Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Epoxy Terrazzo Flooring PDF

Caricato da

Balaji RavikumarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Epoxy Terrazzo Flooring PDF

Caricato da

Balaji RavikumarCopyright:

Formati disponibili

Sustainable Flooring

EPOXY TERRAZZO FLOORING practice expands and complements

the classical building design concerns

A GREEN BUILDING INITIATIVE of economy, utility, durability, and

comfort.

This definition encompasses not

only the products that are used in the

structure, but also the processes being

used in building the structure. Thus the

main criteria that emerge to qualify

green buildings are:

B.M.Nagarajan 1. Conserve natural resources

Director, Neocrete Technologies Pvt Ltd 2. Reduces energy & water consumption,

i.e. resource-efficient

3. Generates less waste

M

ost building designs today conserves natural resources, generates 4. Provides healthier environment

revolve around green less waste and provides healthier spaces

building concept, which for occupants, as compared to a

everyone from Architects to common conventional building."

man agree, is extremely important to

Wikipedia gives a broader definition

reduce construction-related envir-

of green buildings:

onmental impact. This article analyzes

the contribution of interior epoxy Green building (also known as green

terrazzo floorings towards achieving construction or sustainable building)

this goal. refers to a structure using process that

is environmentally responsible and

Indian green building council

resource-efficient throughout life-

defines green buildings as

c y c l e : f r o m siting to design,

"A green building is one which uses construction, operation, maintenance,

less water, optimizes energy efficiency, renovation, and demolition. This

Cement Terrazzo Floor Courtesy: Durocem, Italy

We will now analyze how an epoxy

terrazzo flooring as a contributor to the

concept of green buildings.

The concept of terrazzo introduced

historically in the Middle East thousand

years ago, has been in vogue for many

centuries in many countries including

India. They have been designed and

redesigned, modified, innovated over

the years and thus resemble the

modern cement terrazzo floorings of

the present. In India too, cement

terrazzo floorings a.k.a mosaic were

being used extensively at one time, but

were totally replaced by marbles,

granites and other natural as well as

synthetic stones.

Cast-in-situ cement terrazzo still

had some disadvantages such as

higher thickness, susceptible to

cracks, low stain resistance, not-so-

attractive colours etc. All these

shortcomings have been addressed in

106 The Masterbuilder - September 2011 · www.masterbuilder.co.in

Sustainable Flooring

Epoxy primer applied surface with the pattern set Epoxy terrazzo mix is poured into the respective Cured epoxy terrazzo is ground and polished

on the floor patterns

Epoxy terrazzo floorings that have brass/SS/aluminium strips can be best suited for heavy traffic areas due

the following advantages: embedded to give a tiled appearance. to its low maintenance and proven

Terrazzo floors are durable, waterproof durability. (Expected life span of

1. Thickness ranging from low 6mm to

and easy to maintain. They are a good minimum 20 years)

10mm.

choice for kitchens, bathrooms, - Epoxy terrazzo has little or no

2. 100% solids formula & V.O.C

hallways, lobbies and porches. maintenance, resists a wide variety

compliant.

- Epoxy terrazzo has become of chemicals and detergents, and

3. Vibrant colours & Unmatched

exceedingly popular in abroad, can be laid with a stunning array of

varieties of custom designs

4. Excellent chemical resistance and because of its thin section, light colours.

the lowest maintenance cost of any weight, rich colors and resistance

Application Methodology

hard surface flooring. to cracking. Terrazzo has earned

5. Outstanding workability, colour the reputation of being the floor Epoxy terrazzo floors are typically

consistency and performance.

6. Quick cure, faster turn-around

enables high productivity.

7. In-situ application ensure monolithic

surface and saves space, time,

freight cost etc.

Terrazzo is made by laying stone

chippings in epoxy resin. This mixture

is spread on the floor, and when it has

dried, it is machine ground and

polished. The result is a perfectly

smooth, seamless floor. A grid of

Grouting, Washing & Cleaning Finished Floor

www.masterbuilder.co.in · The Masterbuilder - September 2011 107

Sustainable Flooring

(The photographs were �

Technologies Pvt Ltd)

installed in a 6mm thickness, and in Concept of reducing energy contributes to the essence of green

two different layers. The first layer is just consumption: building concept viz. Sustainable

an epoxy primer that takes around 6 hrs construction. With virtually very low/no

to cure. The epoxy system is then set - Cutting of marble or granite at site maintenance, epoxy terrazzo floors

into place and trowel finished. Once results in a large amount of water as offers the lowest life-cycle cost.

