Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bosch GRO 10.8v

Caricato da

solerviDescrizione originale:

Copyright

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Bosch GRO 10.8v

Caricato da

solerviCopyright:

OBJ_BUCH-2020-001.

book Page 1 Tuesday, November 26, 2013 2:57 PM

Robert Bosch GmbH

Power Tools Division

70745 Leinfelden-Echterdingen

Germany

GRO 10,8 V-LI Professional

www.bosch-pt.com

1 619 P11 460 (2013.11) PS / 239 EURO

de Originalbetriebsanleitung tr Orijinal işletme talimatı mk Оригинално упатство за работа

en Original instructions pl Instrukcja oryginalna sr Originalno uputstvo za rad

fr Notice originale cs Původní návod k používání sl Izvirna navodila

es Manual original sk Pôvodný návod na použitie hr Originalne upute za rad

pt Manual original hu Eredeti használati utasítás et Algupärane kasutusjuhend

it Istruzioni originali ru Оригинальное руководство по lv Instrukcijas oriģinālvalodā

nl Oorspronkelijke эксплуатации lt Originali instrukcija

gebruiksaanwijzing uk Оригінальна інструкція з ar ςТЎϩХʉ ЌТϾϦφЍʉ ʌμВТЎϺυ

da Original brugsanvisning експлуатації fa ΖЎϩʉ ˒μВЖЙʉʓ ИͳϞφЁʑ

sv Bruksanvisning i original kk Пайдалану нұсқаулығының

no Original driftsinstruks түпнұсқасы

fi Alkuperäiset ohjeet ro Instrucţiuni originale

el Πρωτότυπο οδηγιών χρήσης bg Оригинална инструкция

OBJ_BUCH-2020-001.book Page 3 Tuesday, November 26, 2013 2:57 PM

3|

8

7

6

5

4

2

1

10

11

12

13

3

14

GRO 10,8 V-LI

A 9

15

L0

16

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_BUCH-2020-001.book Page 4 Tuesday, November 26, 2013 2:57 PM

4|

B C 5 1

17 5

2

1

1

17

2

13

12 D

18

18

2

20

19

3

12

11

21

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_DOKU-36183-001.fm Page 5 Tuesday, November 26, 2013 3:12 PM

5|

F G

H I

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_BUCH-2020-001.book Page 14 Tuesday, November 26, 2013 2:57 PM

14 | English

Do not abuse the cord. Never use the cord for carrying, Maintain power tools. Check for misalignment or bind-

pulling or unplugging the power tool. Keep cord away ing of moving parts, breakage of parts and any other

from heat, oil, sharp edges and moving parts. Damaged condition that may affect the power tool’s operation. If

or entangled cords increase the risk of electric shock. damaged, have the power tool repaired before use.

When operating a power tool outdoors, use an exten- Many accidents are caused by poorly maintained power

sion cord suitable for outdoor use. Use of a cord suitable tools.

for outdoor use reduces the risk of electric shock. Keep cutting tools sharp and clean. Properly maintained

If operating a power tool in a damp location is unavoid- cutting tools with sharp cutting edges are less likely to bind

able, use a residual current device (RCD) protected and are easier to control.

supply. Use of an RCD reduces the risk of electric shock. Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

Personal safety

the working conditions and the work to be performed.

Stay alert, watch what you are doing and use common Use of the power tool for operations different from those

sense when operating a power tool. Do not use a power intended could result in a hazardous situation.

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op- Battery tool use and care

erating power tools may result in serious personal injury. Recharge only with the charger specified by the manu-

Use personal protective equipment. Always wear eye facturer. A charger that is suitable for one type of battery

protection. Protective equipment such as dust mask, pack may create a risk of fire when used with another bat-

non-skid safety shoes, hard hat, or hearing protection used tery pack.

for appropriate conditions will reduce personal injuries. Use power tools only with specifically designated bat-

Prevent unintentional starting. Ensure the switch is in tery packs. Use of any other battery packs may create a

the off-position before connecting to power source risk of injury and fire.

and/or battery pack, picking up or carrying the tool. When battery pack is not in use, keep it away from oth-

Carrying power tools with your finger on the switch or en- er metal objects, like paper clips, coins, keys, nails,

ergising power tools that have the switch on invites acci- screws or other small metal objects, that can make a

dents. connection from one terminal to another. Shorting the

Remove any adjusting key or wrench before turning battery terminals together may cause burns or a fire.

the power tool on. A wrench or a key left attached to a ro- Under abusive conditions, liquid may be ejected from

tating part of the power tool may result in personal injury. the battery; avoid contact. If contact accidentally oc-

Do not overreach. Keep proper footing and balance at curs, flush with water. If liquid contacts eyes, addition-

all times. This enables better control of the power tool in ally seek medical help. Liquid ejected from the battery

unexpected situations. may cause irritation or burns.

Dress properly. Do not wear loose clothing or jewel- Service

lery. Keep your hair, clothing and gloves away from Have your power tool serviced by a qualified repair per-

moving parts. Loose clothes, jewellery or long hair can be son using only identical replacement parts. This will en-

caught in moving parts. sure that the safety of the power tool is maintained.

