Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aquagalv: Water Borne Inorganic Zinc Silicate

Caricato da

livefreakTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aquagalv: Water Borne Inorganic Zinc Silicate

Caricato da

livefreakCopyright:

Formati disponibili

AQUAGALV®

Water Borne Inorganic Zinc Silicate PC 154

FEATURES • LOW VOC – LESS THAN 10g/L

• HIGH ZINC CONTENT RESULTING IN EXCELLENT CORROSION PROTECTION

• EXTREMELY HARD WEARING AND ABRASION RESISTANT

• SUITABLE FOR SURFACES EXPOSED TO TEMPERATURES UP TO 400°C

• SUPERIOR TO GALVANISING IN MARINE ENVIRONMENTS

• NON FLAMMABLE

• LOW ODOUR

®

USES AQUAGALV is a two pack self-curing water borne inorganic zinc silicate suitable for use as a permanent primer and

as a prime coating underneath specified topcoats. It is the first choice when requiring a long term protective coating

for steel structures that need to meet Green Building Council “GREENSTAR” requirements.

®

When cured, AQUAGALV exhibits a matt grey appearance and is an exceptionally hard coating that resists damage

during transport.

®

AQUAGALV provides excellent corrosion resistant properties for conditions of severe weathering including marine

exposure, moderate chemical environments and hydrocarbon contact. The service life may be extended or a

decorative finish can be achieved by overcoating with a suitable topcoat.

SPECIFICATIONS Conforms to AS2312:2004 – Systems “IZS2” and “IZS3”

RESISTANCE GUIDE

HEAT RESISTANCE -50°C to 400°C dry heat. ALKALIS Resists alkali environments when

overcoated with epoxy topcoats.

WEATHERABILITY Withstands the most severe

weathering conditions. SALTS Suitable for splash/spillage. Not suitable

for immersed conditions.

SOLVENTS Insoluble in chlorinated hydrocarbons

(dry), aromatics, ketones & esters, WATER Excellent when fully cured. Refer to

most petroleum solvents and oil Drying Characteristics.

crudes.

ABRASION Excellent.

ACIDS Not recommended for acid conditions.

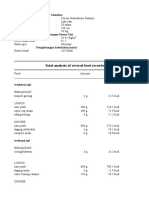

TYPICAL PROPERTIES AND APPLICATION DATA

CLASSIFICATION Water Borne Inorganic Zinc Silicate APPLICATION CONDITIONS Min Max

FINISH Matt Air Temperature 10°C 35°C

COLOUR Grey Substrate Surface Temperature 7°C 50°C

Relative Humidity 30% 80%

COMPONENTS Two

SOLIDS BY VOLUME Not Applicable

VOC < 10 g/L Min Max Recom.

FLASH POINT N/A Wet film per coat (microns) 150 375 225

POT LIFE 4 hours (25°C, 50% RH, 10.77Lmixed)1 Dry film per coat (microns) 50 125 75

ZINC IN DRY FILM 86% minimum by hydrogen evolution

MIXING RATIO (W/W) Liquid : 1.00 Powder : 3.47 SUITABLE SUBSTRATES Abrasive blast cleaned steel.

THINNER No Thinning Required TOPCOATS Most two pack products.

PRODUCT CODE 812-89837 Liquid

812-33225 Powder APPLICATION METHODS Conventional spray.

Drying characteristics at 75 microns dry film thickness

Overcoat

2

Temperature Humidity Touch Handle Full Cure Min Max

3

25° C 50% 30 Minutes 4 Hours 48 Hours 24 Hours Indefinite

These figures are given as a guide only, as ventilation, film thickness, humidity, thinning and other factors will influence the rate of drying.

1

Beyond this time the mixed material may still be liquid, however it MUST not be used. Refer to PRECAUTIONS section over.

2

At this time the product can be put into service, however coating properties will continue to develop after this period and will reach full

performance in 7 – 10 days.

3

This coating must not be overcoated or exposed to atmospheric moisture (eg. condensation, dew, rainfall) before this time.

TYPICAL SPREADING RATE AT RECOMMENDED A spreading rate of 6.0 sq. metres per litre corresponds to 75

DRY FILM BUILD microns dry film thickness assuming no losses. Due to the porous

nature of zinc silicate coatings it is not possible to directly relate

practical spreading rate with theoretical volume solids as is

common with conventional coatings.

