Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BeWa FCU1315 V400 4168086 En-Us 2017-02-28 PDF

Caricato da

nasiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BeWa FCU1315 V400 4168086 En-Us 2017-02-28 PDF

Caricato da

nasiCopyright:

Formati disponibili

FCU 1315

FluidControl Unit

Operating and Maintenance Instructions

English (translation of original instructions)

Valid from firmware version V 4.00 up

Valid from series no. (S/N) 0002S01831K0001000

Keep for future reference.

Document No.: 4168086

Imprint

Imprint

Publisher and responsible for the content:

HYDAC FILTER SYSTEMS GMBH

Postfach 1251

66273 Sulzbach / Saar

Germany

Phone: +49 6897 509 01

Fax: +49 6897 509 9046

E-mail: filtersystems@hydac.com

Homepage: www.hydac.com

Court of Registration: Saarbrücken, HRB 17216

Executive director: Mathias Dieter,

Dipl.Kfm. Wolfgang Haering

Documentation representative

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Phone: +49 6897 509 1511

Fax: +49 6897 509 1394

E-mail: guenter.harge@hydac.com

© HYDAC FILTER SYSTEMS GMBH

All rights reserved. No part of this work may be reproduced in any form (print,

photocopy or by other means) or processed, duplicated or distributed using

electronic systems without the written consent of the publisher.

These documents have been created and inspected with the greatest care.

However, errors cannot be ruled out completely.

Technical specifications are subject to change without notice.

FCU 1315 en(us) Page 2 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Content

Content

Imprint............................................................................................................ 2

Documentation representative .................................................................... 2

Content .......................................................................................................... 3

Preface ........................................................................................................... 7

Technical Support ........................................................................................ 7

Modifications to the Product ........................................................................ 7

Warranty ...................................................................................................... 7

Using the documentation ............................................................................. 8

Safety information ........................................................................................ 9

Hazard symbols ........................................................................................... 9

Signal words and their meaning in the safety information and

instructions ................................................................................................ 10

Structure of the safety information and instructions ................................... 11

Observe regulatory information ................................................................. 11

Proper/Designated Use ............................................................................. 12

Periodic intermittent duty - operating mode S3, (as per DIN EN

60034-1 / DIN VDE 0530, Part 1) ........................................................... 13

Improper Use or Use Deviating from Intended Use ................................... 14

Qualifications of personnel / target group .................................................. 15

Wear personal protection equipment ......................................................... 16

Stoppage in an emergency (EMERGENCY STOP)................................... 16

Opening/Closing the FCU .......................................................................... 17

Transporting the FCU ................................................................................. 18

Storing the FCU........................................................................................... 19

Decoding the name plate ........................................................................... 20

Checking the scope of delivery ................................................................. 22

What can the product do? .......................................................................... 23

Counting contaminant particles ................................................................. 24

How the product works .............................................................................. 26

Overview of operating elements/control panel ........................................... 27

Product measurements.............................................................................. 29

Hydraulic circuit ......................................................................................... 30

Using the BatteryPack (accessory) ........................................................... 31

Preparing the FCU for measurement ........................................................ 36

FCU electrical connection .......................................................................... 36

Plug in/Detach return hose ........................................................................ 38

Selecting the measurement location .......................................................... 39

FCU 1315 en(us) Page 3 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Content

When operating with diesel, note … .......................................................... 40

Select the measurement method according to the pressure

involved ..................................................................................................... 42

Hydraulic fluid / Diesel - Measuring from depressurized containers .......... 43

Diesel - Measuring up to max. 16 bar / 232 psi ......................................... 46

Hydraulic fluid - Measuring up to a maximum of 45 bar / 650 psi .............. 48

Hydraulic fluid - Measuring between 5 … 345 bar / 217 … 5000 psi ......... 51

Operating FCU............................................................................................. 55

Display and keypad elements .................................................................... 55

Clicking through the display ....................................................................... 57

- Display ............................................................................. 57

- Display ............................................................................. 58

Displaying measured variables .................................................................. 59

" " measured variable ........................................................................ 59

" " measured variable ....................................................................... 59

" " measured variable ....................................................................... 59

" " measured variable .................................................. 59

" " measured variable ......................................................... 60

Display service variables ........................................................................... 60

" " service variable ........................................................................... 60

" " service variable .......................................................................... 60

Select operating level / configuration menu ............................................. 61

PowerUp Operate / Set up menu............................................................... 62

– Setting date/time ............................................................. 63

- Set bus address ............................................................... 63

- Delete memory ................................................................ 64

- Set measuring time ............................................................. 64

– Select calibration type ........................................................ 65

– Reset to default settings.................................................. 65

- Cancel .............................................................................. 66

– Save data .............................................................................. 66

Operating/Setting measuring menu ........................................................... 67

– Record measurements .................................................... 68

- Display free memory ........................................................ 69

– Change name of measurement point .............................. 70

- Set temperature unit ........................................................ 71

- Cancel .............................................................................. 72

– Save data .............................................................................. 72

Performing measurements ........................................................................ 73

Reading internal measurement memory................................................... 74

Reading out measured values via DATA interface .................................... 75

Connecting FCU with a CSI-B-2 kit ........................................................ 75

FCU 1315 en(us) Page 4 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Content

Pins used on the DATA interface (HYDAC Sensor Interface –

HSI) ........................................................................................................ 75

Connecting FCU with HMG 510 / HMG 3000 / HMG 4000..................... 76

Reading out USB interface measured values ............................................ 77

Copying measurements onto a USB data stick ...................................... 77

