Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Annex II - Inspection Check Lists

Caricato da

KidanemariamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Annex II - Inspection Check Lists

Caricato da

KidanemariamCopyright:

Formati disponibili

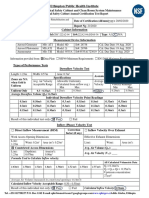

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

Annex II

Inspection Checklists

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

EARTHWORKS IN EMBANKMENT INSPECTION CHECKLIST

Testing:

Has the Contractor carried out the following tests at the specified frequency for borrow material:

Plasticity Index? Yes No

Maximum Dry Density? Yes No

Deleterious Content: as directed by Engineer? Yes No

Moisture Content: 1 test / 400m3? Yes No

CBR: 1 test / 1000m3? Yes No

Sand Replacement Field Density: 1 test / 2000m2? Yes No

Comments: _____________________________________________________________________

_____________________________________________________________________

Are the Contractor’s test results conforming for:

% compaction (min. 95%)? Yes No

PI (max 30) and L.L (max. 60)? Yes No

Comments: _____________________________________________________________________

_____________________________________________________________________

For the section inspected, are the following properties of the earthworks satisfactory based on a

visual examination:

Organic matter content? Yes No

Moisture content? Yes No

Plasticity? Yes No

Field Density (percent compaction): Min. 95 % of MDD? Yes No

Comments: _____________________________________________________________________

_____________________________________________________________________

Signed: Date:

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

CAPPING LAYER INSPECTION CHECKLIST

Has the Contractor prepared the surface? Yes No

Testing:

Has the Contractor carried out the following tests at the specified frequency:

Plasticity Index? 1 test / 2000m 3? Yes No

Maximum Dry Density? 1 Test / 2000m ? 3

Yes No

Deleterious Content: as directed by Engineer? Yes No

Moisture Content: 1 test / 400m ? 3

Yes No

CBR: 1 test / 1000m3? Yes No

Sand Replacement Field Density: 1 test / 1000m2? Yes No

or 1 Test / 100m

Comments: ___________________________________________________________________

___________________________________________________________________

Are the Contractor’s test results conforming for:

California Bearing ratio Test (CBR):

Min. CBR 15%? Yes No

Plasticity and Swell:

Max. PI of 15%? Yes No

Max. Swell of 1.5%? Yes No

Grading Modulus (GM)?

Max. GM 0.75? Yes No

Field Density (percent compaction) : Yes No

Min. 95% of MDD?

Comments: _____________________________________________________________________

_____________________________________________________________________

Signed: ___________________________ Date ________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

SUB-BASE INSPECTION CHECKLIST

Has the Contractor prepared the surface? Yes No

Testing:

Has the Contractor carried out the following tests at the specified frequency:

Plasticity Index? 1 test / 2000m 3? Yes No

Maximum Dry Density? 1 Test / 1000m 3? Yes No

Deleterious Content: as directed by Engineer? Yes No

Moisture Content: 1 test / 500m 3? Yes No

CBR Test: 1 test / 2500m3? Yes No

Grading: As directed by the engineer? Yes No

Sand Replacement Field Density: 1 test / 1000m2? Yes No

or 1 Test / 100m

Comments: _____________________________________________________________________

_____________________________________________________________________

Are the Contractor’s test results conforming for:

California Bearing ratio Test (CBR): Yes No

Min. CBR 45%?

Plasticity and swell: Max. PI 10? Yes No

Max. LL 30? Yes No

Max. LS 5%? Yes No

Max. Swell 0.5%? Yes No

Grading Modulus (GM): Max. {GM 2.5; Min. GM Yes No

1.50}?

Field Density (percent compaction) : Yes No

Min. 95% of MDD?

Comments: _____________________________________________________________________

_____________________________________________________________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

BASE COURSE INSPECTION CHECKLIST

Has the Contractor prepared the surface? Yes No

Testing:

Has the Contractor carried out the following tests at the specified frequency:

10% Fine Aggregate Crushing Test (10%FACT) and

Aggregate Crushing value (ACV)? Yes No

1 Test / 1000m3

Flakiness Index: 1 Test/1000m3 Yes No

Grading? 1 Test/200m3 or

Yes No

2 Tests per day’s production

Atterberg limits of –425 micron aggregate?

Yes No

1 Test/1000m3

CBR Tests: 1 Test / 1000m3 Yes No

Maximum Dry Density? 1 Test / 1000m3? Yes No

Sand Replacement Field Density: 1 test / 500m2? No

Yes

or 1 Test / 50m

Comments:

________________________________________________________________________

Are the Contractor’s test results conforming for:

10% FACT: Dry min. 110 KN and

Yes No

Wet / Dry Ratio: min 75%?