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are con- Safety instructions for all operations

nected and properly used. Use of dust collection can re- Safety Warnings Common for Grinding, Sanding, Wire

duce dust-related hazards. Brushing, Polishing, Carving or Abrasive Cutting-Off Op-

Power tool use and care erations

Do not force the power tool. Use the correct power tool This power tool is intended to function as a grinder,

for your application. The correct power tool will do the sander, wire brush, polisher, carving or cut-off tool.

job better and safer at the rate for which it was designed. Read all safety warnings, instructions, illustrations and

specifications provided with this power tool. Failure to

Do not use the power tool if the switch does not turn it

follow all instructions listed below may result in electric

on and off. Any power tool that cannot be controlled with

shock, fire and/or serious injury.

the switch is dangerous and must be repaired.

Do not use accessories which are not specifically de-

Disconnect the plug from the power source and/or the

signed and recommended by the tool manufacturer.

battery pack from the power tool before making any

Just because the accessory can be attached to your power

adjustments, changing accessories, or storing power

tool, it does not assure safe operation.

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally. The rated speed of the accessory must be at least equal

to the maximum speed marked on the power tool. Ac-

Store idle power tools out of the reach of children and

cessories running faster than their rated speed can break

do not allow persons unfamiliar with the power tool or

and fly apart.

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_BUCH-2020-001.book Page 15 Tuesday, November 26, 2013 2:57 PM

English | 15

The outside diameter and the thickness of your acces- After changing the bits or making any adjustments,

sory must be within the capacity rating of your power make sure the collet nut, chuck or any other adjust-

tool. Incorrectly sized accessories cannot be adequately ment devices are securely tightened. Loose adjustment

guarded or controlled. devices can unexpectedly shift, causing loss of control,

The arbour size of wheels, sanding drums or any other loose rotating components will be violently thrown.

accessory must properly fit the spindle or collet of the Do not run the power tool while carrying it at your side.

power tool. Accessories that do not match the mounting Accidental contact with the spinning accessory could snag

hardware of the power tool will run out of balance, vibrate your clothing, pulling the accessory into your body.

excessively and may cause loss of control. Regularly clean the power tool’s air vents. The motor’s fan

Mandrel mounted wheels, sanding drums, cutters or will draw the dust inside the housing and excessive accumu-

other accessories must be fully inserted into the collet lation of powdered metal may cause electrical hazards.

or chuck. If the mandrel is insufficiently held and/or the Do not operate the power tool near flammable materi-

overhang of the wheel is too long, the mounted wheel may als. Sparks could ignite these materials.

become loose and ejected at high velocity.

Do not use accessories that require liquid coolants. Us-

Do not use a damaged accessory. Before each use in- ing water or other liquid coolants may result in electrocu-

spect the accessory such as abrasive wheels for chips tion or shock.

and cracks, sanding drum for cracks, tear or excess

wear, wire brush for loose or cracked wires. If power Kickback and related warnings

tool or accessory is dropped, inspect for damage or in- Kickback is a sudden reaction to a pinched or snagged rotat-

stall an undamaged accessory. After inspecting and in- ing wheel, backing pad, brush or any other accessory.

stalling an accessory, position yourself and bystanders Pinching or snagging causes rapid stalling of the rotating ac-

away from the plane of the rotating accessory and run cessory which in turn causes the uncontrolled power tool to

the power tool at maximum no-load speed for one min- be forced in the direction opposite of the accessory’s rota-

ute. Damaged accessories will normally break apart during tion at the point of the binding.

this test time. For example, if an abrasive wheel is snagged or pinched by

Wear personal protective equipment. Depending on the workpiece, the edge of the wheel that is entering into the

application, use face shield, safety goggles or safety pinch point can dig into the surface of the material causing

glasses. As appropriate, wear dust mask, hearing pro- the wheel to climb out or kick out. The wheel may either

tectors, gloves and shop apron capable of stopping jump toward or away from the operator, depending on di-

small abrasive or workpiece fragments. The eye protec- rection of the wheel’s movement at the point of pinching.

tion must be capable of stopping flying debris generated Abrasive wheels may also break under these conditions.

by various operations. The dust mask or respirator must be Kickback is the result of power tool misuse and/or incorrect

capable of filtrating particles generated by your operation. operating procedures or conditions and can be avoided by

Prolonged exposure to high intensity noise may cause taking proper precautions as given below.

hearing loss. Maintain a firm grip on the power tool and position your

Keep bystanders a safe distance away from work area. body and arm to allow you to resist kickback forces.

Anyone entering the work area must wear personal The operator can control kickback forces, if proper precau-

protective equipment. Fragments of workpiece or of a tions are taken.

broken accessory may fly away and cause injury beyond Use special care when working corners, sharp edges,

immediate area of operation. etc. Avoid bouncing and snagging the accessory. Cor-

Hold power tool by insulated gripping surfaces only, ners, sharp edges or bouncing have a tendency to snag the

when performing an operation where the cutting ac- rotating accessory and cause loss of control or kickback.

cessory may contact hidden wiring. Cutting accessory Do not use a toothed saw blade. Such blades create fre-

contacting a “live” wire may make exposed metal parts of quent kickback and loss of control over the power tool.

the power tool “live” and shock the operator. Always feed the bit into the material in the same direc-

Always hold the tool firmly in your hand(s) during the tion as the cutting edge is exiting from the material

start-up. The reaction torque of the motor, as it acceler- (which is the same direction as the chips are thrown).

ates to full speed, can cause the tool to twist. Feeding the tool in the wrong direction causes the cutting

Use clamps to support workpiece whenever practical. edge of the bit to climb out of the work and pull the tool in

Never hold a small workpiece in one hand and the tool the direction of this feed.

in the other hand while in use. Clamping a small work- When using rotary files, cut-off wheels, high-speed cut-

piece allows you to use both hands to control the tool. ters or tungsten carbide cutters, always have the work

Round material such as dowel rods, pipes or tubing have a securely clamped. These wheels will grab if they become

tendency to roll while being cut, and may cause the bit to slightly canted in the groove, and can kickback. When a

bind or jump toward you. cut-off wheel grabs, the wheel itself usually breaks. When

Never lay the power tool down until the accessory has the rotary file, high-speed cutter or tungsten carbide cut-

come to a complete stop. The spinning wheel may grab ter grab, it may jump from the groove and you could lose

the surface and pull the power tool out of your control. control of the tool.

