Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

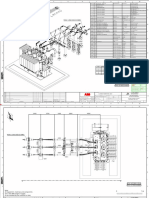

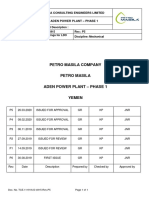

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Caricato da

Valesh MonisCopyright:

Formati disponibili

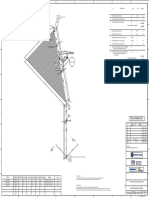

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 100 PAAZZBOZZABAABSAAZZUS 61.1 M B01

A106-B, Seamless, S-40

2 Sockolet® Size on Size, 100X25 MEUAWBVZZAEYABQZZUS 1 B01

A CL3000, Beveled end, A

ASME-B36.10M, A105

3 90 degree elbow, long radius, 100 MCMZZBOZZAAEADCZZUSA 6 B01

, Beveled end, ASME-B16.9,

A234-WPB, S-40

PIPE SUPPORTS

4 Design Pipe Assembly 100 DesignPipeH_5 15 B01

ERECTION MATERIALS

5 Pipe, PE, ASME-B36.10M, 25 PAAZZBPZZABAABSAAZZUS 0.2 M

A106-B, Seamless, S-40

6 Plug, CL3000, Male threaded 25 MFIAWBNZZAAGABQZZUS 1 B01

end, ASME-B16.11, A105

SEE ISO

7 Ball valve, full port, CL600, 25 VAIAPBUZZAAFABQZZBFUS 1 B01 11END02BR001 SHT 02

Threaded end, ASME-B16.10, E 285065

A105 N 244148

EL +207

B <8> 1 S4 B

100DN 11END02BQ033

S4

11END02BQ032 S4

152

11END02BQ034

1513 40

00

181

40 S4

00 11END02BQ035 11 3

S4 S4 2 30 33

6

40 13

431

00 11END02BQ037 11END02BQ043 2 7

93

171

3 <5 STEM EAST

40 S4 > <4> 5

00 1 11END02AA502

11END02BQ038 83

56

44 N 200130

94 S4 152 152 15

S4 11END02BQ041 1 60 171

40 > 2

11END02BQ036 10 3 <6 100X25DN <1> 1 <3> 1 3

C 28 C

20 11 EL +2346

S4 39 08 5

96 152 79 47 152

11END02BQ039 S4

40 1835 11END02BQ045 1838

00 <7> 1 32

S4 5 152 152 152 100

40 S4

2139

11END02BQ040 00 11END02BQ044 47 106

7 3

S4

11END02BQ042 152 152 3 8

152 <2> 1 35

3 100DN

2000 EL +207

1034 2142 S4

11END02BQ046 152

CONN TO

LCO FORWARDING PUMP - UNIT #11 (E004) /TP 418

100 MM BE 150

D E 299129 D

N 199652

EL +204

E E

8 41047 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

7 1835 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

6 12926 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS OWNER

5 2993 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

4 171 25 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS DISTRIBUTION W/C

3 171 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS MATRIX

2 1838 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

1 206 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

11END02BR001 01 of 05

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P4

FILE NAME 11END02BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- Environmental SustainabilityDocumento3 pagineEnvironmental SustainabilityJoseph Michael Perez100% (1)

- Manual Hardware Lenovo Yoga BookDocumento68 pagineManual Hardware Lenovo Yoga BookRADU OCTAVIAN100% (2)

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- H31 SW F34 2475Documento4 pagineH31 SW F34 2475Bini RanishNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 1u01 WW 9002 01Documento1 pagina1u01 WW 9002 01syslor.kimNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Piping Isometric - 3Documento1 paginaPiping Isometric - 3CosminMarianNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Piping Isometric - 4Documento1 paginaPiping Isometric - 4CosminMarianNessuna valutazione finora

- Bill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5Documento1 paginaBill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5chandraditya firmansyahNessuna valutazione finora

- Stlop: (L.M.U Stlop) Skid Pumps Base Oil A520090 B001Documento1 paginaStlop: (L.M.U Stlop) Skid Pumps Base Oil A520090 B001Shelton S S SheltonNessuna valutazione finora

- Sump Discharge Piping - ISOMETRIC DrawingDocumento9 pagineSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNessuna valutazione finora

- E32 P R340 2136Documento5 pagineE32 P R340 2136Ranish P. KurianNessuna valutazione finora