ACV: Max. 25 %? Yes No

Atterberg Limits: Max. PI 6? Yes No

Max. LL 25? Yes No

Max. LS 3 %? Yes No

Flakiness Index : Max. 30 Yes No

Field Density (percent compaction) :

Yes No

Min. 98% of MMDD?

Comments:

_____________________________________________________________________

_____________________________________________________________________

Signed: ________________ Date ______________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

PRIME COAT INSPECTION CHECKLIST

1. Has the surface been properly prepared to receive the Yes No

binder?

2. Is the surface Dry? Yes No

3. Have the proportions of cut back kept as decided? Yes No

4. Is the rate of application decided? Yes No

5. Is the arrangement for measuring temp of cut back Yes No

available?

6. Is the arrangement for measuring rate of application Yes No

including trays & Balance is there?

7. Is the barricading arrangement made? Yes No

8. Is the blotting material arranged? Yes No

Comments:

______________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

__

Are the Contractor’s applications procedures conforming for?

Is tray test done: one test per 500m2 (50m full width)? Yes No

Is application temperature of prime kept at: 45 – 60oC? Yes No

Comments:

_____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Signed: _______________________________ Date: ___________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

PIPE CULVERTS INSPECTION CHECKLIST

Has the pipe culvert location been correctly marked out Yes No

according to the Drawings?

Has the pipe culvert site been excavated according to Yes No

the Drawings?

Have the bed levels of the excavation been checked for Yes No

conformance to the Drawings?

Comments: ___________________________________________________________________

_______________________________________________________________________

Have the bases of the headwalls been concreted Yes No

according to the Drawings?

Does the pipe bedding material conform? Yes No

Has the bedding material been suitably compacted? Yes No

Has the pipe manufacture provided a test certificate Yes No

showing delivered pipes conform?

Comments: ___________________________________________________________________

_______________________________________________________________________

Were the installed pipes free of defects, e.g. cracks, Yes No

exposed reinforcement?

Have the pipe invert levels been checked for Yes No

conformance to the Drawings?

Does the pipe slope conform to the Drawings? Yes No

Have the pipes been jointed correctly and collars Yes No

satisfactorily grouted?

Have the pipes been back filled according to Yes No

specifications?

Have the bricks for the headwalls been tested for Yes No

conformance to relevant clause of contract?

Is the brick work satisfactory? Yes No

Comments: ___________________________________________________________________

_____________________________________________________________________________.

Signed: _____________________________________ Date: _____________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

SLAB CULVERTS INSPECTION CHECKLIST

Has the slab culvert location been correctly marked out Yes No

according to the Drawings?

Has the slab culvert site is excavated according to the Drawings? Yes No

Have the bed levels of the excavation been checked for Yes No

conformance to the Drawings?

Has the surface of the bed for abutments been prepared and Yes No

cleaned properly prior to concreting?

Has the form work for concrete abutments been done correctly? Yes No

Has the proportion of concrete mix been correct? Yes No

Have the cubes for testing compressive strength been taken? Yes No

Does the compressive strength conform to Class? Yes No

Is the concrete poured in the slab prepared as specified a 1:2:4 Yes No

mix according the Drawings?

Is the concrete sampled at the frequency specified Yes No

Was the minimum compressive strength achieved? Yes No

Have the concrete slab surface levels been checked for Yes No

conformance with the Drawings?

Have the bricks for the abutments been checked for Yes No

conformance?

Is the brickwork satisfactory? Yes No

Are the levels at the top of the brickwork conforming to the Yes No

Drawings?

Have concrete bed blocks been cast according to the Drawings? Yes No

Is the concrete compressive strength in these blocks Yes No

conforming?

Have the top levels of the bed blocks been checked for Yes No

conformance to the drawings?

Has the shuttering been placed accordingly to the top slab Yes No

dimensions in the Drawings?

Is the reinforcing steel conforming to the requirements? Yes No

Is the reinforcing steel placed according to the drawings? Yes No

Is the concrete mixed transported placed compacted and cured? Yes No

Is the concrete sampled at the specified frequency? Yes No

Is the compressive strength conforming to the specified minimum Yes No

grade?

