Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

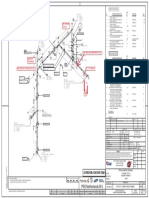

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisCopyright:

Formati disponibili

1 2 3 4 5 6 7 8

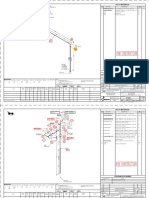

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 250 PAAZZBOZZABAABSAAZZUS 28.4 M B01

A106-B, Seamless, S-40

2 Tee, , Beveled end, 250X250 MDJZZBOZZAAEADCZZUS 2 B01

A ASME-B16.9, A234-WPB, S-40 A

3 Eccentric reducer, , Beveled 250X150 MBJZZBOZZAAEADCZZUS 1 B01

end, ASME-B16.9, A234-WPB,

381

S-40

4 Sockolet® Size on Size, 250X25 MEUAWBVZZAEYABQZZUS 1 B01 381

CL3000, Beveled end,

ASME-B36.10M, A105 19 5

5 90 degree elbow, long radius, 250 MCMZZBOZZAAEADCZZUSA 4 B01 15

, Beveled end, ASME-B16.9,

1

A234-WPB, S-40 >

99 <7

PIPE SUPPORTS 39 250DN

6 Design Pipe Assembly 250 DesignPipeH_5 7 B01 SEE ISO

ERECTION MATERIALS S6 10END32BR001 SHT 02

7 Pipe, PE, ASME-B36.10M, 25 PAAZZBPZZABAABSAAZZUS 0.1 M 10END32BQ005 E 284084

N 221214

A106-B, Seamless, S-40

00 EL +287

8 Plug, CL3000, Male threaded 25 MFIAWBNZZAAGABQZZUS 1 B01 40

B end, ASME-B16.11, A105 8

B

9 Ball valve, full port, CL600, 25 VAIAPBUZZAAFABQZZBFUS 1 B01 158

2

Threaded end, ASME-B16.10,

0 S6

A105

401 10END32BQ004

P4

5 S6

90

S6 39 10END32BQ003

10END32BQ001

381

<4

>

1 3 S6

381 7

34 181 10END32BQ002

<5> 1

C 8 C

440

1094

216 9

497

100

STEM NORTH

95 <3> 7 10END32AA502

738

216 N 221020

249 19

4 159

57 4

178 5 250X25DN

2

250X250DN 381

SEE ISO 216 EL +287

10END35BR001

E 261758 S6 53

3

N 221595 10END35BQ001 5

1248

EL +234 91 EL +1381

<6> 1 4

486

381

3

<2> 1

250X150DN 381

D 52MM OFFSET D

FLAT SIDE D

11

8

381 3

5 <1 SEE ISO

> 58 10END33BR001

1 66 E 262280

40 N 214241

86 EL +133

S6 216

10END32BQ014

216

2

250X250DN

SEE ISO N 214241

10END34BR001

E E 262496 250DN E

7 20991 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS N 214025

6 344 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

EL +133 OWNER

216

5 497 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

4 727 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS DISTRIBUTION W/C

3 100 25 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS MATRIX

2 486 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

1 5269 250 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

10END32BR001 01 of 02

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P4

FILE NAME 10END32BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- PipelineDocumento9 paginePipelineRhoteram VikkuNessuna valutazione finora

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISODocumento1 paginaD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- J3BGDF02BR005 01 01Documento1 paginaJ3BGDF02BR005 01 01saleem naheedNessuna valutazione finora

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Documento1 pagina0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadNessuna valutazione finora

- 150 10xaa1 H50 21RDCH 1004 1Documento1 pagina150 10xaa1 H50 21RDCH 1004 1uma raneNessuna valutazione finora

- BBS BorpileDocumento1 paginaBBS BorpileSurya Bintang RamadhanaNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNessuna valutazione finora

- ISO ExampleDocumento1 paginaISO Examplethe.avishekkNessuna valutazione finora

- Piping Isometric - 3Documento1 paginaPiping Isometric - 3CosminMarianNessuna valutazione finora

- 1 - STEEL STAIRCASE GA DRAWING1.dwgDocumento1 pagina1 - STEEL STAIRCASE GA DRAWING1.dwgnimish.aquamarineNessuna valutazione finora

