Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Q Lab Correlación Entre ASTM D 7869 e Intemperismo Exterior

Caricato da

Juan Angel DechimaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Q Lab Correlación Entre ASTM D 7869 e Intemperismo Exterior

Caricato da

Juan Angel DechimaCopyright:

Formati disponibili

ASTM D7869: A New Xenon-Arc

Accelerated Weathering

Standard with Improved

Outdoor Correlation

Watch Webinar Stream

Andy Francis, Q-Lab Corporation

ASTM D7869 1 We Make Testing Simple

Why Do Weathering Testing?

OR

High gloss and color integrity

Fading, cracking, peeling

Weathering testing can mean the difference between

happy customers and … the customer on the right

ASTM D7869 2 We Make Testing Simple

Why Do Weathering Testing?

OR

High gloss and color integrity Gloss loss and color fade

Weathering testing can mean the difference between

happy customers and … the customer on the right

ASTM D7869 3 We Make Testing Simple

Weathering Testing

• Manufacturers & coatings companies are always

introducing new systems

• Customers may require up to 5 Years natural

outdoor weathering

• Accelerated weathering used to shorten

development & approval time

Weathering testing provides crucial information

about materials’ outdoor performance!

ASTM D7869 4 We Make Testing Simple

Accelerated

Laboratory Weathering

ASTM D7869 5 We Make Testing Simple

Types of Accelerated

weathering tests

Pass/fail

– Quality Control; Qualification ; R&D

– Most accelerated weathering

Comparative

– Usually rank-ordering

– Key is to correlate to outdoor

Service life prediction

– Material-specific

– Need lots of indoor/outdoor data - very difficult!

ASTM D7869 6 We Make Testing Simple

Types of Accelerated

weathering tests

Pass/fail

– Quality Control; Qualification ; R&D

– Most accelerated weathering

Comparative

– Usually rank-ordering

– Key is to correlate to outdoor

Service life prediction

– Material-specific

– Need lots of indoor/outdoor data - very difficult!

ASTM D7869 7 We Make Testing Simple

Types of Accelerated

weathering tests

Pass/fail

– Quality Control; Qualification ; R&D

– Most accelerated weathering

Comparative

– Usually rank-ordering

– Key is to correlate to outdoor

Service life prediction

– Material-specific

– Need lots of indoor/outdoor data - very difficult!

ASTM D7869 8 We Make Testing Simple

Service Life Prediction -

Challenges

• Requires vast amounts of data

• Not currently practical

– Has not been tested or shown to be

successful with available commercial

coating systems

• Shows promise for the future more for

OEM’s than international standards

ASTM D7869 9 We Make Testing Simple

Types of Accelerated

weathering tests

Pass/fail

– Quality Control; Qualification ; R&D

– Most accelerated weathering

Comparative

– Usually rank-ordering

– Key is to correlate to outdoor

Service life prediction

– Material-specific

– Need lots of indoor/outdoor data - very difficult!

ASTM D7869 10 We Make Testing Simple

Accelerated Lab Weathering to

Generate Comparative Data

• Replicate material degradation

observed outdoors

• Do it faster than outdoors!

How can we do this?

ASTM D7869 11 We Make Testing Simple

Historical Test Standards

• Xenon arc’s light sources have been used for many

years - accurate reproduction of full-spectrum sunlight

• Hardware-based “102/18” light/light+spray standards

were the first widely-used weathering standard tests

– Almost 100 years old but still in use

– Most common example is ISO 4892-2

– Not realistic!

• SAE J2527 became the “state of the art” in 1980’s

– Research into primary stressors (light, water, heat)

– Replicated gloss loss seen in Florida exposures

ASTM D7869 12 We Make Testing Simple

Issues with SAE J2527

• Standard was well-researched but did not match

real-world weathering factors

– Light spectra

– Moisture delivery

• As a result, it does not adequately predict

Florida outdoor field failures

– Chemical change (Photo-oxidation, water-based effects)

– Physical change (Cracking, Blistering, Delaminating)

ASTM D7869 13 We Make Testing Simple

Taking the Next Step:

ASTM D7869

• Outdoor weather data collected to understand real-world

weather conditions: light, heat, and water

• Outdoor weathering test dataset collected to provide

basis for correlation

• Accelerated test cycle developed to match those real-

world conditions and degradation mechanisms

• Variety of materials and failure modes evaluated with

accelerated testing to verify validity of test

ASTM D7869 14 We Make Testing Simple

Collecting outdoor

weather data

Laying the groundwork for a new

accelerated test

ASTM D7869 15 We Make Testing Simple

Outdoor weather data

Approach: collect outdoor weather data to better

understanding the forces of natural weathering:

• Sunlight

• Heat

• Water

Goal: Obtain suitable body of field data to

develop the Accelerated laboratory test

ASTM D7869 16 We Make Testing Simple

Outdoor Weather Data

Collection Sites

• Weather Station Installed at

Bayer Site Jacksonville, FL

– 2004 to 2007

• Moved to Homestead, FL

(Q-Lab)

