Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

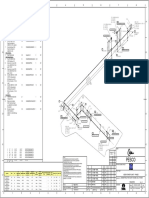

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisCopyright:

Formati disponibili

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 250 PAAZZBOZZABAABSAAZZUS 3.3 M B01

A106-B, Seamless, S-40

2 90 degree elbow, long radius, 250 MCMZZBOZZAAEADCZZUSA 2 B01

A , Beveled end, ASME-B16.9, A

A234-WPB, S-40

3 Spectacle blind, Raised-face 250 MABAHAZZZCAFABQZZUS 1 B01

thru-bolted end without bolt

holes, ,ASME-B16.48, A105 P4 250X250DN

4 Weld neck flange, CL150, 250 FAAAHABZZAADABQZZUS 2 B01

7 SEE ISO

Raised-face flanged end,

381 73 35

6 10END32BR001

ASME-B16.5, A105, Undefined 1 E 262280

>

PIPE SUPPORTS <4 N 214241

5 Design Pipe Assembly 250 DesignPipeH_5 1 B01 EL +133

ERECTION MATERIALS

6 Spiral wound, one ring, CL150, 250 GMAHAQAABFMUS 3 B01 2

4.5mm, ASME-B16.20, 316-W,

graph-F, CS-CR

<3

7 Stud Bolt, ASME-B18.2.1, ASTM 7/8 BAZZZZZZAAYBFZZZUS 12 B01 >

381 1

A193-B7, Zinc Coated, With 2

B heavy Hex nuts A194 Gr.2H and F4 G6 B8 B

2 washers - 145 mm Length

41

0

G6 B7

8 Stud Bolt, ASME-B18.2.1, ASTM 7/8 BAZZZZZZAAYBFZZZUS 12 B01

A193-B7, Zinc Coated, With 2

heavy Hex nuts A194 Gr.2H and 9

STEM UP F4 G6

2 washers - 130 mm Length 10END33AA001

9 Gate valve, short pattern, 250 VABAHABZZAAFADAZZZZUS 1 B01 101 102

<2

CL150, Raised-face flanged > S5

3 15 1

end, ASME-B16.10, A216-WCB, , TAIL U 10END33BQ001

330 47

8

C C

TO

37 NOZZLE N3

21 15

13 LCO UNTREATED TANK A

CONN TO

P4 10ENB01BB001(29A)/N3

10 in BE 150

E 261543

N 210519

EL +1000

486

867

<1> 1

250DN

D D

381

2

EL +133

381

E E

OWNER

4 356 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS DISTRIBUTION W/C

3 410 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS MATRIX

2 1991 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

1 486 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

10END33BR001 01 of 01

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P4

FILE NAME 10END33BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- Questions To Client On SAP HCMDocumento19 pagineQuestions To Client On SAP HCMeurofighterNessuna valutazione finora

- Fesco DatasheetDocumento7 pagineFesco DatasheetDhimas IriantoNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 47XU Gate CraneFS DS p103 0620Documento1 pagina47XU Gate CraneFS DS p103 0620Younis JanNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 47XU F Gate CraneFS DS 1021 p103Documento1 pagina47XU F Gate CraneFS DS 1021 p103Alexander HuamanNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 2.V3 Gan A125Documento1 pagina2.V3 Gan A125Arthur DeiparineNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- 207AB Válvulas RWVDocumento1 pagina207AB Válvulas RWVПабло Рамирес РамиресNessuna valutazione finora

- 280B Válvulas RWVDocumento1 pagina280B Válvulas RWVПабло Рамирес РамиресNessuna valutazione finora

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocumento5 pagineFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNessuna valutazione finora

- 208B Válvulas RWVDocumento1 pagina208B Válvulas RWVПабло Рамирес РамиресNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 1u01 WW 9002 01Documento1 pagina1u01 WW 9002 01syslor.kimNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNessuna valutazione finora

- F1511 Data SheetDocumento2 pagineF1511 Data SheetJV Balisi100% (1)

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Filtro y Eco-FyDocumento1 paginaFiltro y Eco-FydgarciabNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- H31 SW F34 2475Documento4 pagineH31 SW F34 2475Bini RanishNessuna valutazione finora

