Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

View Technical Description in PDF Format - SIS-Tech

Caricato da

mani_208eeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

View Technical Description in PDF Format - SIS-Tech

Caricato da

mani_208eeCopyright:

Formati disponibili

Burner Management Systems (BMS)

Boilers, heaters, and furnaces are considered critical equipment in most operating facilities, posing challenges to

safe and reliable operation. Safety issues are generally related to burner light-off, loss of pass flow containment,

and loss of flame. Even when safety is not a major concern, equipment criticality or replacement cost generally

results in specification of protective functions to prevent equipment damage and downtime. The equipment

reliability is also a high priority, making the avoidance of spurious trips a crucial

design parameter.

The draft technical report ISA-TR84.00.05 Application of ANSI/ISA 84.00.01-

2004 for Safety Instrumented Functions (SIFs) in Burner Management Systems

(BMS) provides guidance on assessing which BMS protective functions should

be implemented according to ANSI/ISA 84.00.01-2004 (IEC 61511). An

analysis of the BMS logic solver often identifies deficiencies in its integrity and/or

reliability, resulting in the need to upgrade it to achieve the required PFDavg and

spurious trip rate.

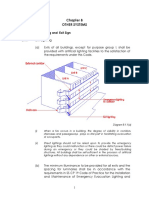

The DIAMOND-SIS® is designed as a low-cost, stand-alone, non-PE logic solver. Rated for –30C to +75C and

constructed using Class I Div II components the DIAMOND-SIS® can be installed in the harshest process units

near the equipment under control. Field installation of the logic solver reduces implementation costs by 50%

compared to safety-PLCs. DIAMOND-SIS® provides the end user with a fault tolerant and on-line testable logic

solver that is functionally independent from the burner control system.

DIAMOND-SIS® receives up to three analog inputs per process variable and has two field adjustable trip points.

This allows the process to be shutdown on high and/or low process variables. Further, the number of inputs and

voting architecture, 1oo1, 1oo2, 2oo2 or 2oo3, can be adjusted per process variable to meet any SIL and

spurious trip rate requirement. For greater flexibility, the DIAMOND-SIS® is modularized to fit your specific

application. The unit may be specified to execute any BMS function, such as purge, light-off, fuel pressure, flame

detection, pass flow, drum level, fire box pressure, and knock-out drum level.

THE LOW COST ALTERNATIVE TO SAFETY PLC’s

SIS-TECH Applications, LP www.sis-tech.com

®

KEY FEATURES

2oo3 version is certified to IEC 61508 SIL 3 in SH3 configuration

High reliability

Proven technology

Rugged design

Field mountable

On-line testable & repairable

Remote process variable & system status monitoring

No programming

Low installed cost alternative to a Safety PLC

SPECIFICATIONS

Supply Power: User specified, 24VDC/110VAC/240VAC

Input: 4-20 mA DC or discreet (dry contact)

Output: 5 Amp resistive dry contact

Accuracy: 1% of span

Temperature: -40 to +80oC Storage / -35 to +75oC Operating

Environment: All internal components rated Class I Div II Groups A/B/C/D

Enclosure: NEMA 4X – choice of materials

ENGINEERING/DOCUMENTATION OPTIONS

Safety requirements specification for complete instrumented loop, including SIL Verification

ORDERING SELECTION

BM -P -S -T -SD -R -B -C -E - *

(SH) Base System

(E) Enclosures

1 Single Channel

1 NEMA 4X Fiberglass

2 Dual Channel

2 NEMA 4X 304 Stainless

3 Triple Channel

3 NEMA 4X 316 Stainless

(P) Power Supply

(C) Communications

1 External 24 Vdc (default)

2 Simplex Power Supply 110/ 1 Modbus RS485-serial)

240VAC - 24 VDC 2 Repeated Signal Isolator

(Discrete 4-20mA)

3 Dual Power Supply 110/240VAC - 24

VDC 3 Ethernet (Modbus/TCPIP)

4 UPS 110VAC - 24 VDC Repeated Signal Isolator

(30 min backup) 4 (Discrete 4-20mA) for Hart

Protocol

5 Simplex & UPS Combination

(B) Bypass

(S) Sequence

1 Local Bypass

Permissive, in Progress,

1 PURGE

Completed & Failure. 2 Remote Bypass

Permissive, sequence

2 PILOTS

completed & Trip (R) Reset

MAIN. Permissive, sequence

3 BURNER completed & Trip 1 Local Reset

4 2, 3 (Options) 2 Remote

5 1, 2, 3 (Options)

