Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Epilux 58 M.I.O.: Product Description

Caricato da

Moin AltafTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Epilux 58 M.I.O.: Product Description

Caricato da

Moin AltafCopyright:

Formati disponibili

EPILUX 58 M.I.O.

High Build Epoxy M.I.O.

PRODUCT Polyamide cured epoxy reinforced with micaceous iron oxide that provides a tough chemical

resistant build/ finish coat.

DESCRIPTION • Lamellar pigment with excellent water and chemical resistance.

• Resistant to moisture, salt spray, mineral oil.

• Excellent resistance to abrasion.

• Very good durability.

• BS 5493 reference. Meets performance of KUID and KFIF

DESIGNED USE • As a build coat for structural steel in onshore and offshore environments.

• As an intermediate coat where long term recoat ability is required.

• Suitable as intermediate for upto C5 Environment as per ISO12944 Part 2 along with suitable

topcoats

PHYSICAL DATA VOLUME SOLIDS

60 % + 2 %

(Based on ASTM D2697)

TYPICAL DRY FILM THICKNESS 125 microns

WET FILM THICKNESS 208 microns

THEORETICAL COVERAGE 4.8 m2/litre @ 125 microns DFT

VOC “As Supplied”

350 gms/ltr

(Based on ASTM D3960)

COLOUR Dark Grey, Light Grey

FINISH Metallic Semi-matt

APPLICATION METHOD OF APPLICATION :

DETAILS This is the recommended method of application:

Maximum 5% Thinner may be added.

AIRLESS SPRAY

Tip Size: 0.48 - 0.53 mm (0.019 - 0.021 in)

Pressure: 140 - 165 kg/cm2 (2000 – 2400 psi)

This is also a suitable method of application.

CONVENTIONAL SPRAY Maximum 20% Thinner may be added

Tip Size: 1.80 - 2.20 mm (0.071 - 0.087 in)

Pressure: 2.75 - 3.45 kg/cm2 (40 - 50 psi)

May be used for difficult shapes or touch-up.

BRUSH OR ROLLER However, additional coats may be required to achieve the

recommended film thickness.

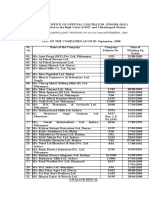

DRYING TIME:

Surface Re coating Interval

Touch Dry Hard Dry Pot Life

Temperature Minimum Maximum

15°C 12 Hrs 24 Hrs 24 Hrs Indefinite 8 Hrs

25°C 6 Hrs 16 Hrs 16 Hrs Indefinite 4 Hrs

35°C 3 Hrs 8 Hrs 8 Hrs Indefinite 3 Hrs

45°C 2 Hrs 6 Hrs 6 Hrs Indefinite 2 Hrs

NO. OF COMPONENTS Two

Mixing Ratio 5 parts Base to 1 part Hardener (by volume)

Do not apply this product if the Relative Humidity exceeds

Application Conditions 85% or if the substrate temperature is within 3°C of the dew

point

ADDITIONAL Thinner / Cleaning solvent Solvalux 7-45

Storage Instruction Store in a cool shaded dry area

INFORMATION Flash Point Mixed 36°C

Packaging 5 liters & 20 liters

Shelf Life 12 months from the date of manufacture.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

EPILUX 58 M.I.O.

High Build Epoxy M.I.O.

SURFACE This product should be applied to a surface that has been blast cleaned and suitably primed (e.g.

PREPARATION EPILUX or ZINCANODE Primers). The primer should be applied to a surface that has been

cleaned as follows:

• Remove all wax, oil and grease by solvent cleaning in accordance with the guide lines given

by SSPC-SPI.

• Where necessary remove weld spatter and round off all rough weld seams and sharp edges to a

smooth surface.

• Abrasive blast clean to a minimum standard of Sa 2½ Swedish Standard SIS 05 59 00 or ISO

8501-1 : 1988

• Any surface defects revealed by blast cleaning should be ground, filled or treated in a suitable

manner.