the floor is allowed to cure for a little, the well as electrical energy, which is Latest advances in pigment

surface is ground and then grouted completely obviated in the cast-in- technologies enable terrazzo floors

with an epoxy grout to fill in all of the situ epoxy terrazzo system to retain the vibrancy of the colours

voids. The final step is to then polish - Near-joint-less epoxy terrazzo

over long periods of time.

and seal the surface. system, provides better insulation

(The photographs were taken properties than any of the - Epoxy terrazzo floors are known to

during the execution of epoxy terrazzo contemporary stone floors having offer better anti-slip characteristics

floors in a commercial cum residential multiple joints and thus provide a when compared to ceramic tiles or

complex in Muscat: Job executed by better energy-efficient option. polished granites. That is why,

Neocrete Technologies Pvt Ltd) epoxy terrazzo floors are the most

Concept of reducing wastage:

You can create beautiful designs preferred flooring systems in USA

and patterns with vibrant and durable - The entire system is cast-in-situ and for airports, hospitals, museums,

colours and the finished floor is hence do not contribute to any malls and other public places since

wastage. Unlike marble or granite they result in lower fatigue compared

exquisite and unmatched.

which need to be cut in order to to those walking over slippery

Now let us look at how epoxy

create a design (balance portion of surfaces.

terrazzo contributes to green building

cut marble becomes a waste),

concept: Conclusion:

epoxy terrazzo system is poured in

Concept of conserving natural place. Thus, the customer gets also Epoxy terrazzo floors, not only offers

resources: the advantage of paying as per the most durable flooring surface with

sq.m of actual floor area, unlike exquisite designs, colours and patterns,

- All natural stones such as marble, marble/granite

granite etc come from quarries and but also qualify as the most ideal flooring

obviously by cutting the mountain - Besides, thin-set terrazzo is only option for green buildings.

and other natural-stone deposits. around 6 to 10mm which is at least

Compared to this, terrazzo floors 3 times lower than other alternatives,

use only marble chips or recycled thus offering lightest load factor of Authors Bio

glass that are only by-products of 20 Kg per sq.m (as against a

B M Nagarajan is one of the three

the quarries, which otherwise minimum of 120 Kg per sq.m for directors of Neocrete Technologies

would have been completely marble/granite with fixing mortar). Pvt Ltd offering value-added

wasted. Thus it does not deplete Such a light load can lead to plenty flooring systems for both Industrial

the natural resources. of advantages in building design, and commercial sector. Neocrete

- The epoxy terrazzo matrix consists higher headroom, higher air Technologies are the pioneers in

of around 70% of marble chips and circulation etc. offering epoxy terrazzo floors in

30% epoxy resin system (which is India. He is a chemical engineer

Durability: having over 36 years of work

again 100% solids), does not

- Epoxy terrazzo floors can virtually experience and can be contacted

contain any solvent and completely at : bmnagarajan@gmail.com

V.O.C compliant. last the life of the building and thus

108 The Masterbuilder - September 2011 · www.masterbuilder.co.in

Potrebbero piacerti anche

- Briquetted Charcoal From Sugarcane Trash Arti IndiaDocumento2 pagineBriquetted Charcoal From Sugarcane Trash Arti Indiavvk557Nessuna valutazione finora

- Composite Bamboo and Its Application As Reinforcement in Structural ConcreteDocumento445 pagineComposite Bamboo and Its Application As Reinforcement in Structural ConcreteDanica Joy AlfarNessuna valutazione finora

- Jayabell BrochureDocumento6 pagineJayabell BrochureAvan Setyo PratamaNessuna valutazione finora

- Brosur OnduplastDocumento3 pagineBrosur Onduplastfuny agustina50% (2)

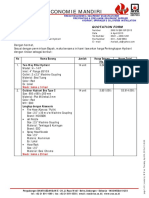

- RAB Instalasi DuctingDocumento1 paginaRAB Instalasi DuctingNugrohoNessuna valutazione finora

- Low2No Manual RexDocumento144 pagineLow2No Manual RexMire PonceNessuna valutazione finora

- A Feasibility Study For The Proposed Research Golf Course and Lea PDFDocumento134 pagineA Feasibility Study For The Proposed Research Golf Course and Lea PDFRechael DadivasNessuna valutazione finora

- Final Harga Rab Furnish Bu YeniDocumento3 pagineFinal Harga Rab Furnish Bu YeniRADEN HENDRANessuna valutazione finora