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Documento1 paginaPE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Remove Support: Issued For ConstructionDocumento1 paginaRemove Support: Issued For Construction86tejasNessuna valutazione finora

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocumento1 paginaFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNessuna valutazione finora

- C.3-141-Temporary Fence H.5MDocumento1 paginaC.3-141-Temporary Fence H.5MYudi CasanovaNessuna valutazione finora

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Documento1 pagina10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanNessuna valutazione finora

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocumento2 pagineFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNessuna valutazione finora

- Erection Drawing SST 36MDocumento14 pagineErection Drawing SST 36MyuwonoNessuna valutazione finora

- Issued For Construction Modular Isometrics: Remove TrunnionDocumento1 paginaIssued For Construction Modular Isometrics: Remove Trunnion86tejasNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Detail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermoDocumento1 paginaDetail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermosilviNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- TR-DM-MI-0218: Issued For ConstructionDocumento2 pagineTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNessuna valutazione finora

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryDocumento1 paginaA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryfaviikaujaNessuna valutazione finora

- Tupi BV: Cosco (Dalian)Documento1 paginaTupi BV: Cosco (Dalian)Robles DreschNessuna valutazione finora

- Piping Isometrics Iso No 16400T BA 300 H19Documento1 paginaPiping Isometrics Iso No 16400T BA 300 H19Oussama Ben AbbesNessuna valutazione finora

- Shop Materials: Exclusive Use of The WorkshopDocumento1 paginaShop Materials: Exclusive Use of The Workshopmiguel angel reynaga acevedoNessuna valutazione finora

- C11 Pillar: Schedule of R.C. Columns & FootingsDocumento1 paginaC11 Pillar: Schedule of R.C. Columns & FootingsHusen GhoriNessuna valutazione finora

- Tal Wsa PNG Iso 1LS051901 - 01 - A01 - 00Documento1 paginaTal Wsa PNG Iso 1LS051901 - 01 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNessuna valutazione finora

- Half Elevation of P.S.C.Girder: Islamabad National Highway AuthorityDocumento1 paginaHalf Elevation of P.S.C.Girder: Islamabad National Highway AuthorityZubair MuhammadNessuna valutazione finora

- Bryston 6b sst2 SCHDocumento2 pagineBryston 6b sst2 SCHElkin BabiloniaNessuna valutazione finora

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Documento1 paginaChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNessuna valutazione finora

- ST 03 CSDocumento1 paginaST 03 CSDareen BaredNessuna valutazione finora

- 1u01 WW 9002 01Documento1 pagina1u01 WW 9002 01syslor.kimNessuna valutazione finora

- HK 0FH 1027Documento1 paginaHK 0FH 1027PaoloNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Piping Isometric Building:: Pengerang Cogeneration PlantDocumento1 paginaPiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNessuna valutazione finora

- H31 SW F34 2475Documento4 pagineH31 SW F34 2475Bini RanishNessuna valutazione finora

- Cyclone Nozzle - 26280-120-M0-0000-00004Documento1 paginaCyclone Nozzle - 26280-120-M0-0000-00004Juan PiedraNessuna valutazione finora

- Piping Isometric - 7Documento1 paginaPiping Isometric - 7CosminMarianNessuna valutazione finora

- Bill of Materials: See Iso 10-P-1202 SHT 02Documento2 pagineBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanNessuna valutazione finora

- Ilovepdf MergedDocumento21 pagineIlovepdf MergedNITHIN MATHEWNessuna valutazione finora

- Productdatasheet Babsl 72 NBR 902Documento2 pagineProductdatasheet Babsl 72 NBR 902narayan46Nessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocumento1 pagina01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- Bus ShelterDocumento1 paginaBus ShelterCHVN NH173Nessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

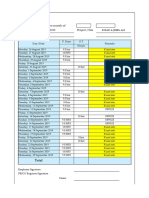

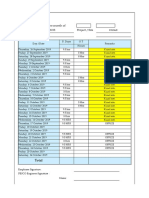

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Asme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Documento2 pagineAsme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 02 WordEditingTextDocumento1 pagina02 WordEditingTextValesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Manual For S PumpsDocumento4 pagineManual For S PumpsPinguim FariaNessuna valutazione finora

- T Mech Clamp CatalogueDocumento29 pagineT Mech Clamp CatalogueKABIR CHOPRANessuna valutazione finora

