Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1639-U-008 R02 Data Sheet 16 Dec 18

Caricato da

HEMANTTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1639-U-008 R02 Data Sheet 16 Dec 18

Caricato da

HEMANTCopyright:

Formati disponibili

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

1 PUMP HOUSE EQUIPMENTS - MECHANICAL

1.1 Main Cenrifugal Pump

a Technical Specifications

Type of pump Horizontal Split Casing/Back Pull Horizontal Split Casing

Out

No. of pumps 1 1

Pump model CPHM 125/26

Pump make Kirloskar(KBL) Kirloskar(KBL)

Pump design standard IS-5120 IS-5120

Service fluid temperature (max.) 50 20

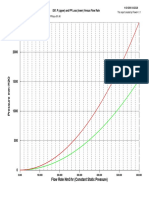

Capacity of pump 273 m3/hr 273 m3/hr

Differential head 88 mWC 88 mWC

Speed 1440 2960 NOT ACCEPTABLE

Pump head at 150 % of rated capacity 88.53 m

Shut off head

Pump shaft power at 150 % of rated discharge 65.33 kw

Type of impeller Closed Closed

Rated impeller diameter 256 mm

NPSHR 5.99 (7.83) / 0.50 m

Pump efficiency at duty point 70%

Pumpshaft input at duty point 80%

Sealing type Gland Gland

Type of coupling Flexible jaw coupling

MOC / Make of coupling CS

Bearing type / make

b Material of Construction of Main Parts

Casing CI IS 210 FG 260 CI IS 210 FG 260

Impeller SS / Bronze SS / Bronze

Pump shaft EN8 EN8

c Motor Specifications

Motor rating 129 kw

Motor make Kirloskar/ABB / Alstom Kirloskar

Design/performance code IS 325 IS 325

Design ambient temperature 50 20

Power supply 415 V +/- 10%,50 Hz +/- 5% 415 V +/- 10%,50 Hz +/- 5%

Protection class IP 55 IP 55

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 1 of 16

Efficiency class of motor Eff. Class-3 Eff. Class-3

Type of enclosure TEFC TEFC

Temperature rise Class B Class B

Insulation class Class F Class F

1.2 Diesel Engine Driven Pump

a Pump

Type of pump Horizontal Split Casing/Back Pull Horizontal Split Casing

Out

No. of pumps 1 1

Pump model GK100/40A

Pump make Kirloskar(KBL) Kirloskar

Pump design standard IS-5120 IS-5120

Service fluid temperature (max.) 50 20

Capacity of pump 273 m3/hr 273 m3/hr

Differential head 88 mWC 88 mWC

Speed 1440 or vendor to specify 2150 rpm

Pump head at 150 % of rated capacity 88.17 m

Shut off head

Pump shaft power at 150 % of rated discharge 116 kw

Type of impeller Closed Closed

Rated impeller diameter 355 mm

NPSHR 4.08

Pump efficiency at duty point 77%

Pumpshaft input at duty point 72%

Sealing type Gland Gland

Type of coupling Flexible jaw coupling

MOC / Make of coupling CS

Bearing type / make

b Material of Construction of Main Parts

Casing CI IS 210 FG 260 CI IS 210 FG 260

Impeller SS / bronze SS / bronze

Pump shaft EN8 EN8

c Drive Engine Specifications

Make Kirloskar (KBL)

Model no. Kirloskar (KBL) Kirloskar (KBL)

Engine type / no. of strokes Air cooled/ 4 troke

Cylinder configuration Two

RPM 3000

Fuel type Diesel Diesel

Bore / Stoke Fire fighting standards

Cylinder displacement / swept volume Fire fighting standards

Compression ratio Fire fighting standards

Cylinder output Fire fighting standards

Mean piston speed Fire fighting standards

Mean effective pressure Fire fighting standards

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 2 of 16

Aspiration Fire fighting standards

Engine rating Fire fighting standards

Fuel tank capacity / retention time 15 Lit

Engine jacket cooling system Fire fighting standards

Lube oil cooling system Fire fighting standards

Type of coupling arrangement Fire fighting standards

Type of governor Fire fighting standards

Ttransient response time of governor Fire fighting standards

Anti-vibration mountings Fire fighting standards

Guaranteed transmission efficiency Fire fighting standards

Specific fuel oil consumption (gms/kwhr) Fire fighting standards

Specific lub oil consumption(litres/kwhr) Fire fighting standards

d Batteries

Type of batteries Fire fighting standards

Rating of batteries V / AH Fire fighting standards

No. of batteries Fire fighting standards

Make of batteries Fire fighting standards

Battery chager type and make Fire fighting standards

e Others

Accessories

Air cleaner Yes Yes

Breather Yes Yes

Filter Yes Yes

Lub oil cooler Yes Yes

Exhaust for engine with silencer Yes Yes

Master engine control switch Yes Yes

Engine operation counter Yes Yes

Alarm and control panel Yes Yes

1.3 Jockey Pumps

Capacity 300 lpm 18 m3/hr

Quantity 2 (1W+1S) 2 (1W+1S)

Head 88 mWC 88

MOC of main parts Casing CI, SS or Bronze Impeller Casing CI, SS or Bronze Impeller

