Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aerators Data Sheet

Caricato da

Rafael CarmoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aerators Data Sheet

Caricato da

Rafael CarmoCopyright:

Formati disponibili

HYFLOW

FLOATING AERATOR/MIXER

FEATURES

The All Purpose Pumps Floating Aerator/Mixer have been specifically designed

and engineered to aerate, transfer oxygen and mix all types of liquids. The

patented design addresses destratification, manages sludge and delivers a

consistent D.O. (Dissolved Oxygen) result throughout an entire water body.

The Floating Aerator/Mixer providing the perfect solution for removing undesired

chemicals, biological contaminants (parasites, bacteria etc.), suspended solids

and gases from contaminated water. The ideal solution for waterbodies requiring

additional oxygen contribution to aid treatment processes or to sustain life.

>> Light weight design constructed from 316 Stainless Steel

>> 8.00 to 10.00 kgO2/kWh

>> ISO9001: 2015 Quality Management Systems

>> AS/NZS4801 Occupational Health and Safety

30 YEARS INDUSTRY EXPERIENCE

RANGE

MODEL POWER L W H

HMA50.4.15 1.5kW 1500mm 1200mm 700mm

HMA65.4.22 2.2kW 1500mm 1200mm 700mm

HMA65.6.55 5.5kW 1500mm 1500mm 900mm

HMA65.6.75 7.5kW 1500mm 1500mm 1000mm

HMA65.8.110 11.0kW 2000mm 2000mm 1000mm

NOTES

1. All systems can be customised to suit any application

2. All measurements are in mm and approximate and subject to change

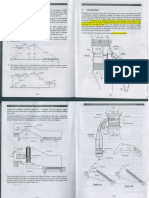

DIMENSIONS

HEIGHT (ABOVE WATER)

LENGTH

WIDTH

T +61 3 8368 0000

www.allpurposepumps.com.au

HYFLOW

FLOATING AERATOR/MIXER

SITE PROBLEMS AND APPLICATIONS

APPLICATION: Purification Storage Dam

PROBLEM: High levels of blue-green algae, resulting in the prevention of reusing the

water for irrigation of the site.

SOLUTION: The installation of a Floating Aerator/Mixer into the dam resulted

the blue-green algae count from 1.2 million cells p/L to 0.324 p/L.

APPLICATION: Fish Farm

PROBLEM: Low oxygen levels; The breeding pond was experiencing oxygen levels in

the low 2s, which was causing stress on the fish within these intensive

breeding programs. The pond carries upwards of 20,000 fish within a

75mx75m, depth of 5 to 6 metres giving a volume of approximately 28

mega-litres.

SOLUTION: The installation of a Floating Aerator/Mixer into the Fish Farm

increased the D.O. (Dissolved Oxygen) levels to 9 in the afternoon and

between 5 and 6 in the mornings, with a natural decrease during the

evening.

APPLICATION: Wastewater pond

PROBLEM: Severe odour problem; EPA (Environmental Protection Authority) Victoria

had issued a warning.

SOLUTION: The installation of a Floating Aerator/Mixer within the pond

eliminated the odour and reduced both the BOD (Biochemical Oxygen

Demand) and TSS (Toxic Shock Syndrome) bacteria count.

APPLICATION: Primary Wastewater pond (4 ponds, 3 evaporation ponds and 1 primary

facultative pond)

PROBLEM: Severe odour problem; Hydrogen sulphide being detected throughout

nearby town.

SOLUTION: The installation of a Floating Aerator/Mixer, engineered specifically

with an inlet draft tube directed towards the surface of the wastewater,

reducing the destabilisation of settled sludge and avoid macroscopic

admixing between the anaerobic and aerobic zones.