– 2008 to 2014

ASTM D7869 17 We Make Testing Simple

Outdoor Weather

Data Collected

• Solar Radiation (Sunlight)

• Temperature

– Air, Black Panel, Relative Humidity and Dew Point

• Wind

– Speed and Direction

• Rain

– Amount, Duration, Rate Accumulation

• Panel Weight

– Wetness, Dew Events and Rain Events

ASTM D7869 18 We Make Testing Simple

Outdoor Weather

Water Data Measurements

• Mass of panel measured

every 5 min

– Panel + Water

• Calibrated regularly

• Care taken to ensure no

animal or bird influence

• Able to see rain vs dew +

water-uptake

ASTM D7869 19 We Make Testing Simple

Water on Test Panels

Rain Dew

ASTM D7869 20 We Make Testing Simple

Dew on Painted Panels

30

C

25

Grams Water on Panel

20

B

E

15

10

D

5

Wind Noise

A

0

Day 1 Day 2 Day 3 Day 4 Day 5

ASTM D7869 21 We Make Testing Simple

Developing a Library of

Outdoor Weathering Data

Driving towards correlation

ASTM D7869 22 We Make Testing Simple

Outdoor Testing

Sample selection

• Sample set includes both

common field failures & controls

• 106 Combinations Prepared

– 4 colors: Black, White, Blue, Red

– Waterborne & Solventborne Base

– Solventborne Clear

– Different layering systems

– With and without Stabilizers

• All Samples prepared by one lab

ASTM D7869 23 We Make Testing Simple

Outdoor Testing

Test Protocol

• Testing conducted per SAE J1976

• Evaluations every 6 months

• Exposure times

• Full Set Summer 2006

• Partial Set Summer 2007

• Expose Until Failure

ASTM D7869 24 We Make Testing Simple

Developing the

ASTM D7869 Accelerated

Laboratory Test Cycle

Using outdoor weather characteristics

to guide accelerated testing

ASTM D7869 25 We Make Testing Simple

Learnings from Outdoor for New

Accelerated Weathering Test

• Global benchmark location: South Florida

• Light intensity: use higher-intensity light with

correct spectrum to increase acceleration

• Heat: Keep temperatures realistic, at or below

service

• Time of wetness: Increase! Mimic real-world

behavior - panels wet 12+ hrs/day in Florida

• Water spray: Never spray panels during light step;

it never rains when sun is shining brightly!

ASTM D7869 26 We Make Testing Simple

Sunlight

• Explored different light sources

• Explored different optical filters

• Accelerated outdoor weathering

(Q-TRAC) provided tantalizing

results

• Better match to sunlight just

might work, but be careful …

ASTM D7869 27 We Make Testing Simple

The wrong light source gives

the wrong results!

Borosilicate filtered

xenon arc Florida

Peters/Misovski/Roberts/Lemaire/Fischer

ASTM D7869 28 We Make Testing Simple

Accelerating irradiance

8

Atlas

CIRA/SL Q-Lab Polyester/Urethane

7 Xenon Daylight-Q

Atlas B/B Xenon

Q-Lab Daylight B/B

6 Q-TRAC

No available filters accurately

5

reproduced photooxidation!

∆(a/b)

QUV UVA340

4 FL

SUPRAX

3

Q-Lab Q/B Xenon

2 AZ

SEPAP

1

Atlas Q/B Xenon

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Peters/Misovski/Roberts/Lemaire/Fischer

∆(c/d)

ASTM D7869 29 We Make Testing Simple

Accelerated Light Source

• Development team sought a light source with a

better match to the solar spectrum

• Result: a new optical filter now commercially

available from all major equipment

manufacturers

– Daylight – F (Q-Lab)

– Right Light (Atlas)

• Produces more realistic results

– Allows higher irradiance, better acceleration

ASTM D7869 30 We Make Testing Simple

New Optical Filters

Very good match to sunlight, ability to accelerate with higher irradiance

ASTM D7869 31 We Make Testing Simple

New Optical Filters

Very good match to sunlight, ability to accelerate with higher irradiance

ASTM D7869 32 We Make Testing Simple

Heat

High temperature serves primarily

to accelerate water uptake. Two

key guiding principles:

1. Do not exceed maximum service

temperature

2. Use realistic temperatures to

increase correlation

ASTM D7869 33 We Make Testing Simple

Water contributes to material

degradation in many ways

• Plasticization – reduced modulus

• Swelling – induced stresses due to differential stresses

• Blistering – localized swelling and rupture

• Adhesion – accumulation of water at interface, breakdown

of interfacial bonds.

• Mass transport – movement of small molecules and

reaction products through film.

• Mass loss – removal of film (degradation products) from

surface of the coating due to erosion.