Is the slump of the concrete conforming? Yes No

Is the maximum temp. of the fresh concrete exceeds 400C? Yes No

Comments:_____________________________________________________________________

_____________________________________________________________________________.

Signed: _____________________________________ Date_____________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

FORMWORK INSPECTION CHECK LIST

LOCATION DATED:

CONTRACTORS’ INSPECTION REQUEST NO.

CONTRACTORS’ DRG OR SKETCH NO.

Sl No Description Yes No N.A.

1. Formwork design/drawing/sketch approved including de-

2. shuttering

Trial panel arrangements.

approved (if required)

3. Formwork alignment correct

4. Formwork levels correct, including screeds

5. Formwork dimensions correct

6. Formwork member spacing correct

7. Formwork member material quality acceptable

8. False work member sizes correct

9. False work member spacing correct

10 False work member material quality acceptable

11 Gaps between primary & secondary members

12 closed/wedged.

Face boarding/Plywood/Metal thickness correct.

13. Joints between panels closed (no gaps)

14. Joints between panels flush (no steps/lips)

15 Panel flatness acceptable

16 Gaps between secondary members and face panels closed

17 Tie rod material and sizes correct

18 Tie rod spacing correct.

19 Tie rods tight, face cones flush

20 Spacers between shutter surface tightly fitting.

21 Box outs, cast-in items, ducts fixed correct, securely.

22 Prestressing sheathing & vents, alignments & spacing of

23 supports acceptable

Empty sheathing secured against floatation

24 Pre-stressing anchorage positions & fixing acceptable

25 Chamfers/fillets sizes, straightness, fixing acceptable

26 Formwork clean

27 Formwork release oil material approved.

28 Formwork release oil applied correctly.

29 Construction joint preparation satisfactory

30 Contraction/expansion joint preparation satisfactory

31 Safe access constructed

32 Adequate work space provided for labour, equipment

33 Shutter vibrators (if required) location & fixing arrangements

approved.

For Contractor/ Name:_________________ Signed:_________ Date:____________

Consultant:

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

REINFORCEMENT INSPECTION CHECKLIST

LOCATION DATED:

CONTRACTORS’ INSPECTION REQUEST NO.

REF DRG. NO.

Sl No Yes No N.A.

1. Description

2. Working drawing checked and approved

3. Latest revision being used

4. Bar schedules approved

5. Reinforcing steel material approved

6. Bar bending & cutting satisfactory

7. Corrosion treatment of bars, if required, satisfactory

8. Bar sizes correct

9. Bar spacing correct

10 Bar lap lengths correct

11 Bar laps at correct locations

12 Bar tied as specified

13. Bar assembly rigid and adequately supported (including

spacers/chair supports).

14. Cover to bottom bars correct.

15 Cover to side bars correct

16 Cover to top bars correct

17 Cover blocks approved including fixing

Inspected by: Name:_________________ Signed:_________ Date:____________

(for Contractor)

Approved by: Name:_________________ Signed:_________ Date:____________

(Consultant)

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

INSPECTION CHECK LIST BEFORE APPROVAL TO CONCRETE

LOCATION DATED:

CONTRACTORS’ INSPECTION REQUEST NO.

Sl No Description Yes No N.A.

1. Method statement approved

2. Batching plant mixers in working order (separate dispenser for

admixture, if required, available)

3. Standby batcher in working order

4. Water, sand, coarse aggregate, cement, admixture approved.

5. Water, sand coarse aggregate, admixture, cement stock

sufficient.

6. Concrete conveying arrangement (including transit mixers)

available in working condition and of sufficient capacity.

7. Formwork approved

8. Reinforcement approved

9. Pre-stressing sheathing approved

10 Concreting equipment in working order

11 Standby crane, vibrators present

12 Tremie in working order (for under water work)

13. Concrete gang present, including carpenter, steel fixer,

mechanics and electricians.

14. Access provided

15 Safety arrangements adequate

16 Lighting provided

17 Communications between various points provided

18 Arrangements for arranging suspension/stoppage of concrete

provided.

19 Curing arrangements made

20 Laboratory notified

Inspected by: Name:_________________ Signed:_________ Date:____________

Approved by: Name:_________________ Signed:_________ Date:____________

(Consultant)

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

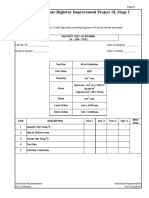

CHECKLIST FOR GRADING TEST

Road No.:__________________ Chainage: From: …….…… km to ……..……km

Name of Contractor:

Contractor’s Representative:______________________________________________________

Test Location: ____________ Chainage: _____________ Offset: _____________

Test No.: ______________ Test Date: ___________________

Does Contractor have correct test equipment? Yes No

Is test equipment calibrated? Yes No

Evidence of equipment sighted? Yes No

Comments:___________________________________________________________________

1) Whether Balance is of the required capacity and Yes No

required sensitivity?