(SD) Manual Shutdown

(T) Inputs Trips (1oo1)

1 Door Mounted ESD (Local)

1 One input Trip

2 Remote ESD

* - NS

2 Two input Trip Systems which include non-standard options.

Three input 3 Both (Local & Remote ESD)

3 Trip

4 Four input Trip

SIS-TECH Applications, LP www.sis-tech.com

Potrebbero piacerti anche

- Basics, Sizing Software For Stationary Applications: Installation and User GuideDocumento16 pagineBasics, Sizing Software For Stationary Applications: Installation and User Guidehidrologia05Nessuna valutazione finora

- Customer Service Training PDFDocumento16 pagineCustomer Service Training PDFmani_208eeNessuna valutazione finora

- Gutor PXW Q410 053 A PDFDocumento4 pagineGutor PXW Q410 053 A PDFTalebNessuna valutazione finora

- Customer Service: Enjoy 24/7 Peace of Mind With Flexible Service Offerings From Schneider ElectricDocumento8 pagineCustomer Service: Enjoy 24/7 Peace of Mind With Flexible Service Offerings From Schneider Electricmani_208eeNessuna valutazione finora

- Application For Opening An RFC Account: PhotographDocumento3 pagineApplication For Opening An RFC Account: PhotographSiddu PamuluruNessuna valutazione finora

- Electrical Switchgear Safety: A Guide For Owners and UsersDocumento9 pagineElectrical Switchgear Safety: A Guide For Owners and Usersmani_208eeNessuna valutazione finora

- Gutor+PxW+AC+UPS UL+NADocumento8 pagineGutor+PxW+AC+UPS UL+NAEko ArdianNessuna valutazione finora

- Ur E21Documento2 pagineUr E21AatNessuna valutazione finora

- Ure PDFDocumento62 pagineUre PDFKartikNessuna valutazione finora

- 8.1 Exit Lighting and Exit Sign: Other SystemsDocumento22 pagine8.1 Exit Lighting and Exit Sign: Other Systemsmani_208eeNessuna valutazione finora

- KHSH-9MK6CZ R0 enDocumento81 pagineKHSH-9MK6CZ R0 enmani_208eeNessuna valutazione finora

- Chapter 8Documento31 pagineChapter 8Mahir MahmoodNessuna valutazione finora

- Nu - 26 3353 - Uninterruptible Power SupplyDocumento12 pagineNu - 26 3353 - Uninterruptible Power Supplymani_208eeNessuna valutazione finora

- Ebitt Motor Katalog R01Documento9 pagineEbitt Motor Katalog R01mani_208eeNessuna valutazione finora

- Iec Standards For Variable Speed Drives and Motor Winding InsulationDocumento4 pagineIec Standards For Variable Speed Drives and Motor Winding Insulationmani_208eeNessuna valutazione finora

- Application For Opening An RFC Account: PhotographDocumento3 pagineApplication For Opening An RFC Account: PhotographSiddu PamuluruNessuna valutazione finora

- CVA Range: Linear and Quarter-TurnDocumento32 pagineCVA Range: Linear and Quarter-Turnmani_208eeNessuna valutazione finora

- Exmax Range: Keeping The World FlowingDocumento12 pagineExmax Range: Keeping The World Flowingmani_208eeNessuna valutazione finora

- Iris Power Epoxy Mica Capacitors (80 PF) : Partial Discharge Sensors For Testing Motors and GeneratorsDocumento2 pagineIris Power Epoxy Mica Capacitors (80 PF) : Partial Discharge Sensors For Testing Motors and Generatorsmani_208eeNessuna valutazione finora

- CMA Range: Linear, Part-Turn and Multi-TurnDocumento16 pagineCMA Range: Linear, Part-Turn and Multi-Turnmani_208eeNessuna valutazione finora

- High Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVDocumento12 pagineHigh Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVmani_208eeNessuna valutazione finora

- Iris Power Stator Slot Couplers Brochure PDFDocumento1 paginaIris Power Stator Slot Couplers Brochure PDFmani_208eeNessuna valutazione finora

- HVCatalogueLowRes PDFDocumento38 pagineHVCatalogueLowRes PDFMahmoud GwailyNessuna valutazione finora

- Iris Power Epoxy Mica Capacitors (80 PF) : Partial Discharge Sensors For Testing High Voltage Electrical EquipmentDocumento2 pagineIris Power Epoxy Mica Capacitors (80 PF) : Partial Discharge Sensors For Testing High Voltage Electrical Equipmentmani_208eeNessuna valutazione finora