ASTM D7869 34 We Make Testing Simple

Water

• Establish maximum amount painted

panel can hold

• Establish minimum amount of water

that must reach the specimens

• Determine if accelerated weathering

devices can produce enough water

• Determine Repeatability &

Reproducibility

ASTM D7869 35 We Make Testing Simple

Water Delivery Calibration:

Sponge Test

• Can be used in both flat array &

rotating drum tester architectures

• Same size & type of sponge in same

holder type used in both machines

• Results were Repeatable &

Reproducible

ASTM D7869 36 We Make Testing Simple

Sponge Water Calibration Tests

Rotating Drum Flat Array

Shielded sponge holder

ASTM D7869 37 We Make Testing Simple

Connecting Accelerated Test to

Outdoor Weather Data

• Needed to better match sunlight spectrum

– New optical filter, increased intensity

• Test temperatures need to be reasonable

– Realistic temperatures chosen, below maximum

• Panels were wet longer that commonly believed

– Water delivery calibration system devised

This data helped construct an accurate model for use in

developing an accelerated test method

ASTM D7869 38 We Make Testing Simple

Development of ASTM

D7869 Test Cycle

ASTM D7869 39 We Make Testing Simple

Test Development

• Many years of experimentation

– 1st group: BASF, Bayer, Ford, Q-Lab

– 2nd group: Honda, Boeing, Atlas

• Dozens of different approaches

• Multiple runs of final test to ensure

repeatability & reproducibility

ASTM D7869 40 We Make Testing Simple

Outdoor Light and Water

Typical Florida Daily Cycle

Light Intensity

Panel Water

Content

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 41 We Make Testing Simple

Irradiance

SAE J2527

Water Spray Not a Good Match with Outdoor Weather

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 42 We Make Testing Simple

Outdoor Light and Water

Typical Florida Daily Cycle

Light Intensity

Panel Water

Content

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 43 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Reproducing Natural Weather Cycles

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 44 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Deep Water Penetration

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

Deep Water

0.5

Penetration

0.4

0.3 Adhesion,

Blistering,

0.2

Diffusion

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 45 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Separating Water and Light

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

No spray

0.5

during light

0.4 steps

0.3

Avoids

unrealistic

0.2

0.1 failures

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 46 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Thermal Cycling

1.0

Cyclic Stresses (cracking)

0.9 Surface Erosion (gloss)

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 47 We Make Testing Simple

ASTM D7869

Comparison to SAE J2527

• In a 24 hr period, SAE J2527 uses more water

than ASTM D7869, but …

– Never delivers enough water at one time

– Sprays water during the light cycle causing unrealistic

failures with modern coatings

• Fundamentally two different test cycles

– As different as 102/18 and SAE J2527

ASTM D7869 48 We Make Testing Simple

ASTM D7869

Step-by-Step

ASTM D7869 49 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 1

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5 Step 1

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 50 We Make Testing Simple

Step 1 240 min Dark + Spray

Air = 40°C RH = 95%+

Purpose: Reproduce Water Uptake

equal to normal night in Florida

• Close to total saturation

• Water uptake in Florida can exceed 5% of

coating volume, typical around 3.5%

• If not enough water test will fail to produce

realistic degradation

• More water uptake is OK, no negative effect

ASTM D7869 51 We Make Testing Simple

Step 1 240 min Dark + Spray

Air = 40°C RH = 95%+

Degradation Caused by Water Uptake

• Cracking

• Loss of inter-coat adhesion

• Delamination

• Loss of low molecular weight materials:

stabilizers, surfactants, acid catalysts.

• Gloss Loss

• Chalking

ASTM D7869 52 We Make Testing Simple

Step 1 240 min Dark + Spray

Air = 40°C RH = 95%+

Why 40oC Temperature?

• Higher temperature only occurs outdoors after

dry-off, as sun warms coating.

• Temperature less then 40°C makes water

uptake happen too slow.

• Water uptake at 40°C is twice as fast as 25°C

• Not so hot as to cause unnatural heat effects.

ASTM D7869 53 We Make Testing Simple

Step 1 240 min Dark + Spray

Air = 40°C RH = 95%+

Why 240 min (4 hours) of Spray?

• Florida wet temperatures are 20°-25°C

• Florida wet times are 8 to 16 hours.

• 4 hours at 40°C produces same water uptake

as longer, cooler Florida wet periods.

• Most outdoors wet time is at night so this

step has no irradiance

ASTM D7869 54 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 2

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2 Step 2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 55 We Make Testing Simple

Step 2 30 min Light 0.40 W/m2

BP = 50°C Air = 42°C RH = 50%

Purpose: Totally Remove Absorbed Water

• Sun completely dries coating by mid-morning

• Low irradiance, 0.40 W/m2, because sun is not

very bright by mid-morning

• 30 min is sufficient time to dry the coating

ASTM D7869 56 We Make Testing Simple

Step 2 30 min Light 0.40 W/m2

BP = 50oC Air = 42oC RH = 50%

Why 50 oC?

• Sun completely dries coating before specimens

get hotter than 50 oC

• Hotter temperature can cause unrealistic

cracking and micro-cracking, caused by coating

drying too fast

ASTM D7869 57 We Make Testing Simple

Step 2 30 min Light 0.40 W/m2

BP = 50oC Air = 42oC RH = 50%

Why 50% RH?