Make of pump Kirloskar (KBL) Kirloskar

Motor rating 15.13 kw

Type of motor TEFC TEFC

Make of motor Kirloskar / ABB / Siemens Kirloskar

Dewatering mono block pump 5 m3/hr capacity- min. 2 HP

1.4 Priming Tank

Qty

As the pumps have positive

suction, so these are not Not required

TS No 1639-U-008 R01 TECHNICAL

requiredDATA SHEET Page 3 of 16

Capacity As the pumps have positive

suction, so these are not Not required

MOC required

Level switches for auto operation of pumps

1.5 Pump House Piping

a Pipe Specifications

MOC up to 150 NB as per IS 1239 and up to 150 NB as per IS 1239 and > 150 NB as

> 150 NB as per IS 3589 per IS 3589

Up to 150 NB Class C / Medium Up to 150 NB Class C / Medium duty and

Thickness duty and above 150 NB min. 6.0

mm thick above 150 NB min. 6.0 mm thick

Make of pipes Jindal / Tata Jindal

Make of fittings reputed make

b Painting for pipes

2 coats of red oxide primer and 1 2 coats of red oxide primer and 1 coat of

Painting coat of final enamel paint final enamel paint

Make Jindal Berger

350 NB pipeline from two reservors to suction header 6 6

250 NB pump suction line from main suction header 4 4

200 NB pipeline for individual pump's discharge 12 12

250 NB discharge header up to the pump house 8 8

boudary

80 NB suction of Jockey Pump 2 2

65 NB discharge of Jockey Pump 6 6

For recirculation, drains, vents, Instruments, monoblock As required As required

pump

1.6 Strainers

a Specifications

Design code / standard IS code IS code

Rating PN 1.6 PN 1.6

End connections Flanged, drilling as per IS 1538 Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260, Body -CI as per IS 210 FG 260, internals- SS

internals- SS 410/ bronze 410

Make KSB / Fluidline KSB

b BOQ

350 NB for main pumps suction line 2 2

1.7 Sluice valves/gate valves

a Specifications

Design code / standard IS:14846 IS:14846

Rating PN 1.6 PN 1.6

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 4 of 16

End connections Flanged, drilling as per IS 1538 Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260, Body -CI as per IS 210 FG 260, internals- SS

spindle- SS 410/ bronze 410

Make KBL / Fluidline / Audco/KSB KBL

b BOQ

350 NB for main connection lines from tanks 2+1 2+1

250 NB for main pumps suction line 2+1 2+1

80 NB for Jockey pump's discharge line 2+1 2+1

For recirulation line, drains, vents, instruments,

monoblock pump As required As required

1.8 NRVs at the discharge of pumps

a Specifications

Design code / standard IS:5312 IS:5312

Rating PN 1.6 PN 1.6

End connections Flanged, drilling as per IS 1538 Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260, Body -CI as per IS 210 FG 260, internals- SS

internals- SS 410/ bronze 410

Make KBL / Fluidline / Audco/KSB KBL

b BOQ

200 NB for individual pumps discharge lines 2+1 2+1

65 NB for discharge of Jockey Pump 2+1 2+1

1.9 Other Miscellaneous Items

Flanges, reducers and other fittings As required As required

Steel supports for pipings within pump house As required As required

2 PUMP HOUSE EQUIPMENTS - ELECTRICAL

2.1 MCC and Control Panels

a Incoming feeder

Incoming Feeder for power supply to MCC 1 nos. MCCB with required 1 nos. MCCB with required switcgears

switcgears

b Outgoing feeders

1 nos. MCCB with required

For main hydrant pump switcgears 1 nos. MCCB with required switcgears

Hydrant diesel engine starter panel/ battery charger 1 nos. MCCB with required 1 nos. MCCB with required switcgears

switcgears

Hydrant jockey pump 1 nos. MCCB with required 1 nos. MCCB with required switcgears

switcgears

1 nos. MCCB with required

Dewatering pump switcgears 1 nos. MCCB with required switcgears

One no. of 10 HP and one no. 5 One no. of 10 HP and one no. 5 HP MCCB

Spare feeder with suitable MCCB HP MCCB with required with required switchgears

switchgears

1 nos. MCB with required

External hooter switcgears 1 nos. MCB with required switcgears

c Starters for individual feeders

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 5 of 16

Star-delta for main electric pump Yes Yes

DOL/star-delta starter for jockey pump Yes Yes

Diesel engine starter panel Yes Yes

Battery charger and battery bank Yes Yes

Auto / manual starting of the diesel engine along with

fault annunciator Yes Yes

Voltmeter and ammeter in each feeder Yes Yes

On/off/trip lights, selector switches for auto/manual Yes Yes

Alarm annunciator panel Yes Yes

Potential free contactors for transfering pump status to

the fire alarm panel/DCS (running, fail to start, in Yes Yes

manual mode)

Make of switchgears ABB/siemen/L&T L&T

2.2 Cables

Copper conductor armoured Copper conductor armoured cables with

Type of cables cables with FRLS (fire retard low

smoke) FRLS (fire retard low smoke)

Cable from MCC panel to individual motors As required As required

Eathing strips inside pump house As required As required

Instrument and control cables inside pump house As required As required

Cable make TCI / Unistar/RPG Use standard make

3 FIRE HYDRANT EQUIPMENTS AND PIPING

3.1 Fire Hydrant Valve

Single Outlet, SS 304 grade, 80

NB flanged inlet, SS Single Outlet, SS 304 grade, 80 NB flanged

spindle,63mm female inst. inlet, SS spindle,63mm female inst. Oblique

Details Oblique outlet, complete with outlet, complete with ABS blank cap & chain

ABS blank cap & chain as per as per IS:5290

IS:5290

Make Newage Newage

3.2 Water Monitors

Water Monitor 32 NB Nozzle

Details bore Water Monitor 32 NB Nozzle bore

Nominal size 80 80

Maximum flow 3030 lpm 3030 lpm

Type Swiwel joint, bronze with double Swiwel joint, bronze with double row of SS

row of SS bearings as per IS:8442 bearings as per IS:8442

360 deg rotation / 90 deg above 360 deg rotation / 90 deg above horizontal

Rotation / through horizontal and 45 deg below and 45 deg below horizontal

horizontal

Nos. 6 6

Make Newage / HD Newage

3.3 Branch Pipe

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 6 of 16

Short, SS 304, 63 MM Short, SS 304, 63 MM male instantaneous

male instantaneous inlet, male

Details threaded outlet, complete with inlet, male threaded outlet, complete with

5/8” bore nozzle as per IS: 903. 5/8” bore nozzle as per IS: 903.