• After blasting, remove dust from the surface.

• The surface to be coated must also be clean and dry.

PRODUCT USE • As common with all epoxies, this product is likely to chalk when exposed to direct sunlight.

RESTRICTIONS This will result in a loss in gloss.

• If recoating with conventional coatings, this must be done within 24 hours.

• Dry heat resistant up to 130°C.

• May also be applied between 75 and 150 Microns DFT.

• Contact Berger Representative for suggesting suitable paint system

SAFETY • Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls,

PRECAUTIONS goggles, dust masks and gloves. Use a barrier cream.

• Ensure that there is adequate ventilation in the area where the product is being applied. Do not

breathe vapor or spray.

• This product is flammable. Keep away from sources of ignition. Do not smoke. Take

precautionary measures against static discharge. In case of fire – blanket flames with foam,

carbon dioxide or dry chemicals

• Refer to MSDS for further information.

FIRST AID • Eyes: In the event of accidental splashes, flush eyes with water immediately and obtain

medical advice

• Skin: Wash skin thoroughly with soap and water or approved industrial cleaner.

• DO NOT USE solvent or thinners.

• Inhalation: Remove to fresh air, loosen collar and keep patient rested.

• Ingestion: In case of accidental ingestion, DO NOT INDUCE VOMITING.

Obtain immediate medical attention

The information provided on this data sheet is not intended to be complete and is provided as general advice only. It is the responsibility

DISCLAIMER of the user to ensure that the product is suitable for the purpose for which he wishes to use it. As we have no control over the treatment of

the product, the standard of surface preparation of the substrate, or other factors affecting the use of this product, we are not responsible

for its performance nor would we accept any liability whatsoever or howsoever arising from the use of this product unless specifically

agreed to in writing by us. The information contained in this data sheet may be modified by us from time to time, and without notice, in

the light of our experience and continuous product development.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

Potrebbero piacerti anche

- Epimastic 4100Documento2 pagineEpimastic 4100Moin AltafNessuna valutazione finora

- Epimastic 4100Documento2 pagineEpimastic 4100Moin AltafNessuna valutazione finora

- Method For The Determination of CarotenesDocumento2 pagineMethod For The Determination of CarotenesNakibuuka Magdalein50% (2)

- Tds Paratherm 600Documento2 pagineTds Paratherm 600yarth880% (1)

- Epilux 219: Product DescriptionDocumento2 pagineEpilux 219: Product DescriptionMoin AltafNessuna valutazione finora

- Pds Epilux 218 VocDocumento2 paginePds Epilux 218 VocmuthukumarNessuna valutazione finora

- Epimastic 5200: Product DescriptionDocumento2 pagineEpimastic 5200: Product DescriptionsreeNessuna valutazione finora

- Epilux 155Documento2 pagineEpilux 155Allana100% (1)

- Epilux 5: Product DescriptionDocumento2 pagineEpilux 5: Product DescriptionShyam ShrishNessuna valutazione finora

- Epilux 218: Product DescriptionDocumento2 pagineEpilux 218: Product DescriptionMoin AltafNessuna valutazione finora

- Pds Epilux 218 Hs VocDocumento2 paginePds Epilux 218 Hs VocmuthukumarNessuna valutazione finora

- Epilux 800Documento2 pagineEpilux 800anandNessuna valutazione finora

- EPIMASTIC 5100-March 2019 Version 2Documento2 pagineEPIMASTIC 5100-March 2019 Version 2PraveenNessuna valutazione finora

- Epimastic 7200: Product DescriptionDocumento2 pagineEpimastic 7200: Product DescriptionSu KaNessuna valutazione finora

- Epilux 8: Product DescriptionDocumento2 pagineEpilux 8: Product DescriptionMoin AltafNessuna valutazione finora

- Steel Shield 1200Documento2 pagineSteel Shield 1200Moin AltafNessuna valutazione finora

- Pds Zincanode 690 VocDocumento2 paginePds Zincanode 690 VocmuthukumarNessuna valutazione finora