• Must control RH. Different RH’s will cause

different rates of drying - 50% produced most

realistic results

• Higher RH would take too long for dry-off

• Lower RH causes unrealistic failures

ASTM D7869 58 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 3

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4 Step 3

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 59 We Make Testing Simple

Step 3 270 min Light 0.80 W/m2

BP = 70°C Air = 50°C RH = 50%

Purpose: Simulate Effects of

Bright Sunlight

• Mostly surface effects. Light does not penetrate

into the bulk polymer like water does.

• Photo-oxidations

• Gloss Loss

• Color Change

• Micro-cracking

ASTM D7869 60 We Make Testing Simple

Step 3 270 min Light 0.80 W/m2

BP = 70°C Air = 50°C RH = 50%

Why 0.80 W/m2/nm irradiance?

• Produces realistic accelerated aging

• Higher than maximum irradiance of noon

midsummer sunlight (~0.68 W/m2)

• Most sunlight exposure is lower than

0.68 W/m2

• Data shows 0.80 W/m2 was highest irradiance

that produced realistic degradation

ASTM D7869 61 We Make Testing Simple

Step 3 270 min Light 0.80 W/m2

BP = 70°C Air = 50°C RH = 50%

Why 70°C?

• Reasonable, realistic temperature

• White specimens rarely exceed 55°C.

• Black specimens may reach 80°C.

• These temperatures only occur near noon in

summertime.

• Produced the most realistic results – higher

temperatures were tried

ASTM D7869 62 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 4

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2 Step 4

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 63 We Make Testing Simple

Step 4 30 min Light 0.40 W/m2

BP = 50°C Air = 42°C RH = 50%

Purpose: Transitional “relaxation”

from hot dry to cool wet.

• Gradually reduces thermal stresses.

• Similar temperature and irradiance as

afternoon sun gets lower.

• Unnatural cracking can occur if cold water is

sprayed on a hot specimen

ASTM D7869 64 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 5

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

Step

0.5

5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 65 We Make Testing Simple

Step 5 150 min Dark + Spray

Air = 40°C RH = 95%+

Purpose: Significant water uptake, but

less than maximum

• Maximum water uptake does not occur every day.

• Simulates days with less than maximum water

uptake.

Note: In combination with Step 6, gives a total of 180 min of wetting,

though only happens once every cycle

ASTM D7869 66 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Steps 6-9 (repeat 4x)

1.0

Steps 6-9, Repeat 4x

0.9 Cyclic Stresses (cracking)

Irradiance (W/m2/nm @340nm)

0.8 Surface Erosion (gloss)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 67 We Make Testing Simple

Steps 6 - 9 Subcycle, Repeated 4 Times

Purpose: Rapid thermal cycling and

wet / dry cycling

• Tests mechanical and viscoelastic properties.

– Cracking & delamination

• Total time of one complete cycle is 24 hours

(first five steps + sub cycles)

ASTM D7869 68 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 6

1.0

0.9 Step 6

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 69 We Make Testing Simple

Step 6 30 min Dark + Spray

Air = 40°C RH = 95%+

Purpose: Simulate Short Water Event

• Event such as a night with little

condensation or brief rain event.

• 30 minutes only creates water uptake in

surface layers.

• Not enough time to permeate lower layers.

ASTM D7869 70 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 7

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2 Step 7

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 71 We Make Testing Simple

Step 7 20 min Light 0.40 W/m2

BP = 50°C Air = 42°C RH = 50%

Purpose: Remove water from

polymer at a controlled rate.

• Similar to Steps 2 and 4, but shorter.

• Because Step 6 was short, Step 7 can

also be short.

ASTM D7869 72 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 8

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

Step

8

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 73 We Make Testing Simple

Step 8 120 min Light 0.80 W/m2

BP = 70°C Air = 50°C RH = 50%

Purpose: Rapid heating to

create mechanical stresses

• Same conditions as Step 3, but shorter

• Time is short to promote rapid thermal cycling

– High irradiance also contributes to

photo-chemical damage

– That is a secondary purpose

ASTM D7869 74 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Step 9

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2 Step

9

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 75 We Make Testing Simple

Step 9 10 min Dark

Air = 40°C RH = 50%

Purpose: Total relaxation from all

stress

• Natural exposure has frequent periods with no

stress from sunlight, temperature or water

• A laboratory exposure with no periods of total

relaxation might cause unnatural effects, like

cracking.