2) Whether sample is in fairly dry Condition? Yes No

3) Whether adequate quantity of sample is taken Yes No

[depending upon the maximum size in the sample](for

63 mm size, Quantity of sample 100kg)

4) Whether, not more than the minimum weight is put on Yes No

individual sieve?

5) Whether all operations on one sieve is completed Yes No

before operation on other sieve has begun?

6) Whether sieving is continued for sufficient time? Yes No

Comments:____________________________________________________________

_____________________________________________________________________

Signed:_________________________________ Dated:_________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

CHECKLIST FOR AGGREGATE IMPACT VALUE TEST

Road No.:__________________ Chainage: From: …………… km to …….……km

Name of Contract:

Contractor’s Representative:______________________________________________________

Test Location: Chainage: ___________ Offset: _______________

Test No.: ______________ Test Date: _____________________

Does Contractor have correct test equipment? Yes No

Is test equipment calibrated? Yes No

Evidence of equipment sighted? Yes No

1) Whether sample is dried before test? Yes No

2) Whether Cup is filled with Aggregate correctly giving Yes No

requisite no. of blows?

3) Whether the guide bars are smooth for rammer to fall Yes No

freely?

4) Whether fall of rammer is as required? Yes No

5) Whether the time gap between consecutive falls is Yes No

maintained (1 second)?

6) Whether counter for counting nos. of falls working Yes No

properly?

7) Whether the samples after being subjected to impact is Yes No

sieved for enough time so that no appreciable fines are

still passing through 2.36 mm sieve?

8) Whether Average of two results test are taken for Yes No

reporting?

Comments:____________________________________________________________

_____________________________________________________________________

Signed: _________________________________ Dated:________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

CHECKLIST FOR MOISTURE DENSITY RELATIONSHIP

Road No.:______________ Chainage: From: ………..… km to ……………km

Name of Contract:

Contractor’s Representative:____________________________________________________

Test Location: Chainage: ___________ Offset: _____________

Test No.: ______________ Test Date: ___________________

Does Contractor have correct test equipment? Yes No

Is test equipment calibrated? Yes No

Evidence of equipment sighted? Yes No

1) Is sampled prepared correctly? Yes No

2) Is Proportion of Fraction (-20mm, 44.75 mm) Yes No

maintained?

3) Is the material compacted into mold correctly? Yes No

4) Is the mold under filled? Yes No

5) Is the mold overfilled by >10 mm? Yes No

6) Are a minimum of 3 points straddling OMC compacted? Yes No

7) Are the moisture content determined satisfactorily? Yes No

8) Is the Moisture Density curve drawn satisfactorily as a Yes No

parabolic curve?

9) Are the calculations checked? Yes No

Comments:_____________________________________________________________________

______________________________________________________________________________

___________________________________________________

Signed: _________________________________ Dated:________________

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Debre Markos – Debre Elias – Kuch Design and Build Road project, Ethiopian Roads Authority

Lot 1: Debre Markos – Debre Elias - Temcha (km0+000 – 75+000) Construction Supervision Manual (Draft), Dec 2019

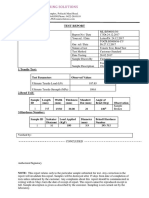

SAND REPLACEMENT FIELD DENSITY TEST CHECKLIST

Road No.:______________ Chainage: From: ……….… km to …….……km

Name of Contract: ____________________________________________________________

Contractor’s Representative:__________________________________

Test Location: Chainage: ___________ Offset: _______________

Test No.: ______________ Test Date: _____________________

Does Contractor have correct test equipment? Yes No

Is test equipment calibrated? Yes No

Evidence of equipment sighted? Yes No

Comments:_______________________________________________________________

________________________________________________________________________

Density Sand Clean? Yes No

Dry? Yes No

Correct grading? Yes No

Poured Correctly? Yes No

Weighing balance Level? Yes No

Wind protected? Yes No

Is balance read Yes No

correctly?