- Strategi Disain Fasad Rumah Tinggal Hemat Energi - EDDY PRIANTODocumento11 pagineStrategi Disain Fasad Rumah Tinggal Hemat Energi - EDDY PRIANTOPAGARNessuna valutazione finora

- Design Teknis Rest Area (1) - 2Documento21 pagineDesign Teknis Rest Area (1) - 2Yasril BachNessuna valutazione finora

- AED Building Physics PDFDocumento48 pagineAED Building Physics PDFaasimalyNessuna valutazione finora

- Hearst Tower Feb 06Documento0 pagineHearst Tower Feb 06denis1808scribdNessuna valutazione finora

- Penangkal Petir&GroundingDocumento2 paginePenangkal Petir&Groundingbasuki100% (1)

- KEMBLA TYPE K L M Catalog-1 PDFDocumento4 pagineKEMBLA TYPE K L M Catalog-1 PDFshahNessuna valutazione finora

- Rab - RMH .RudiDocumento108 pagineRab - RMH .RudiAgung Khairul MuttaqienNessuna valutazione finora

- Pricelist Hayana DoorDocumento10 paginePricelist Hayana DoorSomantri i100% (1)

- Bobot Interior Sym HouseDocumento37 pagineBobot Interior Sym Housemuhammad robinNessuna valutazione finora

- Kabel MetalDocumento2 pagineKabel Metalsri haryadiNessuna valutazione finora

- Rab Type 45Documento64 pagineRab Type 45Ichaa Cullen-way WilliamsNessuna valutazione finora

- RAB Ground Floor Altitude - 20180227Documento1 paginaRAB Ground Floor Altitude - 20180227Rumah Drafter BaliNessuna valutazione finora

- Desain Denah Rumah Tinggal Untuk Kebutuhan Rumah RDocumento12 pagineDesain Denah Rumah Tinggal Untuk Kebutuhan Rumah RWahyu 12Nessuna valutazione finora

- RabDocumento20 pagineRabcmu baliNessuna valutazione finora

- Rancangan Anggaran Peralatan Skateboard: A. Alat Skatepark 1. BoxDocumento5 pagineRancangan Anggaran Peralatan Skateboard: A. Alat Skatepark 1. BoxhavilfandiNessuna valutazione finora

- Rab Smoking Area IsianDocumento26 pagineRab Smoking Area IsianMuh Nasir Lewa100% (1)

- BQ Satuan Furniture BP 7Documento3 pagineBQ Satuan Furniture BP 7Udinez BabeStarNessuna valutazione finora

- Harga Satuan TH 2023Documento106 pagineHarga Satuan TH 2023AndreyNessuna valutazione finora

- Pricelist Roman GranitDocumento7 paginePricelist Roman GranitSudirman SyuaibNessuna valutazione finora

- Fastener BrochureDocumento8 pagineFastener BrochureSugumarNessuna valutazione finora

- Brosur Bed Elevator HyundaiDocumento8 pagineBrosur Bed Elevator HyundaiSeptian Adi SNessuna valutazione finora

- Brosur Blend SeventyDocumento2 pagineBrosur Blend SeventyLilianti AzwarNessuna valutazione finora

- Welded Wire Mesh 50 X 50 X 1 6mm MSDSDocumento3 pagineWelded Wire Mesh 50 X 50 X 1 6mm MSDSMounir BoutaghaneNessuna valutazione finora

- Rumus Perhitungan Screw ConveyorDocumento3 pagineRumus Perhitungan Screw ConveyorZwingCAD AcademyNessuna valutazione finora

- Skematik Desain ArsitekturDocumento10 pagineSkematik Desain ArsitekturozakNessuna valutazione finora

- Rencana Pembiayaan Plaza Bandara Dadap, Tangerang: A. Perhitungan Kontruksi Harga Satuan/m2 m2 JumlahDocumento2 pagineRencana Pembiayaan Plaza Bandara Dadap, Tangerang: A. Perhitungan Kontruksi Harga Satuan/m2 m2 JumlahAgus RahayuNessuna valutazione finora

- RUKO 1 - Sheet - ARS-14 - Denah Pola Lantai - LT 1Documento1 paginaRUKO 1 - Sheet - ARS-14 - Denah Pola Lantai - LT 1Cindar TengikNessuna valutazione finora

- Design Basis L15 - 25X40M Vizag: Location Main Frame::::: End Wall / Gable FramesDocumento5 pagineDesign Basis L15 - 25X40M Vizag: Location Main Frame::::: End Wall / Gable FramesAnonymous MAQrYFQDzVNessuna valutazione finora