ASTM D7869 76 We Make Testing Simple

Irradiance

ASTM D7869

Water Spray Reproducing Natural Weather Cycles

1.0

0.9

Irradiance (W/m2/nm @340nm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hours)

ASTM D7869 77 We Make Testing Simple

Validating the test

method

Putting the ASTM D7869

protocol to the test

ASTM D7869 78 We Make Testing Simple

Paint Systems Tested

Automotive

• ~20 systems, multiple colors

• All systems were base coat / clear coat

• Fortified and unfortified

• Positive controls & known Florida exposure failure

mechanisms

Aerospace

• Four systems, two colors (blue and white)

• Two monocoat systems, two base coat / clear coat systems

• Florida, and in-service performance known

ASTM D7869 79 We Make Testing Simple

Potential Failure Modes to look

for in validation testing

• Chemical change

• Cracking

• Blistering

• Adhesion loss

• Color

• Gloss loss

ASTM D7869 80 We Make Testing Simple

Example: System 86

Florida Exposure SAE J2527 ASTM D7869

Expected Failure Mode: None – positive control

Observed: Excellent performance in all tests

ASTM D7869 81 We Make Testing Simple

Example: System 13

Florida Exposure SAE J2527 ASTM D7869

Expected Failure Mode: Slight BC/E-coat pick off.

Observed: Slight BC/E-coat pick-off on Florida and ASTM D7869

ASTM D7869 82 We Make Testing Simple

Example: System 25

Florida Exposure SAE J2527 ASTM D7869

Expected Failure Mode: BC/E-coat delamination.

Observed: C/E delamination on Florida pick off on New Protocol

Why such a difference?

ASTM D7869 83 We Make Testing Simple

High magnification of Panel 25

Florida Exposure SAE J2527 ASTM D7869

Applied coating thickness was inconsistent!

Correcting this brought FL and ASTM D7869 in line

ASTM D7869 84 We Make Testing Simple

Example: System 103

Florida Exposure SAE J2527 ASTM D7869

Expected Failure Mode: Blistering, gloss loss, adhesion loss

Observed: Gloss loss and adhesion loss seen on all

panels.Blistering on ASTM D7869 mimics that seen on Florida

ASTM D7869 85 We Make Testing Simple

Failure Modes

How did ASTM D7869 perform?

• Chemical change - correctly reproduced

• Cracking – correctly reproduced

• Blistering – correctly reproduced

• Adhesion loss – mostly reproduced

• Correctly reproduced after further review!

• Color - correctly reproduced

• Gloss loss – correctly reproduced

ASTM D7869 86 We Make Testing Simple

ASTM D7869 compared to SAE J2527

and Florida

• Physical failures correctly reproduced.

• Degradation chemistry is correct.

• New protocol is 40% faster

ASTM D7869 87 We Make Testing Simple

Conclusions: ASTM D7869

• ASTM D7869 accelerated lab weathering test cycle is thoroughly

researched - developed using scientific understanding of outdoor

weather phenomena – light, heat, and water

• Test cycle was validated by comparison of results to long-term

outdoor weathering data of a variety of coatings systems

• ASTM D7869 is realistic - it reproduces faithfully almost all physical

failure mechanisms and is 40% faster than current test method.

• Introduction of this new weathering protocol allows for more rapid

and accurate accelerated weathering results. These can be

correlated with outdoor test data to give powerful information.

ASTM D7869 88 We Make Testing Simple

Questions?

info@q-lab.com

www.q-lab.com

ASTM D7869 89 We Make Testing Simple

Potrebbero piacerti anche

- Weatherability of Plastic CompoundsDocumento5 pagineWeatherability of Plastic Compoundsnikopigni2Nessuna valutazione finora

- How to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970Da EverandHow to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970Valutazione: 5 su 5 stelle5/5 (1)

- Astm D4060 14Documento5 pagineAstm D4060 14hadi ebrahimfathNessuna valutazione finora

- Carbon Black - WikipediaDocumento6 pagineCarbon Black - WikipediaAdeleke JosephNessuna valutazione finora

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Da EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Nessuna valutazione finora

- PVC 57ger01Documento1 paginaPVC 57ger01rajesh patelNessuna valutazione finora

- An Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsDocumento4 pagineAn Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsAlejandro 20Nessuna valutazione finora

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975Da EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovValutazione: 5 su 5 stelle5/5 (1)

- Synthetic Resins and Their Raw Materials - United States Tariff CommissionDocumento220 pagineSynthetic Resins and Their Raw Materials - United States Tariff CommissionKevin Lora VillarrealNessuna valutazione finora

- 2 Astm D6943Documento16 pagine2 Astm D6943Boris CardenasNessuna valutazione finora

- Cellulose EstersDocumento45 pagineCellulose Estersmghaffarzadeh1970100% (2)

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsDa EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNessuna valutazione finora

- Hydrolyzable Chloride Content of Liquid Epoxy Resins: Standard Test Methods ForDocumento3 pagineHydrolyzable Chloride Content of Liquid Epoxy Resins: Standard Test Methods Foralienz1988newNessuna valutazione finora

- Adhesive Test MethodsDocumento17 pagineAdhesive Test MethodsTensile TestingNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento18 pagineDisclosure To Promote The Right To Informationsudhir5441Nessuna valutazione finora