- Data transmission failed ..................................... 80

Reading out measured values via Bluetooth interface ............................... 81

Installing the Bluetooth USB adaptor...................................................... 82

Guarantee and liability for the USB adapter ........................................ 82

Connecting/Linking the FCU via Bluetooth ............................................. 82

Evaluating measurement records ............................................................. 83

Measurement record directories according to measurement point ............ 83

Measurement report file names ................................................................. 83

Opening measurement reports .................................................................. 84

The measurements are shown as dates ................................................ 86

Evaluating/Reading measurement reports with FluMoS ......................... 88

Preparing the FCU for transport ................................................................ 89

Performing maintenance ............................................................................ 93

Cleaning the FCU ...................................................................................... 93

FCU flushing .............................................................................................. 94

Clean the suction strainer .......................................................................... 98

Checking the high pressure adapter ........................................................ 102

Cleaning / changing the strainer in the high pressure adapter ............. 103

Cleaning / changing the strainer in the high pressure adapter ............. 104

Identifying and eliminating status/error messages ............................... 105

Restarting/resetting .................................................................................. 109

Taking the FCU out of operation ............................................................. 109

Shutting down the FCU............................................................................ 109

Disposing FCU ........................................................................................ 109

Locating spare parts................................................................................. 110

Selecting accessories .............................................................................. 111

Checking the measuring accuracy .......................................................... 113

Calibrating FCU ....................................................................................... 113

Technical Data........................................................................................... 114

Appendix ................................................................................................... 116

Model Code ............................................................................................. 116

Finding Customer Service / Service stations ........................................... 117

Germany .............................................................................................. 117

USA ...................................................................................................... 117

Australia ............................................................................................... 117

FCU 1315 en(us) Page 5 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Content

Brazil .................................................................................................... 118

Factory default settings............................................................................ 118

Overview / Definition of the cleanliness classes ...................................... 119

Cleanliness class acc. to ISO 4406:1999 ............................................. 119

ISO 4406 overview table ................................................................... 120

Difference between ISO4406:1987 and ISO4406:1999 ....................... 121

Cleanliness class acc. to SAE AS 4059 ............................................... 122

SAE AS 4059 overview table ............................................................ 122

Display cleanliness classes according to SAE Absolute particle

count larger than a defined particle size ............................................... 123

Specifying a cleanliness code for each particle size ......................... 123

Specifying the highest cleanliness code measured ........................... 123

Cleanliness class acc. to NAS 1638 ..................................................... 124

- EGDeclaration of conformity.................................................................. 125

Explanation of terms and abbreviations ................................................... 127

Index ........................................................................................................ 128

FCU 1315 en(us) Page 6 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preface

Preface

These operating instructions were made to the best of our knowledge.

Nevertheless and despite the greatest care, it cannot be excluded that

mistakes could have crept in. Therefore please understand that, in the

absence of any provisions to the contrary hereinafter, our warranty and

liability – for any legal reasons whatsoever – are excluded in respect of the

information in these operating instructions. In particular, we shall not be liable

for lost profit or other financial loss.

This exclusion of liability does not apply in cases of intent and gross

negligence. Moreover, it does not apply to defects which have been

deceitfully concealed or whose absence has been guaranteed, nor in cases

of culpable harm to life, physical injury and damage to health. If we

negligently breach any material contractual obligation, our liability shall be

limited to foreseeable damage. Claims due to Product Liability shall remain

unaffected.

Technical Support

If you have any questions, suggestions, or encounter any problems of a

technical nature, please don't hesitate to contact us. When contacting us,

please always include the model code, serial no. and part no. of the product:

Fax: +49 6897 509 9046

E-mail: filtersystems@hydac.com

Modifications to the Product

We would like to point out that changes to the product (e.g. purchasing

options, etc.) may result in the information in the operating instructions no

longer being completely accurate or sufficient.

After modification or repair work that affects the safety of the product has

been carried out on components, the product may not be returned to

operation until it has been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product

whether by you or a third party.

Warranty

For the warranty provided by us, please refer to the terms of delivery of

HYDAC FILTER SYSTEMS GMBH.

You will find these under www.hydac.com -> Legal information.

FCU 1315 en(us) Page 7 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preface

Using the documentation

Note that the method described for locating specific information

does not release you from your responsibility of carefully reading

all these instructions prior to starting the unit up for the first time

and at regular intervals in the future.

What do I want to know?

I determine which topic I am looking for.

WHERE can I find the information I’m looking for?

The document has a table of contents at the beginning. I select the chapter

I'm looking for and the corresponding page number.

Chapter description

tel

Produkt / Kapi

Page number

HYDAC Filtertechnik GmbH

BeWa 123456a de

de Seite x

200x-xx-xx

Edition date

Documentation no. Document language

with index/

file name

The documentation number with its index enables you to order another copy

of the operating and maintenance instructions. The index is incremented

every time the manual is revised or changed.

FCU 1315 en(us) Page 8 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Safety information

The product was built according to the statutory provisions valid at the time of

delivery and satisfies current safety requirements.

Any residual hazards are indicated by safety information and instructions and

are described in the operating instructions.

Observe all safety and warning instructions attached to the product. They

must always be complete and legible.

Do not operate the product unless all the safety devices are present.

Secure the hazardous areas which may arise between the product and other

equipment.

Maintain the product inspection intervals prescribed by law.

Document the results in an inspection certificate and keep it until the next

inspection.

Hazard symbols

These symbols are listed for all safety information and instructions in these

operating instructions which indicate particular hazards to persons, property

or the environment.

Observe these instructions and act with particular caution in such cases.

