Vol.2, no.2, pp.339-348, 1987.

Souroudi, A., Power System Optimization Modeling in GAMS, Springer International Publishing, 2017.

Statistics Dept. & Information Center, Electrical Energy, Ministry of Electricity and Water, Kuwait, 2015.

Taha, H., Operations Research: An Introduction, 9th edition, Pearson, 2010.

Thakur, N., and Titare, L., Determination of Unit Commitment Problem, Novelty Journals, pp.24-28, 2016.

Tung, N., Bhadoria, A., Kaur, K., Bhadauria, S., and Pg, P., Dynamic programming model based on cost

minimization algorithms for thermal generating units, International Journal of Enhanced Research in

Science Technology & Engineering, Vol.1, no.3, pp.2319-7463, 2012.

Wood, A., and Wollenberg, F., Power Generation Operation and Control. John Wiley & Sons, New York, 1996.

Yang, X., Introduction to mathematical optimization: from linear programming to metaheuristics, Cambridge

International Science Publishing, 2007.

Biographies

Nadine Awadah was born in Kuwait, in 1994. She received her Bachelor degree in Industrial Engineering from the

American University of the Middle East, Eqaila, Kuwait, in 2018. She had continuous AUM honor scholarship

2014-2018. She won the 1st place for the Best Capstone Project in Industrial Engineering Competition- 2018. She

joined as an official candidate for AUM’s elections-2016. She won the 3rd place in International Day Expo

Competition at AUM-2017. Her main interest areas are researching in topics related to renewable energy resources,

optimization, and safety. She had worked with many softwares during her undergraduate study period such as

Minitab, MATLAB, SCILAB, AutoCAD, Arena, Jack, Visual Studio, and MS office programs. She was a

participant for AUM Academic Activities Day, 2014-2018. She won the 2nd place for both Calculas 2 and CS-

programming Competitions.

© IEOM Society International 1946

Proceedings of the International Conference on Industrial Engineering and Operations Management

Paris, France, July 26-27, 2018

Rawan AlShikh Ali was born in 1995, Kuwait. She got her Bachelor degree of Science in Industrial Engineering

from American University of the Middle East- AUM/ Kuwait in 2018. She studied at AUM with an honor

scholarship during 2014-2018. Her senior project won the 1st place as the best Capstone undergraduate Industrial

Engineering project. She achieved the 1st place in Calculus 2 competition during academic activities - 2014. Her

project “Reducing human back pain during heavy lifting using JACK software” was honored as the best work

analysis project during academic activities day - 2016.

Shaikha AlBaijan was born in Kuwait, in 1995. She received her Bachelor degree of Science in Industrial

Engineering from American University of the Middle East, Kuwait, in 2018. Her senior project won the 1st place as

the best Capstone undergraduate Industrial Engineering project. She won the 1st place in Calculus 2 competition

during the academic activities-2014. Her main areas of research interest are operation research, and lean six-sigma.

Ghalia Al-Qallaf born in Kuwait, October 1996, holds a degree in Bachelor of Science in Industrial Engineering in

American University of the Middle East- AUM in 2018, 1st place Capstone Senior project “Smart Grid and

Optimization”.

Muneerah Al-Hasawi born 26th April 1995, entered American university of the Middle East (AUM) in 2013, got a

bachelor degree of science in industrial engineering in 2018. 1st place Capstone Senior project “Smart Grid and

Optimization”- 2017-2018.

Suat Kasap has degrees in electrical-electronics engineering and industrial engineering. He received his Ph.D. in

Industrial Engineering from the University of Oklahoma. His research interests are in human factors and

ergonomics, occupational safety and health, work and process analysis, technology and innovation management,

multi-criteria decision making, financial engineering, data mining, and modeling, analysis, and optimization of

complex engineering problems. He worked in four different Industrial Engineering Departments of the American

University of Middle East, University of Turkish Aeronautics Association, Hacettepe University, and Çankaya

University as an assistant professor. He has taught courses on Work Analysis and Design, Ergonomic Work

Analysis, Cognitive Ergonomics Work Analysis, Technology and Innovation Management, Management of

Information Systems, Introduction to Optimization and Modeling, Deterministic Models of Operation Research,

Project Management, Multi-criteria Decision Making.