Qty 66 66

Make Newage Newage

3.4 Hose Reel and Hose

a Specifications

Type

Rubberized fabric Reinforced Rubberized fabric Reinforced Rubber Lining

MOC Rubber Lining (RRL), (RRL),

Design pressure working pressure 14 kg/cm2, working pressure 14 kg/cm2, proof pressure

proof pressure 22 kg/cm2 22 kg/cm2

Design code as per IS : 636 as per IS : 636

Coupling SS male and female SS male and female

Make Newage / Eversafe Newage

3.5 Fire hose cabinet

Nos. 44 44

Fabricated from min. 16 SWG / 1.5 mm MS sheet min. 16 SWG / 1.5 mm MS sheet

Size Suitable Suitable

Door glass thk. min. 4 mm thk. min. 4 mm thk.

Rubber beading Heavy duty Heavy duty

3.6 Fire Brigade Connections near Main Gate

Gun metal 4 way 63 mm

Type instantaneous coupling with Gun metal 4 way 63 mm instantaneous

accessories coupling with accessories

Fire Brigade inlet connection 2 2

Fire brigade draw out connection 1 1

Make Newage Newage

3.7 Hydrant Pipes and fittings

a Pipe Specifications

MOC up to 150 NB as per IS 1239 and up to 150 NB as per IS 1239 and > 150 NB as

> 150 NB as per IS 3589 per IS 3589

Up to 150 NB Class C / Medium

Thickness duty and above 150 NB min. 6.0 Up to 150 NB Class C / Medium duty and

above 150 NB min. 6.0 mm thick

mm thick

Make of pipes Jindal / Tata Jindal

Make of fittings Lloyds / reputed make Reputed make

b BOQ of Underground Pipes

150 NB 96 96

Drain, vents, instrument connection lines As required As required

Pipe fittings As required As required

c BOQ of above-ground pipes

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 7 of 16

MOC IS 1239, Black MS, heavy grade IS 1239, Black MS, heavy grade

350 NB 20 20

250 NB 20 70

200 NB 710 710

150 NB 304 2104

100 NB 260 260

80 NB 400 400

65 NB 10 10

50 NB 250 250

Drain, vents, instrument connection lines As required As required

d Wrapping and Coating for under ground pipes

Coal Tar tape as per IS:10221 and Coal Tar tape as per IS:10221 and protective

Wrapping type protective coating as per AWWA coating as per AWWA C 203

C 203

Thickness 4 mm 4 mm

Make Rustech / IWL IWL

e Painting for above ground pipes

Painting 2 coats of red oxide primer and 1 2 coats of red oxide primer and 1 coat of

coat of final enamel paint final enamel paint

Make Burger / Asian Paints Berger

3.8 Valve chambers

Size 1 m x 1 m x 1m 1 m x 1 m x 1m

3.9 Butterfly valves

a Specifications

Design code / standard API 609/IS 13095 IS13095

Rating PN 1.6 PN 1.6

End connections Flanged, drilling as per IS 1538 Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260, Body -CI as per IS 210 FG 260, spindle- SS 410

spindle- SS 410/ bronze

Make KBL / Fluidline / Audco / KSB KBL

b BOQ

250 mm 3+1 3+1

200 mm 6+1 6+1

150 mm 10+1 10+1

100 mm 2 2

65 mm 2+1 2+1

3.10 Other Miscellaneous Items

Supply and Installation of Steel Structure Support As required As required

Air releasing vessels with air releasing valves As required As required

Hume pipes 300 mm dia. As per layout's requirements As per layout's requirements

4 CIVIL WORKS

Excavation and Backfilling in soft soil

Excavation and Backfilling in Hard soil

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 8 of 16

Road cutting (150 mm thickness)

PCC Breaking (150 mm thickness)

Valve Chambers

Strcture steel for supporting with painting

7 APPROVAL

Inspection & Approval from TAC accredited third party / Yes Yes

FI / Delhi Fire Service

8 OTHER MISC. SCOPE OF SUPPLY AND SERVICES

To prepare and subbmit the layout of fire hydrant

system for Owner's / Consultant's approval Yes Yes

Supply of equipments / items under scope Yes Yes

Packing and forwarding including any special packing, if Yes Yes

required.

Receipt of material at site, unloading and storing at site. Yes Yes

Handling of material during erection Yes Yes

Excavation and backfilling Yes Yes

Erection and commissioning. Yes Yes

Skilled, unskilled labour and tools and tackles required

for Erection and commissioning activities including the Yes Yes

supervisory staff.

Submission of Quality Assurance Plan for approval Yes Yes

Testing and inspection as per Approved QAP Yes Yes

Training of Purchaser’s staff about the operation and

Yes Yes

maintenance of the plant.