Pass all safety information and instructions on to other users.

General hazard

Danger due to electrical voltage / current

Exposed electrical components

Danger of electrical shock

Danger due to operating pressure

FCU 1315 en(us) Page 9 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Risk of burns due to hot surfaces

Risk of explosion

Signal words and their meaning in the safety information and

instructions

In these instructions you will find the following signal words:

DANGER

DANGER – The signal word indicates a hazardous situation with a high level

of risk, which, if not avoided, will result lethal or serious injury.

WARNING

WARNING – The signal word indicates a hazardous situation with a medium

level of risk, which, if not avoided, can result lethal or serious injury.

CAUTION

CAUTION – The signal word indicates a hazardous situation with a low level

of risk, which, if not avoided, can result in minor or moderate injury.

NOTICE

NOTICE – The signal word indicates a hazardous situation with a high level

of risk, which, if not avoided, will result in damage to property.

FCU 1315 en(us) Page 10 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Structure of the safety information and instructions

All warning instructions in this manual are highlighted with pictograms and

signal words. The pictogram and the signal word indicate the severity of the

danger.

Warning instructions listed before an activity are laid out as follows:

SIGNAL WORD

Type and source of danger

HAZARD SYMBOL

Consequence of the danger

► Measures to avert danger

Observe regulatory information

Observe the following regulatory information and guidelines:

• Legal and local regulations for accident prevention

• Legal and local regulations for environmental protection

• Country-specific regulations, organization-specific regulations

FCU 1315 en(us) Page 11 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Proper/Designated Use

Claims for defects or liability, regardless of the legal foundation, do not apply

with incorrect or improper installation, commissioning, usage, handling,

storage, maintenance, repair, use of unsuitable components or other

circumstances for which HYDAC is not responsible.

HYDAC is not responsible for the installation, integration, selection of

interfaces to / into your system nor for the use or functionality of your system.

Use the product only for the application described below.

The FluidControl Unit FCU is a portable service unit for taking short-term

measurements of the solid particle contamination, temperature und water

saturation level in hydraulic systems and diesel fuels in accordance with DIN

EN 590 / ASTMD975 4-D, with a flash point of > 55°C.

Proper/designated use of the product extends to the following:

• Observing all the instructions contained in these operation and

maintenance instructions.

• Ensuring the execution of all inspection and maintenance work.

NOTICE

Impermissible operating conditions

The FCU will be destroyed

► Use the FCU with mineral oils or mineral oil-based raffinates whose

flash point is higher than 55°C / 131°F.

► Flush the FCU with low-viscosity mineral oils or mineral oil-based

raffinates (e.g. diesel) whose flash point is higher than 55°C / 131°F.

► Never flush the FCU with universal thinners or other degreasing fluids.

► Observe the permissible viscosity range (up to ISO VG 68):

2 - 350 mm²/s / 32.6 - 1622 SUS.

► Operate the FCU only in periodic intermittent duty (S3) with a (relative)

duty cycle of 40% in relation to a useful life of 10 minutes

(S3 in accordance with DIN EN 60034 / VDE 0530).

► Never use the FCU without a suction strainer.

FCU 1315 en(us) Page 12 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

NOTICE

Connection to 24 V DC on-board networks without load dump

The FCU will be destroyed.

► Use the FCU only on 24 V DC on-board networks which have a central

"Load Dump" fuse.

► Before connecting, be sure to check that a load dump is installed with

at least 30 V DC and is effective.

Periodic intermittent duty - operating mode S3,

(as per DIN EN 60034-1 / DIN VDE 0530, Part 1)

Operation t0 in time t1 at power (PN)S3 interchange periodically with the

cooling phases (downtimes) t2. The relative duty cycle is 40% in relation to a

useful life of 10 minutes.

(PN)S3 = Nominal power, operating mode S3

t = Time

t0 = Period (operation t1 + cooling phase t2)

t1 = Operation

t2 = Cooling phase (downtime)

°C (°F) = Temperature

FCU 1315 en(us) Page 13 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Improper Use or Use Deviating from Intended Use

DANGER

Hazard due to use of the product other than

that intended

Bodily injury and damage to property will result

when operated improperly.

► Never operate the product in potentially

explosive atmospheres.

► Only use the product with permissible media.

Any use extending beyond or deviating therefrom shall not be considered

intended use. HYDAC FILTER SYSTEMS GmbH will assume no liability for

any damage resulting from such use. The risk is borne exclusively by the

machine owner.

Improper use may result in hazards and/or will damage the product.

Examples of improper use:

• Operation with fluids that have a flash point under 55°C / 131°F.

• Operate only with fluids whose temperature is not at least 10°C below

their individual flash point.

• Flush with universal thinners or other degreasing fluids

• Operation in potentially explosive atmospheres.

• Operation under non-approved operational conditions.

• Modifications to the product made by the user or purchaser.

• Continuous monitoring of the fluid cleanliness (continuous operation)

• Improper connection of the pressure and return flow hoses.

• Operation at a measurement point with impermissible pressure.

• Operation on 24 V DC on-board networks without central

"Load Dump" fuse.

• Operation with an impermissible fluid.

• Operation with faulty, damaged hoses.

• Operation with damaged connector cable.

• Operation with diesel in pressure operation ≥ 16 bar.

• Operation with diesel without connected voltage equalizing cable.

FCU 1315 en(us) Page 14 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Qualifications of personnel / target group

Auxiliary, operational and specialist personnel must have read and

understood the operating instructions, in particular the safety information and

instructions, and applicable regulations before beginning work.

The operating instructions and applicable regulations are to be kept so they

are accessible for operating and specialist personnel.