- Epimastic 7200 SRDocumento2 pagineEpimastic 7200 SRqc_531040655Nessuna valutazione finora

- Zincanode 620 Voc v1 Jan 2018Documento2 pagineZincanode 620 Voc v1 Jan 2018Moin AltafNessuna valutazione finora

- Apcodur Ehb 500-VocDocumento2 pagineApcodur Ehb 500-VocMoin AltafNessuna valutazione finora

- Pds Zincanode 620 VocDocumento2 paginePds Zincanode 620 VocmuthukumarNessuna valutazione finora

- RobbiathaneDocumento2 pagineRobbiathaneAnson FranklinNessuna valutazione finora

- Epilux 58 - 9702Documento2 pagineEpilux 58 - 9702anandNessuna valutazione finora

- Luxathane 5160Documento2 pagineLuxathane 5160shameelNessuna valutazione finora

- Epilux 82: Product DescriptionDocumento2 pagineEpilux 82: Product DescriptionMoin AltafNessuna valutazione finora

- Rapid Air Dry 10Documento2 pagineRapid Air Dry 10Moin AltafNessuna valutazione finora

- Luxatherm 6200Documento2 pagineLuxatherm 6200PraveenNessuna valutazione finora

- Pds Luxathane 5000 VocDocumento2 paginePds Luxathane 5000 Vocmuthukumar100% (1)

- Pds Luxaprime 1400 VocDocumento2 paginePds Luxaprime 1400 VocmuthukumarNessuna valutazione finora

- Pds Luxol 1000 VocDocumento2 paginePds Luxol 1000 VocmuthukumarNessuna valutazione finora

- Apcotherm Epn 200Documento2 pagineApcotherm Epn 200Moin AltafNessuna valutazione finora

- Pds Luxol 5000 VocDocumento2 paginePds Luxol 5000 VocmuthukumarNessuna valutazione finora

- Pds Luxaprime 1000 VocDocumento2 paginePds Luxaprime 1000 VocmuthukumarNessuna valutazione finora

- EPILUX 850 SF VOC Jan-2017Documento2 pagineEPILUX 850 SF VOC Jan-2017PraveenNessuna valutazione finora

- Apcoline 4100Documento2 pagineApcoline 4100Moin AltafNessuna valutazione finora

- Epilux 155Documento2 pagineEpilux 155Tejinder KumarNessuna valutazione finora

- Luxathane 5160-Voc March 2021 V1Documento2 pagineLuxathane 5160-Voc March 2021 V1PraveenNessuna valutazione finora

- pm002 4446Documento2 paginepm002 4446Dhanush Kumar RamanNessuna valutazione finora

- Pds Luxaprime 1500 VocDocumento2 paginePds Luxaprime 1500 VocmuthukumarNessuna valutazione finora

- Steel Shield 1100Documento3 pagineSteel Shield 1100Moin AltafNessuna valutazione finora

- 3500-00 Simathane Gloss (Finish Coat)Documento3 pagine3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNessuna valutazione finora

- 3500-00 Simathane GlossDocumento3 pagine3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNessuna valutazione finora

- 2401-00 Simacover EP UnicoatDocumento3 pagine2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNessuna valutazione finora

- Paragloss v2Documento2 pagineParagloss v2Adam FauzanNessuna valutazione finora

- Steelshield Ve: Product DescriptionDocumento2 pagineSteelshield Ve: Product DescriptionMoin AltafNessuna valutazione finora

- KANSAI PAINT Paralux - 15HBDocumento2 pagineKANSAI PAINT Paralux - 15HBYogalingam ArumugamNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- HEMPADUR ZINC 15360 15360 en-GB PDFDocumento2 pagineHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNessuna valutazione finora

- Product Data Sheet: Simathane GlossDocumento3 pagineProduct Data Sheet: Simathane GlossAdnan FrrNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- 323+ Data SheetDocumento5 pagine323+ Data SheetSergioNessuna valutazione finora