FEATURE BENEFIT

Allows for remote managing and control of your system, remote access

Remote Monitoring and Management System

via the inbuilt web-server or via wireless phone network

Automated D.O. (Dissolved Oxygen) controls are available, for on-off

Automated D.O. Control control of units to achieve D.O. set point levels throughout your water

body

T +61 3 8368 0000

www.allpurposepumps.com.au

Potrebbero piacerti anche

- Elga Centra - R60-R120Documento16 pagineElga Centra - R60-R120farouk beNessuna valutazione finora

- Steelco Dental WashersDocumento16 pagineSteelco Dental Washerskashif020Nessuna valutazione finora

- Domnick Hunter ES2000 Series Oil Water Separators ManualDocumento8 pagineDomnick Hunter ES2000 Series Oil Water Separators ManualMark CarterNessuna valutazione finora

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDa EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisValutazione: 5 su 5 stelle5/5 (1)

- Original PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFDocumento41 pagineOriginal PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFcynthia.stewart295100% (32)

- 2014 - 006a Reed Bed by UsaidDocumento83 pagine2014 - 006a Reed Bed by UsaidJohn Michael CampitanNessuna valutazione finora

- CAREL Hum Humisonic CompactDocumento31 pagineCAREL Hum Humisonic CompactRoger AklNessuna valutazione finora

- Water System (OSR ECO) PDFDocumento1 paginaWater System (OSR ECO) PDFirfan hussainNessuna valutazione finora

- Ocean Whisper - Technical SpecificationsDocumento8 pagineOcean Whisper - Technical SpecificationsAtanasio PerezNessuna valutazione finora

- Clearwater Tech, LLC: Microzone SeriesDocumento2 pagineClearwater Tech, LLC: Microzone SeriesStaman1988Nessuna valutazione finora

- Aeration SystemsDocumento12 pagineAeration SystemsSaikat MajiNessuna valutazione finora

- AKD BroucherDocumento2 pagineAKD Brouchergora paulNessuna valutazione finora

- Exp 3Documento15 pagineExp 3mjunaidNessuna valutazione finora

- 160 0004 Ozone NewDocumento4 pagine160 0004 Ozone NewRafael Lino De SousaNessuna valutazione finora

- Aqua Culture Brochure - Fusi TechDocumento2 pagineAqua Culture Brochure - Fusi Techsaradhi sravan kumarNessuna valutazione finora

- 700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/minDocumento2 pagine700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/mineduardoNessuna valutazione finora

- FME AquaA GB RGBDocumento4 pagineFME AquaA GB RGBAlejandra M Jiménez JuárezNessuna valutazione finora

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocumento26 pagineProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNessuna valutazione finora

- Bram Cor EQUIPO DE PRE TRATAMIENTO Biopharma Water SystemsDocumento16 pagineBram Cor EQUIPO DE PRE TRATAMIENTO Biopharma Water SystemsYeimer MesaNessuna valutazione finora

- Self Aspirating Turbine Aerator For All Kind of LiquidDocumento16 pagineSelf Aspirating Turbine Aerator For All Kind of LiquidChandra Sekar R0% (1)

- Sanitaire Difussers AerationDocumento16 pagineSanitaire Difussers Aerationxbelda5041Nessuna valutazione finora

- Gasmizer Gas Recovery SystemDocumento2 pagineGasmizer Gas Recovery SystemАлексей ИващенкоNessuna valutazione finora

- Gasmizer Gas Recovery SystemDocumento2 pagineGasmizer Gas Recovery SystemАлексей ИващенкоNessuna valutazione finora

- BWT Septron Line 31-61 EN 2015Documento4 pagineBWT Septron Line 31-61 EN 2015Hadrien PaugnatNessuna valutazione finora

- Presentation1 (Latest)Documento24 paginePresentation1 (Latest)mirdza94Nessuna valutazione finora

- BSS Holland Water Purification ProductsDocumento10 pagineBSS Holland Water Purification ProductsvaglohrdNessuna valutazione finora

- BioReco SlideDocumento12 pagineBioReco SlideNiels WandlerNessuna valutazione finora

- Ultra Clear RO-EDI & LaboStarDocumento8 pagineUltra Clear RO-EDI & LaboStarcristi5cNessuna valutazione finora

