Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boiler Mountings and Accessories

Caricato da

RabinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boiler Mountings and Accessories

Caricato da

RabinCopyright:

Formati disponibili

9

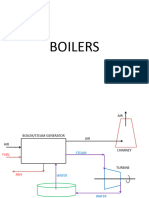

BOILER MOUNTINGS AND ACCESSORIES:

BOILER MOUNTING: BOILER MOUNTINGS are the components generally mounted on the surface of

the boiler to have safety during operation. These are the essential parts of the boiler, without which

the boiler operation is not possible. The following are the important mountings of the boiler:

Water level indicator

Safety valve

Pressure gauge

Steam stop valve

Feed check valve

Main hole

1. Water level indicator: this device indicates the exact level of water in the boiler tube.

2. Safety valve: it is a mechanical device used to safeguard the boiler, in case the pressure

inside the boiler rises above its normal working atmosphere.

3. Pressure gauge: the pressure gauge commonly used is the bourdon pressure gauge

mounted on the front top of the boiler shell.

4. Steam stop valve: the function of the steam stop valve is to stop or open the steam supply

from the boiler to the point of application.

5. Feed check valve: a valve placed at the boiler end to regulate the flow of water.

6. Main hole: it is the opening provided of cleaning or inspection.

BOILER ACCESSORIES

These are those devices which are installed with a boiler and its neighbouring area to

increase the efficiency of the boiler. These are not the essential part of the boiler and

thus without installing these devices, the boiler operation can be accomplished though

at a lower efficiency. The following are the important accessories of the boiler are:

Feed water pump

Injector

Pressure reducing valve

Economiser

Air pre heater

Super heater

Steam drier or separator

Steam trap

1. Feed water pump: the feed water pump is used to feed water to the boiler.

2. Injector: function of the injector is the same as that of feed pump i.e.; to

deliver feed water to boiler under pressure.

9

3. Pressure reducing valve: the function of the pressure reducing valve is to

maintain constant pressure on its delivery side of the valve irrespective of

fluctuating demand of steam from the boiler.

4. Economiser: a considerable quantity of heat of the plant is carried away by

flue gases, so to utilise these waste heat. An economiser is placed in the path

of the flue gases to preheat the feed water.

5. Air pre – heater: the function of the pre- heater is to heat the air before it

enters the combustion chamber.

6. Super heater: super pre-heater is used for stationary boiler. The function of

the super heater is to convert dry saturated steam into super heated at the

desired temperature.

7. Steam drier: the function of the steam drier or separator is to separate

water particles from steam before it is supplied to the point of application.

Potrebbero piacerti anche

- Boiler Mountings and AccessoriesDocumento3 pagineBoiler Mountings and AccessoriesAbdul RehmanNessuna valutazione finora

- Boiler Mountings and AccessoriesDocumento17 pagineBoiler Mountings and AccessoriesYogesh ChaudhariNessuna valutazione finora

- Boiler Mountings and AccessoriesDocumento3 pagineBoiler Mountings and AccessoriesSonjan FloresNessuna valutazione finora

- Boiler Mounting & AccessoriesDocumento14 pagineBoiler Mounting & Accessoriesshiraj36100% (1)

- Boiler Mountings and Accessories Details With Video LectureDocumento15 pagineBoiler Mountings and Accessories Details With Video LectureMahamudul Haque ShawonNessuna valutazione finora

- Boilers ClassificationDocumento4 pagineBoilers ClassificationTech GuruNessuna valutazione finora

- Unit 5Documento44 pagineUnit 5jothik1992_219826838Nessuna valutazione finora

- Boiler Mountings and AccessoriesDocumento14 pagineBoiler Mountings and AccessoriesAnil DamaheNessuna valutazione finora

- Experiment No. 2-To Study The Mountings and Accessories in BoilersDocumento10 pagineExperiment No. 2-To Study The Mountings and Accessories in BoilersShahed100% (1)