- Acer Aspire 5737z - Fingerprint BoardDocumento1 paginaAcer Aspire 5737z - Fingerprint BoardYofo GaytanNessuna valutazione finora

- Ax03-100002090 VPD 001 01Documento1 paginaAx03-100002090 VPD 001 01Roberto RevinsacNessuna valutazione finora

- Piping Isometric - 6Documento1 paginaPiping Isometric - 6CosminMarianNessuna valutazione finora

- PartlistDocumento1 paginaPartlistLuis SemperteguiNessuna valutazione finora

- Piston Pumps Israk SeriesDocumento3 paginePiston Pumps Israk Seriesali kartalNessuna valutazione finora

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryDocumento1 paginaA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryfaviikaujaNessuna valutazione finora

- Ta2 PDFDocumento5 pagineTa2 PDFSugeng Hadi SusiloNessuna valutazione finora

- InputDocumento5 pagineInputSugeng Hadi SusiloNessuna valutazione finora

- InputDocumento3 pagineInputSugeng Hadi SusiloNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- Piping Isometric - 9Documento1 paginaPiping Isometric - 9CosminMarianNessuna valutazione finora

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocumento1 paginaFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNessuna valutazione finora

- 2300 52 AAA CW 280 281307 04 - RevS2Documento1 pagina2300 52 AAA CW 280 281307 04 - RevS2CosminMarianNessuna valutazione finora

- 10P 2L8M B5 V2 Line DrawingDocumento1 pagina10P 2L8M B5 V2 Line Drawingyou are awesomeNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- Iso Mre S70 002Documento6 pagineIso Mre S70 002celonevesNessuna valutazione finora

- 2300 52 AAA BD 280 282181 01 - RevS2Documento1 pagina2300 52 AAA BD 280 282181 01 - RevS2CosminMarianNessuna valutazione finora

- Pra Da 050 0040 0 2 2 1 1 1 Bas - 1 - 10436 - 20180626144909Documento4 paginePra Da 050 0040 0 2 2 1 1 1 Bas - 1 - 10436 - 20180626144909Anirudh JavagalNessuna valutazione finora

- Piping Isometric - 5Documento1 paginaPiping Isometric - 5CosminMarianNessuna valutazione finora

- Nandhimangalam Sb-Plinth Beam DetailDocumento1 paginaNandhimangalam Sb-Plinth Beam DetailWillip Desert KingNessuna valutazione finora

- Bumper Guide DrawingDocumento1 paginaBumper Guide DrawingarunNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Piping Isometric - 8Documento1 paginaPiping Isometric - 8CosminMarianNessuna valutazione finora

- DMW 3305 30116 1 3305 602 - Is00Documento1 paginaDMW 3305 30116 1 3305 602 - Is00nuramirah2023Nessuna valutazione finora

- En-Blr 0 RDocumento2 pagineEn-Blr 0 RVedran HorvatNessuna valutazione finora

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISODocumento1 paginaD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodNessuna valutazione finora

- Mark 7 Isometric DrawingDocumento1 paginaMark 7 Isometric Drawingroman kucingNessuna valutazione finora

- Petrol Chemical Onshore Structure ModuleDocumento18 paginePetrol Chemical Onshore Structure ModulehavutaNessuna valutazione finora

- 26148-220-V1B-EVC0-00088 (003) Patio StatcomDocumento5 pagine26148-220-V1B-EVC0-00088 (003) Patio StatcomDomingo esteban perez ceballoNessuna valutazione finora

- RV365D-M-V2 Line DrawingDocumento1 paginaRV365D-M-V2 Line Drawingyou are awesomeNessuna valutazione finora

- Longitudinal Detail Section 1-1: Top Slab Reinforcement DetailsDocumento1 paginaLongitudinal Detail Section 1-1: Top Slab Reinforcement DetailsMwesigwa DaniNessuna valutazione finora

- Box Culvert Twin CellDocumento3 pagineBox Culvert Twin CellMwesigwa DanielNessuna valutazione finora

- For Construction: B1 13 P 1 6 L0 R0 01 3V B1 19 P 03 2 7 L0 R0 01 3V B1 19 P 03 2 7Documento1 paginaFor Construction: B1 13 P 1 6 L0 R0 01 3V B1 19 P 03 2 7 L0 R0 01 3V B1 19 P 03 2 7rajendraNessuna valutazione finora

- NG 910CV11 04 00 (Rev00)Documento4 pagineNG 910CV11 04 00 (Rev00)Saeed MahmoudabadiNessuna valutazione finora