- Schneider Electric Industries: Date: Wednesday, March 25, 2020Documento2 pagineSchneider Electric Industries: Date: Wednesday, March 25, 2020mani_208eeNessuna valutazione finora

- SLM TMDocumento29 pagineSLM TMTrịnh Đức HạnhNessuna valutazione finora

- Schneider Electric Industries: Date: Wednesday, March 25, 2020Documento2 pagineSchneider Electric Industries: Date: Wednesday, March 25, 2020mani_208eeNessuna valutazione finora

- Fail Safe Unit FQM 05.1 - FQM 12.1 Fqmex 05.1 - Fqmex 12.1: Assembly, Operation, Commissioning Operation InstructionsDocumento40 pagineFail Safe Unit FQM 05.1 - FQM 12.1 Fqmex 05.1 - Fqmex 12.1: Assembly, Operation, Commissioning Operation Instructionsmani_208eeNessuna valutazione finora

- Performance With Ultra Low Maintenance: Ultima SLM Ni-Cd BatteryDocumento8 paginePerformance With Ultra Low Maintenance: Ultima SLM Ni-Cd Batterymani_208eeNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ERPtips SAP Training Manual SAMPLE CHAPTER From Basic PayrollDocumento20 pagineERPtips SAP Training Manual SAMPLE CHAPTER From Basic Payrollravibabu1620Nessuna valutazione finora

- Electronic Let Off MotionDocumento3 pagineElectronic Let Off MotionWaqar Baloch100% (2)

- Thesis FYPDocumento50 pagineThesis FYPEyka ZulaikaNessuna valutazione finora

- Chpt6 Taylor Made HONDocumento23 pagineChpt6 Taylor Made HONManju MudakaviNessuna valutazione finora

- S2N Gyro Interface ManualDocumento20 pagineS2N Gyro Interface ManualAfrizal Setiawan100% (1)

- Wedding Show Proposal BaliDocumento10 pagineWedding Show Proposal BaliGirie d'PrayogaNessuna valutazione finora

- Classiffication of ComputerDocumento15 pagineClassiffication of Computervenkat sai bharatNessuna valutazione finora

- Novel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorDocumento7 pagineNovel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorGanesh ChallaNessuna valutazione finora

- ABB REL5xx RIOConverterDocumento10 pagineABB REL5xx RIOConverterzinab90100% (1)

- Passport Appointment PDFDocumento5 paginePassport Appointment PDFRitu AgarwalNessuna valutazione finora

- 06 NetNumen U31 System DescriptionDocumento39 pagine06 NetNumen U31 System Descriptionمحيي الدين الكميشى100% (1)

- Sheet 3Documento5 pagineSheet 3Yasmin RedaNessuna valutazione finora

- Android User GuideDocumento15 pagineAndroid User GuideAnonymous 1Wb6JCkNessuna valutazione finora

- Ar10 Jig Instructions PDFDocumento5 pagineAr10 Jig Instructions PDFterrencebelles100% (2)

- Osisense ManualDocumento2 pagineOsisense ManualLki SelfNessuna valutazione finora

- Etic HackDocumento31 pagineEtic HackJOrdi CrespoNessuna valutazione finora

- Tata MotorsDocumento9 pagineTata MotorsNaim Ahmed SisirNessuna valutazione finora

- Addressing Corrosion Under Pipe Supports (CUPS) (PRS200a)Documento2 pagineAddressing Corrosion Under Pipe Supports (CUPS) (PRS200a)Trajko GorgievskiNessuna valutazione finora

- Three-Phase Induction Motor Dynamic Mathematical ModelDocumento3 pagineThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- Pump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Documento1 paginaPump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Yosif BabekerNessuna valutazione finora

- Electrica QC Check ListDocumento21 pagineElectrica QC Check Listmakana qc100% (1)

- ConnectorsDocumento3 pagineConnectorsmatrixworld20Nessuna valutazione finora

- Oisd STD-141Documento31 pagineOisd STD-141Jyotsana Rawat83% (6)

- BTD-Final Lesson PlanDocumento22 pagineBTD-Final Lesson PlanSunil BajantriNessuna valutazione finora

- Contoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Documento2 pagineContoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Izla MajidNessuna valutazione finora

- Company in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Documento7 pagineCompany in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Vinod KumarNessuna valutazione finora

- Chapter 1: INTRODUCTION: 1.1 BackgroundDocumento5 pagineChapter 1: INTRODUCTION: 1.1 BackgroundAhsan azizNessuna valutazione finora

- Power GenerationDocumento34 paginePower GenerationTaufiq AkbarNessuna valutazione finora