These operating instructions are intended for:

Auxiliary personnel: such persons have been instructed about the product

and informed about potential hazards that can result from improper use.

Operating personnel: such persons have been instructed in product

operation and are aware of potential dangers due to improper use.

Specialist personnel: such persons with corresponding specialist training

and several years' work experience. They are able to assess and perform the

work assigned to them, they are also able to recognize potential hazards.

Activity Person Knowledge

Transport / storage Auxiliary • No specialist knowledge

personnel required

Startup operation, Auxiliary • Product-specific knowledge

operation personnel

• Knowledge about how to

Operations control handle operating media.

troubleshooting, Specialist • Safe handling/use of tools

personnel

maintenance, • Product-specific knowledge

Decommissioning,

Disassembly Service staff • Very detailed product-specific

(only with knowledge

authorized

HYDAC

Service)

Disposal Specialist • Proper and environmentally-

personnel friendly disposal of materials

and substances

• Decontamination of

contaminants

• Knowledge about reuse

FCU 1315 en(us) Page 15 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Safety information

Wear personal protection equipment

Observe the information relating to personal protection equipment in the

safety data sheet of the operations fluid.

• Wear eye protection.

• Wear gloves.

Stoppage in an emergency (EMERGENCY STOP)

In the event of an emergency, disconnect the FCU from the power supply

and from the hydraulic system.

FCU 1315 en(us) Page 16 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Opening/Closing the FCU

Opening/Closing the FCU

Open the FCU by releasing both clips.

Close the FCU using both clips. Make sure that these audibly snap into

place.

FCU 1315 en(us) Page 17 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Transporting the FCU

Transporting the FCU

Transport the FCU only when it is in closed position; carry it flat or by the

handle.

FCU 1315 en(us) Page 18 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Storing the FCU

Storing the FCU

Drain and rinse the FCU completely before putting it into storage. See page

94 in the "FCU flushing" chapter for details on rinsing the FCU.

Observe permissible conditions required for storage on page 114 in the

"Technical Data" chapter.

Store the FCU closed and in a horizontal position in a dry, clean place. If

stored in a vertical position, the FCU must not be exposed to any shaking or

vibration.

FCU 1315 en(us) Page 19 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Decoding the name plate

Decoding the name plate

For identification details of the FluidControl Unit, see the nameplate. The type

label displays the product ID and important technical data.

Item -> Description

(1) -> Name plate of the FCU.

(2) -> Model code; for details, see page 116.

(3) -> Data regarding the flash point of the permitted fluid.

(4) -> Permissible fluids.

FCU 1315 en(us) Page 20 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Decoding the name plate

The following information can be found on the name plate of the product:

Row -> Description

Model -> Model code; for details, see page 116.

Date -> Production year/week

P/N -> Part number

S/N -> Serial no.

Flow rate -> Flow rate

Weight -> Weight when empty

Viskosity range -> Permissible viscosity range

Pressures -> Pressure specifications

In -> Permissible pressure at port INLET

Out -> Permissible pressure at port OUTLET

Temperatures -> Temperature specifications

Fluid -> Permitted fluid temperature range

Ambient -> Permitted ambient temperature range

Power -> Power consumption

Voltage -> Voltage

Current -> Current consumption

FCU 1315 en(us) Page 21 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Checking the scope of delivery

Checking the scope of delivery

The FluidControl Unit comes factory-assembled. Before commissioning the

FCU, check the contents of the consignment to make sure everything is

present.

The following items are supplied:

Qty Description

1 FluidControl Unit FCU, including attachable bag for cables and

hoses

1 Power supply, primary: 100-240 V AC / secondary:

24 V DC / 5 A

4 Connection cable for power adapter (Europe, USA/Canada,

UK, Australia, Japan)

1 INLET Suction tube for sampling from the bottle

1 Adapter for suction hose

1 High pressure hose with screwed joint, type 1620, color: black,

L=2m

1 High-pressure adapter

2 INLET / OUTLET Suction hose / return hose,

transparent, L = 2 m

1 Voltage equalizing cable (grounding connection)

1 Technical documentation, consisting of:

- Operating and maintenance instructions (this document)

- Certificate of calibration

- CE Declaration of Conformity

- CD-ROM with FluMoS light software

1 USB memory stick with operating and maintenance

instructions (PDF file) in additional languages

1 Quick start manual

A USB bluetooth adapter for the PC is a free gift and is not part of the

delivery.

FCU 1315 en(us) Page 22 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

What can the product do?

The FluidControl Unit FCU is a portable service unit for taking short-term

measurements of the solid particle contamination, temperature und water

saturation level in hydraulic systems and diesel fuels in accordance with DIN

EN 590 / ASTM D975 4-D, with a flash point of ≥ 55°C.

Knowledge on the level and amount of contamination allows you to check

and document quality standards and introduce the required optimization

measures.

The integrated pump and the hoses supplied enable usage with:

• Control circuits

• Pressure circuit runs (diesel up to a maximum of 16 bar)

• Depressurised containers

The internal data memory enables measurements to be recorded together

with a time-stamp.

The USB interface can be used to copy all measurements to a USB memory

stick or to send them to a mobile device via Bluetooth where they can be

analyzed using MS Excel or the Fluid Monitoring software FluMoS.

Additional features include:

• Optical measurement of the degree of solid particle contamination

• Capacitive recording of the water saturation in % saturation

• Resistive measurement of the temperature

• Suitable for hydraulic fluids (up to ISO VG 68)

2 - 350 mm²/s / 32.6 - 1622 SUS

• suitable for diesel fuels in accordance with DIN EN 590 / ASTM D975

4-D, with a flash point > 55°C.