Bosch Power Tools 1 619 P11 460 | (26.11.13)

OBJ_BUCH-2020-001.book Page 16 Tuesday, November 26, 2013 2:57 PM

16 | English

Safety warnings specific for Grinding and Abrasive Cut- Additional safety warnings

ting-Off operations Wear safety goggles.

Use only wheel types that are recommended for your

power tool and only for recommended applications.

For example: do not grind with the side of a cut-off

wheel. Abrasive cut-off wheels are intended for peripheral

grinding, side forces applied to these wheels may cause Use appropriate detectors to determine if utility lines

them to shatter. are hidden in the work area or call the local utility compa-

For threaded abrasive cones and plugs use only undam- ny for assistance. Contact with electric lines can lead to fire

aged wheel mandrels with an unrelieved shoulder and electric shock. Damaging a gas line can lead to explo-

flange that are of correct size and length. Proper man- sion. Penetrating a water line causes property damage.

drels will reduce the possibility of breakage. Secure the workpiece. A workpiece clamped with clamp-

Do not “jam” the cut-off wheel or apply excessive pres- ing devices or in a vice is held more secure than by hand.

sure. Do not attempt to make an excessive depth of cut. The power tool is not suitable for stationary operation.

Overstressing the wheel increases the loading and suscep- For example, it may not be clamped in a vice or fastened on

tibility to twisting or binding of the wheel in the cut and the a workbench.

possibility of kickback or wheel breakage.

Do not open the battery. Danger of short-circuiting.

Do not position your hand in line with and behind the ro-

Protect the battery against heat, e. g., against

tating wheel. When the wheel, at the point of operation, is

continuous intense sunlight, fire, water, and mois-

moving away from your hand, the possible kickback may

ture. Danger of explosion.

propel the spinning wheel and the power tool directly at you.

In case of damage and improper use of the battery, va-

When wheel is pinched, snagged or when interrupting a

pours may be emitted. Ventilate the area and seek

cut for any reason, switch off the power tool and hold the

medical help in case of complaints. The vapours can irri-

power tool motionless until the wheel comes to a com-

tate the respiratory system.

plete stop. Never attempt to remove the cut-off wheel

from the cut while the wheel is in motion otherwise kick- Use the battery only in conjunction with your Bosch

back may occur. Investigate and take corrective action to power tool. This measure alone protects the battery

eliminate the cause of wheel pinching or snagging. against dangerous overload.

Do not restart the cutting operation in the workpiece. The battery can be damaged by pointed objects such as

Let the wheel reach full speed and carefully re-enter nails or screwdrivers or by force applied externally. An

the cut. The wheel may bind, walk up or kickback if the internal short circuit can occur and the battery can burn,

power tool is restarted in the workpiece. smoke, explode or overheat.

Support panels or any oversized workpiece to minimize

the risk of wheel pinching and kickback. Large work- Product Description and Specifications

pieces tend to sag under their own weight. Supports must Read all safety warnings and all instruc-

be placed under the workpiece near the line of cut and near tions. Failure to follow the warnings and in-

the edge of the workpiece on both sides of the wheel. structions may result in electric shock, fire

Use extra caution when making a “pocket cut” into ex- and/or serious injury.

isting walls or other blind areas. The protruding wheel

may cut gas or water pipes, electrical wiring or objects that While reading the operating instructions, unfold the graphics

can cause kickback. page for the machine and leave it open.

Safety warnings specific for wire brushing operations

Intended Use

Be aware that wire bristles are thrown by the brush

even during ordinary operation. Do not overstress the The power tool is intended for cutting metal and stone materi-

wires by applying excessive load to the brush. The wire als, and for grinding, sanding and polishing metal and painted

bristles can easily penetrate light clothing and/or skin. surfaces without the use of water. In addition to this, the pow-

er tool is suitable for drilling in wood, soft metal, plastic and

Allow brushes to run at operating speed for at least one

light building materials when used with the appropriate ac-

minute before using them. During this time no one is to

cessories.

stand in front or in line with the brush. Loose bristles or

wires will be discharged during the run-in time. The light of this power tool is intended to illuminate the power

tool’s direct area of working operation and is not suitable for

Direct the discharge of the spinning wire brush away

household room illumination.

from you. Small particles and tiny wire fragments may be

discharged at high velocity during the use of these brushes

and may become imbedded in your skin.