- CI Wafer / DI Lug Butterfly Valves: Series 0160Documento2 pagineCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNessuna valutazione finora

- Api 602 Forged Steel Valve PDFDocumento4 pagineApi 602 Forged Steel Valve PDFThomasFrenchNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Cast Steel Swing Check Valve Class 150: MaterialDocumento1 paginaCast Steel Swing Check Valve Class 150: Materialadewunmi olufemiNessuna valutazione finora

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocumento7 pagineGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNessuna valutazione finora

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocumento2 pagineSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNessuna valutazione finora

- ISO ExampleDocumento1 paginaISO Examplethe.avishekkNessuna valutazione finora

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryDocumento1 paginaA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryfaviikaujaNessuna valutazione finora

- Fig. No. 208: RED WHITE Bronze Gate Valve - 125 LBDocumento1 paginaFig. No. 208: RED WHITE Bronze Gate Valve - 125 LBSergio DjbucaneroNessuna valutazione finora

- 600scjs#cy 2-12 - 15Documento2 pagine600scjs#cy 2-12 - 15MohamadIbnuHassanNessuna valutazione finora

- UL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Documento1 paginaUL Listed Y Strainer - 300 Psi - Fire Protection - Model 3800Nicolás Fernández CanepaNessuna valutazione finora

- Walworth Cast Stainless Steel SPCL AlloyDocumento2 pagineWalworth Cast Stainless Steel SPCL AlloySamano ComercializadoraNessuna valutazione finora

- Spade Storage Rack-200Documento1 paginaSpade Storage Rack-200miorNessuna valutazione finora

- Van C NG OS & Y GATE VALVE KVS-4150Documento1 paginaVan C NG OS & Y GATE VALVE KVS-4150Nguyễn Kỳ TúNessuna valutazione finora

- 2309+QT04 - Gala-Motorized Butterfly ValveDocumento4 pagine2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- C.S Gate ValveDocumento4 pagineC.S Gate Valvearmin heidariNessuna valutazione finora

- Gate Valve Class 1500Documento1 paginaGate Valve Class 1500Hamdi Al-sarooryNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)vishwas salunkheNessuna valutazione finora

- Swing Check Valves: Hinge and Hinge PinDocumento4 pagineSwing Check Valves: Hinge and Hinge PinTheVirus PapaNessuna valutazione finora

- NZ - Valvula de BolaDocumento2 pagineNZ - Valvula de Bolajorge manuelNessuna valutazione finora

- Bill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5Documento1 paginaBill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5chandraditya firmansyahNessuna valutazione finora

- Cast Steel Y-Strainer - Ansi Class 300: YS-2-B.REV.ADocumento1 paginaCast Steel Y-Strainer - Ansi Class 300: YS-2-B.REV.AFery FebryantoNessuna valutazione finora

- Cast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"Documento1 paginaCast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"OceanexNessuna valutazione finora

- V5-GRS-A125: Gate ValveDocumento1 paginaV5-GRS-A125: Gate ValveChristian oliverosNessuna valutazione finora

- Piping Isometric - 3Documento1 paginaPiping Isometric - 3CosminMarianNessuna valutazione finora

- GroomingDocumento1 paginaGroomingIkbal AlanisNessuna valutazione finora

- Jasa Perancangan, Pengadaan Dan Konstruksi (Epc) Pembangunan Pipa Gas Cikarang ListrindoDocumento1 paginaJasa Perancangan, Pengadaan Dan Konstruksi (Epc) Pembangunan Pipa Gas Cikarang ListrindoJakarta RahmanNessuna valutazione finora

- 4261 Targ P TP 202 001 H7Documento1 pagina4261 Targ P TP 202 001 H7SantiagoNicolásBergesioNessuna valutazione finora

- Penawaran Harga Pipa R0Documento3 paginePenawaran Harga Pipa R0PT FaengNessuna valutazione finora

- Y STRAINER FLANGED END 150 Model PDFDocumento1 paginaY STRAINER FLANGED END 150 Model PDFsajanchaudhariNessuna valutazione finora

- Mss Sp-80 Globe Valve: Threaded Bonnet, Threaded Ends 1/4 - 3" (6 - 75 MM) CLASS 125 BronzeDocumento2 pagineMss Sp-80 Globe Valve: Threaded Bonnet, Threaded Ends 1/4 - 3" (6 - 75 MM) CLASS 125 Bronzeenjamamul hoqNessuna valutazione finora