• Automatic measurement and display of cleanliness ratings in

accordance with:

• ISO 4406:1987; NAS 1638

• ISO 4406:1999; SAE AS 4059 (D)

• Measurement accuracy +/- ½ ISO code in the calibrated range

• Supply voltage of 24 V DC / 4 A for operation on mobile machine on-

board networks

• Network adapter 100 - 240 V AC / 24 V DC 5 A included in the scope

of delivery

• Operating pressure without high-pressure adapter max. 45 bar / max.

650 psi,

FCU 1315 en(us) Page 23 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Operating pressure with high-pressure adapter max. 345 bar / max.

5000 psi

• Integrated pump for the automatic control of oil flow

Counting contaminant particles

The measuring principle of the light blockade procedure is shown in

simplified form in the following sketch.

The light source transmits monochromatic light through the flow of oil to a

photo detector, which produces a particular electrical signal. If a particle gets

between the light source and the photo detector, then a shadow will be cast

on the photo detector.

This shadow causes a change in the electrical signal generated by the photo

detector. This change makes it possible to determine the size of the shadow

cast by the particle and thus to gauge the size of the particle itself.

This procedure makes it possible to determine the cleanliness class

according to ISO 4406:1987, ISO 4406:1999, NAS 1638 and SAE AS 4059.

The disruption factors of this measurement principle are foreign fluids and

small gas bubbles that lead to refractions, thus causing them to be counted

as particles as well.

Item Designation

1 Light source

2 Particle

3 Photo detector

FCU 1315 en(us) Page 24 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Each of the signal peaks corresponds to the shadow cast by one particle.

The signal height or amplitude reflects the particle size. Thresholds are used

to classify the particle sizes >2, >5, >15, >25 µm or >4, >6, >14, >21 µm(c).

Threshold values

Time

FCU 1315 en(us) Page 25 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

How the product works

From the fluid source (either a pressure port or depressurized vessel), a

continuous oil flow is established through the port (1) INLET by an electrically

controlled gear pump (3).

A suction strainer (2) protects the pump from coarse contamination.

The oil current flows through an optical ContaminationUnit (CU) (6). The

contaminant particles contained in the fluid current cause the light beam to

be darkened in a pulse-like manner. An electronic evaluation module

classifies and counts these measurement signals. The evaluation module

continuously computes the cleanliness classes for the reference volume of

100°ml based on the measurement signals of the optical sensor.

A defined pressure is generated in the oil flow via a counter balance valve

(7). This serves to minimize air bubbles in the system, which could skew the

measurement results.

The pressure relief valve (5) protects the pump and the measuring cell from

excessive pressure.

The fluid flows out of the port (9) OUTLET and is routed by the return hose

into a depressurized tank.

The electronic evaluation module monitors:

• the function of the ContaminationSensors

• the fluid flow

• the power supply voltage

• the function of the AquaSensors

When a malfunction occurs, an error message automatically appears in the

display and interrupts the measurement. The evaluation module will

recognize when the cause of error has been corrected, and the unit will reset

automatically and resume the measurement operation.

FCU 1315 en(us) Page 26 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Overview of operating elements/control panel

FCU 1315 en(us) Page 27 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Item Designation

1 Display of “ISO, SAE/NAS, Flow, Drive” with keypad

2 Display of the percentage "water saturation"

3 "Fluid temperature" display

4 ON / OFF switch for the internal pump

5 Supply voltage 24 V DC

6 Data interface (DATA)

7 Connection OUTLET

8 Connection INLET, type 1604

9 USB interface with cover

10 Connection socket for equipotential bonding

11 Equipotential bonding cable

14 Closure to the connection OUTLET

15 Clamp of the user interface

16 Attachable bag for hoses, cables and accessories

- Bluetooth interface

FCU 1315 en(us) Page 28 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Product measurements

The FCU has the following dimensions.

All dimensions in mm.

FCU 1315 en(us) Page 29 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

What can the product do?

Hydraulic circuit

Item Designation

1 INLET, gauge port type 1604

2 Suction screen, 400 µm

3 Gear pump

4 Electric motor

5 Pressure relief valve

6 ContaminationSensor Unit CU

7 Counter balance valve

8 AquaSensor

9 OUTLET, DN7 Quick coupling nipple

FCU 1315 en(us) Page 30 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Using the BatteryPack (accessory)

Using the BatteryPack (accessory)

With the BatteryPack, which is available as an accessory, you can make the

FCU independent of the electrical supply network.

For technical details on the BatteryPack, see its instruction brochure.

With the locking pin (2), the

BatteryPack (1) is held securely in the

mounting rails (3) during transport.

For operation with the BatteryPack, fit the connector into the socket labeled

DC IN of the FCU.

FCU 1315 en(us) Page 31 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Using the BatteryPack (accessory)

To fit the BatteryPack into its holder, proceed as follows:

1. Remove the connector (A) from the

socket on the BatteryPack.

2. Slide the BatteryPack into the

mounting rails from above.

FCU 1315 en(us) Page 32 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Using the BatteryPack (accessory)

3. Pull the locking pin (1).

Slide the BatteryPack down until it

touches the lower stop in the guide

rails (2).

Release the locking pin (3). A spring

will return the locking pin to its

original position, thus securing the

BatteryPack.

Check that the BatteryPack is firmly

seated.

4. Insert the connector into the socket

on the BatteryPack.

FCU 1315 en(us) Page 33 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Using the BatteryPack (accessory)

To remove it, proceed as follows:

1. Remove the connector from the

socket.