- Boiler Mountings and AccessoriesDocumento9 pagineBoiler Mountings and AccessoriesArpit KapoorNessuna valutazione finora

- Elements of Mechanical Engineering: Sub:Boiler MountingDocumento15 pagineElements of Mechanical Engineering: Sub:Boiler MountinglalaNessuna valutazione finora

- Different Feat.Documento11 pagineDifferent Feat.TITU NATHNessuna valutazione finora

- Steam Generators Lecture No.-3Documento21 pagineSteam Generators Lecture No.-3rathoraryan2003Nessuna valutazione finora

- BOILER MOUNTINGS ADocumento17 pagineBOILER MOUNTINGS Ahafiz aiman100% (1)

- BoilerDocumento17 pagineBoilerVictoryNessuna valutazione finora

- Water Tube Boiler: Babcock and WilcoxDocumento8 pagineWater Tube Boiler: Babcock and WilcoxJosue Carubio Ricalde Jr.Nessuna valutazione finora

- Boiler Mountings and AccessoriesDocumento4 pagineBoiler Mountings and AccessorieshumshkhNessuna valutazione finora

- Salient Features of Boiler MountingsDocumento48 pagineSalient Features of Boiler MountingsShridhar ShirodkerNessuna valutazione finora

- Boiler Operation and Safety PrecautionDocumento66 pagineBoiler Operation and Safety PrecautionSahil Mishra100% (1)

- Boiler Expt 2Documento15 pagineBoiler Expt 2aashiquear100% (2)

- Engine Rating BoilerDocumento3 pagineEngine Rating BoilerPranjyoti SaikiaNessuna valutazione finora

- To Study The Working and Function of Mounting & Accessories in BoilerDocumento10 pagineTo Study The Working and Function of Mounting & Accessories in BoilerMDR PRAPHUNessuna valutazione finora

- Boiler Mountings & AccessoriesDocumento4 pagineBoiler Mountings & Accessoriesshiraj36Nessuna valutazione finora

- BoilersDocumento39 pagineBoilerstheNessuna valutazione finora

- 03-Aux BoilerDocumento2 pagine03-Aux Boilernilakhan456790Nessuna valutazione finora

- Design, Development & AnallysisDocumento7 pagineDesign, Development & AnallysisBhavya SoamNessuna valutazione finora

- Hand Out-Boiler CompleteDocumento40 pagineHand Out-Boiler Completemuhammad umarNessuna valutazione finora

- Working and Function of Mounting & Accessories in BoilersDocumento6 pagineWorking and Function of Mounting & Accessories in BoilersaibelscribdNessuna valutazione finora

- Research Paper On ME LabDocumento12 pagineResearch Paper On ME LabJherel BerinNessuna valutazione finora

- Boiler Operation and ControlDocumento99 pagineBoiler Operation and Controlwassli100% (1)

- Power Plant EngineeringDocumento5 paginePower Plant EngineeringMonglafru MogNessuna valutazione finora

- Submitted To: Submitted To: Er - Janender Kumar Mahesh Er - Abhimanyu Verma 1710623 MechanicalDocumento36 pagineSubmitted To: Submitted To: Er - Janender Kumar Mahesh Er - Abhimanyu Verma 1710623 MechanicalMahesh KumarNessuna valutazione finora

- Boilers: By: Khalid Nawaz Institute of Chemical Engineering and Technology University of The Punjab Lahore PakistanDocumento26 pagineBoilers: By: Khalid Nawaz Institute of Chemical Engineering and Technology University of The Punjab Lahore PakistanTamer Abd ElrasoulNessuna valutazione finora

- What Are Boiler AccessoriesDocumento7 pagineWhat Are Boiler AccessoriesTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Boiler Exp 2Documento9 pagineBoiler Exp 2Naimul Hoque Shuvo100% (1)

- Boiler Mountings and AccessoriesDocumento15 pagineBoiler Mountings and AccessoriesAtul atulNessuna valutazione finora