- Bergerlac Aluminium Finish PDFDocumento2 pagineBergerlac Aluminium Finish PDFMuthuKumarNessuna valutazione finora

- PDS Hempadur Multi-Strength 45753 en-GBDocumento2 paginePDS Hempadur Multi-Strength 45753 en-GBJosip LasanNessuna valutazione finora

- Tds Parapex No3Documento2 pagineTds Parapex No3Anonymous Nb6t2ezcZ100% (1)

- b3) Zincanode685 4586Documento2 pagineb3) Zincanode685 4586Syed FaridNessuna valutazione finora

- Hempadur Zinc 17360Documento2 pagineHempadur Zinc 17360Bang OchimNessuna valutazione finora

- PDS Hempaprime Multi 500 Summer en-GBDocumento2 paginePDS Hempaprime Multi 500 Summer en-GBFreddyNessuna valutazione finora

- HEMPADUR 47182 47182 en-GB PDFDocumento3 pagineHEMPADUR 47182 47182 en-GB PDFwilfran villegasNessuna valutazione finora

- Microsoft Word - L3 - Epilux82Documento2 pagineMicrosoft Word - L3 - Epilux82vitharvanNessuna valutazione finora

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocumento2 pagineGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNessuna valutazione finora

- Creative Resin: Easy techniques for contemporary resin artDa EverandCreative Resin: Easy techniques for contemporary resin artNessuna valutazione finora

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- 2023-RegisterBook Version 202212Documento95 pagine2023-RegisterBook Version 202212Moin AltafNessuna valutazione finora

- HilonDeco Cryl 9200-MCDocumento2 pagineHilonDeco Cryl 9200-MCMoin AltafNessuna valutazione finora

- DEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesDocumento30 pagineDEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesMoin AltafNessuna valutazione finora

- Rapid Air Dry 10Documento2 pagineRapid Air Dry 10Moin AltafNessuna valutazione finora

- Apcoline 4100Documento2 pagineApcoline 4100Moin AltafNessuna valutazione finora

- Epilux 8: Product DescriptionDocumento2 pagineEpilux 8: Product DescriptionMoin AltafNessuna valutazione finora

- PDS-Supreme Eggshell - Silk Version 1Documento2 paginePDS-Supreme Eggshell - Silk Version 1Moin AltafNessuna valutazione finora

- Steel Shield 1100Documento3 pagineSteel Shield 1100Moin AltafNessuna valutazione finora

- Apcotherm Epn 200Documento2 pagineApcotherm Epn 200Moin AltafNessuna valutazione finora

- Steelshield Ve: Product DescriptionDocumento2 pagineSteelshield Ve: Product DescriptionMoin AltafNessuna valutazione finora

- Epilux 218: Product DescriptionDocumento2 pagineEpilux 218: Product DescriptionMoin AltafNessuna valutazione finora

- Apcodur Ehb 500-VocDocumento2 pagineApcodur Ehb 500-VocMoin AltafNessuna valutazione finora

- Zincanode 620 Voc v1 Jan 2018Documento2 pagineZincanode 620 Voc v1 Jan 2018Moin AltafNessuna valutazione finora

- Epilux 82: Product DescriptionDocumento2 pagineEpilux 82: Product DescriptionMoin AltafNessuna valutazione finora

- Steel Shield 1200Documento2 pagineSteel Shield 1200Moin AltafNessuna valutazione finora

- Can A SUNNI Man Marry A SHIA GirlDocumento2 pagineCan A SUNNI Man Marry A SHIA GirlMoin AltafNessuna valutazione finora

- ENGLISH Manual For Washing Machine Whirlpool 60410Documento2 pagineENGLISH Manual For Washing Machine Whirlpool 60410stavia4050% (1)

- Components of Railway Track 1Documento21 pagineComponents of Railway Track 1Mudasar HussainNessuna valutazione finora

- English Hand Out: For Civil Engineering StudentsDocumento6 pagineEnglish Hand Out: For Civil Engineering StudentsZaenal AbidinNessuna valutazione finora