First fill of lubricants. Yes Yes

Maintenance service kit/special tools and tackles, if any. Yes Yes

A list of 2 years operation and maintenance spares (if Yes Yes

any) to be provided with price list valid for 2 years.

Initial manufacturing schedule and bar chart. Yes Yes

Monthly progress reports Yes Yes

Any other item that is not mentioned but is necessary

for safe and efficient operation of the plant. Yes Yes

Note:-

1. Autocad copy of the final layout will be provided to the vendor along with the floor plan details of building for preparing final layout.

2. Vendor will submit the hydrant layout for Owner's / Consultant's approval.

3. The above BOQ is only approximation based on the tentative layout. The final BOQ will be as per the approved layout. So vendor should give the unit prices.

4. All the details which are not provided are to be considered as pet TAC rule and regulations.

5. Vendor should fill up the pending data and in case required vendor can add the data in the sheet.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 9 of 16

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

5 PORTABLE AND MOBILE FIRE EXTINGUISHERS

5.1 Dry Chemical Powder Type 5 Kgs

a Specifications

Fire extiguisher complete with

gunmetal cap, bracket and initial Fire extiguisher complete with gunmetal cap,

charge of 6 kgs Sodium -bi- bracket and initial charge of 6 kgs Sodium

Details carbonate based dry chemical -bi-carbonate based dry chemical powder

powder and fully charged 120 and fully charged 120 gms CO2 gas catridge

gms CO2 gas catridge

Extinguisher as per IS: 15683, dry

powder as per IS:4308, gas Extinguisher as per IS: 15683, dry powder as

catridge as per IS:4947, body as per IS:4308, gas catridge as per IS:4947,

Design standards

per IS: 513, gunmetal cap as per body as per IS: 513, gunmetal cap as per IS:

IS: 318, Siphon tube as per 318, Siphon tube as per IS:3601

IS:3601

Filled weight 11.3 kgs 11.3 kgs

Test pressure 35 kgf/cm2 for 2

Testing minutes Test pressure 35 kgf/cm2 for 2 minutes

b Quantity 35 35

5.3 CO2 Type portable fire extinguishers - 4.5 Kgs

a Specifications

Assembled from brand new Assembled from brand new explosive

explosive approved cylinders,

complete with screw down / approved cylinders, complete with screw

Details squeeze grip type valve, internal down / squeeze grip type valve, internal

discharge tube, one meter high pressure

discharge tube, one meter high rayon braided hose etc.

pressure rayon braided hose etc.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 10 of 16

Extinguisher as per IS: 2878, CO2

cylinder as per IS: 7285 CCE Extinguisher as per IS: 2878, CO2 cylinder as

per IS: 7285 CCE approved, valve as per

Design standards approved, valve as per IS:3224,

CO2 gas as per IS:307, internal IS:3224, CO2 gas as per IS:307, internal

discharge tube as per IS:708 discharge tube as per IS:708

Discharge duration 10 to 24 sec. 10 to 24 sec.

Filled weight 17 kgs 17 kgs

Testing Test pressure 250 kgf/cm2 Test pressure 250 kgf/cm2

b Quantity 30 45

5.4 Mechanical water Type Fire extinguishers -9 ltrs

a Specifications

Extinguisher complete with

gunmetal cap, bracket, fitted Extinguisher complete with gunmetal cap,

with flexible hose terminating in bracket, fitted with flexible hose terminating

branch pipe, initial charge of in branch pipe, initial charge of AFFF

Details AFFF concentrate and fully concentrate and fully charged CO2 gas

charged CO2 gas catridge 60 gms catridge 60 gms with powder coated

with powder coated internally internally and externally towards protection

and externally towards against corrosion.

protection against corrosion.

Filled weight 14.35 kgs 14.35 kgs

Testing Test pressure 35 kgf/cm2 for 2 Test pressure 35 kgf/cm2 for 2 minutes

minutes

b Quantity 2 2

5.5 Mechanical Foam Type Fire extinguishers -50 ltrs

a Specifications

Extinguisher with gunmetal cap,

fitted with discharge hose and Extinguisher with gunmetal cap, fitted with

foam making mounted on rubber discharge hose and foam making mounted

tyred wheels complete with on rubber tyred wheels complete with initial

Details initial charge of AFFF concentrate charge of AFFF concentrate (6 %) and fully

(6 %) and fully charged CO2 gas charged CO2 gas catridge 300 gms and

catridge 300 gms and suitable for suitable for class B fire

class B fire

Design standards As per IS:13386 As per IS:13386

Filled weight 80 kgs 80 kgs

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 11 of 16

Test pressure 35 kgf/cm2 for 2

Testing minutes Test pressure 35 kgf/cm2 for 2 minutes

b Quantity 2 6

5.6 Fire sand bucket along with stand and canopy

Capacity 9 ltrs water volume 9 ltrs water volume

Nos. 17 sets of 4 buckets each 17 sets of 4 buckets each

7 APPROVAL

Inspection & Approval from TAC accredited third party / Yes Yes

FI / Delhi Fire Service

8 OTHER MISC. SCOPE OF SUPPLY AND SERVICES

To prepare and subbmit the layout of fire hydrant

system for Owner's / Consultant's approval Yes Yes

Supply of equipments / items under scope Yes Yes

Packing and forwarding including any special packing, if Yes Yes

required.

Receipt of material at site, unloading and storing at site. Yes Yes

Handling of material during erection Yes Yes

Excavation and backfilling Yes Yes

Erection and commissioning. Yes Yes

Skilled, unskilled labour and tools and tackles required

for Erection and commissioning activities including the Yes Yes

supervisory staff.

