Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1639-U-005 - R05 Datasheet Latest Datasheet

Caricato da

HEMANTDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1639-U-005 - R05 Datasheet Latest Datasheet

Caricato da

HEMANTCopyright:

Formati disponibili

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

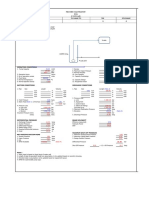

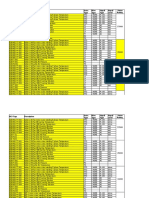

Annexure - I : TECHNICAL DATA SHEET FOR COOLING WATER CIRCULATING PUMPS & OTHER PUMPS (UPDATED FOR SUBMERSIBEL PUMP)

Sl.No. Description Units

DW Water Tranfer Leachate Transfer

Raw Water Pumps N.Pit To LTP Pumps Cooling Water Pumps

Pumps Pumps

A General

Submersible Sump Pump

Horizontal Split Casing, with all accessories like

Type Non Clog Self Priming Horizontal Pump Horizontal Back Pull Out Vertical Sump Pump

Self Priming guide,chain,cable and

panel

Qty Nos. 1W+1S 1W+1S 1W+1S 1W+1S 1W+1S

Type of flow Raw Water DW water Netulralised Waste Water Industrial water Leachate

Flow m3/h 60 30 10 300 10

Head (TDH) mWc 25 45 15 40 30

Tempurature of Feed Water °C 40 32 40 40 40

Suction Level mWc 3 meter suction lift (max.) Flooded Suction Flooded Suction Flooded Suction NA

Speed RPM 1500 1500 1500 1500 1500

Minimum Water Level M NA NA NA NA NA

Maximum Water Level M NA NA 0 NA 0

Pump/Motor Floor Level M 0 0 0 0 0

Type of Impeller Non clog design Closed impeller Non clog design Closed Non clog design

Suspended solids allowed up to 50 mm NA up to 50 mm NA up to 50 mm

B Site Data

Location Guntur (Andhra Pradesh) Guntur (Andhra Pradesh) Guntur (Andhra Pradesh) Guntur (Andhra Pradesh) Guntur (Andhra Pradesh)

Plant elevation (above MSL) m ~60 ~60 ~60 ~60 ~60

Seismic Zone Zone III As per IS:1893 Zone III As per IS:1893 Zone III As per IS:1893 Zone III As per IS:1893 Zone III As per IS:1893

Ambient temperature

For performance guarantee 0

C 35 35 35 35 35

For electrical design 0

C 50 50 50 50 50

Average high temperature 0

C 43 43 43 43 43

Average low temperature 0

C 17 17 17 17 17

C Pump Data (To Be Filled By Supplier)

Model/Size

Pump Type

Design Fluid Temperature °C

Rated Flow Cu.m/h

Rated Head m

NPSH required (at strainer inlet) m

Efficiency

BKW kw

Range of Operation %

Recommended Motor KW/ speed KW

Impeller Diameter mm

Pump shut off head m

TS No 1639-U-005 R0 TECHNICAL DATA SHEET Page 1 of 4

Annexure - I : TECHNICAL DATA SHEET FOR COOLING WATER CIRCULATING PUMPS & OTHER PUMPS (UPDATED FOR SUBMERSIBEL PUMP)

Sl.No. Description

Pressure drop across strainer at full flow Units

condition and 50% clogged condition mWc

Suction/Discharge Size mm

D Electrical

Power Consumption at rated parameters kW

Motor Driver Rating kW

Voltage V

Frequency Hz

Combined Variation %

E Major codes

Design

Pumps IS-6595:1993-Part2 IS-6595:1993-Part2 IS-6595:1993-Part2

Material

Piping Components

Electrical motors

F Material

Impeller A743 CF8M A743 CF8M A743 CF8M A743 CF8M Supplier to provide as per

Suction casing Cast iron, Grade FG200 of IS 210 A743 CF8M Cast iron, Grade FG200 of Cast iron, Grade FG200 of suitability. Pump must be

IS 210 IS 210 suitable for sewerage

Discharge casing Cast iron, Grade FG200 of IS 210 A743 CF8M Cast iron, Grade FG200 of Cast iron, Grade FG200 of water quality

IS 210 IS 210

Shaft SS410 SS410 SS410 SS410

Shaft Sleeve SS410 (H) SS410 (H) SS410 (H) SS410 (H)

Base plate MS MS MS MS

Flange & Counter Flanges ASME B16.5 Class 150 ASME B16.5 ASME B16.5 ASME B16.5

G Equipment Weights

Weight of Pump with Base Frame & Motor kg

TS No 1639-U-005 R0 TECHNICAL DATA SHEET Page 2 of 4

Korus Engineering Solutions Pvt. Ltd Jindal Urban Waste Management (Guntur) Ltd.