December 2009 Page 1 of 3 PC 154

AQUAGALV®

TYPICAL SYSTEMS

(The typical systems are offered as a guide only and are not to be used as a specification. It is recommended that the specific needs of a project

be discussed with a Dulux Protective Coatings Consultant.)

SURFACE PREPARATION GUIDE SYSTEM DRY FILM THICKNESS

®

STEEL Abrasive blast to AS1627.4 Class 2.5 1st Coat AQUAGALV 75 Microns

®

2nd Coat DUREMAX GPE 100 Microns

®

3rd Coat AQUANAMEL 25 Microns

®

1st Coat AQUAGALV 75 Microns

SURFACE PREPARATION Round off all rough welds, sharp edges and remove weld spatter. Remove grease, oil and other

contaminants in accordance with AS1627.1. Rinse surface thoroughly to remove acid or alkali

contamination. Abrasive blast clean to a minimum of AS1627.4 Class 2.5 with a blast profile of 35-50

microns. Immersed steel must be prepared to AS1627.4 Class 3. Remove all dust by brushing or

vacuum cleaning. Apply product before any surface deterioration occurs.

APPLICATION All equipment should be flushed sequentially: firstly with acetone, then with Ethanol (Methylated

Spirits) and then water before use.

Use an air powered stirrer to thoroughly mix the liquid component and ensure it is uniform before addition

of the zinc. Slowly add the zinc in the supplied ratio under continuous stirring until all of the zinc powder

is fully incorporated and a smooth mix is obtained. Strain the mix through a 30-60 mesh screen. Push dry

and larger zinc particles through the mesh with a clean, dry paint brush, re-mix and repeat the straining

process. Discard any large zinc particles caught on the mesh. Mix only enough product that may be

used within the pot life period. An air powered automatic agitation stirrer should be used for the entire

time the product is being applied. All incoming air for pressure pots should be free of moisture, oil

vapour, or any other contamination. Compressors should be fitted with moisture and oil separators.

Inorganic Zinc coatings are very heavy liquids and spray techniques need to be adapted accordingly.

BRUSH/ROLLER Apply the mixed coating by brush technique to edges and welds for "stripe coating" as called for in the

specification. Not recommended for brush application to large areas. It is recommended to use new

brushes that have been rinsed in Ethanol (Methylated Spirits) and then water prior to using.

CONVENTIONAL SPRAY Do not Thin. The atomising pressure at the gun should be adjusted between 2.7 - 4 bar (40-60 p.s.i.) so

that the fan is uniform across the width of the spray pattern. The material flow rate through the gun

should be adjusted so that a solid stream of zinc flows from the material nozzle for approximately 200mm

(8”) to 254mm (10”) before dropping. Adjust the width of the fan so that an even thickness of coating is

deposited to the substrate. Having the fan too wide or the atomising air pressure too high will result in

uneven film thickness, dry spray at edges and the possibility of mud cracking in the middle sections of

the spray pattern. Apply even, wet coats in a multiple pass method (wet on wet) to achieve the wet film

thickness required for the specified dry film thickness. Fluid hoses should be as short as possible and

12mm minimum bore.

Ensure paint pressure pots are be fitted with a continuous operation mixing impeller / paddle to

ensure that the mixed zinc does not settle during application.

Typical Set-up

Graco Delta Gun: 1.8mm (239543)

Pressure at Pot: 70-105 kPa (10-15 p.s.i.)

Pressure at Gun: 380-415 kPa (55-60 p.s.i.)

®

SITE REPAIR/ TOUCH UP For small areas of repair use AQUAGALV . For broader areas or for repairs over weld joints use

® ®

Zincanode 202 Epoxy Zinc rich primer, where the primer is not going to be topcoated, and Zincanode

®

402 where topcoating is required (Please note that there is a colour difference between AQUAGALV

®

and Zincanode 202.)

Small areas of repair can be prepared by hand and power tool methods to AS 1627.2 St 3 to remove

damaged coating and to ensure the leading edges of surrounding coatings are "feathered". Apply the

® ® ®

AQUAGALV , Zincanode 202 or Zincanode 402 by brush or spray method in one coat to achieve a

minimum of 75 microns DFT. Large areas of damaged coating should be removed by Abrasive Blast

cleaning to AS 1627.4 Class 2.5 and re-applied as per the original specification.