- D344 Standard Test Method For Relative Hiding Power of Paints by The Visual Evaluation of BrushoutsDocumento4 pagineD344 Standard Test Method For Relative Hiding Power of Paints by The Visual Evaluation of BrushoutsGiovanni Osorio100% (1)

- Water Vapor Transmission of Materials: Standard Test Methods ForDocumento12 pagineWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573Nessuna valutazione finora

- Latapoxy SP 100 TDSDocumento3 pagineLatapoxy SP 100 TDSBithika DattaNessuna valutazione finora

- Gloss MeterDocumento2 pagineGloss Meterravi00098Nessuna valutazione finora

- Wet-to-Dry Hiding Change: Standard Test Method ForDocumento5 pagineWet-to-Dry Hiding Change: Standard Test Method ForShaker QaidiNessuna valutazione finora

- Astm D2613Documento5 pagineAstm D2613Kevin RojasNessuna valutazione finora

- C827 PDFDocumento5 pagineC827 PDFRam Kumar JaiswalNessuna valutazione finora

- D4946 Block Resistance PDFDocumento2 pagineD4946 Block Resistance PDFMaurice Davis100% (1)

- Astm D332Documento3 pagineAstm D332NizarHamrouniNessuna valutazione finora

- ASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible PaintsDocumento2 pagineASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible Paintshenry rojasNessuna valutazione finora

- D 2574 - 97 Rdi1nzqtukveDocumento4 pagineD 2574 - 97 Rdi1nzqtukveGuritno GustiantoNessuna valutazione finora

- Dow Construction ChemcalDocumento7 pagineDow Construction ChemcalchayanunNessuna valutazione finora

- Oven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDocumento3 pagineOven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDiego100% (1)

- Natural Wathering Vs Uv FluorecsentDocumento12 pagineNatural Wathering Vs Uv Fluorecsentnikopigni2Nessuna valutazione finora

- Blindside WaterproofingDocumento4 pagineBlindside WaterproofingPramod V PatilNessuna valutazione finora

- ASTMD937-97 PetrolatumDocumento2 pagineASTMD937-97 Petrolatuminfinity1200100% (1)

- Advances in Aerogel Composites for Environmental RemediationDa EverandAdvances in Aerogel Composites for Environmental RemediationAftab Aslam Parwaz KhanNessuna valutazione finora

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachDa EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudValutazione: 5 su 5 stelle5/5 (1)

- Anticarbonation CoatingsDocumento19 pagineAnticarbonation CoatingsNikhil R DhoreNessuna valutazione finora

- RAHN Resinas FotocurablesDocumento25 pagineRAHN Resinas FotocurablesMargaret RogersNessuna valutazione finora

- Aniket Dharanakar ReportDocumento82 pagineAniket Dharanakar ReportAKSHAY JEDHENessuna valutazione finora

- ASTM D-4541-Adhesion-Testing-CrollDocumento15 pagineASTM D-4541-Adhesion-Testing-CrollsanjaigNessuna valutazione finora

- Epoxy Bonding AgentDocumento2 pagineEpoxy Bonding AgentbarunNessuna valutazione finora

- Krebs Unit Viscometer Model Ku-2: Digital Direct Display of Viscosity in Krebs UnitsDocumento3 pagineKrebs Unit Viscometer Model Ku-2: Digital Direct Display of Viscosity in Krebs UnitsAndre Santiago100% (1)

- 1411 - Explanation To Product Data SheetsDocumento0 pagine1411 - Explanation To Product Data SheetseraswastaNessuna valutazione finora

- ASTM Color y Poder TintoreoDocumento5 pagineASTM Color y Poder TintoreoLuis Felipe BenavidesNessuna valutazione finora

- Product Data Sheet: Butyl AcetateDocumento1 paginaProduct Data Sheet: Butyl AcetateHemant RathvaNessuna valutazione finora

- Handbook of Vinyl FormulatingDa EverandHandbook of Vinyl FormulatingRichard F GrossmanValutazione: 3 su 5 stelle3/5 (1)

- C61-C61M - 00 (Reapproved 2011)Documento3 pagineC61-C61M - 00 (Reapproved 2011)Black Goku100% (1)

- Additive Reference GuideDocumento41 pagineAdditive Reference GuideUsama AwadNessuna valutazione finora

- Optimizing Catalytic Drying of Paints and Varnishes Case Study at SmaltoDocumento10 pagineOptimizing Catalytic Drying of Paints and Varnishes Case Study at SmaltoKAVYANSH SAXENANessuna valutazione finora

- One-Part Epoxy ResinDocumento10 pagineOne-Part Epoxy ResinyangboNessuna valutazione finora

- Molybdate and Borate Complexes For Enhanced Cable Compound Fire Performance Technical PaperDocumento7 pagineMolybdate and Borate Complexes For Enhanced Cable Compound Fire Performance Technical PapernilayNessuna valutazione finora

- D2094-00 (2014) Standard Practice For Preparation of Bar and Rod Specimens For Adhesion TestsDocumento4 pagineD2094-00 (2014) Standard Practice For Preparation of Bar and Rod Specimens For Adhesion Testsjose flores100% (1)