© IEOM Society International 1947

Potrebbero piacerti anche

- College of Engineering: Optimal Economic Load Dispatch Using Novel Bat AlgorithmDocumento23 pagineCollege of Engineering: Optimal Economic Load Dispatch Using Novel Bat AlgorithmJean-nette BarlisanNessuna valutazione finora

- Efficacy of Water Wheel in Generating EnergyDocumento5 pagineEfficacy of Water Wheel in Generating EnergyAlcedo Karen R.Nessuna valutazione finora

- Operational Planning of Power System: An Integrated ApproachDocumento17 pagineOperational Planning of Power System: An Integrated ApproachDa DebebeNessuna valutazione finora

- A Practical Model For Generator Maintenance Scheduling With Transmission ConstraintsDocumento14 pagineA Practical Model For Generator Maintenance Scheduling With Transmission Constraintsaijazkhan013Nessuna valutazione finora

- Optimization of Production Scheduling With Time-Dependent and Machine-Dependent Electricity Cost For Industrial Energy EfficiencyDocumento13 pagineOptimization of Production Scheduling With Time-Dependent and Machine-Dependent Electricity Cost For Industrial Energy EfficiencyKathleen CampbellNessuna valutazione finora

- A Novel Opposition Based Tuned Chaotic Differential Evolution Technique For Techno Economic Analysis by Optimal Placement of Distributed GenerationDocumento23 pagineA Novel Opposition Based Tuned Chaotic Differential Evolution Technique For Techno Economic Analysis by Optimal Placement of Distributed Generationredstitch15Nessuna valutazione finora

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Documento11 pagineIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationNessuna valutazione finora

- Generation Expansion Planning Considering Renewable EnergiesDocumento11 pagineGeneration Expansion Planning Considering Renewable EnergiesAJER JOURNALNessuna valutazione finora

- International Journal of Multidisciplinary Research and Growth EvaluationDocumento8 pagineInternational Journal of Multidisciplinary Research and Growth EvaluationJames UjamNessuna valutazione finora

- PLC Case StudyDocumento16 paginePLC Case StudyBhawna SinghalNessuna valutazione finora

- Power Generation Schedule For Economical Aspects Using Evolutionary TechniqueDocumento3 paginePower Generation Schedule For Economical Aspects Using Evolutionary TechniqueInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Dynamic Economic Dispatch Based On Simple Algorithm: S. Ganesan and S. SubramanianDocumento7 pagineDynamic Economic Dispatch Based On Simple Algorithm: S. Ganesan and S. SubramanianPhamNangVanNessuna valutazione finora

- MILP Unit Commitment FormulationDocumento8 pagineMILP Unit Commitment FormulationAhmed AsimNessuna valutazione finora

- 10 Optimizing InfocomDocumento9 pagine10 Optimizing InfocomNoe JoseNessuna valutazione finora

- Electrical Power and Energy Systems: C. Christober Asir RajanDocumento8 pagineElectrical Power and Energy Systems: C. Christober Asir RajanSalman ZafarNessuna valutazione finora

- Test Methods For Determining The Impact of Motor Condition On Motor Efficiency and ReliabilityDocumento9 pagineTest Methods For Determining The Impact of Motor Condition On Motor Efficiency and ReliabilityAmin Mustangin As-SalafyNessuna valutazione finora

- Energy Conversion and Management: Hugo Morais, Tiago Sousa, Zita Vale, Pedro FariaDocumento15 pagineEnergy Conversion and Management: Hugo Morais, Tiago Sousa, Zita Vale, Pedro FariaChino PlagaNessuna valutazione finora

- Lack of Power and Public Improvement Strategies in Senegalese Electric System: An Economic and Managerial PerspectiveDocumento6 pagineLack of Power and Public Improvement Strategies in Senegalese Electric System: An Economic and Managerial PerspectiveNovelty JournalsNessuna valutazione finora

- Tool of The Complete Optimal Control For Variable Speed Electrical DrivesDocumento36 pagineTool of The Complete Optimal Control For Variable Speed Electrical DrivesrijilpoothadiNessuna valutazione finora

- Fast Technique For Unit Commitment by Genetic Algorithm Based On Unit ClusteringDocumento9 pagineFast Technique For Unit Commitment by Genetic Algorithm Based On Unit ClusteringAn Nguyễn KhánhNessuna valutazione finora

- A Genetic Algorithm Approach For Solving Ac-Dc Optimal Power Flow ProblemDocumento14 pagineA Genetic Algorithm Approach For Solving Ac-Dc Optimal Power Flow ProblemJoe RanteNessuna valutazione finora

- Energy: Gwo-Ching LiaoDocumento12 pagineEnergy: Gwo-Ching LiaoRobert MaximilianNessuna valutazione finora

- Optimization Algorithms For Solving Combined Economic Emission Dispatch: A ReviewDocumento6 pagineOptimization Algorithms For Solving Combined Economic Emission Dispatch: A ReviewPurushottam SethyNessuna valutazione finora