December 2009 Page 2 of 3 PC 154

AQUAGALV®

PRECAUTIONS This is an industrial product designed for use by experienced Protective Coating applicators. Where

conditions may require variation from the recommendations on this Product Data Sheet contact your

nearest Dulux® Protective Coatings Specialist for advice prior to painting. Do not apply in conditions

outside the parameters stated in this document without the express written consent of Dulux® Australia.

Freshly mixed material must not be added to material that has been mixed for some time. The rate of

cure is dependent upon temperature. Do not apply at temperatures below 10°C. Do not apply at relative

humidity above 80%, below 30% or when the surface is less than 3°C above the dewpoint.

If the recommended profile is not achieved there is a risk that the coating will not adhere to the substrate

once cured. When excessive builds are applied the zinc will sink to the bottom of the wet film and leave

the surface glossy and hazy in appearance. The product is prone to mud crack in corners where it has

been excessively overbuilt (Greater than 300μm). Mist coating with water to assist cure is NOT allowed.

Minimum top-coating interval of 24hrs, during this period the coating MUST be protected from moisture

(eg. condensation, dew, rainfall).Top-coating before this interval can result in adhesion failures at the

primer/topcoat interface, and cohesive failure within the primer layer.

If the atmospheric temperature is very low and the humidity high (above 80%) then crystals of resin may

form on the surface of the coating. This is likely to occur if condensation forms on the surface during

curing. Before top-coating these crystals need to be removed by abrading (scotch brite sufficient) and

then thoroughly water washing and drying. Care MUST be taken to ensure the application equipment is

totally free of any solvent contamination. Low humidity will affect the rate of cure. Topcoats of a

®

saponifiable nature such as alkyds must never be applied directly to AQUAGALV . Material that has been

mixed for a period longer than the stated pot life of 4 hours may appear to still be suitable for use and will

form a film of normal appearance, however this material must NOT be used as the protective properties of

the coating will be compromised.

Do not exceed 150 microns DFT in one application. If applied below 30% relative humidity or onto a very

hot surface, curing will be retarded and may even be prevented. When the relative humidity is below 30%

contact a Dulux® Protective Coatings Specialist prior to applying the product. Product should not be

thinned.

CLEAN UP Clean all equipment by thoroughly flushing with water and then Ethanol (Methylated Spirits). All gun parts

can be soaked in water overnight to remove dried on product. If these parts are not cleaned within 24hrs

they may require soaking in caustic, however this can also damage the metal and should not be done

regularly.

OVERCOATING Aged coating should be tested for lifting by a method appropriate for the coating thickness, for example

‘X’ cut or cross-hatch methods. If it lifts, remove it. The surface must be free of oil, grease, zinc corrosion

products and other contaminants. High-pressure water wash at 8.3 to 10.3 MPa (1,200 - 1,500 p.s.i.) to

remove loosely adhering chalk and dust.

It is not recommended to recoat aged AQUAGALV with itself. Use ZINCANODE® 202.

®

SAFETY PRECAUTIONS Read Data Sheet, Material Safety Data Sheet and any precautionary labels on containers.

STORAGE Both components are NOT classified as dangerous goods for transport or storage Store in a bunded

area under cover. Keep containers closed at all times. Avoid moisture contamination of Zinc Dust

component.

HANDLING Avoid moisture contamination of the Zinc Dust component as gassing may occur. As with any chemical,

ingestion, inhalation and prolonged or repeated skin contact should be avoided by good occupational

work practice. Eye protection approved to AS1337 should be worn where there is a risk of splashes

entering the eyes. Always wash hands before smoking, eating, drinking or using the toilet.

USING Use with good ventilation and avoid inhalation of spray mists and fumes. If risk of inhalation of spray

mists exists, wear combined organic vapour/particulate respirator. When spray painting, users should

comply with the provisions of the respective State Spray Painting Regulations.

FLAMMABILITY Not Flammable

WELDING Avoid inhalation of fumes if welding surfaces coated with this paint. Grind off coating before welding.

