Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Allocating Device: TP101 Festo Didactic

Caricato da

olivia curtisDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Allocating Device: TP101 Festo Didactic

Caricato da

olivia curtisCopyright:

Formati disponibili

A-3

Exercise 1

Pneumatics Subject

Allocating device Title

Operation of a single-acting cylinder Training aims

Direct actuation of a single-acting cylinder

Use of a 3/2-way directional control valve

Application of a service unit with on-off valve and manifold

Drawing the displacement-step diagram in simplified form without Problem

signal lines

Designing and drawing the displacement-step diagram with the help

of the exercise description and positional sketch

Comparing one’s own solution with the one proposed

Selection of the required components from the mobile laboratory

workstation

Insert the components selected in the Festo Didactic profile plate. It

is advisable to arrange the components as on the circuit diagram

Pipe up your circuit with the air pressure switched off

Switch on air supply and carry out a function check

Follow up (see part C)

Dismantle your control system and put the components back in order

in the mobile laboratory workstation

TP101 • Festo Didactic

A-4

Exercise 1

Problem description The allocating device supplies aluminium valve blanks to a machining

station.

By operating a push button, the piston rod of the single-acting cylinder

(1A) is made to advance. After releasing the actuating button, the piston

rod returns.

Fig. 1/1: Positional sketch

1A

TP101 • Festo Didactic

C-3

Solution 1

Allocating device

Fig. 1/2a: Circuit diagram

Detailed representation of service unit with on-off valve

TP101 • Festo Didactic

C-4

Solution 1

Fig. 1/2b: Circuit diagram

Simplified representation of service unit with on-off valve

Fig. 1/3: Displacement-

step diagram

1

Simplified representation without signal lines

1 Displacement-step diagram

From exercise 6 on, all diagrams are shown complete with signal lines.

TP101 • Festo Didactic

C-5

Solution 1

The description of the solution makes reference to the circuit diagram Solution description

and the displacement-step diagram. With regard to the circuit diagram,

we distinguish between the detailed representation and the simplified

representation.

Service unit with on-off valve and manifold

Component (0Z2) represents the manifold (8 connections) (see also

circuit design). Component (0Z1) symbolises the service unit and on-off

valve.

Initial position (first vertical line in the motion diagram)

2

The initial position of the cylinder and valves can be ascertained from

the circuit diagram. The internal spring of cylinder (1A) holds the piston

in the retracted end position. The volume of air in the cylinder is evacu-

ated via the 3/2-way valve (1S).

Step 1-2

Through operating the 3/2-way valve (1S) via the push button, air is

applied to the chamber on the piston rod side of cylinder (1A). The pis-

ton rod of the cylinder advances, and pushes a valve blank out of the

magazine. If valve (1S) continues to be operated, the piston rod remains

in the forward end position.

Step 2-3

After releasing the valve actuating button, the air in the cylinder is ex-

hausted via the 3/2-way valve (1S). The force of the return spring

pushes the piston back to its initial position. The valve blanks are sup-

plied from the magazine by gravity.

Marginal condition

If the push button (1S) is briefly pressed, piston rod (1A) advances only

part of the way and returns immediately.

2 Initial position

The components assume the specified states required to start the sequence of op-

erations, i.e. the on-off valve (0Z1) is switched on and the system pressurised. If the

start button (1S.) is pressed, the piston rod of the cylinder (1A) advances.

TP101 • Festo Didactic

C-6

Solution 1

Fig. 1/4: Circuit design

Components list Components Description

0Z1 Service unit with on-off valve

0Z2 Manifold

1A Single-acting cylinder

1S 3/2-way valve with push button, normally closed

Apart from the above mentioned components, you will need the Festo

Didactic profile plate on which to build the systems, as well as a source

of compressed air.

Follow up Switch off the compressed air supply by means of the 3/2-way on-off

valve (0Z1). Exchange the connections on the 3/2-way push button

valve (1S).

Re-check the operation of the control system after switching on the

compressed air.