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocumento44 pagineMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet1-ModelDocumento1 pagina10ENA01BR003 Sheet1-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- February 2023 PROGRAM OF THE MPLEDocumento8 pagineFebruary 2023 PROGRAM OF THE MPLEDale Iverson LacastreNessuna valutazione finora

- Industrial SpecialtiesDocumento103 pagineIndustrial SpecialtiesRahul ThekkiniakathNessuna valutazione finora

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocumento16 pagineSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarNessuna valutazione finora

- PDAJChallenge KitDocumento15 paginePDAJChallenge KitElango Minnoor100% (1)

- Gastroschisis and Omphalocele PDFDocumento8 pagineGastroschisis and Omphalocele PDFUtama puteraNessuna valutazione finora

- BMC Brochure WebDocumento4 pagineBMC Brochure WebVikram Pratap SinghNessuna valutazione finora

- PACKET 1 - Exercises and ActivitiesDocumento7 paginePACKET 1 - Exercises and ActivitiesPrantsir Pernes100% (2)

- 15-Statutory Report Statutory Define Law (Legal Protection) Statutory MeetingDocumento2 pagine15-Statutory Report Statutory Define Law (Legal Protection) Statutory MeetingRaima DollNessuna valutazione finora

- Diagnostic Test 12Documento3 pagineDiagnostic Test 12Honorato BugayongNessuna valutazione finora

- Wax Depilation ManualDocumento17 pagineWax Depilation ManualAmit Sharma100% (1)

- Level 9 - Unit 34Documento7 pagineLevel 9 - Unit 34Javier RiquelmeNessuna valutazione finora

- Achievement Test Science 4 Regular ClassDocumento9 pagineAchievement Test Science 4 Regular ClassJassim MagallanesNessuna valutazione finora

- Tenses Các NămDocumento4 pagineTenses Các NămAnh MinhNessuna valutazione finora

- Quarter 2 Week 5Documento54 pagineQuarter 2 Week 5rixzylicoqui.salcedoNessuna valutazione finora

- LNG Simulation PDFDocumento28 pagineLNG Simulation PDFRobert WatersNessuna valutazione finora

- Water Quantity Estimation PDFDocumento3 pagineWater Quantity Estimation PDFOladunni AfolabiNessuna valutazione finora

- 8582d Soldering Station English User GuideDocumento9 pagine8582d Soldering Station English User Guide1valdasNessuna valutazione finora

- DefibrillatorDocumento2 pagineDefibrillatorVasanth VasanthNessuna valutazione finora

- Audio AmplifierDocumento8 pagineAudio AmplifierYuda Aditama100% (2)

- Annual Sustainability Report 2022-23 FinalDocumento93 pagineAnnual Sustainability Report 2022-23 FinalLakshay JajuNessuna valutazione finora

- Group 13Documento4 pagineGroup 13Surisetti Jyothsna LathaNessuna valutazione finora

- Strep Throat FactsDocumento2 pagineStrep Throat FactsFactPaloozaNessuna valutazione finora

- Case Diagnosis For RomanDocumento4 pagineCase Diagnosis For RomanChris Marie JuntillaNessuna valutazione finora

- Tugas Gizi Caesar Nurhadiono RDocumento2 pagineTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNessuna valutazione finora

- Anesthesia 3Documento24 pagineAnesthesia 3PM Basiloy - AloNessuna valutazione finora

- CITEC Genesis & GenXDocumento45 pagineCITEC Genesis & GenXPutra LangitNessuna valutazione finora

- Excerpts From Roe v. Wade Majority OpinionDocumento2 pagineExcerpts From Roe v. Wade Majority OpinioncatherinewangcNessuna valutazione finora

- HIPULSE U 80kVA 500kVA-Manual - V1.1Documento157 pagineHIPULSE U 80kVA 500kVA-Manual - V1.1joseph mendezNessuna valutazione finora

- ECO-321 Development Economics: Instructor Name: Syeda Nida RazaDocumento10 pagineECO-321 Development Economics: Instructor Name: Syeda Nida RazaLaiba MalikNessuna valutazione finora