- 1738 PharmaBiotech Loopo enDocumento4 pagine1738 PharmaBiotech Loopo enYoustina PhillipeNessuna valutazione finora

- Lamella 012517Documento2 pagineLamella 012517workingNessuna valutazione finora

- Datasheet Osmose Gambro HCEN2016 - WRO300 - Datasheet en ORIDocumento2 pagineDatasheet Osmose Gambro HCEN2016 - WRO300 - Datasheet en ORIfernandomeiraNessuna valutazione finora

- MP-Filtri Catalogue ProtectedDocumento48 pagineMP-Filtri Catalogue Protectedvut73 aNessuna valutazione finora

- VP-2215-1 VaPure® Vapor Compression Still - Paul Mueller CompanyDocumento6 pagineVP-2215-1 VaPure® Vapor Compression Still - Paul Mueller CompanyChrisNessuna valutazione finora

- Operation and Maintenance Manual For Onsite Wastewater Systems.... 0..0 PDFDocumento63 pagineOperation and Maintenance Manual For Onsite Wastewater Systems.... 0..0 PDFنيرمين احمدNessuna valutazione finora

- Bio Sea Solution BenefitsDocumento3 pagineBio Sea Solution BenefitsClaudio Santellanes100% (1)

- Turbojet AeratorDocumento2 pagineTurbojet AeratorEndro A Mufti100% (1)

- Waterland Water Treatment Environmental TechnologiesDocumento36 pagineWaterland Water Treatment Environmental TechnologiesSiraj AL sharifNessuna valutazione finora

- Hospital Wastewater Treatment Plant - RT ECODocumento8 pagineHospital Wastewater Treatment Plant - RT ECOPatricia Tungpalan100% (1)

- Process Systems: Tri-Oval SystemDocumento2 pagineProcess Systems: Tri-Oval SystemJ MIGUEL CERVANTES ANessuna valutazione finora

- On-Site Hypochlorite Generation System OSEC® B-Pak: Product SheetDocumento2 pagineOn-Site Hypochlorite Generation System OSEC® B-Pak: Product SheetNguyễn NgọcNessuna valutazione finora

- Nalco Reverse OsmosisDocumento4 pagineNalco Reverse OsmosisFarras Hanif Kaltim MethanolNessuna valutazione finora

- 105 0020 4100B - Nov2018 PDFDocumento4 pagine105 0020 4100B - Nov2018 PDFdevendra bansalNessuna valutazione finora

- SV Catalogue Design R11 3Documento20 pagineSV Catalogue Design R11 3Lim Yew KwangNessuna valutazione finora

- Filtration For Ballast Water TreatmentDocumento22 pagineFiltration For Ballast Water Treatmentjoujoukos kritikosNessuna valutazione finora

- Soni8 BrochureDocumento6 pagineSoni8 BrochureAliasgar PatrawalaNessuna valutazione finora

- Eco Water Solutions - RO PlantDocumento19 pagineEco Water Solutions - RO PlantRabindra SinghNessuna valutazione finora

- Modern Water - AquaPak-B - BrochureDocumento4 pagineModern Water - AquaPak-B - BrochureYoo BoyyooNessuna valutazione finora

- TASMAN SEA - T2 NEW BrochureDocumento4 pagineTASMAN SEA - T2 NEW BrochurePSC RFQNessuna valutazione finora

- LỌC CAO ÁPDocumento16 pagineLỌC CAO ÁPbuivantruongNessuna valutazione finora

- Aqua Series Vapor Compression DistillerDocumento1 paginaAqua Series Vapor Compression DistillerMohd Khairul Ahmad AliasNessuna valutazione finora

- Ion Enterprise BrochureDocumento10 pagineIon Enterprise BrochureKanika PrakashNessuna valutazione finora

- Ionpro LXDocumento2 pagineIonpro LXAlon CarlosNessuna valutazione finora

- Contoh Commercial ProposalDocumento8 pagineContoh Commercial ProposalkhristprasatyaNessuna valutazione finora