Moisture Content Determination Method : Yes No

Speedy? Yes No

Alcohol? Yes No

Oven? Yes No

Are calculations correct? Yes No

Have calculations been checked? Yes No

Comments:_______________________________________________________________

________________________________________________________________________

Signed:

Date:

Hong- Ik in JV with Lidet in sub-consultancy with G and Y Consultants

Potrebbero piacerti anche

- Paint Inspection:: Daily Coating Inspection ReportDocumento1 paginaPaint Inspection:: Daily Coating Inspection ReportEhsan KhanNessuna valutazione finora

- Report PaintDocumento1 paginaReport PaintEhsan KhanNessuna valutazione finora

- BSC Field Test ReportDocumento2 pagineBSC Field Test ReportSàkâtã ÁbéŕàNessuna valutazione finora

- Surface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerDocumento2 pagineSurface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerRekhis OussamaNessuna valutazione finora

- Establishing A Coating Maintenance Plan PDFDocumento11 pagineEstablishing A Coating Maintenance Plan PDFRicardo MendesNessuna valutazione finora

- Design of BridgeDocumento213 pagineDesign of BridgeKidanemariam75% (4)

- Piston RingDocumento43 paginePiston RingSudath Kularathna67% (3)

- Construction Testing Services Soils Compaction Testing by ASTM StandardsDocumento3 pagineConstruction Testing Services Soils Compaction Testing by ASTM StandardsChikadibia OkoroNessuna valutazione finora

- Concrete Pre-Construction Checklist: Second Edition - Revised 6/22/00Documento7 pagineConcrete Pre-Construction Checklist: Second Edition - Revised 6/22/00Diane Wetzel DialNessuna valutazione finora

- SOP For Bioburden TestDocumento2 pagineSOP For Bioburden TestBejoy KarimNessuna valutazione finora

- Karnataka Highway Project Viscosity TestDocumento1 paginaKarnataka Highway Project Viscosity TestKarumuri JayaramNessuna valutazione finora

- Weld Inspection Reporting ProcedureDocumento5 pagineWeld Inspection Reporting Proceduresharif1974Nessuna valutazione finora

- Corrosion Survey - Maintenance Painting ProjectDocumento8 pagineCorrosion Survey - Maintenance Painting ProjectAmit NimbalkarNessuna valutazione finora

- Maharashtra State Board Estimating and Costing Model AnswerDocumento16 pagineMaharashtra State Board Estimating and Costing Model AnswerDipankar NathNessuna valutazione finora

- Road Works - ChecklistDocumento3 pagineRoad Works - ChecklistHAKAN100% (1)

- SPYTL - Anti TermiteDocumento6 pagineSPYTL - Anti TermiteMohd TameziNessuna valutazione finora

- JC Ceiling PaintDocumento2 pagineJC Ceiling PaintGrace tpplNessuna valutazione finora

- Form Daily Report Painting (TOP COAT)Documento2 pagineForm Daily Report Painting (TOP COAT)alifaliminNessuna valutazione finora

- CHECKLIST FOR UPGRADING HIGHWAY PAVEMENTDocumento1 paginaCHECKLIST FOR UPGRADING HIGHWAY PAVEMENTIsmail MydeenNessuna valutazione finora

- Trial Paper HandoutDocumento13 pagineTrial Paper HandoutPradeep Kumar BowmarajuNessuna valutazione finora

- Env-F003 Environmental Performance ReportDocumento2 pagineEnv-F003 Environmental Performance ReportnagaaNessuna valutazione finora

- Site Inspection Report TemplateDocumento13 pagineSite Inspection Report TemplateGunprida Teu Bara OTAZENNessuna valutazione finora

- Test Report of BricksDocumento1 paginaTest Report of BricksKumar Abhishek67% (3)

- AISC Paint Inspection LOG (Use This One)Documento2 pagineAISC Paint Inspection LOG (Use This One)Richard100% (1)

- Sand Blasting ProcedureDocumento4 pagineSand Blasting Proceduresuria qaqcNessuna valutazione finora

- Attachment 3 Specific Gravity Test: (A) Calibration of PycnometerDocumento9 pagineAttachment 3 Specific Gravity Test: (A) Calibration of PycnometerFrezer AmareNessuna valutazione finora

- 1 PT CBRDocumento18 pagine1 PT CBRmihiretu TeferaNessuna valutazione finora

- MCQ Ucmp Unit Iii Chemical and Electro Chemical Energy Based ProcessesDocumento38 pagineMCQ Ucmp Unit Iii Chemical and Electro Chemical Energy Based ProcessesBollu SatyanarayanaNessuna valutazione finora

- Sealion Tiecoat DataDocumento4 pagineSealion Tiecoat DataSergeyNessuna valutazione finora