Annexure - II : PERFORMANCE GUARANTEE - COOLING WATER CIRCULATING PUMPS P1 & P2

Sl.No. Description Units Input Value by Korus Remarks

Pump P1 for RO Pump P2 for DM Pump P3 for STP

P4 for Drain Pit P5 for Leachate

water water water

1 Pump flow M3/hr

2 Pump head MWC

3 Efficiency of the pump %

4 Power consumption KW

TS No 1638-U-005 R0 Performance Table Page 3 of 4

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

ANNEXURE - III : SCOPE MATRIX FOR COOLING WATER CIRCULATING PUMPS P1&P2

( S - Supplier, P- Purchaser )

Supervision of

Mfg. &

Basic Detail erection &

S. No. Description Supply / Remarks

Engg. Engg. commissioning

Services

up to PG

Pumps

1 Pumps with complete assembly S S S S

2 Drive motors for the pumps S S S S

3 Coupling between Pump and Drive motor S S S S

Base Frame (Common For Pump+Motor) with

4 S S S S

foundation bolts

5 Matting flanges with fasteners at all terminal points S S S S

6 Commissioning Spares S S S S

7 Spares for 2 Years Operation S S S S

8 Maintenance Tools & Tackles-1 set for all pumps S S S S

9 Pressure gauges at suction and discharge S S S S

TS No. 1639-U-005 R0 SCOPE MATRIX Page 4 of 4

Potrebbero piacerti anche

- 01 - (2005) HVAC Manual (S16025) PDFDocumento246 pagine01 - (2005) HVAC Manual (S16025) PDFluis eduardo corzo enriquez100% (4)

- General Engineering Manual: Training DocumentDocumento34 pagineGeneral Engineering Manual: Training DocumentNguyễn Thống NhấtNessuna valutazione finora

- BOP Drawing Template BaseDocumento38 pagineBOP Drawing Template BaseSamir MuzaffarovNessuna valutazione finora

- Pumps PDFDocumento31 paginePumps PDFYURI G. MELLIZANessuna valutazione finora

- BOILERSDocumento116 pagineBOILERSBhargav Balu100% (1)

- 10-T-101 10-P-101A/B: Revision HistoryDocumento7 pagine10-T-101 10-P-101A/B: Revision HistoryAlfonNessuna valutazione finora

- 1 SRP FundamentalDocumento50 pagine1 SRP FundamentalAiham AltayehNessuna valutazione finora

- Chemical Reaction EngineeringDocumento93 pagineChemical Reaction EngineeringGuru Raj BhattNessuna valutazione finora

- Bop Drawing TemplateDocumento65 pagineBop Drawing TemplateMohd AmaniNessuna valutazione finora

- York Ys Style D MANTT0Documento48 pagineYork Ys Style D MANTT0Jose LuisNessuna valutazione finora

- Major Cheat Sheet Chemical EngineeringDocumento6 pagineMajor Cheat Sheet Chemical EngineeringtolomontNessuna valutazione finora

- 8 Centrifugal Compressor PerformanceDocumento28 pagine8 Centrifugal Compressor PerformanceHazem RamdanNessuna valutazione finora

- Calculation of Heat and Mass BalanceDocumento16 pagineCalculation of Heat and Mass BalanceHEMANTNessuna valutazione finora

- Pump Sizing SpreadsheetDocumento2 paginePump Sizing Spreadsheetandrew rachmanNessuna valutazione finora

- BFP, BP, CEP & CW Pumps PDFDocumento138 pagineBFP, BP, CEP & CW Pumps PDFsrikanth100% (1)

- Week 4 - Concept of Natural Purification and Engineered Treatment of Pollutants in Wastewater - LMDocumento35 pagineWeek 4 - Concept of Natural Purification and Engineered Treatment of Pollutants in Wastewater - LMDarasingh KiradeNessuna valutazione finora

- 1639-U-008 R02 Data Sheet 16 Dec 18Documento16 pagine1639-U-008 R02 Data Sheet 16 Dec 18HEMANTNessuna valutazione finora

- BOP Drawing Template BaseDocumento39 pagineBOP Drawing Template BaseSergio Ali TerrazasNessuna valutazione finora