Submission of Quality Assurance Plan for approval Yes Yes

Testing and inspection as per Approved QAP Yes Yes

Training of Purchaser’s staff about the operation and Yes Yes

maintenance of the plant.

First fill of lubricants. Yes Yes

Maintenance service kit/special tools and tackles, if any. Yes Yes

A list of 2 years operation and maintenance spares (if

Yes Yes

any) to be provided with price list valid for 2 years.

Initial manufacturing schedule and bar chart. Yes Yes

Monthly progress reports Yes Yes

Any other item that is not mentioned but is necessary

for safe and efficient operation of the plant. Yes Yes

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 12 of 16

Note:-

1. Autocad copy of the final layout will be provided to the vendor along with the floor plan details of building for preparing final layout.

2. Vendor will submit the hydrant layout for Owner's / Consultant's approval.

3. The above BOQ is only approximation based on the tentative layout. The final BOQ will be as per the approved layout. So vendor should give the unit prices.

4. All the details which are not provided are to be considered as pet TAC rule and regulations.

5. Vendor should fill up the pending data and in case required vendor can add the data in the sheet.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 13 of 16

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

6 FIRE ALARM SYSTEM

6.1 Smoke & Heat Detectors

a Specification

Type Multi criteria monitors Multi criteria monitors

Operating voltage 24V

Current drawn at above operaing voltage 2.4 mA

Automatic drift compensation Yes Yes

Bi-colour LED detector status Yes Yes

Make System sensors / Apollo ATSS

b Quantity

Multi criteria monitors 71 71

6.2 Response Indicators

a Specification

Type Temperature thermal detector

Operating voltage 24V

Current drawn at above operaing voltage 2.4 mA

Bi-colour LED detector status Yes Yes

Make System sensors / Apollo ATSS

b Quantity 13 13

6.3 Manual Call Point & Hooters

MS enclosure made from 1.5

Enclosure mm thk sheet MS enclosure made from 1.5 mm thk sheet

Make ATSS

Quantity 30 30

6.5 Fire Alarm Panel

Type of panel Conventional with LCD display Conventional with LCD display and battery ,

and battery , battery charger battery charger

Nos. 1 1

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 14 of 16

No. of zones 8 8

Battery back-up Yes Yes

Make Daksh / Advance / National Ravel/Rittal

Interconnecting cables as required as required

7 APPROVAL

Inspection & Approval from TAC accredited third party / Yes Yes

FI / Delhi Fire Service

8 OTHER MISC. SCOPE OF SUPPLY AND SERVICES

To prepare and subbmit the layout of fire hydrant Yes Yes

system for Owner's / Consultant's approval

Supply of equipments / items under scope Yes Yes

Packing and forwarding including any special packing, if

required. Yes Yes

Receipt of material at site, unloading and storing at site. Yes Yes

Handling of material during erection Yes Yes

Excavation and backfilling Yes Yes

Erection and commissioning. Yes Yes

Skilled, unskilled labour and tools and tackles required

for Erection and commissioning activities including the Yes Yes

supervisory staff.

Submission of Quality Assurance Plan for approval Yes Yes

Testing and inspection as per Approved QAP Yes Yes

Training of Purchaser’s staff about the operation and

maintenance of the plant. Yes Yes

First fill of lubricants. Yes Yes

Maintenance service kit/special tools and tackles, if any. Yes Yes

A list of 2 years operation and maintenance spares (if

any) to be provided with price list valid for 2 years. Yes Yes

Initial manufacturing schedule and bar chart. Yes Yes

Monthly progress reports Yes Yes

Any other item that is not mentioned but is necessary

for safe and efficient operation of the plant. Yes Yes

Note:-

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 15 of 16

1. Autocad copy of the final layout will be provided to the vendor along with the floor plan details of building for preparing final layout.

2. Vendor will submit the hydrant layout for Owner's / Consultant's approval.

3. The above BOQ is only approximation based on the tentative layout. The final BOQ will be as per the approved layout. So vendor should give the unit prices.

4. All the details which are not provided are to be considered as pet TAC rule and regulations.

5. Vendor should fill up the pending data and in case required vendor can add the data in the sheet.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 16 of 16

Potrebbero piacerti anche

- Code of Ethics Multiple Choice QuestionsDocumento4 pagineCode of Ethics Multiple Choice QuestionsGideon P. Casas88% (24)

- Isuzu 4be1 Engine Manual KolesooreDocumento5 pagineIsuzu 4be1 Engine Manual KolesooreRaymart Dealca75% (8)

- Boq 108292Documento6 pagineBoq 108292ashish.mathur1Nessuna valutazione finora

- PM IS - 12818 June2021Documento10 paginePM IS - 12818 June2021Mahendra AhirwarNessuna valutazione finora

- Arocity-Water BOQ 2010Documento23 pagineArocity-Water BOQ 2010Hemn Rafiq TofiqNessuna valutazione finora

- Structural Steel Design DetailsDocumento7 pagineStructural Steel Design DetailsJanya AssociatesNessuna valutazione finora

- Boq For Saraya BandarDocumento12 pagineBoq For Saraya BandarPresanna RajasekaranNessuna valutazione finora

- AEL Comments On STP Punch PointsDocumento14 pagineAEL Comments On STP Punch PointsEphrem GizachewNessuna valutazione finora