- Generating of Fuel From Plastic WasteDocumento6 pagineGenerating of Fuel From Plastic WasteInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Cat 0550 Uk BD PDFDocumento52 pagineCat 0550 Uk BD PDFbelenNessuna valutazione finora

- 2003-Novel PEEK Membranes For Fuel Cell ApplicationsDocumento2 pagine2003-Novel PEEK Membranes For Fuel Cell Applicationssomething100% (1)

- Summative Test TleDocumento18 pagineSummative Test TleGillyn Ruiz - AntonioNessuna valutazione finora

- Piping Stress CriteriaDocumento11 paginePiping Stress CriteriasbrencuNessuna valutazione finora

- Brosur Deltagrout CG - REV - 20100725MTDocumento2 pagineBrosur Deltagrout CG - REV - 20100725MTjimdabrondNessuna valutazione finora

- DEMO-ASME Filler Metals DatabaseDocumento6 pagineDEMO-ASME Filler Metals DatabaseadammzjinNessuna valutazione finora

- Sokalan RO - Performance ChemicalsDocumento8 pagineSokalan RO - Performance ChemicalsshoyebNessuna valutazione finora

- Civil Estimate With BoqDocumento88 pagineCivil Estimate With Boqsagar pradhanNessuna valutazione finora

- Potash CrystallizerDocumento34 paginePotash CrystallizerBuddhima SiriweeraNessuna valutazione finora

- Powder Perfect: Tungsten Carbide ProductsDocumento3 paginePowder Perfect: Tungsten Carbide ProductsNadjNessuna valutazione finora

- C1, C2 & C3 - Combined Module - (v13) - CLDocumento84 pagineC1, C2 & C3 - Combined Module - (v13) - CLHemanth C NNessuna valutazione finora

- Professional Window Mounting With Greenteq: Edition I / 2011Documento36 pagineProfessional Window Mounting With Greenteq: Edition I / 2011Bejinariu ValentinNessuna valutazione finora

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Documento4 pagineStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Nessuna valutazione finora

- Elcometer 128 Pictorial Surface Standards Data SheetDocumento2 pagineElcometer 128 Pictorial Surface Standards Data SheetBalaji GuruNessuna valutazione finora

- Quality 11Smnpb37: Lucefin GroupDocumento1 paginaQuality 11Smnpb37: Lucefin GroupPaulo ZechinNessuna valutazione finora

- PSOW2 - MS For Waterproofing Dated 04.11.2023Documento5 paginePSOW2 - MS For Waterproofing Dated 04.11.2023projectsNessuna valutazione finora

- Handbook of CompositesDocumento17 pagineHandbook of CompositesSathish KumarNessuna valutazione finora

- Can The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Documento2 pagineCan The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Jovito EdillonNessuna valutazione finora

- 2nd Quarter Post Test in Technology and Livelihood Education EIM 10Documento3 pagine2nd Quarter Post Test in Technology and Livelihood Education EIM 10Citrus National High School100% (1)

- Cebex 031: Constructive SolutionsDocumento3 pagineCebex 031: Constructive SolutionsBalasubramanian AnanthNessuna valutazione finora

- Mongolian Gold MiningDocumento61 pagineMongolian Gold MiningBaasankhuu JrNessuna valutazione finora

- Comparison of Gas Dehydration Methods Based On Energy Consumption PDFDocumento6 pagineComparison of Gas Dehydration Methods Based On Energy Consumption PDFABULARA2K6Nessuna valutazione finora

- pRESSURE gAUGESDocumento28 paginepRESSURE gAUGESrf140789_20264585Nessuna valutazione finora

- Mahalakshmi: Engineering CollegeDocumento16 pagineMahalakshmi: Engineering CollegeVijeesh VijayalayamNessuna valutazione finora

- How Does A Fan Work?Documento2 pagineHow Does A Fan Work?HadiNessuna valutazione finora