- D1199Documento2 pagineD1199Ненад КнежевићNessuna valutazione finora

- The Determination of Epoxide Groups: Monographs in Organic Functional Group AnalysisDa EverandThe Determination of Epoxide Groups: Monographs in Organic Functional Group AnalysisNessuna valutazione finora

- Faster Return To Service Prospector October 2019 PDFDocumento20 pagineFaster Return To Service Prospector October 2019 PDFJuan Angel DechimaNessuna valutazione finora

- Elementary Linear AlgebraDocumento202 pagineElementary Linear AlgebraMohamed HassanNessuna valutazione finora

- Astm D4060-10Documento5 pagineAstm D4060-10Diomer Alzate Berrio100% (1)

- Solsperse 76400: Product DescriptionDocumento2 pagineSolsperse 76400: Product DescriptionJuan Angel DechimaNessuna valutazione finora

- BASF April 2019 Solyfast Webinar Final PDFDocumento20 pagineBASF April 2019 Solyfast Webinar Final PDFJuan Angel DechimaNessuna valutazione finora

- Contact Worldwide: Asia North AmericaDocumento7 pagineContact Worldwide: Asia North AmericaJuan Angel DechimaNessuna valutazione finora

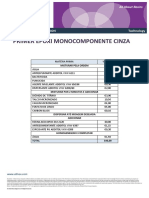

- Primer Epoxy Acuoso Monocomponente GrisDocumento1 paginaPrimer Epoxy Acuoso Monocomponente GrisJuan Angel DechimaNessuna valutazione finora

- NANOBYK-3652: Product DataDocumento2 pagineNANOBYK-3652: Product DataJuan Angel DechimaNessuna valutazione finora

- BASF April 2019 Solyfast Webinar Final PDFDocumento20 pagineBASF April 2019 Solyfast Webinar Final PDFJuan Angel DechimaNessuna valutazione finora

- Byk 4510Documento2 pagineByk 4510Juan Angel DechimaNessuna valutazione finora

- Faster Return To Service Prospector October 2019 PDFDocumento20 pagineFaster Return To Service Prospector October 2019 PDFJuan Angel DechimaNessuna valutazione finora

- Achieve Bestin Class Durability of Your Polyurethanebased Coatings Adhesives Thanks To Breakthrough Polycarbonate DiolsDocumento36 pagineAchieve Bestin Class Durability of Your Polyurethanebased Coatings Adhesives Thanks To Breakthrough Polycarbonate DiolsJuan Angel DechimaNessuna valutazione finora

- Silikophen Ac 1000 ManualDocumento5 pagineSilikophen Ac 1000 ManualJuan Angel Dechima100% (1)

- Esmalte Epóxi Monocomponente-Beckopox em 2120 - Metal PDFDocumento1 paginaEsmalte Epóxi Monocomponente-Beckopox em 2120 - Metal PDFJuan Angel DechimaNessuna valutazione finora

- FLTM Bi 160-01 Florida and Arizona Outdoor Exposure TestDocumento5 pagineFLTM Bi 160-01 Florida and Arizona Outdoor Exposure TestJuan Angel DechimaNessuna valutazione finora

- Naya EpoxyDocumento20 pagineNaya EpoxySao BangNessuna valutazione finora

- Aptalon Polyamide Polyurethane Technology BrochureDocumento8 pagineAptalon Polyamide Polyurethane Technology BrochureJuan Angel DechimaNessuna valutazione finora

- The Degradation of Coatings by Ultraviolet LightDocumento159 pagineThe Degradation of Coatings by Ultraviolet LightJuan Angel DechimaNessuna valutazione finora

- HojaDocumento1 paginaHojaJuan Angel DechimaNessuna valutazione finora

- ASTM D714-02 (2009) Standard Test Method For Evaluating Degree of Blistering of PaintsDocumento6 pagineASTM D714-02 (2009) Standard Test Method For Evaluating Degree of Blistering of PaintsJuan Angel DechimaNessuna valutazione finora

- Acrylic Resins For Metal CoatingsDocumento1 paginaAcrylic Resins For Metal CoatingsJuan Angel DechimaNessuna valutazione finora

- WSS M16J19 BDocumento10 pagineWSS M16J19 BJuan Angel DechimaNessuna valutazione finora

- Waxes For Wood CoatingsDocumento2 pagineWaxes For Wood CoatingsJuan Angel DechimaNessuna valutazione finora

- The Degradation of Coatings by Ultraviolet Light PDFDocumento4 pagineThe Degradation of Coatings by Ultraviolet Light PDFJuan Angel DechimaNessuna valutazione finora

- WSS M2P180 DDocumento12 pagineWSS M2P180 DJuan Angel DechimaNessuna valutazione finora

- Products For Radiation CuringDocumento12 pagineProducts For Radiation CuringJuan Angel DechimaNessuna valutazione finora

- SilberlineBrochure2011 SmallDocumento18 pagineSilberlineBrochure2011 SmallJuan Angel DechimaNessuna valutazione finora