- Cube Format1Documento2 pagineCube Format1jyothis_joy8315Nessuna valutazione finora

- Anti Graffiti Paint PresentationDocumento10 pagineAnti Graffiti Paint PresentationpricettNessuna valutazione finora

- 4final ExaminationDocumento22 pagine4final ExaminationAlice KingsleighNessuna valutazione finora

- Chennai pipeline hydro testsDocumento4 pagineChennai pipeline hydro testsBoopathi DhanasekaranNessuna valutazione finora

- ASTM D5402-93 - Assessing Solvent Resistance of Coatings Using Solvent Rub.Documento2 pagineASTM D5402-93 - Assessing Solvent Resistance of Coatings Using Solvent Rub.Hoang Tuan Kiet100% (1)

- Fire Extinguisher ChecklistDocumento1 paginaFire Extinguisher ChecklistCirilo G. Amigo Jr.Nessuna valutazione finora

- LAMP. 4. 4. Draft Lifting Plan ProcedureDocumento12 pagineLAMP. 4. 4. Draft Lifting Plan ProcedureKONSULTAN RELOKASI RTGNessuna valutazione finora

- Measurement Contact Area of Crankshaft PinDocumento3 pagineMeasurement Contact Area of Crankshaft PinGeraldo GazetoNessuna valutazione finora

- CEP 304 Concrete Engineering Practical Quiz Batch 3 Date: 03/11/17 Time: 40 Min Name: - Roll NoDocumento2 pagineCEP 304 Concrete Engineering Practical Quiz Batch 3 Date: 03/11/17 Time: 40 Min Name: - Roll NoKaustubh SaysardarNessuna valutazione finora

- Daily Points To Recall (Day 6) : 1. GeneralDocumento5 pagineDaily Points To Recall (Day 6) : 1. GeneralGeorge KudiaborNessuna valutazione finora

- Cqi -12 - Audit Report of Aum Dacro 24.06.2023Documento37 pagineCqi -12 - Audit Report of Aum Dacro 24.06.2023vinay majukarNessuna valutazione finora

- Retarder DatasheetDocumento3 pagineRetarder DatasheetElisa Pavez A.Nessuna valutazione finora

- In-Process Inspection Report For Infant Incubator PartsDocumento1 paginaIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNessuna valutazione finora

- NDT Audit Findings or Observations at IPL DT 18th Aug 2020Documento3 pagineNDT Audit Findings or Observations at IPL DT 18th Aug 2020Muhammad AftabNessuna valutazione finora

- Test Reports PDFDocumento25 pagineTest Reports PDFAbdelhamid ElgasaierNessuna valutazione finora

- 1340 Hse FRM - 16 Crane Safety ChecklistDocumento1 pagina1340 Hse FRM - 16 Crane Safety Checklistvenkateshr.193Nessuna valutazione finora

- CL 0010 00Documento1 paginaCL 0010 00Ismail MydeenNessuna valutazione finora

- CLEANKEEP 5000 solvent free epoxy coating for drinking water tanksDocumento2 pagineCLEANKEEP 5000 solvent free epoxy coating for drinking water tankscelescopitoNessuna valutazione finora

- RCC Reynolds Construction Company (NIG.) LTD.: Ministry of Roads and Public Works Kenya Urban Road Authority (KURA)Documento1 paginaRCC Reynolds Construction Company (NIG.) LTD.: Ministry of Roads and Public Works Kenya Urban Road Authority (KURA)GikonyoNessuna valutazione finora

- Sub-Regional Transport Enhancement Project: Daily Chipping Spray Control (Tray Test)Documento8 pagineSub-Regional Transport Enhancement Project: Daily Chipping Spray Control (Tray Test)sakar shresthaNessuna valutazione finora

- 2 Assessment PacketDocumento15 pagine2 Assessment Packetnigussu temesganeNessuna valutazione finora

- National Highways Authority of IndiaDocumento2 pagineNational Highways Authority of IndiajitendraNessuna valutazione finora

- 275kV T TS 11 001 EnvProtReq SC 2021Documento3 pagine275kV T TS 11 001 EnvProtReq SC 2021Huang HanNessuna valutazione finora

- 22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesDocumento16 pagine22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesToufiq Bhati100% (2)

- Automotive Coaches and Components LTD Proto Gun Hardened Cab Final Inspection Check List PART No: GENERAL DIM A0Y45400 - Rev - #1 Sl. NoDocumento5 pagineAutomotive Coaches and Components LTD Proto Gun Hardened Cab Final Inspection Check List PART No: GENERAL DIM A0Y45400 - Rev - #1 Sl. NoSridharan VenkatNessuna valutazione finora