TP101 • Festo Didactic

Potrebbero piacerti anche

- p2714 Opel 6t45Documento5 paginep2714 Opel 6t45Валентин ДNessuna valutazione finora

- MCS-011 Solved Assignment 2015-16 IpDocumento12 pagineMCS-011 Solved Assignment 2015-16 IpJigar NanduNessuna valutazione finora

- Droop Vs Iso Control Modes For Gas TurbinesDocumento3 pagineDroop Vs Iso Control Modes For Gas TurbinesArdvark100% (1)

- Bell Desk-2Documento96 pagineBell Desk-2Arrow PrasadNessuna valutazione finora

- OTM Reports FTI Training ManualDocumento78 pagineOTM Reports FTI Training ManualAquib Khan100% (2)

- Renovation Modernization and Uprating of Hydro Power StationsDocumento5 pagineRenovation Modernization and Uprating of Hydro Power StationsAbhijeet SinghNessuna valutazione finora

- 1.1 Mechatronics Technology PRESENTATIONDocumento46 pagine1.1 Mechatronics Technology PRESENTATIONInnocent katengulaNessuna valutazione finora

- Is 15707 2006Documento23 pagineIs 15707 2006anupam789Nessuna valutazione finora

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDocumento39 pagine02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezeNessuna valutazione finora

- On Brushless Motor.Documento45 pagineOn Brushless Motor.KUMAR_AMIT199189% (9)

- Grafcet Step 7Documento34 pagineGrafcet Step 7Mazarel AurelNessuna valutazione finora

- Tailless AircraftDocumento17 pagineTailless AircraftVikasVickyNessuna valutazione finora

- Lab - State SpaceDocumento15 pagineLab - State SpaceSohaib Sajid100% (1)

- 1757 Um007 - en P PDFDocumento160 pagine1757 Um007 - en P PDFfitasmounirNessuna valutazione finora

- Two Degrees of Freedom PID Control For Active Vibration Control of StructuresDocumento9 pagineTwo Degrees of Freedom PID Control For Active Vibration Control of StructuresndjedouiNessuna valutazione finora

- Assignment 2010Documento6 pagineAssignment 2010Rafael BarriosNessuna valutazione finora

- Control Lab Report Experiment No. 05Documento2 pagineControl Lab Report Experiment No. 05Nahin AminNessuna valutazione finora

- 十字路口交通灯PLC控制程序的研究与设计Documento35 pagine十字路口交通灯PLC控制程序的研究与设计Zeng LinNessuna valutazione finora

- KL 200 PDFDocumento4 pagineKL 200 PDFghenriquezNessuna valutazione finora

- InTech-Omnidirectional Mobile Robot Design and ImplementationDocumento18 pagineInTech-Omnidirectional Mobile Robot Design and ImplementationSenthil KumarNessuna valutazione finora

- Dan Saks C++ in Embedded SystemsDocumento24 pagineDan Saks C++ in Embedded SystemsarunksahaNessuna valutazione finora

- Diploma Project 1st Presentation PPT TemplateDocumento13 pagineDiploma Project 1st Presentation PPT TemplateJay PatelNessuna valutazione finora

- Real-Time Fuzzy Microcontroller PDFDocumento6 pagineReal-Time Fuzzy Microcontroller PDFsamyNessuna valutazione finora

- Using LEGO NXT Mobile Robots With LabVIEW For Undergraduate Courses On MechatronicsDocumento7 pagineUsing LEGO NXT Mobile Robots With LabVIEW For Undergraduate Courses On MechatronicsPravin BeheraNessuna valutazione finora

- Ball and Beam1Documento6 pagineBall and Beam1Saeed AsiriNessuna valutazione finora

- A Seminar ON Compliant Mechanisms: Kaje Rajesh S. En. No. 30802009 TY B-Tech Mechanical EngineeringDocumento21 pagineA Seminar ON Compliant Mechanisms: Kaje Rajesh S. En. No. 30802009 TY B-Tech Mechanical EngineeringRajesh Shyamrao Kaje100% (2)

- System Identification Using MATLABDocumento37 pagineSystem Identification Using MATLABMarwan Elmahdi89% (9)

- Holonomic Control of A Robot With An Omni-Directional DriveDocumento7 pagineHolonomic Control of A Robot With An Omni-Directional DriveGuilherme Pohl100% (1)

- Simple, Real-Time Obstacle Avoidance Algorithm For Mobile RobotsDocumento6 pagineSimple, Real-Time Obstacle Avoidance Algorithm For Mobile RobotsStefania MihaiNessuna valutazione finora

- Trajectory Modification Considering Dynamic Constraints of Autonomous RobotsDocumento6 pagineTrajectory Modification Considering Dynamic Constraints of Autonomous RobotsOswin SoNessuna valutazione finora

- Mechatronics (2015) Unit IIDocumento38 pagineMechatronics (2015) Unit IIkishan100% (1)