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_BUCH-2020-001.book Page 17 Tuesday, November 26, 2013 2:57 PM

English | 17

Product Features Noise/Vibration Information

The numbering of the product features refers to the illustra- Measured sound values determined according to EN 60745.

tion of the machine on the graphics page. Typically the A-weighted sound pressure level of the product

1 Cutting disc is 74 dB(A). Uncertainty K=3 dB.

2 Holding rod The noise level when working can exceed 80 dB(A).

3 Grinding accessory* Wear hearing protection!

4 “PowerLight” Vibration total values ah (triax vector sum) and uncertainty K

5 Spindle lock determined according to EN 60745:

6 On/Off switch ah =9 m/s2, K=1.5 m/s2.

7 Speed regulator The vibration level given in this information sheet has been

8 Battery charge-control indicator measured in accordance with a standardised test given in

9 Battery pack EN 60745 and may be used to compare one tool with anoth-

10 Direction-of-rotation arrow for grinding spindle er. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main ap-

11 Dust protection cap (for detailed work)

plications of the tool. However if the tool is used for different

12 Clamping nut

applications, with different accessories or insertion tools or is

13 Collet of the collet chuck poorly maintained, the vibration emission may differ. This

14 Handle (insulated gripping surface) may significantly increase the exposure level over the total

15 Inner shank dimension L0 working period.

16 Battery unlocking button An estimation of the level of exposure to vibration should also

17 Open-end spanner/Screwdriver take into account the times when the tool is switched off or

18 Shank when it is running but not actually doing the job. This may sig-

19 Collet nificantly reduce the exposure level over the total working

period.

20 Drive spindle

Identify additional safety measures to protect the operator

21 Dust protection cap (for working close to surfaces) from the effects of vibration such as: maintain the tool and the

* The accessories illustrated or described are not included as accessories, keep the hands warm, organisation of work pat-

standard delivery.

terns.

Technical Data Declaration of Conformity

Cordless multi rotary tool GRO 10,8 V-LI We declare under our sole responsibility that the product de-

Article number 3 601 JC5 0.. scribed under “Technical Data” is in conformity with the fol-

Rated voltage V= 10.8 lowing standards or standardisation documents: EN 60745

according to the provisions of the directives 2009/125/EC

Rated speed min-1 5000 –35000 (Regulation 1194/2012), 2011/65/EU, 2004/108/EC,

Collet chuck-Ø mm 3.2 2006/42/EC.

Spanner flat of collet chuck mm 9.55 Technical file (2006/42/EC) at:

Max. outer diameter: Robert Bosch GmbH, PT/ETM9,

– Cutting disc mm 38 D-70745 Leinfelden-Echterdingen

– Grinding accessory mm 22.5 Henk Becker Helmut Heinzelmann

– Wire brush mm 20 Executive Vice President Head of Product Certification

– Grinding disc mm 20 Engineering PT/ETM9

– Drill bit mm 3.2

Max. inner shank dimension L0 mm 10

Max. shank length mm 35

Weight according to Robert Bosch GmbH, Power Tools Division

EPTA-Procedure 01/2003 kg 0.6 D-70745 Leinfelden-Echterdingen

Technical data determined with battery from delivery scope. Leinfelden, 26.11.2013

Battery

Permitted ambient tempera-

Assembly

ture Battery Charging

– when charging °C 0...+45

– during operation* °C –20...+50 Use only the battery chargers listed on the accessories

– during storage °C –20...+60 page. Only these battery chargers are matched to the lith-

ium ion battery of your power tool.

Recommended batteries GBA 10,8V x,xAh 0-.

* Limited performance at temperatures <0 °C

Bosch Power Tools 1 619 P11 460 | (26.11.13)

OBJ_BUCH-2020-001.book Page 18 Tuesday, November 26, 2013 2:57 PM

18 | English

Note: The battery is supplied partially charged. To ensure full – Press and hold the spindle lock and loosen the clamping

capacity of the battery, completely charge the battery in the nut 12 with the open-end spanner 17 by turning it in an an-

battery charger before using your power tool for the first time. ticlockwise direction.

The lithium-ion battery can be charged at any time without re- – Insert the dust-free application tool (e.g. holding rod 2,

ducing its service life. Interrupting the charging procedure grinding accessory 3 or drill bit) into the collet 13 of the

does not damage the battery. collet chuck 19.

The lithium ion battery is protected against deep discharging Note: Ensure that the shank 18 of the application tool sits in

by the “Electronic Cell Protection (ECP)”. When the battery is as far as possible, but at least 10 mm into the collet chuck.

empty, the machine is switched off by means of a protective – Press and hold the spindle lock 5 and tighten the applica-

circuit: The inserted tool no longer rotates. tion tool by turning the clamping nut 12 with the open-end

Do not continue to press the On/Off switch after the spanner 17 in a clockwise direction.

machine has been automatically switched off. The bat- Removing

tery can be damaged. – Loosen the clamping nut 12 as previously described and

Observe the notes for disposal. remove the application tool.

Removing the battery (see figure A) Mounting a Cutting Disc (see figure C)

– To remove the battery 9, press the unlocking buttons 16 Cutting discs reinforced with fibreglass are included in the

and pull the battery out of the machine to the rear. Do not scope of delivery. They can be used for grooving, routing and

exert any force. cutting metal, wood and plastic.

Battery Charge-control Indication – Insert the holding rod 2 into the collet (see “Inserting”,

The three green LEDs of the battery charge-control indicator page 18).

8 indicate the charge condition of the battery 9. – Press and hold the spindle lock 5 and completely unscrew

the screw on the holding rod 2 using the screwdriver 17.

LED Meaning – Attach the cutting disc 1 to the holding rod 2 and reinsert

Continuous lighting Battery Capacity ≥2/3 and tighten the screw.

3 x green

Changing the Collet Chuck (see figure D)

Continuous lighting Battery Capacity ≥1/3

2 x green – Press the spindle lock 5 and turn the clamping nut 12 by

hand until locked.

Continuous lighting Battery Capacity <1/3

– Press and hold the spindle lock and loosen the clamping

1 x green

nut 12 with the open-end spanner 17 by turning it in an an-

Flashing light 1 x green Reserve ticlockwise direction.