- Technical Specfications For 5 Ton EOT CraneDocumento10 pagineTechnical Specfications For 5 Ton EOT CraneMoses_JakkalaNessuna valutazione finora

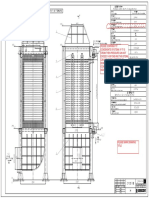

- Drawing of Chimney Frame PDFDocumento1 paginaDrawing of Chimney Frame PDFsridharNessuna valutazione finora

- Is 1742 1983Documento55 pagineIs 1742 1983Shobhit AcharyaNessuna valutazione finora

- EI Erection Tender Additional Work Silo, ConvDocumento18 pagineEI Erection Tender Additional Work Silo, ConvSaurabh Kumar SinghNessuna valutazione finora

- Technical Data Sheet BD 004 Rev 4Documento9 pagineTechnical Data Sheet BD 004 Rev 4debu1985Nessuna valutazione finora

- K.P.Mondal&Sons: N No. of Hole H Hole DiaDocumento1 paginaK.P.Mondal&Sons: N No. of Hole H Hole DiaTanmoy DuttaNessuna valutazione finora

- MoEF ManualDocumento256 pagineMoEF Manualjack jNessuna valutazione finora

- Manhole DetailsDocumento1 paginaManhole DetailsJanakiram GoudNessuna valutazione finora

- Annexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)Documento2 pagineAnnexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)eagles1109Nessuna valutazione finora

- Is 16088 2012Documento26 pagineIs 16088 2012kishor150688Nessuna valutazione finora

- Air Eliminator DatasheetDocumento2 pagineAir Eliminator DatasheetbecpavanNessuna valutazione finora

- S.no Description Data For ApprovalDocumento2 pagineS.no Description Data For ApprovalVenkatNessuna valutazione finora

- F0512 Manhole DatasheetDocumento2 pagineF0512 Manhole DatasheetAbrar HussainNessuna valutazione finora

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetDocumento3 pagineWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarNessuna valutazione finora

- Design of Chemical House - 03.11.2009Documento120 pagineDesign of Chemical House - 03.11.2009Sai GnanadeepNessuna valutazione finora

- PDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMDocumento24 paginePDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMSISIR KR BARMAN0% (1)

- Mechanical CommentsDocumento2 pagineMechanical CommentsMichael FaridNessuna valutazione finora

- NELTAS ECAT Prospectus 19 20 TD PDFDocumento11 pagineNELTAS ECAT Prospectus 19 20 TD PDFCharles Aronnax50% (2)

- How To MEP SetupDocumento9 pagineHow To MEP SetupparatchanaNessuna valutazione finora

- Hvac Catalogue 201710 25 (3.8 MB)Documento20 pagineHvac Catalogue 201710 25 (3.8 MB)AMEENNessuna valutazione finora

- Sedimentation BasinsDocumento14 pagineSedimentation Basinsفردوس سليمانNessuna valutazione finora

- PDN Handbook Volume IDocumento188 paginePDN Handbook Volume IVikram DesaiNessuna valutazione finora

- SFRC Manhole Frames & Covers: Concrete ProductsDocumento3 pagineSFRC Manhole Frames & Covers: Concrete ProductsNIKUNJ PARMARNessuna valutazione finora

- 11qvul PDFDocumento14 pagine11qvul PDFghaffaryanNessuna valutazione finora

- Is 6595 2 1993Documento10 pagineIs 6595 2 1993mishraenggNessuna valutazione finora

- VSD Calculator For PumpsDocumento10 pagineVSD Calculator For PumpsKhaldoon AlnashiNessuna valutazione finora

- Dosing PumpDocumento10 pagineDosing PumpniceseshaNessuna valutazione finora

- Permeate Line Pressure Drop CalculationsDocumento2 paginePermeate Line Pressure Drop Calculationsask.kulkarni KulkarniNessuna valutazione finora

- ETP Combined Spec - R0Documento60 pagineETP Combined Spec - R0Pravash Chandra Senapaty100% (1)

- IE - LESSON 16. Design and Operation of Underground Pipeline SystemDocumento5 pagineIE - LESSON 16. Design and Operation of Underground Pipeline SystemEfremWakjiraHodeNessuna valutazione finora

- 12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineDocumento19 pagine12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineImamul HaqueNessuna valutazione finora

- Hydrological AnalysisDocumento6 pagineHydrological AnalysisIfeanyi UmehNessuna valutazione finora

- H Water Supply, Sewerage and Drainage WorkDocumento14 pagineH Water Supply, Sewerage and Drainage WorkDushyantha JayawardenaNessuna valutazione finora

- Boq For Abb Flow MeterDocumento166 pagineBoq For Abb Flow MeterDeepak RajanNessuna valutazione finora

- Faida WTP - Control PhilosophyDocumento19 pagineFaida WTP - Control PhilosophyDelshad DuhokiNessuna valutazione finora

- Comparison of 4 Different Flow Control Methods of PumpsDocumento5 pagineComparison of 4 Different Flow Control Methods of PumpsSebastianCicognaNessuna valutazione finora

- Flow and CV Calculation ToolDocumento3 pagineFlow and CV Calculation Toolmohan babuNessuna valutazione finora

- Section 1 PDFDocumento438 pagineSection 1 PDFAnfal BarbhuiyaNessuna valutazione finora

- M.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleDocumento7 pagineM.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleShubhankar SharmaNessuna valutazione finora

- Sample - Pipe Manufacturer Data SheetDocumento22 pagineSample - Pipe Manufacturer Data SheetAmal KaNessuna valutazione finora