- GA 01 - Down Hopper Stage 1BDocumento1 paginaGA 01 - Down Hopper Stage 1BsudarsonoNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Asme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Documento2 pagineAsme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Valesh MonisNessuna valutazione finora

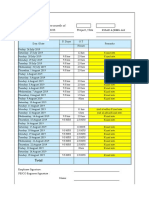

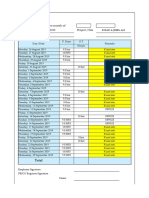

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

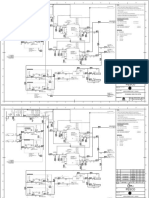

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- 02 WordEditingTextDocumento1 pagina02 WordEditingTextValesh MonisNessuna valutazione finora

- Acid CleaningDocumento32 pagineAcid Cleaningsekhar_ntpcNessuna valutazione finora

- C D C SDocumento4 pagineC D C SandriNessuna valutazione finora

- Generator ProtectionDocumento11 pagineGenerator Protectionyogeshsahu100% (2)

- Antony Kungu - Final Project AssignmentDocumento11 pagineAntony Kungu - Final Project Assignmentapi-420816837Nessuna valutazione finora

- R Values For Z PurlinsDocumento71 pagineR Values For Z PurlinsJohn TreffNessuna valutazione finora

- Sterling Trader Pro en PDFDocumento91 pagineSterling Trader Pro en PDFAyush ChaudhariNessuna valutazione finora

- St3133 Reading Dancing ManualDocumento2 pagineSt3133 Reading Dancing ManualdfsaNessuna valutazione finora

- Decline Curve AnalysisDocumento37 pagineDecline Curve AnalysisAshwin VelNessuna valutazione finora

- Thermodynamics Nozzle 1Documento19 pagineThermodynamics Nozzle 1waseemjuttNessuna valutazione finora

- CMMIDocumento23 pagineCMMIChaithanya KumarNessuna valutazione finora

- Control Cable SpecificationDocumento8 pagineControl Cable Specificationloli2323Nessuna valutazione finora

- ES Service Transition PlanDocumento7 pagineES Service Transition PlanShamsher Singh BainsNessuna valutazione finora

- MailDocumento2 pagineMailSurya Ganesh SaitanaNessuna valutazione finora

- Short Notes On Building ConstructionDocumento20 pagineShort Notes On Building Constructionlarnz0% (1)

- Unit of Work Football Y9Documento5 pagineUnit of Work Football Y9api-282209830Nessuna valutazione finora

- Methodology: Procedure For Checking of VerticalityDocumento6 pagineMethodology: Procedure For Checking of VerticalityDinesh Kumar PatelNessuna valutazione finora

- MIL-W-22759 Rev E - Part34Documento1 paginaMIL-W-22759 Rev E - Part34David WongNessuna valutazione finora

- Manual para Tarjeta Reguladora de Voltaje AVR MX321Documento6 pagineManual para Tarjeta Reguladora de Voltaje AVR MX321Rodrigo ObregonNessuna valutazione finora

- Chandigarh Shep PDFDocumento205 pagineChandigarh Shep PDFAkash ThakurNessuna valutazione finora

- Data0305 KX18DCDocumento3 pagineData0305 KX18DCAbdelhamid SammoudiNessuna valutazione finora

- EN - 61558 - 2 - 4 (Standards)Documento12 pagineEN - 61558 - 2 - 4 (Standards)RAM PRAKASHNessuna valutazione finora

- University of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementDocumento15 pagineUniversity of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementPrasanga WdzNessuna valutazione finora

- Acord and IAADocumento4 pagineAcord and IAABHASKARA_20080% (1)

- Recruitment of Junior Associates (Customer Support & Sales) PDFDocumento2 pagineRecruitment of Junior Associates (Customer Support & Sales) PDFSingh ShivamNessuna valutazione finora

- Rotork: Product TrainingDocumento4 pagineRotork: Product TraininghieuNessuna valutazione finora

- Riviera Sponsorship LetterDocumento7 pagineRiviera Sponsorship LetterAnirudh Reddy YalalaNessuna valutazione finora

- Model 7691Documento1 paginaModel 7691Khiết trầnNessuna valutazione finora

- Dana Trailer Suspension: SpicerDocumento14 pagineDana Trailer Suspension: SpicerCarlos Manuel Vazquez SanchezNessuna valutazione finora