Continuous lighting Power tool has overheated! – Remove the clamping nut 12 together with the collet chuck

1 x red – Switch the power tool off and al- 19.

low it to cool down completely. – Insert the required collet chuck into the drive spindle 20.

Flashing light Power tool has overloaded! – Screw the clamping nut 12 onto the drive spindle 20 and

1 x red tighten it slightly in a clockwise direction using the open-

– Exert less pressure on the work- end spanner 17.

piece during work.

Changing the Tool Replacing the Dust Protection Cap (see figure E)

When inserting an application tool, pay attention that Two dust protection caps are included in the scope of deliv-

the shank of the application tool is firmly seated in the ery.

tool holder. When the shank of the application tool is not Use the dust protection cap 11 when you need a good grip for

inserted deep enough in the tool holder, the application detailed work.

tool can become loose again and not be controlled. Use the dust protection cap 21 when you have to work close

to the workpiece surface.

Use only flawless tool bits that are not worn. Defective

tool bits can break, for example, and cause injury or dam- The dust protection cap largely prevents the penetration of

age. dust into the tool holder during operation. When inserting the

tool, pay attention that the dust protection cap is not damaged.

Only use brand accessories for grinding, sanding,

brushing, polishing, routing and cut-off grinding from – Unscrew the dust protection cap used.

the dealer for the power tool, which are approved for a – Screw on the new dust protection cap and tighten it.

speed of 35000 rpm and which have a shank with an

Dust/Chip Extraction

outside diameter of 3.2 mm.

Dusts from materials such as lead-containing coatings,

Inserting (see figure B) some wood types, minerals and metal can be harmful to

– Press the spindle lock 5 and turn the clamping nut 12 by one’s health. Touching or breathing-in the dusts can cause

hand until locked. allergic reactions and/or lead to respiratory infections of

the user or bystanders.

1 619 P11 460 | (26.11.13) Bosch Power Tools

OBJ_BUCH-2020-001.book Page 19 Tuesday, November 26, 2013 2:57 PM

English | 19

Certain dusts, such as oak or beech dust, are considered Recommended Cutting Methods

as carcinogenic, especially in connection with wood-treat- – Panel materials (see figure H)

ment additives (chromate, wood preservative). Materials – Bars (see figure I)

containing asbestos may only be worked by specialists. – Pipes (see figure J)

– Provide for good ventilation of the working place. Blockage protection

– It is recommended to wear a P2 filter-class respirator.

The built-in blockage protection protects the motor and bat-

Observe the relevant regulations in your country for the

tery in case of a blockage. If the application tool becomes

materials to be worked.

jammed in the workpiece or if too much pressure is exerted on

Prevent dust accumulation at the workplace. Dusts can

the workpiece, the motor will stop.

easily ignite.

– Determine the cause of the blockage and correct it.

Operation Maintenance and Service

Starting Operation

Maintenance and Cleaning

Inserting the battery

Before any work on the machine itself (e. g. mainte-

– Insert the charged battery 9 into the battery port until it nance, tool change, etc.) as well as during transport

can be felt to engage and is seated flush. and storage, remove the battery from the power tool.

Switching On and Off There is danger of injury when unintentionally actuating

To save energy, only switch the power tool on when using it. the On/Off switch.

– To start the power tool, push the On/Off switch 6 for- For safe and proper working, always keep the machine

wards. and ventilation slots clean.

– To switch off the machine, push On/Off switch 6 toward

After-sales Service and Application Service

the rear.

In all correspondence and spare parts order, please always in-

Adjusting the Speed clude the 10-digit article number given on the type plate of

The speed regulator 7 enables continuously variable adjust- the machine.

ment of the speed of the power tool even during operation. Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

Speed setting Speed control adjustment parts. Exploded views and information on spare parts can al-

1 5000 –8000 min-1 so be found under:

2 9000 –12000 min-1 www.bosch-pt.com

3 16000 –19000 min-1 Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

4 20000 –24000 min-1

Great Britain

5 24000 –28000 min-1

Robert Bosch Ltd. (B.S.C.)

6 30000 –35000 min-1

P.O. Box 98

– When working with plastics and other materials with a low Broadwater Park

melting point, use low speeds. North Orbital Road

– Perform cutting work in wood, iron or steel at high speeds. Denham

– When polishing, buffing and cleaning, work with speeds of Uxbridge

up to max. 15000 rpm in order to avoid damaging the UB 9 5HJ

workpiece and application tool. Tel. Service: (0844) 7360109

Fax: (0844) 7360146

Working Advice E-Mail: boschservicecentre@bosch.com

Detailed work can be carried out best if you hold the power

Ireland

tool as a pen between thumb and index finger (see figure F).

Origo Ltd.

For heavy work such as cutting or grinding, use the “golf grip

Unit 23 Magna Drive

method” (see figure G).

Magna Business Park

Move the cutting disc or grinding accessory with light pres- City West

sure to achieve an optimum work result. Too much pressure Dublin 24

will reduce the performance of the power tool and lead to fast- Tel. Service: (01) 4666700

er wear of the application tool. Fax: (01) 4666888

Ensure that grinding tools and cutting discs are pro-

tected against impact when stored.