- CE155P-2 - Measurement & Quantification (Part 1)Documento56 pagineCE155P-2 - Measurement & Quantification (Part 1)pamelaNessuna valutazione finora

- WaterproofingDocumento4 pagineWaterproofingrounakmulikNessuna valutazione finora

- Ultrasonic TestingDocumento1 paginaUltrasonic TestingTaesik KimNessuna valutazione finora

- Gutters, Downpipes and Overflow: CalculatorDocumento5 pagineGutters, Downpipes and Overflow: CalculatorThaiNguyenNessuna valutazione finora

- FDD FormatsDocumento1 paginaFDD FormatsSandeep JoshiNessuna valutazione finora

- JC For Tile Installation On WallDocumento1 paginaJC For Tile Installation On WallGrace tpplNessuna valutazione finora

- Test ReportDocumento1 paginaTest Reportpramo_dassNessuna valutazione finora

- Exam Prep for:: Mastery Study Guide (Micro/Macro) for Economics: Principles and ApplicationsDa EverandExam Prep for:: Mastery Study Guide (Micro/Macro) for Economics: Principles and ApplicationsNessuna valutazione finora

- Cover Supervision Manual PDFDocumento1 paginaCover Supervision Manual PDFKidanemariamNessuna valutazione finora

- Annex - QAM Standard FormatsDocumento56 pagineAnnex - QAM Standard FormatsKidanemariamNessuna valutazione finora

- Annex III - Job Description PDFDocumento29 pagineAnnex III - Job Description PDFKidanemariamNessuna valutazione finora

- Quality Assurance Manual (Draft) : HONG-IK Engineering Consultants Co., LTDDocumento1 paginaQuality Assurance Manual (Draft) : HONG-IK Engineering Consultants Co., LTDKidanemariam100% (1)

- Cover Supervision Manual PDFDocumento1 paginaCover Supervision Manual PDFKidanemariamNessuna valutazione finora

- Annex I - Svrvey, Investigation and Design ChecklistDocumento12 pagineAnnex I - Svrvey, Investigation and Design ChecklistKidanemariam100% (1)

- DMDE Construction Supervision Manual (Draft) PDFDocumento54 pagineDMDE Construction Supervision Manual (Draft) PDFKidanemariam50% (2)

- DMDE Construction Supervision Manual (Draft) PDFDocumento54 pagineDMDE Construction Supervision Manual (Draft) PDFKidanemariam50% (2)

- Annex III - Job Description PDFDocumento29 pagineAnnex III - Job Description PDFKidanemariamNessuna valutazione finora

- Nptel ceTEI L14Documento6 pagineNptel ceTEI L14Arpit SinghNessuna valutazione finora

- Horizontal Alignment PDFDocumento15 pagineHorizontal Alignment PDFAnteneh Geremew100% (1)

- Road Construction StepsDocumento113 pagineRoad Construction StepsWiZZZ PLAYerNessuna valutazione finora

- Chapter 01 Road ConstructionDocumento134 pagineChapter 01 Road ConstructionKidanemariam75% (4)

- HM 2019TableofContentsDocumento74 pagineHM 2019TableofContentsKidanemariamNessuna valutazione finora

- Horizontal Alignment III: 16.2.1 Type of Transition CurveDocumento5 pagineHorizontal Alignment III: 16.2.1 Type of Transition Curveneeraj856Nessuna valutazione finora

- Aashto Publications-2019 Editorial Calendar Publications Released To DateDocumento2 pagineAashto Publications-2019 Editorial Calendar Publications Released To DateKidanemariamNessuna valutazione finora

- Nptel ceTEI L5Documento5 pagineNptel ceTEI L5Charan Prasad MNessuna valutazione finora

- Addis Ababa University RC T-Girder Bridge DesignDocumento1 paginaAddis Ababa University RC T-Girder Bridge DesignAbrehaAbayNessuna valutazione finora

- Sight Distance (Highway Engineering)Documento8 pagineSight Distance (Highway Engineering)MAND33P0% (1)

- Lec 9 PDFDocumento7 pagineLec 9 PDFSourabhThakurNessuna valutazione finora

- Nptel ceTEI L10 PDFDocumento8 pagineNptel ceTEI L10 PDFdkavitiNessuna valutazione finora