- Kusen AluminiumDocumento11 pagineKusen AluminiumNan BudiNessuna valutazione finora

- Rencana Anggaran Biaya: NO Vulome SAT Spesifikasi Harga Satuan Jumlah Harga A. Persiapan UraianDocumento2 pagineRencana Anggaran Biaya: NO Vulome SAT Spesifikasi Harga Satuan Jumlah Harga A. Persiapan UraianAmran AchmadyNessuna valutazione finora

- Analisa Harga SatuanDocumento15 pagineAnalisa Harga SatuanWeldy Armando Yannes100% (1)

- Pricelist Valentino GressDocumento8 paginePricelist Valentino GressSeptian CahyanaNessuna valutazione finora

- Ruukki Sandwich Panels For Walls and RoofsDocumento24 pagineRuukki Sandwich Panels For Walls and RoofsDouglas Taylor100% (1)

- PT - Economie MandiriDocumento8 paginePT - Economie MandiriHariadi Budi SantosoNessuna valutazione finora

- Haefele Movable Walls Catalogue 2017Documento32 pagineHaefele Movable Walls Catalogue 2017alexmilarNessuna valutazione finora

- Lampiran Material KusenDocumento191 pagineLampiran Material KusenOktavian Bless AnyaNessuna valutazione finora

- Presentasi GP 2018 - GROUP 1Documento335 paginePresentasi GP 2018 - GROUP 1RICKY SHIMADHIBRATA ISKANDARNessuna valutazione finora

- Price List: Zelltech Sandwich Panel Polyurethane 40 Kg/M3 Harga Per-MeterDocumento1 paginaPrice List: Zelltech Sandwich Panel Polyurethane 40 Kg/M3 Harga Per-Meterasia bangun karyaNessuna valutazione finora

- Lampiran RabDocumento27 pagineLampiran RabDENTISA GARININessuna valutazione finora

- RetailBook 2018Documento174 pagineRetailBook 2018Shreeya AdhikariNessuna valutazione finora

- Work Method of Mezzanine-1 Extension Rev.01Documento14 pagineWork Method of Mezzanine-1 Extension Rev.01NiamDe'Nessuna valutazione finora

- Ahs Paving Blok 2020 UpdateDocumento2 pagineAhs Paving Blok 2020 Updatei akbarNessuna valutazione finora

- Tasblock CatalogDocumento25 pagineTasblock CatalogJessica KhowNessuna valutazione finora

- Boq 15535 Update Design 3-8cc5af0cd3Documento8 pagineBoq 15535 Update Design 3-8cc5af0cd3Irawan PrastyaNessuna valutazione finora

- Analisa Harga Satuan Palembang 2014Documento176 pagineAnalisa Harga Satuan Palembang 2014fandinistyNessuna valutazione finora

- BIOCOMPDocumento4 pagineBIOCOMPdeddyNessuna valutazione finora

- Jotafloor SF Primer (Technical Data Sheet)Documento5 pagineJotafloor SF Primer (Technical Data Sheet)Arif JoelNessuna valutazione finora

- Rab Samsat Babel FinalDocumento126 pagineRab Samsat Babel FinalLinda TanthiNessuna valutazione finora

- Departemen Pom & Project Bill of Quantity: No Detail Pekerjaan QTY Unit Unit Price (RP) Material Upah Total Price (RP)Documento1 paginaDepartemen Pom & Project Bill of Quantity: No Detail Pekerjaan QTY Unit Unit Price (RP) Material Upah Total Price (RP)Cv RONATAMA GUSLHANNessuna valutazione finora

- 19 (6 Files Merged)Documento100 pagine19 (6 Files Merged)Kathrine DisuzaNessuna valutazione finora

- Design Determinants of Building Envelope For Sustainable Built Environment: A ReviewDocumento8 pagineDesign Determinants of Building Envelope For Sustainable Built Environment: A ReviewMEHUL HOTWANINessuna valutazione finora

- Cameron Kunsthal-Rotterdam TechniqueDocumento18 pagineCameron Kunsthal-Rotterdam TechniqueSancho ŽuljevićNessuna valutazione finora

- БаугаузDocumento14 pagineБаугаузolya martinyuk242Nessuna valutazione finora

- The Language of SpaceDocumento32 pagineThe Language of Spaceozian yayehyradNessuna valutazione finora

- Heraklith-C ENG 2012-11 PDFDocumento2 pagineHeraklith-C ENG 2012-11 PDFCalin AncutaNessuna valutazione finora