Bosch Power Tools 1 619 P11 460 | (26.11.13)

Potrebbero piacerti anche

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsDa EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsValutazione: 1 su 5 stelle1/5 (1)

- Notice Detecteur D-Tect 120 BoschDocumento13 pagineNotice Detecteur D-Tect 120 BoschMathieu DreanoNessuna valutazione finora

- Notice AXT25TC BoschDocumento14 pagineNotice AXT25TC BoschPatrice GervoisNessuna valutazione finora

- Bosch GSB 13REDocumento11 pagineBosch GSB 13RENilesh ButeNessuna valutazione finora

- 328 DreDocumento16 pagine328 Drestari692002Nessuna valutazione finora

- GCM 12 GDL Professional PDFDocumento30 pagineGCM 12 GDL Professional PDFmijnmik jonesNessuna valutazione finora

- GWS Professional: 22-180 H - 22-180 JH - 22-230 H - 22-230 JH - 24-180 JH - 24-230 H - 24-230 JH - 26-180 JH - 26-230 JHDocumento13 pagineGWS Professional: 22-180 H - 22-180 JH - 22-230 H - 22-230 JH - 24-180 JH - 24-230 H - 24-230 JH - 26-180 JH - 26-230 JHاحمد النجارNessuna valutazione finora

- GMF - Gof - GKF 1600 Ce: ProfessionalDocumento20 pagineGMF - Gof - GKF 1600 Ce: Professionalthierry loutteNessuna valutazione finora

- Bosch Gll-2-80-P-ManualDocumento14 pagineBosch Gll-2-80-P-Manualrafael oliveiraNessuna valutazione finora

- Bosch GST 85 PbeDocumento43 pagineBosch GST 85 Pbej_abendstern4688Nessuna valutazione finora

- Aspirateur Bosch GAS 55 M AFC - Manuel PDFDocumento19 pagineAspirateur Bosch GAS 55 M AFC - Manuel PDFBoulangerNessuna valutazione finora

- Bosch GST 18v ManualDocumento13 pagineBosch GST 18v ManualmanishNessuna valutazione finora

- Bosch GMS 120Documento9 pagineBosch GMS 120Ronald SubangNessuna valutazione finora

- Hand Held Circular Saw Gks 7000 123745 06016760k1Documento76 pagineHand Held Circular Saw Gks 7000 123745 06016760k1yuswan212Nessuna valutazione finora

- Bosch GWS 10-125 ManualDocumento16 pagineBosch GWS 10-125 ManualAlberto CapchaNessuna valutazione finora

- GKS 66 X Professional: OBJ - BUCH-2048-002.book Page 1 Tuesday, November 24, 2015 3:34 PMDocumento49 pagineGKS 66 X Professional: OBJ - BUCH-2048-002.book Page 1 Tuesday, November 24, 2015 3:34 PMDumitrescu MihaiNessuna valutazione finora

- 1.5. 800W GSB 20-2 Re BoscDocumento89 pagine1.5. 800W GSB 20-2 Re BoscNirundorn UdomphenNessuna valutazione finora

- Bosch YOUseries DrillDocumento408 pagineBosch YOUseries DrillСергей ГордейNessuna valutazione finora

- Bosch GCO220 User ManualDocumento72 pagineBosch GCO220 User Manualmichael manzanoNessuna valutazione finora

- Manual de Esmeril Bosch de 4.5 GWS 18-125Documento76 pagineManual de Esmeril Bosch de 4.5 GWS 18-125sinar peru sacNessuna valutazione finora

- O273079v21 160992A40T 201710Documento54 pagineO273079v21 160992A40T 201710cosmin_xfNessuna valutazione finora

- Bosch GAM 220 MFDocumento241 pagineBosch GAM 220 MFGustavo CorreiaNessuna valutazione finora

- Manual GST 8000 E PTDocumento61 pagineManual GST 8000 E PTGustavo CorreiaNessuna valutazione finora

- Bosch Drill ManualDocumento71 pagineBosch Drill ManualVenkat SubramanianNessuna valutazione finora

- Bosch GDM 13 34 ProDocumento46 pagineBosch GDM 13 34 Protaufik sajaNessuna valutazione finora

- Manual Taladro Bosch InalambricoDocumento80 pagineManual Taladro Bosch InalambricoMauroNessuna valutazione finora

- Installation Manual - Ceiling Ducted (High&Low Static Pressure) - 60Hz - AVD-07 - 54 - P00540Q - 201803-V01Documento22 pagineInstallation Manual - Ceiling Ducted (High&Low Static Pressure) - 60Hz - AVD-07 - 54 - P00540Q - 201803-V01Leonardo RamirezNessuna valutazione finora

- Bosch GBM 10Documento143 pagineBosch GBM 10Mustafa KutanisNessuna valutazione finora

- C ParaleloDocumento3 pagineC ParaleloCésar Benavente-PecesNessuna valutazione finora

- GSB Professional: 10 - 10 RE - 13 - 13 RE - 16 - 16 REDocumento75 pagineGSB Professional: 10 - 10 RE - 13 - 13 RE - 16 - 16 RECristian Camilo Rubiano CotameNessuna valutazione finora

- WEEI2002 AAaa 530087796Documento4 pagineWEEI2002 AAaa 530087796jomakerNessuna valutazione finora

- Gho 2682Documento11 pagineGho 2682nicehornetNessuna valutazione finora

- Bosch GBH 2-26Documento261 pagineBosch GBH 2-26Laurentiu BaiuNessuna valutazione finora

- A6WP - Bizhub 3320 - PM PDFDocumento25 pagineA6WP - Bizhub 3320 - PM PDFAndrew KudrikNessuna valutazione finora