- A Dynamic Programming Based Fast Computation Hopfield Neural Network For Unit Commitment and Economic DispatchDocumento9 pagineA Dynamic Programming Based Fast Computation Hopfield Neural Network For Unit Commitment and Economic DispatchAlwin Anno SastraNessuna valutazione finora

- Quantum in EnergyDocumento34 pagineQuantum in EnergyCan of BeansNessuna valutazione finora

- Power Systems Generation Scheduling and Optimization Using Fuzzy Logic TechniquesDocumento8 paginePower Systems Generation Scheduling and Optimization Using Fuzzy Logic TechniquesInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Multiple Objective Particle Swarm Optimization Technique For Economic Load DispatchDocumento8 pagineMultiple Objective Particle Swarm Optimization Technique For Economic Load DispatchbaalaajeeNessuna valutazione finora

- 08 Chapter 1Documento33 pagine08 Chapter 1ashutoshNessuna valutazione finora

- Unit Commitment by An Improved Priority List Method: Karamjeet Kaur Bawa, Amarjeet KaurDocumento3 pagineUnit Commitment by An Improved Priority List Method: Karamjeet Kaur Bawa, Amarjeet KaurAlluri Appa RaoNessuna valutazione finora

- Improved Tabu Search Algorithm To Economic Emission Dispatch With Transmission Line ConstraintDocumento5 pagineImproved Tabu Search Algorithm To Economic Emission Dispatch With Transmission Line ConstraintMohandRahimNessuna valutazione finora

- Preventive Maintenance Scheduling of Multi-Cogeneration Plants Using Integer ProgrammingDocumento8 paginePreventive Maintenance Scheduling of Multi-Cogeneration Plants Using Integer Programmingabu1jubairNessuna valutazione finora

- Saber 1Documento22 pagineSaber 1Izudin SoftićNessuna valutazione finora

- A Case Study of Various Constraints Affecting Unit Commitment in Power System PlanningDocumento5 pagineA Case Study of Various Constraints Affecting Unit Commitment in Power System PlanningAlluri Appa RaoNessuna valutazione finora

- Fuzzified Multiobjective PSO For Optimising The Cost, Emission, Losses With Voltage Stability ConstraintsDocumento14 pagineFuzzified Multiobjective PSO For Optimising The Cost, Emission, Losses With Voltage Stability ConstraintsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Nav PreetDocumento7 pagineNav PreetER Publications, IndiaNessuna valutazione finora

- Electrical Power and Energy Systems: Chia-Liang Lu, Chun-Lung Chen, Daw-Shang Hwang, Yuang-Tung ChengDocumento9 pagineElectrical Power and Energy Systems: Chia-Liang Lu, Chun-Lung Chen, Daw-Shang Hwang, Yuang-Tung Chengteju2812Nessuna valutazione finora

- Expansion Planning For Electric Power Systems: by A.J. CovarrubiasDocumento12 pagineExpansion Planning For Electric Power Systems: by A.J. CovarrubiasNurul ArdiNessuna valutazione finora

- Randriantsoa 2021Documento18 pagineRandriantsoa 2021Ferdaws BNasr BSalahNessuna valutazione finora

- Congestion Management in Deregulated Power System: A ReviewDocumento7 pagineCongestion Management in Deregulated Power System: A ReviewGJESRNessuna valutazione finora

- Recent Innovations in Power Supply To Improve Reliability, Environmental Compatibility and Economic ViabilityDocumento13 pagineRecent Innovations in Power Supply To Improve Reliability, Environmental Compatibility and Economic ViabilityAnonymous MFh19TBNessuna valutazione finora

- Unit Commitment Solution MethodsDocumento6 pagineUnit Commitment Solution MethodsPatrick SmithNessuna valutazione finora

- Energy Auditing: Tool To Increase Energy EfficiencyDocumento36 pagineEnergy Auditing: Tool To Increase Energy Efficiencyabubakarsha100% (1)

- Electricity Load Forecasting - A Systematic ReviewDocumento19 pagineElectricity Load Forecasting - A Systematic ReviewWollace PicançoNessuna valutazione finora

- PLC-based Load Management in Steel Rolling MillsDocumento17 paginePLC-based Load Management in Steel Rolling MillsSahil JhambNessuna valutazione finora

- Menezes 2017Documento26 pagineMenezes 2017Mauricio OhseNessuna valutazione finora

- M.E.Electrical Power System - 2 PDFDocumento32 pagineM.E.Electrical Power System - 2 PDFAnonymous 9VcxlFErfNessuna valutazione finora