2. Pull the locking pin out to release the

BatteryPack (1).

Slide the BatteryPack upwards (2).

FCU 1315 en(us) Page 34 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Using the BatteryPack (accessory)

3. Pull the BatteryPack up and out of

the mounting rails.

Then insert the connector back into

the socket on the BatteryPack.

FCU 1315 en(us) Page 35 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Preparing the FCU for measurement

Before operation, the FCU must first be hydraulically and electrically

connected, as described below.

FCU electrical connection

The FCU has a 3-way plug to connect to a 24 V DC supply. Insert the 3-pin

jack plugs of the adapter (included in the FCU delivery). Connect the power

plug of the adaptor into the power supply.

1. After the unit is plugged in, HYDAC FCU 1### appears in moving

letters, followed by the firmware version, which appears for 2 seconds.

2. The internal sensors will then be checked.

The display will show as well as the sensor firmware.

3. The self-test with countdown follows in the display

3. The FCU is now ready.

4. Flashing in the displays and indicates that the FCU is

in a safety disconnection. Details regarding this can be found in the

"Identifying and eliminating status/error messages" chapter on page

105.

5. As long as the pump is not running and no fluid is being pumped, the

status LED will flash red, and the display will show .

This means that there is no oil flow.

FCU 1315 en(us) Page 36 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

To insert the connector To remove the connector

Insert the connector into the Press the catch (1) on the connector

socket until it audibly snaps in ( and then pull (2) the connector out.

).

FCU 1315 en(us) Page 37 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Plug in/Detach return hose

NOTICE

Closed or blocked outlet at the connection OUTLET

The FCU can be damaged.

► Never seal the connection OUTLET.

► Put the free end of the OUTLET return hose into an unpressurized

container.

Plug in return hose Detach return hose

Fit the quick-action coupling on the return hose to the nipple. Make sure that

the coupling audibly snaps into place ( ). Make sure that the quick-action

coupling is firmly seated.

Put the other end of the return hose into a depressurized container or tank.

FCU 1315 en(us) Page 38 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Selecting the measurement location

(1) Select the measurement location so that the sample measured comes

from a turbulent location, with a good flow. For example on a pipe

bend. This ensures that a typical sample is analyzed.

(2) If the FCU is installed near the measurement point, avoid delayed

measurement results and sedimentation (particle deposits in the line).

While installing the inlet hose INLET, make sure that no siphon

(3)

results.

FCU 1315 en(us) Page 39 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

When operating with diesel, note …

WARNING

Statically charged fluid

Risk of explosion

► Connect the FCU during the measurement of

the operation to the plant, to the system, to

the tank or to the container, etc. via the

voltage equalizing cable.

► Use the hoses included in the scope of

delivery or the suction tube for measuring

fluids.

► Guide the measured fluid back into an often,

well-ventilated vessel below the liquid level.

The permissible types of diesel have a low conductivity. This means that

static charges can come about during flows through tubes or pipes which, in

the event of an uncontrolled electrostatic discharges can become an ignition

source for explosive mixtures.

The flow speed through the FCU is so low that the fluid cannot build up a

static charge as a result. The possibility cannot however be excluded that

statically loaded fluid will be aspirated from the system, that will then result in

FCU 1315 en(us) Page 40 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

an uncontrolled electrostatic discharge when it exits the FCU. This can lead

to spark formation, which will become an ignition source for any ignitable

mixtures that may be on hand.

The FCU has a safety disconnection that switches off the pump when the

ambient temperature of > 45°C is exceeded in the FCU.

If the safety disconnection is active, there will be flashing in the displays

and , Details regarding this can be found in the "Identifying

and eliminating status/error messages" chapter on page 105.

FCU 1315 en(us) Page 41 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Select the measurement method according to the pressure involved

After you have selected the measurement point, according to criteria such as

fluid / pressure, determine what the operating pressure is at that

measurement point.

Select the measurement method that is suitable for the pressure at the

measurement point:

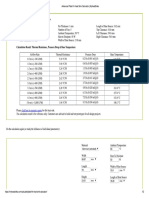

Pressure at the Measurement method Details

measurement are on

point page

0 bar / Hydraulic fluid / Diesel - Measuring from 43

0 psi depressurized containers

0 - 16 bar / Diesel - Measuring up to max. 43

0 - 232 psi 16 bar / 232 psi

1 - 45 bar / Hydraulic fluid - Measuring up to a maximum 48

14 - 650 psi of 45 bar / 650 psi

15 - 345 bar / Hydraulic fluid - Measuring between 5 … 345 51

217 - 5000 psi bar / 217 … 5000 psi

FCU 1315 en(us) Page 42 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Hydraulic fluid / Diesel - Measuring from depressurized containers

Required hoses:

- Return hose

- Suction tube (A) or suction hose (B) + hose adapter

To guarantee valid and direct measurements, prime the FCU. To do this,

draw in approx. 120 ml fluid via the inlet hose in order to completely fill the

hydraulic circuit and the inlet hose.

If the FCU is not primed, an air-oil mixture at the start of measurement will

flow through the FCU. The sensor will interpret this air-oil mixture as

particulate soiling and will thus falsify the measurement result.

For an initial test without priming the FCU and hoses, you need at least

300 ml of fluid.

FCU 1315 en(us) Page 43 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Make sure that the following sequence is observed:

1. Go through the steps in chapter

"Preparing the FCU for

measurement“ on pages 36 to 42.

2. Connect the suction hose

(transparent in color) to the INLET

connection of the FCU with the help

of the hose adapter.