MATERIAL SAFETY DATA SHEET is available from Customer Service (132377) or www.duluxprotectivecoatings.com.au

Dulux Protective Coatings a division of DuluxGroup (Australia) Pty Ltd PACKAGING Available in 10.77 litre pack

1956 Dandenong Road, Clayton 3168 TRANSPORTATION WEIGHT 2.85 kg/litre (Average of components)

A.B.N. 67 000 049 427 DANGEROUS GOODS Liquid: Non Dangerous Goods

Dulux, Aquagalv, Duremax, and Aquanamel are registered trademarks. DuluxGroup is a

Powder: Non Dangerous Goods

trademark.

Any advice, recommendation, information, assistance or service provided by DULUX Australia in relation to goods manufactured by it or their use and

application is given in good faith and is believed by Dulux to be appropriate and reliable. However, any advice, recommendation, information, assistance or

service provided by Dulux is provided without liability or responsibility PROVIDED THAT the foregoing shall not exclude, limit, restrict or modify the right

entitlements and remedies conferred upon any person or the liabilities imposed upon Dulux by any condition or warranty implied by Commonwealth, State or

Territory Act or ordinance void or prohibiting such exclusion limitation or modification. Products can be expected to perform as indicated in this sheet so

long as applications and application procedures are as recommended. Specific advice should be sought from Dulux for application in coastal areas and for

large projects to ensure proper performance.

December 2009 Page 3 of 3 PC 154

Potrebbero piacerti anche

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Zincanode 304: Solvent Borne Inorganic Zinc SilicateDocumento3 pagineZincanode 304: Solvent Borne Inorganic Zinc SilicatelivefreakNessuna valutazione finora

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocumento2 pagineZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNessuna valutazione finora

- Luxepoxy UHB: Ultra High Build EpoxyDocumento2 pagineLuxepoxy UHB: Ultra High Build EpoxylivefreakNessuna valutazione finora

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocumento2 pagineLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakNessuna valutazione finora

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocumento2 pagineLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNessuna valutazione finora

- Duremax Gpe ZP Aug 2018Documento3 pagineDuremax Gpe ZP Aug 2018Biju_PottayilNessuna valutazione finora

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Documento2 pagineLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNessuna valutazione finora

- Luxafloor Rollcoat: High Build High Solids Epoxy Floor CoatingDocumento3 pagineLuxafloor Rollcoat: High Build High Solids Epoxy Floor CoatinglivefreakNessuna valutazione finora

- Durebild HSE: High Build Two Pack Epoxy CoatingDocumento3 pagineDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNessuna valutazione finora

- Steel Shield 1200Documento2 pagineSteel Shield 1200Moin AltafNessuna valutazione finora

- Duremax GPE: General Purpose Epoxy CoatingDocumento4 pagineDuremax GPE: General Purpose Epoxy CoatinglivefreakNessuna valutazione finora

- Zinc Rich 1p pc102Documento2 pagineZinc Rich 1p pc102livefreakNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- Durebild Ste Glass Flake pc239Documento3 pagineDurebild Ste Glass Flake pc239livefreakNessuna valutazione finora

- P3) Water Based Universal PrimerDocumento2 pagineP3) Water Based Universal PrimerBrandon LimNessuna valutazione finora

- Revchem HRC 870Documento3 pagineRevchem HRC 870marciobispoalmeidaNessuna valutazione finora

- Pds Epilux 218 VocDocumento2 paginePds Epilux 218 VocmuthukumarNessuna valutazione finora

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocumento2 pagineGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNessuna valutazione finora

- k2) Luxatherm5200 5219Documento2 paginek2) Luxatherm5200 5219Syed FaridNessuna valutazione finora

- l2) Steelshield1200 3041Documento2 paginel2) Steelshield1200 3041Syed FaridNessuna valutazione finora

- EPILUX 850 SF VOC Jan-2017Documento2 pagineEPILUX 850 SF VOC Jan-2017PraveenNessuna valutazione finora

- Apexior-No 1 Aug 2018Documento2 pagineApexior-No 1 Aug 2018emadsafy20002239Nessuna valutazione finora

- EPIMASTIC 5100-March 2019 Version 2Documento2 pagineEPIMASTIC 5100-March 2019 Version 2PraveenNessuna valutazione finora

- Microsoft Word - L3 - Epilux82Documento2 pagineMicrosoft Word - L3 - Epilux82vitharvanNessuna valutazione finora