- PPS Steam Boiler Operation and AuxiliariesDocumento9 paginePPS Steam Boiler Operation and AuxiliariesAraNessuna valutazione finora

- Boiler OperationDocumento97 pagineBoiler Operationdeeli1100% (2)

- Basic Mech Lab BE-203Documento27 pagineBasic Mech Lab BE-203ravindrapathak123100% (1)

- Boiler Mounting and AccesoriesDocumento5 pagineBoiler Mounting and AccesoriesTejas MirashiNessuna valutazione finora

- Thermal LabDocumento38 pagineThermal LabKRRISH MAHESHWARINessuna valutazione finora

- Boiler Safety Systems and InstrumentsDocumento6 pagineBoiler Safety Systems and InstrumentsАртем БабенкоNessuna valutazione finora

- Experiment 1: Steam Boiler Operation and Boiler MountingDocumento4 pagineExperiment 1: Steam Boiler Operation and Boiler Mountingsarjenputra07Nessuna valutazione finora

- What Is A Boiler? What Are Parts of A Boiler?Documento24 pagineWhat Is A Boiler? What Are Parts of A Boiler?dharanistrikezNessuna valutazione finora

- Steam Power PlantDocumento47 pagineSteam Power PlantNazuan NazriNessuna valutazione finora

- Babcock BoilerDocumento11 pagineBabcock BoilerKhuram IqbalNessuna valutazione finora

- Prepared By: Zerihun Kassa: UM at EABSC, Dec 2018Documento32 paginePrepared By: Zerihun Kassa: UM at EABSC, Dec 2018zerihun kassaNessuna valutazione finora

- MLAB 3 - BoilerDocumento3 pagineMLAB 3 - BoilerReden LopezNessuna valutazione finora

- Boiler Mountings and Accessories1Documento31 pagineBoiler Mountings and Accessories1anuranjanshardaNessuna valutazione finora

- Steam Boiler Operation and AuxiliariesDocumento9 pagineSteam Boiler Operation and Auxiliariesshin deiruNessuna valutazione finora

- Steam Boiler Instrument and Control: 1. Horizontal, Vertical or InclinedDocumento20 pagineSteam Boiler Instrument and Control: 1. Horizontal, Vertical or InclinedmorolosusNessuna valutazione finora

- Lecture 3 - 4 - Boiler Mountings and AccessoriesDocumento34 pagineLecture 3 - 4 - Boiler Mountings and AccessoriesFEALABREPORTSNessuna valutazione finora

- Boiler - Mountings & AccesssesoriesDocumento17 pagineBoiler - Mountings & AccesssesoriesNitric AcidNessuna valutazione finora

- Marine BoilerDocumento31 pagineMarine BoilerydwkpteagmNessuna valutazione finora

- Anhydrous Ammonia Vaporizer SystemDocumento2 pagineAnhydrous Ammonia Vaporizer Systemavinash-mokashiNessuna valutazione finora

- INDUSTRIAL BOILERS-editedDocumento9 pagineINDUSTRIAL BOILERS-editedComputer Graphics classNessuna valutazione finora

- BANAGADocumento5 pagineBANAGAKelly RobinNessuna valutazione finora

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewDa EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNessuna valutazione finora

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Introduction To Corporate Finance: Answers To Concept Questions 1Documento2 pagineIntroduction To Corporate Finance: Answers To Concept Questions 1tlatlaodNessuna valutazione finora

- Variety of MCQDocumento22 pagineVariety of MCQRabinNessuna valutazione finora

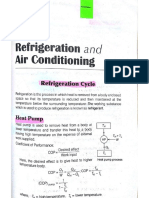

- RacDocumento17 pagineRacRabinNessuna valutazione finora

- L-23 (SM) (Ia&c) ( (Ee) Nptel)Documento23 pagineL-23 (SM) (Ia&c) ( (Ee) Nptel)Jayesh BaldotaNessuna valutazione finora