- Parts Price ListDocumento5.325 pagineParts Price ListAlva100% (1)

- Compresor Sullair LS25S-257KWDocumento83 pagineCompresor Sullair LS25S-257KWEduardo Saúl Tapia100% (4)

- Summary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoDocumento32 pagineSummary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoHEMANTNessuna valutazione finora

- CSTR in SeriesDocumento12 pagineCSTR in Seriesmnizamarzuki0% (2)

- Bombas Kawasaky PDFDocumento11 pagineBombas Kawasaky PDFRoberth Alexander Ríos NievesNessuna valutazione finora

- AMIE Project Synopsis ReportDocumento10 pagineAMIE Project Synopsis ReportpavanNessuna valutazione finora

- 1639-U-005 - R06 Datasheet Latest DatasheetDocumento4 pagine1639-U-005 - R06 Datasheet Latest DatasheetHEMANTNessuna valutazione finora

- DM Plant DrawingDocumento1 paginaDM Plant DrawingMd SuruzzamanNessuna valutazione finora

- Teral: Portable Submersible PumpDocumento4 pagineTeral: Portable Submersible Pumppankaj attardeNessuna valutazione finora

- Catalog Pump Etaprime L KSBDocumento32 pagineCatalog Pump Etaprime L KSBFabricio SabadiniNessuna valutazione finora

- Field Inspection - ST Side - F20 (SOPN-P-01)Documento3 pagineField Inspection - ST Side - F20 (SOPN-P-01)BUET ENGINEERNessuna valutazione finora

- Sbi 2Documento11 pagineSbi 2cristianNessuna valutazione finora

- Overview Kerja PraktekDocumento42 pagineOverview Kerja PraktekAmanda Talia LumentutNessuna valutazione finora

- Split Case PDFDocumento8 pagineSplit Case PDFnitin lageju100% (1)

- 1002 A Series Variable Displacement Piston PumpsDocumento48 pagine1002 A Series Variable Displacement Piston PumpsLuis Enrique López LeónNessuna valutazione finora

- Bombas de Desagüe Sumergibles SJ 150-400Documento2 pagineBombas de Desagüe Sumergibles SJ 150-400Dennis MedinaNessuna valutazione finora

- Pompa WarmanDocumento2 paginePompa WarmanRahmad Saleh SiregarNessuna valutazione finora

- Unit 2Documento22 pagineUnit 2vortofolmeNessuna valutazione finora

- Catalogue Models F10 and F50 Flow SwitchesDocumento12 pagineCatalogue Models F10 and F50 Flow SwitchesNUR AFIFAHNessuna valutazione finora

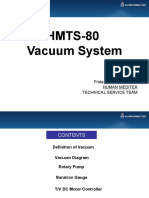

- 2.HMTS 80 Vacuum System - X-Axis & M.P Model Rev2018Documento14 pagine2.HMTS 80 Vacuum System - X-Axis & M.P Model Rev2018lehuutruong7Nessuna valutazione finora

- Iron Removal-Softener & Drinking Water Treatment Plant - DrawingDocumento1 paginaIron Removal-Softener & Drinking Water Treatment Plant - DrawingMd SuruzzamanNessuna valutazione finora

- Property Maintenance FormDocumento37 pagineProperty Maintenance FormKrisnadewaNessuna valutazione finora

- Evolve 40 NBLeafletw FiltraDocumento2 pagineEvolve 40 NBLeafletw Filtrasandeep patilNessuna valutazione finora

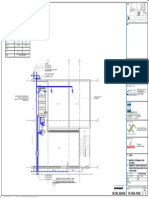

- W302 76-10526-Detail Design: 3 Domestic Water Services - Pump Room Enlarged Plan & SectionsDocumento1 paginaW302 76-10526-Detail Design: 3 Domestic Water Services - Pump Room Enlarged Plan & SectionsMazen IsmailNessuna valutazione finora

- RUH Umpen: Ruhrpumpen GMBHDocumento40 pagineRUH Umpen: Ruhrpumpen GMBHjacobo nasimbaNessuna valutazione finora

- Pump Stairs SB, SBI, SBN - VerticalMultistageCentrifugal50Hz PDFDocumento60 paginePump Stairs SB, SBI, SBN - VerticalMultistageCentrifugal50Hz PDFHadi Sutoyo100% (1)

- t6d Denison Vane Pumps IndustrialDocumento5 paginet6d Denison Vane Pumps Industrialisrael ruiz gallardoNessuna valutazione finora