- Class 2: Servomotors - Basics & Working: Ice 3015: Control System ComponentsDocumento19 pagineClass 2: Servomotors - Basics & Working: Ice 3015: Control System ComponentsArchit DasguptaNessuna valutazione finora

- HX711 Weighing Sensor ModuleDocumento2 pagineHX711 Weighing Sensor ModuleuqinkNessuna valutazione finora

- C++ Project: BombermanDocumento10 pagineC++ Project: BombermanTsepo ShataNessuna valutazione finora

- Me6702 Mechatronics Unit 4Documento23 pagineMe6702 Mechatronics Unit 4Niyas AhamedNessuna valutazione finora

- BigDog OverviewDocumento22 pagineBigDog Overviewroky23Nessuna valutazione finora

- IpbalanceDocumento1 paginaIpbalancephuceltnNessuna valutazione finora

- Feedback 38-004Documento15 pagineFeedback 38-004aditya narayan shuklaNessuna valutazione finora

- TM1112TRE.433-EnG - Robotics Technology Mapp ROBOTICS - V5.2Documento52 pagineTM1112TRE.433-EnG - Robotics Technology Mapp ROBOTICS - V5.2Bhavesh BharambeNessuna valutazione finora

- Project Report: Optical Character Recognition Using Artificial Neural NetworkDocumento9 pagineProject Report: Optical Character Recognition Using Artificial Neural NetworkRichard JamesNessuna valutazione finora

- Trajectory Planning - MelchiorriDocumento140 pagineTrajectory Planning - MelchiorrirrqNessuna valutazione finora

- Switched Systems, Stability of Switched Systems in Sense of LyapunovDocumento200 pagineSwitched Systems, Stability of Switched Systems in Sense of LyapunovMamdouh KhudaydusNessuna valutazione finora

- Gryphon EC Final ReportDocumento12 pagineGryphon EC Final Reportsanjiv0909Nessuna valutazione finora

- Project Year Design A Disk Type: Tool Magazine For A CNC MachineDocumento46 pagineProject Year Design A Disk Type: Tool Magazine For A CNC MachineIustina LacatusNessuna valutazione finora

- Extra Exercise Pneumatics Sequence CircuitDocumento1 paginaExtra Exercise Pneumatics Sequence CircuitJ.m.MoraNessuna valutazione finora

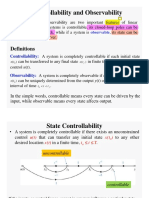

- Controllability and ObservabilityDocumento20 pagineControllability and ObservabilityAya FlyahNessuna valutazione finora

- Z.H. Sikder University of Science and Technology: 'Mobile Application Project"Documento11 pagineZ.H. Sikder University of Science and Technology: 'Mobile Application Project"omit senNessuna valutazione finora

- Multi-Dimensional Vision System CV-X/XG-X SeriesDocumento20 pagineMulti-Dimensional Vision System CV-X/XG-X SeriesJahidul IslamNessuna valutazione finora

- Corexy 04926139Documento11 pagineCorexy 04926139CicciputtNessuna valutazione finora

- How To Make Mobile Controlled Robot Using BluetoothDocumento11 pagineHow To Make Mobile Controlled Robot Using BluetoothAvian WorkshopsNessuna valutazione finora

- PLC Question BankDocumento3 paginePLC Question BankAjay kumarNessuna valutazione finora

- Bode Plot ExamplesDocumento3 pagineBode Plot ExamplesZaidoon MohsinNessuna valutazione finora

- Modeling and Control of 2-DOF Robot Arm: November 2018Documento9 pagineModeling and Control of 2-DOF Robot Arm: November 2018Lavinia CuldaNessuna valutazione finora

- A Generic RTOS Model For Real-Time Systems Simulation With SystemCDocumento6 pagineA Generic RTOS Model For Real-Time Systems Simulation With SystemCnithin s gowdaNessuna valutazione finora

- BLDC Sinusoidal ControlDocumento6 pagineBLDC Sinusoidal ControlOctavian MîrţiNessuna valutazione finora

- Design of A Safe and Smart Medicine BoxDocumento13 pagineDesign of A Safe and Smart Medicine BoxAnonymous UXBSV13cNessuna valutazione finora

- Testing StationDocumento4 pagineTesting StationJairo Vásquez0% (1)

- A New Design 6T Full Adder Circuit Using Novel 2T XNOR GatesDocumento7 pagineA New Design 6T Full Adder Circuit Using Novel 2T XNOR GatesdycsteiznNessuna valutazione finora