- SN Normsno Description of Works Labour (A) Materials (B) Category Man (Days) Type Quantity Unit Analyzed ForDocumento5 pagineSN Normsno Description of Works Labour (A) Materials (B) Category Man (Days) Type Quantity Unit Analyzed ForKiran Kumar AcharyaNessuna valutazione finora

- Void TubesDocumento6 pagineVoid TubesAistė VaitkuvienėNessuna valutazione finora

- Jabatan Pengairan Dan Saliran Malaysia: Lampiran FDocumento5 pagineJabatan Pengairan Dan Saliran Malaysia: Lampiran FWan ApaiNessuna valutazione finora

- Varon - Indication in Architectural DesignDocumento162 pagineVaron - Indication in Architectural DesignVictor TironiNessuna valutazione finora

- Arch and AntropomorhismDocumento262 pagineArch and AntropomorhismAndreea CarabusNessuna valutazione finora

- Architectural Portfolio by Abdallah DahirDocumento25 pagineArchitectural Portfolio by Abdallah DahirabdallahNessuna valutazione finora

- CEO Building PermitDocumento2 pagineCEO Building PermitBotenes Mallorca RhonNessuna valutazione finora

- Concrete TechnologyDocumento24 pagineConcrete TechnologyPrantik Adhar SamantaNessuna valutazione finora

- Afry.4649.03.005 R1Documento1 paginaAfry.4649.03.005 R1Varadha rajanNessuna valutazione finora

- Master Procurement Plan: National Housing CompanyDocumento2 pagineMaster Procurement Plan: National Housing Company江西水电工程局Nessuna valutazione finora

- Planning It ParkDocumento79 paginePlanning It ParkMdshZubair100% (1)

- CRPF DrawingDocumento1 paginaCRPF DrawingZaidNessuna valutazione finora

- PreStressed Concrete Structures Unit 4 With ANS PDFDocumento7 paginePreStressed Concrete Structures Unit 4 With ANS PDFNatarajan SaravananNessuna valutazione finora

- Chapter - 4, Ribbed Slabs or Waffle Slabs: Y.BOOPATHI /lecturer - CIVILDocumento11 pagineChapter - 4, Ribbed Slabs or Waffle Slabs: Y.BOOPATHI /lecturer - CIVILBoopathi YoganathanNessuna valutazione finora

- Aquino, Ringo CV 20170727Documento6 pagineAquino, Ringo CV 20170727Cj OrebucNessuna valutazione finora

- Architecture Is The Art of Building Structures of EnclosedDocumento3 pagineArchitecture Is The Art of Building Structures of EnclosedNirbhay SinghNessuna valutazione finora

- E702.1 Allowable Stress Design of RC Masonry Shear Wall 2006-03-29Documento17 pagineE702.1 Allowable Stress Design of RC Masonry Shear Wall 2006-03-29mamandaweNessuna valutazione finora

- Architectural Interiors TerminologiesDocumento2 pagineArchitectural Interiors TerminologiesHana YeppeodaNessuna valutazione finora

- HS523217-63-CIV-DTL-0001-0001 REV4-ModelDocumento1 paginaHS523217-63-CIV-DTL-0001-0001 REV4-ModelAlparslan GureNessuna valutazione finora

- GSWC Standard Drawings 2016 (Final Version) - Part 1Documento77 pagineGSWC Standard Drawings 2016 (Final Version) - Part 1david anthonyNessuna valutazione finora

- TSFDC Kothagudem WorkDocumento42 pagineTSFDC Kothagudem WorkS UDAY KUMARNessuna valutazione finora

- The Sky Towers: Report by Sneh Dhengare - 06 Vaishnavi C. Kamble - 16 Shruti Teli - 39Documento4 pagineThe Sky Towers: Report by Sneh Dhengare - 06 Vaishnavi C. Kamble - 16 Shruti Teli - 39Vaishnavi KambleNessuna valutazione finora

- Ceramic Tile InstallationDocumento4 pagineCeramic Tile InstallationAjit Singh RathoreNessuna valutazione finora

- THE RIDGE - Front ElevationDocumento1 paginaTHE RIDGE - Front ElevationKatipunan Elite Eagles ClubNessuna valutazione finora

- Manpower Activity 11-10-2020Documento6 pagineManpower Activity 11-10-2020Joshua MidelNessuna valutazione finora

- Traditional Mediterranean Architecture: House With Three ArchesDocumento12 pagineTraditional Mediterranean Architecture: House With Three ArchesfofiNessuna valutazione finora