- Service Manual: Auto WasherDocumento26 pagineService Manual: Auto WasherRaul Quinatzin Carranza TovarNessuna valutazione finora

- Steam Valves With Rotary Actuators: Technical DatabookDocumento12 pagineSteam Valves With Rotary Actuators: Technical DatabookUziNessuna valutazione finora

- Transvazare EngDocumento3 pagineTransvazare EngGeorge PopescuNessuna valutazione finora

- Pumps and CompressorsDocumento127 paginePumps and CompressorsbalasundarNessuna valutazione finora

- PompaDocumento2 paginePompaviviNessuna valutazione finora

- Arwana Home Booster Pump APP-pw-125Documento2 pagineArwana Home Booster Pump APP-pw-125LarryMatiasNessuna valutazione finora

- Vacuum Pumps For Table Top Steam Autoclaves: Application BrochureDocumento8 pagineVacuum Pumps For Table Top Steam Autoclaves: Application Brochurenotaden1849Nessuna valutazione finora

- Z2FS 6 New Series... 40BDocumento6 pagineZ2FS 6 New Series... 40Bnemi90Nessuna valutazione finora

- TDK-humidifier - Element Nebulizer - NB - enDocumento5 pagineTDK-humidifier - Element Nebulizer - NB - enKemenesh HNessuna valutazione finora

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocumento48 pagine22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNessuna valutazione finora

- En3672640Documento3 pagineEn3672640M YasserNessuna valutazione finora

- t6dc t6dcw Denison Vane Pumps Industrial PDFDocumento5 paginet6dc t6dcw Denison Vane Pumps Industrial PDFtecnicomanelNessuna valutazione finora

- Yuken 8 EDFHG-AMN English LeafletDocumento4 pagineYuken 8 EDFHG-AMN English LeafletJose2806Nessuna valutazione finora

- Cajn4519zhr FZ FZDocumento2 pagineCajn4519zhr FZ FZionut ciobanuNessuna valutazione finora

- Manual de Uso y Manutencion Dragon 60Documento22 pagineManual de Uso y Manutencion Dragon 60Andrea RiannaNessuna valutazione finora

- Flupec Overview Hawe v30dDocumento4 pagineFlupec Overview Hawe v30dArdeleana TisaNessuna valutazione finora

- Artificial LiftDocumento81 pagineArtificial Liftramzi aidliNessuna valutazione finora

- Quantite D'eau Et Aire Pour Les MachinesDocumento1 paginaQuantite D'eau Et Aire Pour Les MachinesMouaad BenammouNessuna valutazione finora

- DWF - R810S - Service ManualDocumento15 pagineDWF - R810S - Service ManualEnrique HerreraNessuna valutazione finora

- AquaCulture Application Process and Product ChartDocumento1 paginaAquaCulture Application Process and Product ChartBhavya MewadaNessuna valutazione finora

- NPT Analysis ProjectDocumento5 pagineNPT Analysis ProjectJohan DrillerNessuna valutazione finora

- Inject WaterDocumento8 pagineInject WaterStivNessuna valutazione finora

- Aquamet Multi Jet MeterDocumento1 paginaAquamet Multi Jet MeterkrmchariNessuna valutazione finora

- Dynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsDocumento2 pagineDynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsMohammad ZeeshanNessuna valutazione finora

- Mechanical DesignDocumento15 pagineMechanical Designandry_setiawanall4jcNessuna valutazione finora

- VISA Power 28th July - VGV R4Documento37 pagineVISA Power 28th July - VGV R4HEMANTNessuna valutazione finora

- Kitchen WorkingDocumento1 paginaKitchen WorkingHEMANTNessuna valutazione finora

- User Manual For General Trade/Storage License Application - SDMC and NDMCDocumento14 pagineUser Manual For General Trade/Storage License Application - SDMC and NDMCHEMANTNessuna valutazione finora

- Construction Joints in Concrete Structures - Structural GuideDocumento15 pagineConstruction Joints in Concrete Structures - Structural GuideHEMANTNessuna valutazione finora

- Technical Annexure - PODocumento27 pagineTechnical Annexure - POHEMANTNessuna valutazione finora

- 1639-U-008 R02 Data SheetDocumento15 pagine1639-U-008 R02 Data SheetHEMANTNessuna valutazione finora

- FP00484 - Complainces Sheet On Water System DatasheetsDocumento1 paginaFP00484 - Complainces Sheet On Water System DatasheetsHEMANTNessuna valutazione finora