- 060 Actuators For RobotsDocumento69 pagine060 Actuators For RobotsMohamad YazidNessuna valutazione finora

- MicroMouse and Random Maze Generator ArticleDocumento9 pagineMicroMouse and Random Maze Generator ArticleAdrian QuinteroNessuna valutazione finora

- SS Lab ManualDocumento48 pagineSS Lab ManualKannan RNessuna valutazione finora

- Ball and Beam AssignmentDocumento4 pagineBall and Beam AssignmentBalayogi GNessuna valutazione finora

- Adaptive Cruise Control Using Model Predictive ControllerDocumento3 pagineAdaptive Cruise Control Using Model Predictive ControllerInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Indrum Qualica en PDFDocumento183 pagineIndrum Qualica en PDFVeronicaNistorNessuna valutazione finora

- Copy Ball and Beam Report XDXDDocumento5 pagineCopy Ball and Beam Report XDXDEdu AguirreNessuna valutazione finora

- Omron Microswitch PDFDocumento283 pagineOmron Microswitch PDFJosephus Ravanera100% (1)

- Advanced Control SystemDocumento1 paginaAdvanced Control Systemsaxenamohit_853663Nessuna valutazione finora

- Reductoare MotoareDocumento243 pagineReductoare MotoareDragosNessuna valutazione finora

- Input Station For Laser Cutter: TP101 Festo DidacticDocumento13 pagineInput Station For Laser Cutter: TP101 Festo Didacticsudesh_bhugaloo0% (1)

- Suzuki B-King Indicator Mod CompleteDocumento9 pagineSuzuki B-King Indicator Mod Completehookuspookus1Nessuna valutazione finora

- (TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529Documento109 pagine(TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529jeffersonNessuna valutazione finora

- Activation and Deactivation of CatalystsDocumento16 pagineActivation and Deactivation of Catalystsshan0214Nessuna valutazione finora

- Circuito PCB Control Pedal V3 TerminadoDocumento1 paginaCircuito PCB Control Pedal V3 TerminadoMarcelo PereiraNessuna valutazione finora

- Item Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkDocumento3 pagineItem Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkBittudubey officialNessuna valutazione finora

- Fm-II Quiz 1 19-20 - Section1 - Set1Documento2 pagineFm-II Quiz 1 19-20 - Section1 - Set1nivedithashetty0123Nessuna valutazione finora

- Limak 2017 Annual ReportDocumento122 pagineLimak 2017 Annual Reportorcun_ertNessuna valutazione finora

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsDocumento32 pagineA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueNessuna valutazione finora

- AN127Documento32 pagineAN127piyushpandeyNessuna valutazione finora

- 2ND 3RD Typical Floor Plan PDFDocumento1 pagina2ND 3RD Typical Floor Plan PDFSamuel ZaraNessuna valutazione finora

- Libeskind Daniel - Felix Nussbaum MuseumDocumento6 pagineLibeskind Daniel - Felix Nussbaum MuseumMiroslav MalinovicNessuna valutazione finora

- 2g SSV Drive Test Report 154128 - Yos - SudrsoDocumento8 pagine2g SSV Drive Test Report 154128 - Yos - SudrsohimmuraaNessuna valutazione finora

- Wear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialDocumento5 pagineWear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialRing MasterNessuna valutazione finora

- Seminar Report ON "Linux"Documento17 pagineSeminar Report ON "Linux"Ayush BhatNessuna valutazione finora

- Ex Delta Ex Delta - Dia: OVAL CorporationDocumento8 pagineEx Delta Ex Delta - Dia: OVAL CorporationDaniela GuajardoNessuna valutazione finora

- CambuzaDocumento45 pagineCambuzaMia Marin Pâslaru100% (2)

- Avaya Call History InterfaceDocumento76 pagineAvaya Call History InterfaceGarrido_Nessuna valutazione finora

- QBDC - Season 5-RulebookDocumento50 pagineQBDC - Season 5-RulebookHggvgNessuna valutazione finora

- Building 16 PrintDocumento112 pagineBuilding 16 PrintNALEEMNessuna valutazione finora

- Green Line TransformerDocumento4 pagineGreen Line TransformerwakasNessuna valutazione finora

- 3 3 1 Material Sorter Design ChallengeDocumento3 pagine3 3 1 Material Sorter Design Challengeapi-343534512Nessuna valutazione finora