- Gen - Assembly Dwg-Energy ChainDocumento2 pagineGen - Assembly Dwg-Energy ChainJohn Renzel Rivera IIINessuna valutazione finora

- Bid Document of 4th B LiftDocumento670 pagineBid Document of 4th B LiftSuresh Kumar100% (1)

- SCPL Phe BoqDocumento120 pagineSCPL Phe BoqSajeshKumarNessuna valutazione finora

- 2015 Foster HVAC Selection GuideDocumento2 pagine2015 Foster HVAC Selection Guidesiva_nagesh_2Nessuna valutazione finora

- Pump Performance Datasheet: Operating Conditions LiquidDocumento25 paginePump Performance Datasheet: Operating Conditions Liquidrusli bahtiarNessuna valutazione finora

- FiltriDocumento255 pagineFiltriLavinia CalinNessuna valutazione finora

- Return Period & Others GuidelinesDocumento1 paginaReturn Period & Others GuidelinesHarish Kumar MahavarNessuna valutazione finora

- Storage Tank Spesification: Operating/Design Data Nozzles/Connections MarkDocumento4 pagineStorage Tank Spesification: Operating/Design Data Nozzles/Connections Markandryani octavia sari nasutionNessuna valutazione finora

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Documento31 pagineSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12Nessuna valutazione finora

- Str. Design of TWO Pole STR and TFR Yard R1Documento17 pagineStr. Design of TWO Pole STR and TFR Yard R1epe civil1Nessuna valutazione finora

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Documento1 paginaTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNessuna valutazione finora

- 1639-U-008 R02 Data SheetDocumento15 pagine1639-U-008 R02 Data SheetHEMANTNessuna valutazione finora

- 600mw Rtps Equipmemt ParametersDocumento65 pagine600mw Rtps Equipmemt ParametersANOY KUMAR MONDALNessuna valutazione finora

- Perkins 45 KVADocumento4 paginePerkins 45 KVASadiman SadimanNessuna valutazione finora

- Kitchen WorkingDocumento1 paginaKitchen WorkingHEMANTNessuna valutazione finora

- User Manual For General Trade/Storage License Application - SDMC and NDMCDocumento14 pagineUser Manual For General Trade/Storage License Application - SDMC and NDMCHEMANTNessuna valutazione finora

- Pressure Safety Valve Sizing Calculation Rev 01Documento3 paginePressure Safety Valve Sizing Calculation Rev 01Athiphap SrisupareerathNessuna valutazione finora

- Summary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoDocumento32 pagineSummary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoHEMANTNessuna valutazione finora

- Construction Joints in Concrete Structures - Structural GuideDocumento15 pagineConstruction Joints in Concrete Structures - Structural GuideHEMANTNessuna valutazione finora

- VISA Power 28th July - VGV R4Documento37 pagineVISA Power 28th July - VGV R4HEMANTNessuna valutazione finora

- Rectangular Tank Design ExelDocumento40 pagineRectangular Tank Design Exelhabibur Rahman Khan100% (1)

- Calculation of Heat and Mass BalanceDocumento16 pagineCalculation of Heat and Mass BalanceHEMANTNessuna valutazione finora

- Technical Annexure - PODocumento27 pagineTechnical Annexure - POHEMANTNessuna valutazione finora

- FP00484 - Complainces Sheet On Water System DatasheetsDocumento1 paginaFP00484 - Complainces Sheet On Water System DatasheetsHEMANTNessuna valutazione finora

- Bill of Quantity Fir Figting SystemDocumento20 pagineBill of Quantity Fir Figting SystemHEMANTNessuna valutazione finora

- Rectification Sheet of Classic On Comments 14.11.18 PLC PanelDocumento1 paginaRectification Sheet of Classic On Comments 14.11.18 PLC PanelHEMANTNessuna valutazione finora

- 1639-U-008 R02 Data SheetDocumento15 pagine1639-U-008 R02 Data SheetHEMANTNessuna valutazione finora

- 1639-U-005 - R06 Datasheet Latest DatasheetDocumento4 pagine1639-U-005 - R06 Datasheet Latest DatasheetHEMANTNessuna valutazione finora

- Spec. No. 7311-DE-042Documento1 paginaSpec. No. 7311-DE-042HEMANTNessuna valutazione finora

- CURV DP Vs FLOW RATE FE-201 FONG170203 PDFDocumento1 paginaCURV DP Vs FLOW RATE FE-201 FONG170203 PDFHEMANTNessuna valutazione finora

- 1.1 Type of Check Shall Be D.P. Test in Place of VisualDocumento1 pagina1.1 Type of Check Shall Be D.P. Test in Place of VisualHEMANTNessuna valutazione finora

- Flow Meter Data SheetDocumento1 paginaFlow Meter Data SheetHEMANTNessuna valutazione finora

- 112N06-2-0 Secondary Air Preheater-Model PDFDocumento1 pagina112N06-2-0 Secondary Air Preheater-Model PDFHEMANTNessuna valutazione finora

- 1639-U-005 - R05 Datasheet Latest DatasheetDocumento4 pagine1639-U-005 - R05 Datasheet Latest DatasheetHEMANTNessuna valutazione finora

- DCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingDocumento7 pagineDCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingHEMANTNessuna valutazione finora

- Spec. No. 7311-DE-041Documento1 paginaSpec. No. 7311-DE-041HEMANTNessuna valutazione finora

- 9 IO and Parameter ListDocumento5 pagine9 IO and Parameter ListHEMANTNessuna valutazione finora