- Spec. No. 7311-DE-041Documento1 paginaSpec. No. 7311-DE-041HEMANTNessuna valutazione finora

- 9 IO and Parameter ListDocumento5 pagine9 IO and Parameter ListHEMANTNessuna valutazione finora

- 1.1 Type of Check Shall Be D.P. Test in Place of VisualDocumento1 pagina1.1 Type of Check Shall Be D.P. Test in Place of VisualHEMANTNessuna valutazione finora

- DCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingDocumento7 pagineDCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingHEMANTNessuna valutazione finora

- Flow Meter Data SheetDocumento1 paginaFlow Meter Data SheetHEMANTNessuna valutazione finora

- E-Mail - : Navinender - Gupta@korus - inDocumento1 paginaE-Mail - : Navinender - Gupta@korus - inHEMANTNessuna valutazione finora

- Spec. No. 7311-DE-042Documento1 paginaSpec. No. 7311-DE-042HEMANTNessuna valutazione finora

- DGN-205 Doc. Rev.03 PDFDocumento3 pagineDGN-205 Doc. Rev.03 PDFHEMANTNessuna valutazione finora

- DGN-205 Doc. Rev.03 PDFDocumento3 pagineDGN-205 Doc. Rev.03 PDFHEMANTNessuna valutazione finora

- Control Philosophy of DearatorDocumento2 pagineControl Philosophy of DearatorHEMANTNessuna valutazione finora

- CVNG 2005 - Mechanics of Fluids Ii - Experiment 2: Broad Crested WeirDocumento14 pagineCVNG 2005 - Mechanics of Fluids Ii - Experiment 2: Broad Crested WeirKirk Woo Chong100% (1)

- Technical Catalog HRA10VSO100DFR/31R: FeaturesDocumento13 pagineTechnical Catalog HRA10VSO100DFR/31R: FeaturesMichail ArmitageNessuna valutazione finora

- 04 Shankar Rajasekaran - Design and Testing of Unidirectional Air Flow SystemsDocumento38 pagine04 Shankar Rajasekaran - Design and Testing of Unidirectional Air Flow SystemsVignesh BalajiNessuna valutazione finora

- Reciprocating Pumps - LectureDocumento21 pagineReciprocating Pumps - LectureLorenz BanadaNessuna valutazione finora

- Effects of NACA 65-BladeDocumento6 pagineEffects of NACA 65-BladeRonaldo LeiteNessuna valutazione finora

- Aqsoa 1210eDocumento4 pagineAqsoa 1210em.khurana093425Nessuna valutazione finora

- Wessington Catalogue June 2015Documento46 pagineWessington Catalogue June 2015ritesh kumarNessuna valutazione finora

- LM Advanced Pumping AFAC Licenced WebDocumento160 pagineLM Advanced Pumping AFAC Licenced WebFromOzNessuna valutazione finora

- ESP and Cyclone SepratorDocumento1 paginaESP and Cyclone SepratorRonak ChavdaNessuna valutazione finora

- Example Problems ConductionDocumento9 pagineExample Problems ConductionAJ100% (1)

- 5.6 Water Purification: I. Natural Sources of WaterDocumento8 pagine5.6 Water Purification: I. Natural Sources of WaterWillie ChitNessuna valutazione finora

- Neraca Air Daerah Aliran SungaiDocumento27 pagineNeraca Air Daerah Aliran SungaiArif Rachman HaqimNessuna valutazione finora

- Servo System 68 PDFDocumento1 paginaServo System 68 PDFmuralioooooNessuna valutazione finora

- Best Practice Manual-Fluid PipingDocumento43 pagineBest Practice Manual-Fluid Pipingapi-3869476100% (1)

- Soil Physics ExerciseDocumento14 pagineSoil Physics ExerciseChanako DaneNessuna valutazione finora

- AerodynamicsDocumento284 pagineAerodynamicsCaptRavi PooniaNessuna valutazione finora

- High-Velocity Oxygent Fuel (HVOF) Metal SprayDocumento16 pagineHigh-Velocity Oxygent Fuel (HVOF) Metal SprayEdy SuprayitnoNessuna valutazione finora

- OBS - 510 - Rev 01 - Eng MilliporeDocumento4 pagineOBS - 510 - Rev 01 - Eng MilliporeSakthy ArunaNessuna valutazione finora

- Efflux Time: TOGUN Iyanuoluwa JohnDocumento24 pagineEfflux Time: TOGUN Iyanuoluwa JohnJohnNessuna valutazione finora