- d2) Epilux218 4267Documento2 pagined2) Epilux218 4267Syed FaridNessuna valutazione finora

- 19.abcolux18hs Content 237Documento3 pagine19.abcolux18hs Content 237MbimbikNessuna valutazione finora

- ROYALPOXY UW 410-tdsDocumento3 pagineROYALPOXY UW 410-tdsSyed FaridNessuna valutazione finora

- Epilux 82: Product DescriptionDocumento2 pagineEpilux 82: Product DescriptionMoin AltafNessuna valutazione finora

- Metalshield Premium Aug 2018Documento2 pagineMetalshield Premium Aug 2018Biju_PottayilNessuna valutazione finora

- Coaltar Epoxy - Epilux5 - 0474Documento2 pagineCoaltar Epoxy - Epilux5 - 0474GautamNessuna valutazione finora

- Luxatherm 6200Documento2 pagineLuxatherm 6200PraveenNessuna valutazione finora

- Epoxy Primer - Epilux610 - 4079Documento2 pagineEpoxy Primer - Epilux610 - 4079GautamNessuna valutazione finora

- Steelshield Ve: Product DescriptionDocumento2 pagineSteelshield Ve: Product DescriptionMoin AltafNessuna valutazione finora

- Pds Zincanode 690 VocDocumento2 paginePds Zincanode 690 VocmuthukumarNessuna valutazione finora

- Epilux 155Documento2 pagineEpilux 155Allana100% (1)

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocumento3 pagineDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNessuna valutazione finora

- Apcotherm Epn 200Documento2 pagineApcotherm Epn 200Moin AltafNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsMuthuKumarNessuna valutazione finora

- Zincanode 620 Voc v1 Jan 2018Documento2 pagineZincanode 620 Voc v1 Jan 2018Moin AltafNessuna valutazione finora

- Apcodur Ehb 500-VocDocumento2 pagineApcodur Ehb 500-VocMoin AltafNessuna valutazione finora

- Pds Zincanode 620 VocDocumento2 paginePds Zincanode 620 VocmuthukumarNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocumento2 pagineLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNessuna valutazione finora

- Luxaprime1200 Alkyd QD PrimerDocumento2 pagineLuxaprime1200 Alkyd QD PrimerGurdeep Sungh AroraNessuna valutazione finora

- Epilux 218: Product DescriptionDocumento2 pagineEpilux 218: Product DescriptionMoin AltafNessuna valutazione finora

- Steel Shield 1100Documento3 pagineSteel Shield 1100Moin AltafNessuna valutazione finora

- Epilux 800Documento2 pagineEpilux 800anandNessuna valutazione finora

- g9) Berger Apcofine 905 - 8096Documento2 pagineg9) Berger Apcofine 905 - 8096Wasek SarkerNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- Pds Luxol 1000 VocDocumento2 paginePds Luxol 1000 VocmuthukumarNessuna valutazione finora

- Epilux 155Documento2 pagineEpilux 155Tejinder KumarNessuna valutazione finora

- b3) Zincanode685 4586Documento2 pagineb3) Zincanode685 4586Syed FaridNessuna valutazione finora

- Fosroc Renderoc LA: Constructive SolutionsDocumento2 pagineFosroc Renderoc LA: Constructive SolutionsshahidNessuna valutazione finora

- Epilux 78Documento2 pagineEpilux 78MuthuKumar100% (1)

- E3) Epimastic5100 4292Documento2 pagineE3) Epimastic5100 4292Syed FaridNessuna valutazione finora

- Galvit EZ P40.01: Previous Suitable CoatDocumento2 pagineGalvit EZ P40.01: Previous Suitable CoatDamian RoweNessuna valutazione finora

- Apcoline 4100Documento2 pagineApcoline 4100Moin AltafNessuna valutazione finora

- KCC DataSheet LT313ENGDocumento2 pagineKCC DataSheet LT313ENGNasir AnsariNessuna valutazione finora

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Documento2 pagineLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNessuna valutazione finora

- Luxafloor Rollcoat: High Build High Solids Epoxy Floor CoatingDocumento3 pagineLuxafloor Rollcoat: High Build High Solids Epoxy Floor CoatinglivefreakNessuna valutazione finora

- Zinc Rich 1p pc102Documento2 pagineZinc Rich 1p pc102livefreakNessuna valutazione finora