Put the other end of the transparent

suction hose into an unpressurized

container.

3. This completes the hydraulic

installation.

FCU 1315 en(us) Page 44 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

4. Switch on the internal pump.

5. The FCU will start with the

measurement.

FCU 1315 en(us) Page 45 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Diesel - Measuring up to max. 16 bar / 232 psi

Required equipment from the scope of delivery:

- Return hose

- High-pressure hose

- Voltage equalizing cable

Make sure that the following sequence is observed:

1. Go through the steps in chapter

"FCU für die Messung vorbereiten“

on pages 36 to 42.

Observe the details in section "When

operating with diesel, note …" on

page 40.

2. Check the pressure at the

measurement location. The pressure

there must be in the range from 0 -

16 bar / 0 - 32.6 psi.

If the pressure is greater

than 16 bar / 32.6 psi, then

measurement with the FCU is not

permissible.

FCU 1315 en(us) Page 46 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

3. Connect the inlet pressure hose

(black) to the port INLET of the FCU

(1).

Screw the measurement coupling

clockwise (2) onto the connection

and screw it finger tight.

4. Connect the other end of the INLET

pressure hose to the measurement

point of the system.

5. Switch on the internal pump.

6. This completes the hydraulic

installation.

7. The FCU will start with the

measurement.

FCU 1315 en(us) Page 47 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Hydraulic fluid - Measuring up to a maximum of 45 bar / 650 psi

WARNING

Hydraulic systems are under pressure

Danger of bodily injury

► The system must be depressurized before

performing any work on the product.

► If the pressurized connection is connected to

the hydraulic system, oil will flow through the

FCU.

► Make sure that the specified sequence is

followed.

NOTICE

If the operating pressure exceeds 45 bar / 650 psi

The excess pressure will be discharged via port OUTLET

► Never seal the connection OUTLET.

► Put the free end of the OUTLET return hose into an unpressurized

container.

► When operating, always observe the permissible operating pressure.

The FCU can withstand pressures up to 345 bar / 5000 psi.

FCU 1315 en(us) Page 48 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Required hoses:

- Return hose

- High-pressure hose

Make sure that the following sequence is observed:

1. Go through the steps in chapter

"FCU für die Messung vorbereiten“

on pages 36 to 42.

2. Check the pressure at the

measurement location. The pressure

there must be in the range from 1 -

45 bar / 14 - 650 psi.

If the pressure exceeds

45 bar / 650 psi, use the high-

pressure adapter (see page 51).

FCU 1315 en(us) Page 49 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

3. Connect the inlet pressure hose

(black) to the port INLET of the FCU

(1).

Screw the measurement coupling

clockwise (2) onto the connection

and screw it finger tight.

4. Connect the other end of the INLET

pressure hose to the measurement

point of the system.

5. Switch on the internal pump.

6. This completes the hydraulic

installation.

7. The FCU will start with the

measurement.

FCU 1315 en(us) Page 50 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Hydraulic fluid - Measuring between 5 … 345 bar / 217 … 5000 psi

WARNING

Hydraulic systems are under pressure

Danger of bodily injury

► The system must be depressurized before

performing any work on the product.

► If the pressurized connection is connected to

the hydraulic system, oil will flow through the

FCU.

► Make sure that the specified sequence is

followed.

NOTICE

If the operating pressure exceeds 345 bar / 5000 psi

The excess pressure will be discharged via port OUTLET

► Never seal the connection OUTLET.

► Put the free end of the OUTLET return hose into an unpressurized

container.

► When operating, always observe the permissible operating pressure.

The FCU can withstand pressures up to 345 bar / 5000 psi.

FCU 1315 en(us) Page 51 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

Required hoses / adapters:

- Return hose

- High-pressure adapter

- High-pressure hose

Make sure that the following sequence is observed:

1. Go through the steps in chapter

"Preparing the FCU for

measurement“ on pages 36 to 42.

FCU 1315 en(us) Page 52 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

2. Check the pressure at the

measurement location. The pressure

there must be in the range from 15 -

345 bar / 217 - 5000 psi.

If the pressure is greater

than 345 bar / 5000 psi, please

cancel the process. Look for a

different measurement point.

3. Screw the high-pressure adapter

onto the INLET connection of the

FCU

4. Connect the high pressure hose to

the high pressure adaptor.

5. Connect the other end of the high

pressure hose to the measurement

point of the hydraulic system.

FCU 1315 en(us) Page 53 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Preparing the FCU for measurement

6. Switch on the internal pump.

7. This completes the hydraulic

installation.

8. The FCU will start with the

measurement.

FCU 1315 en(us) Page 54 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

Operating FCU

When the FCU is powered up, it is ready for use and the parameters can be

set.

In the following, the individual controls and their use are described.

Display and keypad elements

Item LED Designation

A Status Status display

(see page 105 for details).

B Display Consists of a 6-digit display and shows the

selected measured values.

C Measured Indicates the displayed variable of the display

variable value, e.g.: .

D Service variable Indicates the service variable of the display

value, i.e.: .

E Unit The units for the fluid temperature display

.

FCU 1315 en(us) Page 55 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

The keyboard consists of six buttons. These buttons are used to operate the

FCU and to navigate through the menus (hierarchically structured).

Keyboard Description

- one level down

- confirm changed value (lowest level)

- confirm when changes are to be saved or canceled

(top level)

- one level up

- No value change

- Change values at the lowest levels

(if you are at the lowest menu level, the display will

flash)

- Scroll through display

- Scroll through menu

- select digit

FCU 1315 en(us) Page 56 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

Clicking through the display

According to the calibration type ( ) in the PowerUp up menu, the

following displays can be clicked through by actuating the

buttons.