- E-Mail - : Navinender - Gupta@korus - inDocumento1 paginaE-Mail - : Navinender - Gupta@korus - inHEMANTNessuna valutazione finora

- DGN-205 Doc. Rev.03 PDFDocumento3 pagineDGN-205 Doc. Rev.03 PDFHEMANTNessuna valutazione finora

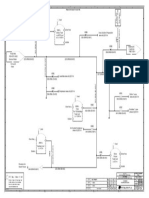

- 1639-501 Sh03 R2-Model SERVICE WATERDocumento1 pagina1639-501 Sh03 R2-Model SERVICE WATERHEMANTNessuna valutazione finora

- DGN-205 Doc. Rev.03 PDFDocumento3 pagineDGN-205 Doc. Rev.03 PDFHEMANTNessuna valutazione finora

- Appendix IIIDocumento1 paginaAppendix IIIHEMANTNessuna valutazione finora

- 1639-531 SH 05 R7-Model (BFP)Documento1 pagina1639-531 SH 05 R7-Model (BFP)HEMANTNessuna valutazione finora

- RFP For Corporate Engagement Platform PDFDocumento28 pagineRFP For Corporate Engagement Platform PDFAnupriya Roy ChoudharyNessuna valutazione finora

- Transport ADRDocumento3 pagineTransport ADRZbinca CristianNessuna valutazione finora

- METHODOLOG1Documento3 pagineMETHODOLOG1Essa M RoshanNessuna valutazione finora

- Price List Ciaz AccessoriesDocumento4 paginePrice List Ciaz AccessoriesAsif RazviNessuna valutazione finora

- Coreapb3: Nivin PaulDocumento19 pagineCoreapb3: Nivin PaulNivin PaulNessuna valutazione finora

- 34-Samss-718 (12-02-2015)Documento14 pagine34-Samss-718 (12-02-2015)Mubin100% (1)

- Ujar10 10434839Documento11 pagineUjar10 10434839Fitryane LihawaNessuna valutazione finora

- 01 FundamentalsDocumento20 pagine01 FundamentalsTay KittithatNessuna valutazione finora

- Woodworking SyllabusDocumento3 pagineWoodworking SyllabusLeonard Andrew ManuevoNessuna valutazione finora

- Text-Book P3Documento147 pagineText-Book P3Nat SuphattrachaiphisitNessuna valutazione finora

- Power GREPDocumento392 paginePower GREPCeles NubesNessuna valutazione finora

- Cisa 2Documento6 pagineCisa 2Ahmad MaaytahNessuna valutazione finora

- MEMORIAL ON BEHALF OF APPELLANTS DocsDocumento29 pagineMEMORIAL ON BEHALF OF APPELLANTS DocsPrashant KumarNessuna valutazione finora

- BA Trolley AMC PO Vijay Sabre Cont - PrintDocumento7 pagineBA Trolley AMC PO Vijay Sabre Cont - PrintParag ChandankhedeNessuna valutazione finora

- Appointments & Other Personnel Actions Submission, Approval/Disapproval of AppointmentDocumento7 pagineAppointments & Other Personnel Actions Submission, Approval/Disapproval of AppointmentZiiee BudionganNessuna valutazione finora

- Uy & Roxas vs. CADocumento19 pagineUy & Roxas vs. CAThea P PorrasNessuna valutazione finora

- 2019 - All Heads of Bureaus & Offices - Disconnection of Old Dti Telephone Lines - 64562Documento8 pagine2019 - All Heads of Bureaus & Offices - Disconnection of Old Dti Telephone Lines - 64562dannalauraNessuna valutazione finora

- BedZED - Beddington Zero Energy Development SuttonDocumento36 pagineBedZED - Beddington Zero Energy Development SuttonMaria Laura AlonsoNessuna valutazione finora

- Kumara SwamiyamDocumento21 pagineKumara SwamiyamVijey KumarNessuna valutazione finora

- Entrepreneurial Management - Midterm ReviewerDocumento6 pagineEntrepreneurial Management - Midterm ReviewerAudrey IyayaNessuna valutazione finora

- Evaporative Cooling Design Spreadsheet 2014 - MetricDocumento1 paginaEvaporative Cooling Design Spreadsheet 2014 - MetricCristian MoratayaNessuna valutazione finora

- SI 2023-005 Base Minerals Export Control (Unbeneficiated Base Mineral Ores) Order, 2023Documento2 pagineSI 2023-005 Base Minerals Export Control (Unbeneficiated Base Mineral Ores) Order, 2023tapiwaNessuna valutazione finora

- Thoughts On Iphone Demand - Update On Delivery Times, Carrier IncentivesDocumento10 pagineThoughts On Iphone Demand - Update On Delivery Times, Carrier Incentivesalpha123@tutopiaNessuna valutazione finora

- Royal Classic e BrochureDocumento14 pagineRoyal Classic e Brochureidreesali8654Nessuna valutazione finora

- Due Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxDocumento3 pagineDue Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxankstamanNessuna valutazione finora

- Full Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full ChapterDocumento36 pagineFull Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full Chapterfluiditytrenail7c8j100% (16)

- USA v. Sussmann - Durham Filing - Motion On Potential Conflicts of InterestDocumento13 pagineUSA v. Sussmann - Durham Filing - Motion On Potential Conflicts of InterestWashington Examiner100% (3)

- EWBB TDD 3.0 DBS3900 Product Description 01 (20130107)Documento24 pagineEWBB TDD 3.0 DBS3900 Product Description 01 (20130107)estebanarcaNessuna valutazione finora