- Ceilcote 2000 Flakeline+ds+engDocumento4 pagineCeilcote 2000 Flakeline+ds+englivefreakNessuna valutazione finora

- Durebild Ste Glass Flake pc239Documento3 pagineDurebild Ste Glass Flake pc239livefreakNessuna valutazione finora

- Ceilcote 140 Flakeline+ds+engDocumento4 pagineCeilcote 140 Flakeline+ds+englivefreakNessuna valutazione finora

- Ceilcote 180 Flakeline+ds+engDocumento4 pagineCeilcote 180 Flakeline+ds+englivefreakNessuna valutazione finora

- Ceilcote 222GF Flakeline+ds+engDocumento4 pagineCeilcote 222GF Flakeline+ds+englivefreakNessuna valutazione finora

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocumento3 pagineDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNessuna valutazione finora

- Ceilcote 505 Coroline+ds+engDocumento4 pagineCeilcote 505 Coroline+ds+englivefreakNessuna valutazione finora

- Ceilcote 64 Lining: Description ApplicationDocumento3 pagineCeilcote 64 Lining: Description ApplicationlivefreakNessuna valutazione finora

- Ceilcote 6640 Ceilcrete+ds+engDocumento4 pagineCeilcote 6640 Ceilcrete+ds+englivefreakNessuna valutazione finora

- Ceilcote 262 Flakeline+ds+engDocumento2 pagineCeilcote 262 Flakeline+ds+englivefreakNessuna valutazione finora

- Ceilcote 242AR Flakeline+ds+engDocumento4 pagineCeilcote 242AR Flakeline+ds+englivefreakNessuna valutazione finora

- Duremax GPE: General Purpose Epoxy CoatingDocumento4 pagineDuremax GPE: General Purpose Epoxy CoatinglivefreakNessuna valutazione finora

- Interline 984Documento4 pagineInterline 984livefreakNessuna valutazione finora

- Durebild HSE: High Build Two Pack Epoxy CoatingDocumento3 pagineDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNessuna valutazione finora

- Guia Laboratorio Refrigeración-2020Documento84 pagineGuia Laboratorio Refrigeración-2020soniaNessuna valutazione finora

- Jis C 8156-2017, EngDocumento32 pagineJis C 8156-2017, Eng7620383tlNessuna valutazione finora

- Amniotic Fluid DisordersDocumento16 pagineAmniotic Fluid DisordersLytiana Williams100% (2)

- Oseco Elfab BioPharmaceuticalDocumento3 pagineOseco Elfab BioPharmaceuticalAdverNessuna valutazione finora

- 5219-PRP Support Tool CounsellingDocumento10 pagine5219-PRP Support Tool CounsellingRodhi AnshariNessuna valutazione finora

- Complete Denture TechniquesDocumento6 pagineComplete Denture TechniquesJohn Hyunuk ChoNessuna valutazione finora

- Level 9 - Unit 34Documento7 pagineLevel 9 - Unit 34Javier RiquelmeNessuna valutazione finora

- CA02 ParchamentoJVMDocumento6 pagineCA02 ParchamentoJVMJohnrey ParchamentoNessuna valutazione finora

- Industrial SpecialtiesDocumento103 pagineIndustrial SpecialtiesRahul ThekkiniakathNessuna valutazione finora

- Human Evolution SE Skull Analysis GizmoDocumento9 pagineHuman Evolution SE Skull Analysis GizmoTamia WashingtonNessuna valutazione finora

- CEB 3103 Geotechnical Engineering I: Soil Water and Water FlowDocumento39 pagineCEB 3103 Geotechnical Engineering I: Soil Water and Water FlowKia MahiksinhoNessuna valutazione finora

- CHAPTER 5 - STATES OF MATTER (S) Edit20152016Documento12 pagineCHAPTER 5 - STATES OF MATTER (S) Edit20152016PAKK20622P Syarifah Nor Izzah binti Syed Abd HamidNessuna valutazione finora

- Resume Rough DraftDocumento1 paginaResume Rough Draftapi-392972673Nessuna valutazione finora

- Narrative Pathophysiology of PregnancyDocumento2 pagineNarrative Pathophysiology of PregnancyMarvin ChulyaoNessuna valutazione finora