- Optimization and Intelligent Techniques For Electrical VehicleDocumento15 pagineOptimization and Intelligent Techniques For Electrical VehicleViswanathanBalajiNessuna valutazione finora

- Bi-Criteria FormulationDocumento22 pagineBi-Criteria FormulationGuilherme WeisNessuna valutazione finora

- Profit Based Unit Commitment Problem With Power Flow ConstraintsDocumento8 pagineProfit Based Unit Commitment Problem With Power Flow ConstraintsvshalshethNessuna valutazione finora

- A Literature Review of Recent Advances in Optimal Power FlowDocumento5 pagineA Literature Review of Recent Advances in Optimal Power FlowInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Review of Electrical Energy Management Techniques: Supply and Consumer Side (Industries)Documento8 pagineA Review of Electrical Energy Management Techniques: Supply and Consumer Side (Industries)zak5555Nessuna valutazione finora

- Grid Connected PV System ThesisDocumento5 pagineGrid Connected PV System Thesisafktlrreerdihj100% (2)

- Decomposition-Based Bi-Objective Optimization For Sustainable Robotic Assembly Line Balancing ProblemsDocumento14 pagineDecomposition-Based Bi-Objective Optimization For Sustainable Robotic Assembly Line Balancing Problemslei liNessuna valutazione finora

- Fast Solution Technique For Large-Scale Unit Commitment Problem Using Genetic AlgorithmDocumento8 pagineFast Solution Technique For Large-Scale Unit Commitment Problem Using Genetic AlgorithmSravan KumarNessuna valutazione finora

- Sustainability 11 03060 v2Documento18 pagineSustainability 11 03060 v2Andrea ScardaNessuna valutazione finora

- Modelling Electrical Energy Consumption in AutomotDocumento9 pagineModelling Electrical Energy Consumption in Automot4t43t34yNessuna valutazione finora

- Mathematical Modelling and Optimisation of Energy-Conscious Hybrid Flow Shop Scheduling Problem With Unrelated Parallel MachinesDocumento28 pagineMathematical Modelling and Optimisation of Energy-Conscious Hybrid Flow Shop Scheduling Problem With Unrelated Parallel MachinesOlivia brianneNessuna valutazione finora

- Pensar !!!Documento6 paginePensar !!!Jamerson RamosNessuna valutazione finora

- Solution To VTU Question Bank Unit 1 1. Explain Lease Cost Planning With Flowchart. (Dec 2013/jan 2014) (June/July 2015) Least Cost Utility PlanningDocumento33 pagineSolution To VTU Question Bank Unit 1 1. Explain Lease Cost Planning With Flowchart. (Dec 2013/jan 2014) (June/July 2015) Least Cost Utility PlanningCharan H SNessuna valutazione finora

- Microsoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideDa EverandMicrosoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideNessuna valutazione finora

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyDa EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorNessuna valutazione finora

- Lesson 16 - Blues Practice WorkoutDocumento1 paginaLesson 16 - Blues Practice WorkoutGrd doNessuna valutazione finora

- Lesson 5 - Diminished, Whole Tone. Chromatic Scales PDFDocumento2 pagineLesson 5 - Diminished, Whole Tone. Chromatic Scales PDFGrd doNessuna valutazione finora

- 1.1 Section9-Complete PDFDocumento120 pagine1.1 Section9-Complete PDFGrd do100% (1)

- Lesson 2 - Memory Tricks For Major Scales (Flats Keys)Documento2 pagineLesson 2 - Memory Tricks For Major Scales (Flats Keys)Grd doNessuna valutazione finora

- Lesson 3 - Natural Minor Scales PDFDocumento1 paginaLesson 3 - Natural Minor Scales PDFGrd doNessuna valutazione finora

- Lesson 6 - Arpeggios PDFDocumento3 pagineLesson 6 - Arpeggios PDFGrd doNessuna valutazione finora

- Lesson 6 - Arpeggios PDFDocumento3 pagineLesson 6 - Arpeggios PDFGrd doNessuna valutazione finora

- Lesson 2 - Rhythm 1 Left NoteRight Chord'Documento4 pagineLesson 2 - Rhythm 1 Left NoteRight Chord'Grd doNessuna valutazione finora

- Lesson 3 - New Chords - CM, FM, GM, DB, Eb, Ab PDFDocumento5 pagineLesson 3 - New Chords - CM, FM, GM, DB, Eb, Ab PDFGrd doNessuna valutazione finora

- Corrosion On BoilersDocumento105 pagineCorrosion On BoilersPlínio Silveira100% (1)