- Manual Multierramineta GOP 40-30Documento325 pagineManual Multierramineta GOP 40-307013131870131318Nessuna valutazione finora

- GrinderDocumento66 pagineGrinderRhyan EdwinNessuna valutazione finora

- Art Combitrim PDFDocumento13 pagineArt Combitrim PDFTom RosterNessuna valutazione finora

- Bosch GBH 180-LI Rotary HammerDocumento211 pagineBosch GBH 180-LI Rotary Hammerc55076894931Nessuna valutazione finora

- Bosch Drill OperationDocumento39 pagineBosch Drill Operationoka PradanaNessuna valutazione finora

- 7 Segment Display Interfacing With Arm7Documento12 pagine7 Segment Display Interfacing With Arm7Rahi SarkarNessuna valutazione finora

- Rotopercutor Bosch GBH 240Documento233 pagineRotopercutor Bosch GBH 240Laurentiu BaiuNessuna valutazione finora

- CWC120 CK160000282 3x230V 60 HZ La FazendaDocumento24 pagineCWC120 CK160000282 3x230V 60 HZ La FazendaMariana HerreraNessuna valutazione finora

- O331245v21 160992A5JG 202001Documento58 pagineO331245v21 160992A5JG 202001xdd broNessuna valutazione finora

- Cutter-Marble - Bosch GDM13-34Documento79 pagineCutter-Marble - Bosch GDM13-34tamilmanoharNessuna valutazione finora

- YA212A IND.: Service ManualDocumento18 pagineYA212A IND.: Service Manualmrv8outboardNessuna valutazione finora

- GSR 120-LI ProfessionalDocumento63 pagineGSR 120-LI ProfessionalBrunoLuyaNessuna valutazione finora

- Impact Drill GSB 500 Re 128148 06012161f8 PDFDocumento63 pagineImpact Drill GSB 500 Re 128148 06012161f8 PDFRb SarangNessuna valutazione finora

- Manual Bosch GLM 40Documento442 pagineManual Bosch GLM 40Alessandro AquinoNessuna valutazione finora

- Fm140a Service ManualDocumento22 pagineFm140a Service Manualairmaster100% (2)

- Parts List: RB-456-C12DDocumento14 pagineParts List: RB-456-C12DSidratul MuntahaNessuna valutazione finora

- O323264v21 160992A51Z 201909Documento119 pagineO323264v21 160992A51Z 201909TatianaNessuna valutazione finora

- EinhellDocumento128 pagineEinhellAnonymous t9zWrllKPNessuna valutazione finora

- Manual - Operation GSB 10 REDocumento15 pagineManual - Operation GSB 10 REajannifarNessuna valutazione finora

- ALU Series Service Parts List: 24 Volt Alternator Replacement ListDocumento3 pagineALU Series Service Parts List: 24 Volt Alternator Replacement ListJacksonNessuna valutazione finora

- JBF 3Documento6 pagineJBF 3Sherozia IrakliyNessuna valutazione finora

- Sierra Sable GSA 1100Documento167 pagineSierra Sable GSA 11007013131870131318Nessuna valutazione finora

- Usermanual AI W5 1 (3 6 8) P1 EU ESSDocumento51 pagineUsermanual AI W5 1 (3 6 8) P1 EU ESSMunkh NasanNessuna valutazione finora

- BUSH 1433: General Information CRT DifferencesDocumento5 pagineBUSH 1433: General Information CRT DifferencesFec Kko RaNessuna valutazione finora

- Bosch Amoladora GWS 9-125SDocumento297 pagineBosch Amoladora GWS 9-125SfacugomezNessuna valutazione finora

- Lincoln Coolarc-Spare PartsDocumento4 pagineLincoln Coolarc-Spare PartsZsolt KovacsNessuna valutazione finora

- KT913Documento5 pagineKT913solerviNessuna valutazione finora

- OSRAM Reference Flyer A5 v12Documento4 pagineOSRAM Reference Flyer A5 v12solerviNessuna valutazione finora

- Worx Sonicrafter XW679Documento76 pagineWorx Sonicrafter XW679solerviNessuna valutazione finora

- BMW Carplay Head Unit Instruction v3.0Documento10 pagineBMW Carplay Head Unit Instruction v3.0solerviNessuna valutazione finora

- SI 38B0A 001 ENG - Czech - TDocumento1 paginaSI 38B0A 001 ENG - Czech - TsolerviNessuna valutazione finora

- Si 7C26C 000 EngDocumento1 paginaSi 7C26C 000 EngsolerviNessuna valutazione finora

- NEXUS 7-Speed Internal Hub W/coaster BrakeDocumento1 paginaNEXUS 7-Speed Internal Hub W/coaster BrakesolerviNessuna valutazione finora

- Ee10 N 1 PTH: VCC-3V3Documento2 pagineEe10 N 1 PTH: VCC-3V3solerviNessuna valutazione finora

- Floureon TS-838 Electronic Energy Meter PDFDocumento22 pagineFloureon TS-838 Electronic Energy Meter PDFsolerviNessuna valutazione finora

- Universal 4 Buttons Cloning 433mhz Remote Control Key PDFDocumento2 pagineUniversal 4 Buttons Cloning 433mhz Remote Control Key PDFsolerviNessuna valutazione finora

- Professional Enlgish - Working and Socializing Internationally Today (UNED)Documento267 pagineProfessional Enlgish - Working and Socializing Internationally Today (UNED)solerviNessuna valutazione finora

- Nexus 7 Installation Service ManualDocumento2 pagineNexus 7 Installation Service ManualsolerviNessuna valutazione finora