- Network Access Control Quiz3 PDFDocumento2 pagineNetwork Access Control Quiz3 PDFDaljeet SinghNessuna valutazione finora

- 2 Avaliação Edros 2023 - 7º Ano - ProvaDocumento32 pagine2 Avaliação Edros 2023 - 7º Ano - Provaleandro costaNessuna valutazione finora

- ICT ContactCenterServices 9 Q1 LAS3 FINALDocumento10 pagineICT ContactCenterServices 9 Q1 LAS3 FINALRomnia Grace DivinagraciaNessuna valutazione finora

- All About 304 Steel (Properties, Strength, and Uses)Documento7 pagineAll About 304 Steel (Properties, Strength, and Uses)ZebNessuna valutazione finora

- File3 PDFDocumento119 pagineFile3 PDFikkemijnnaam0% (1)

- Tugas Gizi Caesar Nurhadiono RDocumento2 pagineTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNessuna valutazione finora

- API Filter Press - Test ProcedureDocumento8 pagineAPI Filter Press - Test ProcedureLONG LASTNessuna valutazione finora

- February 2023 PROGRAM OF THE MPLEDocumento8 pagineFebruary 2023 PROGRAM OF THE MPLEDale Iverson LacastreNessuna valutazione finora

- WEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCODocumento4 pagineWEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCOBianca LouiseNessuna valutazione finora

- NICUDocumento15 pagineNICUkavyarkrnagarNessuna valutazione finora

- Rekapan Belanja JKNDocumento5 pagineRekapan Belanja JKNAPOTEK PUSKESMAS MALEBERNessuna valutazione finora

- Cardiac PacemakerDocumento25 pagineCardiac PacemakerDhvij KmlNessuna valutazione finora

- Raffles Hotel Jakarta Pricelist 2020Documento2 pagineRaffles Hotel Jakarta Pricelist 2020kielachela aaNessuna valutazione finora

- CSF LeaksDocumento3 pagineCSF LeaksDrTarek Mahmoud Abo KammerNessuna valutazione finora

- Profile of RespondentsDocumento36 pagineProfile of RespondentsPratibha SharmaNessuna valutazione finora

- Final Plant Diversity Lab ReportDocumento6 pagineFinal Plant Diversity Lab Reportapi-508660724Nessuna valutazione finora

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDa EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseValutazione: 3.5 su 5 stelle3.5/5 (69)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDa EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsValutazione: 3.5 su 5 stelle3.5/5 (13)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDa EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNessuna valutazione finora

- Spoiled Rotten America: Outrages of Everyday LifeDa EverandSpoiled Rotten America: Outrages of Everyday LifeValutazione: 3 su 5 stelle3/5 (19)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDa EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionValutazione: 4 su 5 stelle4/5 (812)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 3.5 su 5 stelle3.5/5 (35)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDa EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildValutazione: 4.5 su 5 stelle4.5/5 (44)

- Fire Season: Field Notes from a Wilderness LookoutDa EverandFire Season: Field Notes from a Wilderness LookoutValutazione: 4 su 5 stelle4/5 (142)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDa EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldValutazione: 4 su 5 stelle4/5 (596)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDa EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorValutazione: 4.5 su 5 stelle4.5/5 (137)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 5 su 5 stelle5/5 (5)

- The Other End of the Leash: Why We Do What We Do Around DogsDa EverandThe Other End of the Leash: Why We Do What We Do Around DogsValutazione: 5 su 5 stelle5/5 (65)

- The Hawk's Way: Encounters with Fierce BeautyDa EverandThe Hawk's Way: Encounters with Fierce BeautyValutazione: 4.5 su 5 stelle4.5/5 (19)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignDa EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignValutazione: 4 su 5 stelle4/5 (19)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDa EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsValutazione: 4 su 5 stelle4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDa EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDa EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeValutazione: 4.5 su 5 stelle4.5/5 (6)

- Come Back, Como: Winning the Heart of a Reluctant DogDa EverandCome Back, Como: Winning the Heart of a Reluctant DogValutazione: 3.5 su 5 stelle3.5/5 (10)

- The Mind of Plants: Narratives of Vegetal IntelligenceDa EverandThe Mind of Plants: Narratives of Vegetal IntelligenceValutazione: 4.5 su 5 stelle4.5/5 (11)