- CDM Projects - Middle EastDocumento2 pagineCDM Projects - Middle Eastedward_007Nessuna valutazione finora

- Total 200: Present Installed Capacity of CSPGCLDocumento1 paginaTotal 200: Present Installed Capacity of CSPGCLajjuNessuna valutazione finora

- منهج تانية كهرباءDocumento180 pagineمنهج تانية كهرباءbalaeee123Nessuna valutazione finora

- Renewable Energy Systems Other Renewables Source: Rashid (Chapter 16)Documento63 pagineRenewable Energy Systems Other Renewables Source: Rashid (Chapter 16)Shadan ArshadNessuna valutazione finora

- Power SystemDocumento170 paginePower SystemArshad RasheedNessuna valutazione finora

- Zumma Energy Consulting - IndustryUpdate - May2020Documento8 pagineZumma Energy Consulting - IndustryUpdate - May2020Pedro MentadoNessuna valutazione finora

- Scie9 - Q3 - M3 - Geothermal Energy - V3Documento32 pagineScie9 - Q3 - M3 - Geothermal Energy - V3Precious Arni75% (8)

- Applied Thermal Engineering: P. Regulagadda, I. Dincer, G.F. NatererDocumento7 pagineApplied Thermal Engineering: P. Regulagadda, I. Dincer, G.F. Natererjhugo_mirandaNessuna valutazione finora

- Transco Abu DhabiDocumento30 pagineTransco Abu DhabiIsagani MadridNessuna valutazione finora

- Kazunari Sasaki, Hai-Wen Li. Hydrogen Energy Engineering 2016Documento578 pagineKazunari Sasaki, Hai-Wen Li. Hydrogen Energy Engineering 2016Fernando SalinasNessuna valutazione finora

- Country Update Report For Kenya 2015-2019Documento16 pagineCountry Update Report For Kenya 2015-2019innocent ndikubwimanaNessuna valutazione finora

- Hydro NewsDocumento32 pagineHydro NewslufimanNessuna valutazione finora

- Uttrakhand Jal Vidhyut Nigam LTDDocumento35 pagineUttrakhand Jal Vidhyut Nigam LTDmohitNessuna valutazione finora

- Pipe Conveyor SystemDocumento6 paginePipe Conveyor Systemsurajit81100% (2)

- Geography 2059 Markscheme 2004-2019Documento382 pagineGeography 2059 Markscheme 2004-2019Justice LeaugeNessuna valutazione finora

- Nuclear Power Plant Virtual Tour: Directions: You Will Use The Information Given During The Tour To Complete ThisDocumento5 pagineNuclear Power Plant Virtual Tour: Directions: You Will Use The Information Given During The Tour To Complete ThisathenalavegaNessuna valutazione finora

- ResumeDocumento3 pagineResumeDevendra KiteNessuna valutazione finora

- Wind Power Plants MacedoniaDocumento26 pagineWind Power Plants MacedoniaMonikaNessuna valutazione finora

- Power Plant Instrumentation: Lecture NotesDocumento35 paginePower Plant Instrumentation: Lecture NotesmaanwarNessuna valutazione finora

- 3RD Quarter Las G9Documento3 pagine3RD Quarter Las G9vash deynnielNessuna valutazione finora

- SIEMENS TurbinesDocumento8 pagineSIEMENS TurbinesTasawwur TahirNessuna valutazione finora

- List of Solar Power Plant Projects: Year Name of Project ClientDocumento4 pagineList of Solar Power Plant Projects: Year Name of Project ClientPoonam SharmaNessuna valutazione finora

- L&T Annual Report 2012-13Documento316 pagineL&T Annual Report 2012-13Niyati VaidyaNessuna valutazione finora

- Design and Analysis of Hydroelectric Generation Using WaterwheelDocumento6 pagineDesign and Analysis of Hydroelectric Generation Using WaterwheelVinu KohliNessuna valutazione finora

- Bid Doc Tender Gas Turbine Combine - 445118aDocumento547 pagineBid Doc Tender Gas Turbine Combine - 445118aMas ZuhadNessuna valutazione finora

- Hypower Hypower: Lorem IpsumDocumento29 pagineHypower Hypower: Lorem IpsumnourooziNessuna valutazione finora

- Online Remote Condition Monitoring, Case Study Thermal Power Plant in ZimbabweDocumento15 pagineOnline Remote Condition Monitoring, Case Study Thermal Power Plant in ZimbabweLeanmark MayahleNessuna valutazione finora

- Company Profile PLN RE Academy - EngDocumento22 pagineCompany Profile PLN RE Academy - EngagungbayukusumoNessuna valutazione finora