- Long-Term Financial Planning and Growth: Answers To Concepts Review and Critical Thinking Questions 1Documento33 pagineLong-Term Financial Planning and Growth: Answers To Concepts Review and Critical Thinking Questions 1RabinNessuna valutazione finora

- Fao and IloDocumento6 pagineFao and IloRabinNessuna valutazione finora

- Constitution of Nepal 2015 EnglishDocumento240 pagineConstitution of Nepal 2015 Englishtm515Nessuna valutazione finora

- Cost of Capital Solved ProblemsDocumento16 pagineCost of Capital Solved ProblemsHimanshu Sharma85% (207)

- Effects of Price ControlDocumento7 pagineEffects of Price ControlRabinNessuna valutazione finora

- Vibration-SOP EdittedDocumento2 pagineVibration-SOP EdittedRabinNessuna valutazione finora

- Mathematics: Concepts and QuestionnaireDocumento3 pagineMathematics: Concepts and QuestionnaireRabinNessuna valutazione finora

- Cost of Capital PDFDocumento40 pagineCost of Capital PDFRabinNessuna valutazione finora

- Cost of Capital Solved ProblemsDocumento16 pagineCost of Capital Solved ProblemsHimanshu Sharma85% (207)

- Nepal Electricity Authority ActDocumento16 pagineNepal Electricity Authority ActLeo KhkNessuna valutazione finora

- Chapter 4: Time Value of Money (Numerical Problems)Documento2 pagineChapter 4: Time Value of Money (Numerical Problems)RabinNessuna valutazione finora

- Day 1Documento1 paginaDay 1RabinNessuna valutazione finora

- InTech-Lubrication and Lubricants PDFDocumento22 pagineInTech-Lubrication and Lubricants PDFHarish BishtNessuna valutazione finora

- Climate Change Mitigation PoliciesDocumento11 pagineClimate Change Mitigation PoliciesRabinNessuna valutazione finora

- Climate Adapt 10 Case Studies OnlineDocumento28 pagineClimate Adapt 10 Case Studies OnlineRabinNessuna valutazione finora

- The Value of Linking Mitigation and Adaptation: A Case Study of BangladeshDocumento12 pagineThe Value of Linking Mitigation and Adaptation: A Case Study of BangladeshRabinNessuna valutazione finora

- Tutorial Set 9 SolutionsDocumento8 pagineTutorial Set 9 SolutionsRabinNessuna valutazione finora

- Solution Manual Financial Management 3rd Edition Raymond BrooksDocumento16 pagineSolution Manual Financial Management 3rd Edition Raymond BrooksRabin0% (1)

- Classical Rhetoric For The Modern Student, 4th Edition by Edward P. J. Corbett, Robert J. ConnorsDocumento4 pagineClassical Rhetoric For The Modern Student, 4th Edition by Edward P. J. Corbett, Robert J. ConnorsRabin17% (6)

- RoutineDocumento1 paginaRoutineRabinNessuna valutazione finora

- Understanding Financial StatementsDocumento19 pagineUnderstanding Financial StatementsRabinNessuna valutazione finora

- Agroforestry ClassDocumento2 pagineAgroforestry ClassRabinNessuna valutazione finora

- Air Pollution Is A Global Public Health EmergencyDocumento19 pagineAir Pollution Is A Global Public Health EmergencyRabinNessuna valutazione finora

- 25Documento1 pagina25RabinNessuna valutazione finora

- Ag Model Exam Question 2073-03-25Documento6 pagineAg Model Exam Question 2073-03-25RabinNessuna valutazione finora

- Ag Model Exam Question 2073-02-22Documento8 pagineAg Model Exam Question 2073-02-22RabinNessuna valutazione finora

- Business EthicsDocumento10 pagineBusiness EthicsTeguh HardiNessuna valutazione finora

- Hazop Close Out ReportDocumento6 pagineHazop Close Out ReportKailash PandeyNessuna valutazione finora