- A Review On Durability of Fiber Reinforced Polymer (FRP) Bars ReinforcedDocumento18 pagineA Review On Durability of Fiber Reinforced Polymer (FRP) Bars Reinforcedsherif fodaNessuna valutazione finora

- Boilers OperationDocumento50 pagineBoilers Operationtsrinivasan5083100% (1)

- B. Importance of Preheat, Interpass, DHT, Isr, PWHTDocumento19 pagineB. Importance of Preheat, Interpass, DHT, Isr, PWHTJay ShahNessuna valutazione finora

- Hydrogen Fuel Cells AbstractDocumento3 pagineHydrogen Fuel Cells AbstractAKNessuna valutazione finora

- TP07 Castillo PDFDocumento8 pagineTP07 Castillo PDFJefreyMatuanMondranoNessuna valutazione finora

- CEN 512 Pile Capacity and Settlement Based On Soil PropertiesDocumento4 pagineCEN 512 Pile Capacity and Settlement Based On Soil PropertiesGrace SantiagoNessuna valutazione finora

- Generic TWS600S Service ManualDocumento113 pagineGeneric TWS600S Service ManualWise So100% (2)

- Soil Type DatasheetsDocumento13 pagineSoil Type DatasheetsAoife FitzgeraldNessuna valutazione finora

- Oceanography For General Studies UPSC Civil Services Exam: Short Notes PDFDocumento71 pagineOceanography For General Studies UPSC Civil Services Exam: Short Notes PDFHari ShankarNessuna valutazione finora

- An Interceu Busbar Topology To Improve Resilience To Anomalies of Copper Electrorefining ProcessDocumento6 pagineAn Interceu Busbar Topology To Improve Resilience To Anomalies of Copper Electrorefining ProcessPablo ParraguezNessuna valutazione finora

- K1 Level Multiple Choice Questions: vib - hυDocumento11 pagineK1 Level Multiple Choice Questions: vib - hυJack AndrewNessuna valutazione finora

- heat-exchangers-TEMA TYPEDocumento12 pagineheat-exchangers-TEMA TYPEvaibhavNessuna valutazione finora

- Aplicatii Keyence - Digitalizari - Masuratori 2020 PDFDocumento8 pagineAplicatii Keyence - Digitalizari - Masuratori 2020 PDFArjocan Emil DanNessuna valutazione finora

- Chapter 1 - Gas LawDocumento52 pagineChapter 1 - Gas LawLolindah ChinNessuna valutazione finora

- Engine Lubrication & Cooling Systems: SectionDocumento5 pagineEngine Lubrication & Cooling Systems: SectionGastonNessuna valutazione finora

- ME320 Professor John M. Cimbala: Water Draining From A TankDocumento6 pagineME320 Professor John M. Cimbala: Water Draining From A TankShohag HossainNessuna valutazione finora

- Idemitsu - Mechanic Oil SeriesDocumento2 pagineIdemitsu - Mechanic Oil SeriesarieprachmanNessuna valutazione finora

- Course:: CeramicsDocumento56 pagineCourse:: CeramicsSobhe ShoshaNessuna valutazione finora

- Gazil, Jerico June C. Module 3 With AnswerDocumento2 pagineGazil, Jerico June C. Module 3 With AnswerJunior PayatotNessuna valutazione finora

- Water Pumps and Pumping SystemsDocumento38 pagineWater Pumps and Pumping SystemsmelgamalNessuna valutazione finora

- Gonzalo Castro SlidesDocumento34 pagineGonzalo Castro SlidesFrancisco Javier Acuña OlateNessuna valutazione finora

- RFDA Basic EquipmentDocumento1 paginaRFDA Basic EquipmentRaida Ben SalahNessuna valutazione finora

- Me Trology 8Documento25 pagineMe Trology 8HARIMETLYNessuna valutazione finora

- Thermal ConductivityDocumento5 pagineThermal ConductivitySiva Kumar SalumuriNessuna valutazione finora

- VRF Application DAIKIN PDFDocumento256 pagineVRF Application DAIKIN PDFMohamed Yassine LahianiNessuna valutazione finora

- Exercise 6Documento4 pagineExercise 6JorgeNessuna valutazione finora

- Steel Making Processes: Dr. Laraib Sarfraz KhanzadaDocumento23 pagineSteel Making Processes: Dr. Laraib Sarfraz KhanzadaAsher AhmedNessuna valutazione finora

- Poly (Vinylidene Fluoride) Clay Nanocomposites Prepared byDocumento8 paginePoly (Vinylidene Fluoride) Clay Nanocomposites Prepared byPrapto PraptNessuna valutazione finora

- Indian Standard: Methods of Test For CablesDocumento3 pagineIndian Standard: Methods of Test For CablesVatsalNessuna valutazione finora

- Nadca - Overview of Defets in Die CastingDocumento197 pagineNadca - Overview of Defets in Die CastingJayabharath Rajadurai100% (8)