- Contourline / Pureline Warming Drawer: 8 Shown Above: Esw 6114Documento5 pagineContourline / Pureline Warming Drawer: 8 Shown Above: Esw 6114junjaxNessuna valutazione finora

- Mechanical Drives PracticalsDocumento2 pagineMechanical Drives PracticalsabyzenNessuna valutazione finora

- R Series: Operation and Maintenance Manual Positive Displacement PumpDocumento132 pagineR Series: Operation and Maintenance Manual Positive Displacement PumpNathawatNessuna valutazione finora

- Design of Vertical Pressure VesselsDocumento15 pagineDesign of Vertical Pressure VesselsMohit SinghNessuna valutazione finora

- ThermodynamicsDocumento28 pagineThermodynamicsJack Lupino100% (2)

- Circle Seal Controls 500 Series Relief ValveDocumento6 pagineCircle Seal Controls 500 Series Relief ValveJai BhandariNessuna valutazione finora

- Psychrometry of Air Conditioning ProcessDocumento56 paginePsychrometry of Air Conditioning ProcessNazia ZamanNessuna valutazione finora

- Cilindri PDFDocumento40 pagineCilindri PDFSlobodan SavicNessuna valutazione finora

- 5114 21 03.kitDocumento3 pagine5114 21 03.kitTimon2005Nessuna valutazione finora

- Scalar Wars The Brave New World of Scalar ElectromagneticsDocumento76 pagineScalar Wars The Brave New World of Scalar ElectromagneticsPerfectKey21Nessuna valutazione finora

- Approved List of Manufacturers: CategoryDocumento3 pagineApproved List of Manufacturers: Categorytomj9104Nessuna valutazione finora

- BSW BS AF BA and Metric Tool Size Equivalents PDFDocumento5 pagineBSW BS AF BA and Metric Tool Size Equivalents PDFZool HilmiNessuna valutazione finora

- Plano 236D PDFDocumento27 paginePlano 236D PDFArle SalasNessuna valutazione finora

- Class 18 March 2020 PDFDocumento13 pagineClass 18 March 2020 PDFMuskan NehraNessuna valutazione finora

- Bernoullis Equation EngineeringduniyacomDocumento26 pagineBernoullis Equation EngineeringduniyacomMuhammad DodyNessuna valutazione finora

- Ps-1 Unit 3Documento21 paginePs-1 Unit 3Prathap VuyyuruNessuna valutazione finora

- 11 - 09 - Equippements Iacs 11 - 09 - Iacs Positioning EquipmentsDocumento2 pagine11 - 09 - Equippements Iacs 11 - 09 - Iacs Positioning EquipmentssxturboNessuna valutazione finora

- Physics 151 LectureDocumento72 paginePhysics 151 LecturechioNessuna valutazione finora

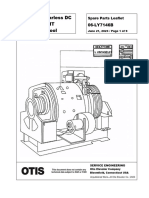

- 06 Ly7146bDocumento9 pagine06 Ly7146bm.omeracarNessuna valutazione finora

- Fluid3a Trawneh PDFDocumento39 pagineFluid3a Trawneh PDFWesam abo HalimehNessuna valutazione finora

- Centrifugal BlowerDocumento3 pagineCentrifugal BlowerVicy gostNessuna valutazione finora

- Parafusos Com Gargantachapter 3Documento7 pagineParafusos Com Gargantachapter 3Miguel QueirosNessuna valutazione finora

- Cryogenic Heat Exchangers For Process Cooling and Renewable Energy StorageDocumento16 pagineCryogenic Heat Exchangers For Process Cooling and Renewable Energy StoragelalithaNessuna valutazione finora

- 08y PDFDocumento306 pagine08y PDFFilmorePainNessuna valutazione finora

- H-3860D - Man - 0816 DesgasteDocumento8 pagineH-3860D - Man - 0816 Desgastealvaro almendarezNessuna valutazione finora

- Droppper PopperDocumento5 pagineDroppper Popperapi-302421116Nessuna valutazione finora

- Act 01 AnsDocumento1 paginaAct 01 AnsSrinivasulu PuduNessuna valutazione finora

- HP300 GA and Dimensional Drawings MM1472950 - 0Documento10 pagineHP300 GA and Dimensional Drawings MM1472950 - 0Thiago PaivaNessuna valutazione finora