- Complex Poly (Lactic Acid) - Based - 1Documento20 pagineComplex Poly (Lactic Acid) - Based - 1Irina PaslaruNessuna valutazione finora

- Bubble Deck SlabDocumento29 pagineBubble Deck SlabJhimy Rusbel Gutierrez YanapaNessuna valutazione finora

- Check List For Design Program of A Parish ChurchDocumento11 pagineCheck List For Design Program of A Parish ChurchQuinn HarloweNessuna valutazione finora

- PLX Model OfficialDocumento105 paginePLX Model OfficialBảo Ngọc LêNessuna valutazione finora

- AC MachinesDocumento32 pagineAC Machinesjoeney guardiarioNessuna valutazione finora

- Part 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each AnswerDocumento13 paginePart 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each Answerahmad amdaNessuna valutazione finora

- Probecom 11.3M Antenna System Datasheet 2Documento2 pagineProbecom 11.3M Antenna System Datasheet 2Hugo MateoNessuna valutazione finora

- Autodesk Design Review: About DWF and DWFXDocumento7 pagineAutodesk Design Review: About DWF and DWFXNesreNessuna valutazione finora

- VDRL - Press. GaugesDocumento9 pagineVDRL - Press. GaugesSourav RayNessuna valutazione finora

- Education Programme: The School of Concrete TechnologyDocumento28 pagineEducation Programme: The School of Concrete TechnologyThabiso Jacob MokwenaNessuna valutazione finora

- Pu3-Mo A1 MoversDocumento40 paginePu3-Mo A1 MoversMiss María José SalasNessuna valutazione finora

- Hotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahDocumento2 pagineHotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahSyukron PribadiNessuna valutazione finora

- Appendicitis Case StudyDocumento6 pagineAppendicitis Case StudyKimxi Chiu LimNessuna valutazione finora

- Auburn Bsci ThesisDocumento5 pagineAuburn Bsci Thesisafksaplhfowdff100% (1)

- Review Systems of Linear Equations All MethodsDocumento4 pagineReview Systems of Linear Equations All Methodsapi-265647260Nessuna valutazione finora

- 7094 Bangladesh Studies: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of TeachersDocumento11 pagine7094 Bangladesh Studies: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of Teachersmstudy123456Nessuna valutazione finora

- Practice Quiz Reflection Project Initiation and Key ComponentsDocumento3 paginePractice Quiz Reflection Project Initiation and Key ComponentsFalastin Tanani67% (3)

- Day 1 Training Material FlowDocumento200 pagineDay 1 Training Material FlowGhazouani AymenNessuna valutazione finora

- Cambridge IGCSE Physics 0625 Complete Notes PDocumento5 pagineCambridge IGCSE Physics 0625 Complete Notes PYamikani ManthandoNessuna valutazione finora

- DTS Nozzles R3Documento2 pagineDTS Nozzles R3meilia teknikNessuna valutazione finora

- No Experience ResumeDocumento2 pagineNo Experience ResumeNatalia PantojaNessuna valutazione finora

- The Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaDocumento15 pagineThe Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaAasvogel Felodese Carnivora64% (14)

- Business English ExerciseDocumento11 pagineBusiness English ExerciseAdeline KwanNessuna valutazione finora

- MetLife CaseDocumento4 pagineMetLife Casekatee3847Nessuna valutazione finora

- SM-G900F Esquematico Completo Anibal Garcia IrepairDocumento2 pagineSM-G900F Esquematico Completo Anibal Garcia Irepairfix marketNessuna valutazione finora

- List of Famous Cities On River Banks in The WorldDocumento2 pagineList of Famous Cities On River Banks in The WorldDiptangshu DeNessuna valutazione finora

- QLD Plan Draft Review Raw DataDocumento242 pagineQLD Plan Draft Review Raw DataRohit Jain100% (1)

- I - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsDocumento6 pagineI - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsHaNessuna valutazione finora