- HydroDocumento8 pagineHydroFahad Al MuttairiNessuna valutazione finora

- Side Channel BlowersDocumento8 pagineSide Channel BlowersGraham BarrNessuna valutazione finora

- Cathelco HEM Brochure 2018Documento16 pagineCathelco HEM Brochure 2018chefmeca.australNessuna valutazione finora

- HUI Service CatalogDocumento12 pagineHUI Service CatalogSaefuddin SaefuddinNessuna valutazione finora

- Water Vision Company & ProductsDocumento21 pagineWater Vision Company & ProductsRodrigo VieiraNessuna valutazione finora

- Otterbine Catalog 2014Documento36 pagineOtterbine Catalog 2014KarenNessuna valutazione finora

- PK1024-MKF-MDB060-365097 01Documento9 paginePK1024-MKF-MDB060-365097 01waqas_a_shaikh4348Nessuna valutazione finora

- Ultra ClearDocumento16 pagineUltra ClearPriasalesNessuna valutazione finora

- How Reverse Osmosis Works: A Look at Industrial RODa EverandHow Reverse Osmosis Works: A Look at Industrial ROValutazione: 2.5 su 5 stelle2.5/5 (2)

- Compact Multiprotocol I/O Module For Ethernet 8 Universal Digital Channels, Configurable As PNP Inputs or 0.5A Outputs TBEN-S1-8DXPDocumento6 pagineCompact Multiprotocol I/O Module For Ethernet 8 Universal Digital Channels, Configurable As PNP Inputs or 0.5A Outputs TBEN-S1-8DXPRafael CarmoNessuna valutazione finora

- Delta Ia-Plc Ispsoft Um en 20200630Documento1.183 pagineDelta Ia-Plc Ispsoft Um en 20200630Rafael CarmoNessuna valutazione finora

- I/O Hub For Connecting Digital Signals To IO-Link Master 16 Universal Digital Channels, PNP TBIL-M1-16DXPDocumento4 pagineI/O Hub For Connecting Digital Signals To IO-Link Master 16 Universal Digital Channels, PNP TBIL-M1-16DXPRafael CarmoNessuna valutazione finora

- Siemens GermanyDocumento20 pagineSiemens GermanyRafael CarmoNessuna valutazione finora

- PNOZ s6.1: Safety RelaysDocumento18 paginePNOZ s6.1: Safety RelaysRafael CarmoNessuna valutazione finora

- TBEN-L - PLC - : Compact Codesys V3 PLCDocumento126 pagineTBEN-L - PLC - : Compact Codesys V3 PLCRafael CarmoNessuna valutazione finora

- E-STOP Relays, Safety Gate Monitors: PNOZ X3.10PDocumento8 pagineE-STOP Relays, Safety Gate Monitors: PNOZ X3.10PRafael CarmoNessuna valutazione finora

- 01a55 06 PDFDocumento1 pagina01a55 06 PDFRafael CarmoNessuna valutazione finora

- Compact Manifold Regulator: SeriesDocumento75 pagineCompact Manifold Regulator: SeriesRafael CarmoNessuna valutazione finora

- Drum and Transfer Pumps: Hilger U. Kern / DopagDocumento13 pagineDrum and Transfer Pumps: Hilger U. Kern / DopagRafael CarmoNessuna valutazione finora

- Danfoss Reciprocating Compressors: MT / MTZ / NTZ / VTZDocumento16 pagineDanfoss Reciprocating Compressors: MT / MTZ / NTZ / VTZRafael CarmoNessuna valutazione finora

- DIY Particle Detector Schematic v1-2Documento1 paginaDIY Particle Detector Schematic v1-2Rafael Carmo100% (1)

- Experiment # 10: Jar TestDocumento12 pagineExperiment # 10: Jar TestAbo SmraNessuna valutazione finora

- Plumbing LectureDocumento5 paginePlumbing LectureJohn Zedrick MacaisaNessuna valutazione finora

- P.V.AWARD-Tapas RoyDocumento4 pagineP.V.AWARD-Tapas RoysssadangiNessuna valutazione finora