- Lec 11 PDFDocumento1 paginaLec 11 PDFBUKA RAMAKANTHNessuna valutazione finora

- Reinforcement Details: DiaphragmsDocumento1 paginaReinforcement Details: DiaphragmsKidanemariamNessuna valutazione finora

- Nptel ceTEI L05Documento4 pagineNptel ceTEI L05Mona Abu HamdNessuna valutazione finora

- Nptel ceTEI L07 PDFDocumento5 pagineNptel ceTEI L07 PDFdkavitiNessuna valutazione finora

- Martin Luthers Fascination With Ethiopian ChristianityDocumento3 pagineMartin Luthers Fascination With Ethiopian ChristianityKidanemariamNessuna valutazione finora

- Abegede by Aleqa Kidane Welde KifleDocumento36 pagineAbegede by Aleqa Kidane Welde KifleKidanemariam100% (1)

- FP TackifierDocumento8 pagineFP TackifierNguyễn Viết LươngNessuna valutazione finora

- Optiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorDocumento6 pagineOptiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorJuan Manuel Bedoya AcevedoNessuna valutazione finora

- Geotehnics of SoftsoilDocumento44 pagineGeotehnics of SoftsoilVinna RinayaniNessuna valutazione finora

- Assignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsDocumento61 pagineAssignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsHarshil JainNessuna valutazione finora

- Lec 3Documento14 pagineLec 3anuda09Nessuna valutazione finora

- Lec 6 Module 1Documento18 pagineLec 6 Module 1vedant chavanNessuna valutazione finora

- DEGASSING AGENT AF 100 - Ind1 - AngDocumento1 paginaDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDocumento1 paginaCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımNessuna valutazione finora

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocumento1 paginaASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNessuna valutazione finora

- Defects / Imperfections in Crystalline MaterialsDocumento41 pagineDefects / Imperfections in Crystalline Materialsjayant thakareNessuna valutazione finora

- 3M - VHB - Structural Glazing Tapes Technical GuideDocumento32 pagine3M - VHB - Structural Glazing Tapes Technical GuideMahadeva PrasadNessuna valutazione finora

- Lecture 3 Coagulation and FlocculationDocumento53 pagineLecture 3 Coagulation and FlocculationAbo-Khaled Mohammed100% (1)

- Group No 6 - Boge 2 Well Logging and FormationDocumento26 pagineGroup No 6 - Boge 2 Well Logging and FormationAlhaj MassoudNessuna valutazione finora

- Slon Magnetic Separators Applied in TheDocumento8 pagineSlon Magnetic Separators Applied in TheMulti DELLNessuna valutazione finora

- GasesDocumento38 pagineGaseshNessuna valutazione finora

- Rockwool Vs GlasswoolDocumento8 pagineRockwool Vs Glasswooly2karein100% (1)

- 2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions HyderabadDocumento4 pagine2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions Hyderabadnithish0% (1)

- Virtual Lab Bending Test AnalysisDocumento12 pagineVirtual Lab Bending Test AnalysisDKM3C-F1056-PRAVINESHNessuna valutazione finora

- Lecture 1Documento7 pagineLecture 1Dr. Aung Ko LattNessuna valutazione finora

- Determination of Alcohol Content in WineDocumento5 pagineDetermination of Alcohol Content in WineAna María Vallejo TorresNessuna valutazione finora

- Sai Water Tub AgreementDocumento67 pagineSai Water Tub Agreementvinodhcivil9Nessuna valutazione finora

- Tic206 Series Silicon TriacsDocumento6 pagineTic206 Series Silicon TriacsIgorCostaCorreiaNessuna valutazione finora

- Civil Engineering MCQDocumento19 pagineCivil Engineering MCQSuhail RazaNessuna valutazione finora

- Msds Hidrogen PeroxideDocumento6 pagineMsds Hidrogen PeroxideIntan Yeti SeptiyaniNessuna valutazione finora

- CH 13Documento30 pagineCH 13Laurertan TavaresNessuna valutazione finora

- Balancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Documento9 pagineBalancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Venice Gwyn ChavezNessuna valutazione finora

- Daphne Eponex No2Documento5 pagineDaphne Eponex No2Fu NamNessuna valutazione finora

- Mechanics of Materials Beer 7th Edition Solutions ManualDocumento5 pagineMechanics of Materials Beer 7th Edition Solutions Manualjosephpetersonjaczgqxdsw100% (45)

- The Optical Properties of Magnesium Oxide ContainiDocumento6 pagineThe Optical Properties of Magnesium Oxide ContainiAbdulbar kelilNessuna valutazione finora