- Omron MC-246 PDFDocumento1 paginaOmron MC-246 PDFsolerviNessuna valutazione finora

- Dielectric ChartDocumento1 paginaDielectric ChartapichanNessuna valutazione finora

- Silver Dynamic: Key BenefitsDocumento2 pagineSilver Dynamic: Key BenefitssolerviNessuna valutazione finora

- Muller Kamins - Device Electronics For Integrated Circuits 3ed - Solutions ManualDocumento144 pagineMuller Kamins - Device Electronics For Integrated Circuits 3ed - Solutions ManualsolerviNessuna valutazione finora

- Semiconductores de Potencia de Gap Ancho en Semiconductores de Potencia de Gap Ancho en Organismos InternacionalesDocumento19 pagineSemiconductores de Potencia de Gap Ancho en Semiconductores de Potencia de Gap Ancho en Organismos InternacionalessolerviNessuna valutazione finora

- Gupta Et Al. 1996 - Microstrip Lines and Slotlines. 2nd Ed.Documento547 pagineGupta Et Al. 1996 - Microstrip Lines and Slotlines. 2nd Ed.solervi100% (9)

- E WasteDocumento1 paginaE WasteIkmal AhmadNessuna valutazione finora

- Toughswitch Poe DsDocumento8 pagineToughswitch Poe DsEdgarEmilioPalmaMarroquínNessuna valutazione finora

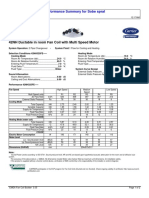

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDocumento2 pagine42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87Nessuna valutazione finora

- SDI PDP Repair Manual: Colour TelevisionDocumento77 pagineSDI PDP Repair Manual: Colour TelevisiontommyyNessuna valutazione finora

- B777 FuelDocumento0 pagineB777 Fuelandrinjo100% (3)

- Broadcom Wireless Card TutorialDocumento124 pagineBroadcom Wireless Card TutorialopsinghNessuna valutazione finora

- Current-Source DC-DC ConverterDocumento53 pagineCurrent-Source DC-DC ConverterpepenitoNessuna valutazione finora

- Bluetooth SPKDocumento15 pagineBluetooth SPKCZUBILLAGANessuna valutazione finora

- Capacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics ApplicationsDocumento11 pagineCapacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics Applicationssueng666Nessuna valutazione finora

- Manual de Uso Rm6Documento82 pagineManual de Uso Rm6Leonel Márquez EspinozaNessuna valutazione finora

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: ALLDocumento23 pagineAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: ALLRameswar PradhanNessuna valutazione finora

- Optoma Ex631 SchematicDocumento48 pagineOptoma Ex631 SchematicBoopathi RameshNessuna valutazione finora

- Track Pads Usa Fresadoras Varias MarcasDocumento2 pagineTrack Pads Usa Fresadoras Varias MarcasHECTOR ESCALLONNessuna valutazione finora

- Wire Rope SlingsDocumento27 pagineWire Rope Slingsnasirfahim100% (1)

- Preconnectorized "Stubbed" Hardware: Features and BenefitsDocumento12 paginePreconnectorized "Stubbed" Hardware: Features and BenefitsSergio Denis UCNessuna valutazione finora

- Casio TV-1800Documento16 pagineCasio TV-1800Berenice LopezNessuna valutazione finora

- Ta27 8891Documento494 pagineTa27 8891jose coco100% (2)

- Series: Pumping Unit Technical DataDocumento2 pagineSeries: Pumping Unit Technical DataRolandas GaudėšiusNessuna valutazione finora

- Deep Sea Ro-Ro ShippingDocumento14 pagineDeep Sea Ro-Ro Shippingmayuresh100% (1)

- Chapter-2 Operation of 140T CraneDocumento114 pagineChapter-2 Operation of 140T CraneSaptarshi PalNessuna valutazione finora

- Eee 1Documento77 pagineEee 1Sanyok GanzNessuna valutazione finora

- CVC Inline Filling PresentationDocumento26 pagineCVC Inline Filling PresentationFithrul Mubarok100% (1)

- 9 - Timer ProgrammingDocumento39 pagine9 - Timer ProgrammingSamuelClementNessuna valutazione finora

- Siemens RAB21 (3 Hızlı Daikin Heating Ve Veya Cooling Yapabilir)Documento6 pagineSiemens RAB21 (3 Hızlı Daikin Heating Ve Veya Cooling Yapabilir)Bora ÜnsalNessuna valutazione finora

- D3 Remote ManualDocumento2 pagineD3 Remote ManualbobanmiNessuna valutazione finora

- RT22-677 Cooking 592 E-84 E-85 ErrorDocumento2 pagineRT22-677 Cooking 592 E-84 E-85 ErrorpasantitoNessuna valutazione finora

- ZXM8 TPLDD120 600Documento2 pagineZXM8 TPLDD120 600SOLUCIONES ENERGETICAS Y PROCESOS INNOVADORESNessuna valutazione finora

- FIG. 1828T: Gate Valve Ansi Class 800 Threaded End, Forged SteelDocumento1 paginaFIG. 1828T: Gate Valve Ansi Class 800 Threaded End, Forged SteelAlejandro NietoNessuna valutazione finora

- Skilsaw Sawsquatch ManualDocumento56 pagineSkilsaw Sawsquatch ManualAhmedy PNessuna valutazione finora

- Impact - 5 2Documento8 pagineImpact - 5 2Demianus DemmaNessuna valutazione finora