- Theory of Practice WaterDocumento5 pagineTheory of Practice WaterTemimi Feras0% (1)

- 5a. STP Daily Log BookDocumento1 pagina5a. STP Daily Log BookNISHANTH GANESHNessuna valutazione finora

- Introduction To Environmental Engineering Worksheet: Vocabulary DefinitionsDocumento3 pagineIntroduction To Environmental Engineering Worksheet: Vocabulary DefinitionssaritasahuNessuna valutazione finora

- Manual On Sewerage and Sewage Treatment: Part B: Operation and MaintenanceDocumento454 pagineManual On Sewerage and Sewage Treatment: Part B: Operation and MaintenanceB D WNessuna valutazione finora

- Session 9 Hazardous Waste ManagementDocumento44 pagineSession 9 Hazardous Waste ManagementhazlanNessuna valutazione finora

- Ketonic Resin - Resin and Allied Pre Feasibility ReportDocumento31 pagineKetonic Resin - Resin and Allied Pre Feasibility ReportdevangNessuna valutazione finora

- Case Study - Rane (Madras) Ltd. - 100 KLD STPDocumento12 pagineCase Study - Rane (Madras) Ltd. - 100 KLD STPjeykumar.BalannairNessuna valutazione finora

- Universiti Teknologi Mara Laboratory: Confidential EH/OCT 2021/CHE332Documento6 pagineUniversiti Teknologi Mara Laboratory: Confidential EH/OCT 2021/CHE332farenfarhan5Nessuna valutazione finora

- Water Management - Procedure 13Documento7 pagineWater Management - Procedure 13Prem PrakashNessuna valutazione finora

- Design of Sedimentation Tank and Coagulation With SedimentationDocumento20 pagineDesign of Sedimentation Tank and Coagulation With SedimentationJay Reghe100% (1)

- Design An Extended Aeration Package PlantDocumento5 pagineDesign An Extended Aeration Package PlantFortaengineering FortaenviroNessuna valutazione finora

- SS 2006 by Taylor & Francis Group, LLCDocumento50 pagineSS 2006 by Taylor & Francis Group, LLCMICHAEL STEVEN CERON MALESNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNessuna valutazione finora

- Doctors Vet Pharma - CFO Order PDFDocumento6 pagineDoctors Vet Pharma - CFO Order PDFGovind DasuNessuna valutazione finora

- Project Description STPDocumento5 pagineProject Description STPBroker GlendieNessuna valutazione finora

- Geography Chapter4Documento21 pagineGeography Chapter4davedtruth2Nessuna valutazione finora

- Teri and LeedDocumento29 pagineTeri and LeedkaranNessuna valutazione finora

- MLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyDocumento5 pagineMLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyRanadive AnanthNessuna valutazione finora

- KUZU SUNU2013revDocumento51 pagineKUZU SUNU2013revMehmet Emre BastopcuNessuna valutazione finora

- SULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029Documento31 pagineSULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029zainudin simonNessuna valutazione finora

- The Long-Term Fates of Land-Disposed Plastic WasteDocumento3 pagineThe Long-Term Fates of Land-Disposed Plastic WasteXI CHENNessuna valutazione finora

- Sanjeev BaralDocumento30 pagineSanjeev BaralPujan Bajracharya33% (3)

- Baseline Water Consumption WorksheetDocumento2 pagineBaseline Water Consumption WorksheetFarhsa Dhom Eemihahs Dhom100% (1)

- Edelmiro Salas González Attomey at LawDocumento6 pagineEdelmiro Salas González Attomey at LawEdelmiroAntonioSalas-GonzalezNessuna valutazione finora

- The Feasibility Study On Improvement of The Water Supply System in Al-Basrah City and Its Surroundings in The Republic of IraqDocumento124 pagineThe Feasibility Study On Improvement of The Water Supply System in Al-Basrah City and Its Surroundings in The Republic of IraqŃí ĆéNessuna valutazione finora