- Display

Display Description

3-digit ISO code

SAE Class A

SAE Class B

SAE Class C

SAE Class D

SAE Max.

Flow status

LED current in %

FCU 1315 en(us) Page 57 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

- Display

Display Description

3-digit ISO code

NAS 2-5 µm channel

NAS 5-15 µm channel

NAS 15-25 µm channel

NAS > 25 µm channel

NAS Max.

Flow status

LED current in %

FCU 1315 en(us) Page 58 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

Displaying measured variables

The measurements provide you with information about the purity of the fluid

in the system concerned. The measurement variables are calibrated. They

indicate a measured value with an accuracy of +/- 1/2 ISO codes.

" " measured variable

Display Description

The measurement value is updated

independently of the set measuring time.

Display of the 3-digit ISO code.

Example: ISO code 20.18.15

" " measured variable

Display Description

The measurement value is updated

independently of the set measuring time.

Display of a channel in the SAE class.

Example: SAE class, channel A = 6.1

" " measured variable

Display Description

The measurement value is updated

independently of the set measuring time.

Display of a channel in the NAS class.

Example: NAS class, channel 15-25 =

13.2 µm

" " measured variable

Display Description

The integrated AquaSensor continuously

measures the water saturation. The

measured value is shown on the display

expressed as percentage saturation.

Example: 19.3% water saturation

FCU 1315 en(us) Page 59 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Operating FCU

" " measured variable

Display Description

The integrated AquaSensor continuously

measures the fluid temperature. The

output as Celsius °C or Fahrenheit °F can

be selected under the setting

on page 71.

Example: Temperature = 37.8 °C

Display service variables

These values give you information about the determined flow and the light

source power. The service variables are not calibrated.

" " service variable

Display Description

Here, you can see the averaged flow

status through the ContaminationUnit.

Example: Flow rate = OK

" " service variable

Display Description

Display of the light source efficiency (1-

100%) with which the ContaminationUnit

currently works.

Example: Light source efficiency = 60%

FCU 1315 en(us) Page 60 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

Select operating level / configuration menu

The FCU has the following two operating levels / configuration menus:

Menu Description Details are

on page

PowerUp Menu The basic settings for the FCU 62

Settings for the recording and storing of

Measuring Menu the measurements and naming the 67

measurement points.

FCU 1315 en(us) Page 61 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

PowerUp Operate / Set up menu

In the PowerUp menu, the basic settings for the operation of the FCU are

made.

Selection To do

Press any button and hold it down while

PowerUp Start menu

switching on the supply voltage.

PowerUp Exit the menu without Scroll to and press , or

saving the option will be selected automatically

after 30 seconds

PowerUp Exit the menu with

Save Scroll to and press

Description For details,

see page:

Set the system date 63

Set bus address 63

Delete the records 64

Set measuring time 64

Select the calibration 65

Reset to factory defaults 65

Discard changes and exit 66

Save changes and exit 66

Press to change to a sub-menu.

FCU 1315 en(us) Page 62 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

– Setting date/time

In this option you can set or alter the system date / time.

If the date has never been set, or if the buffer battery is flat , the system date

will be and the time will be .

The date format is: => year / month / day.

The time uses 24 hour format: => hour / minute.

Use the following buttons to set the

date and time:

To change the

value

To change digit

To confirm the

change

Cancel and back

- Set bus address

With , you set the bus address to transmit the measurements

over the data interface, using the HSI protocol.

There are 26 bus addresses available, from A - Z. Please note that each

address may occur only once on any bus.

Use the following buttons to set the

address:

To change the

value

To change digit

To confirm the

change

Cancel and back

The factory setting of the bus address is:

FCU 1315 en(us) Page 63 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

- Delete memory

With , you permanently delete all of the measurement records in

the internal memory.

Before deletion, back up all of the measurement records on the USB

memory stick.

Push the following buttons to:

Confirm deletion

Cancel and back

- Set measuring time

Under you set the duration of the measurement. Select the

duration in the range from 10 to 300 seconds.

Use the following buttons to set the

duration of the measurement:

To change the

value

To change digit

To confirm the

change

Cancel and back

The factory setting is:

FCU 1315 en(us) Page 64 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

– Select calibration type

Under , select the desired calibration type, either or

.

The calibration type is based on ISO4406:1999 / SAE.

The calibration type is based on ISO4406:1987 / NAS.

Use the following buttons:

To change

between the types

of calibration

To confirm the

change

Cancel and back

– Reset to default settings

resets the FCU back to default settings. For the factory settings,

see page 65.

Use the following buttons:

To change the

value

To change digit

To confirm the

change

Cancel and back

FCU 1315 en(us) Page 65 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

- Cancel

discards all changes and exits the PowerUp menu.

Use the following buttons:

To change digit

To confirm the

change

Cancel and back

– Save data

With , you save all changes and exit the PowerUp menu.

Use the following buttons:

To change digit

To confirm the

change

Cancel and back

FCU 1315 en(us) Page 66 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

Operating/Setting measuring menu

The Measuring Menu allows you to change settings during operation.

Selection To do

Start the measuring menu

Press the button

Scroll to and press or

Exit the measuring menu

wait for 30 seconds with no further action

without saving

and the FCU will automatically switch to

display mode.

Save and exit the measuring

menu Scroll to and press

Measuring Description For

Menu details,

see page

Record measurements 68

Show free memory 69

Change measurement location 70

name

Change temperature units 71

Discard changes and exit 72

Save changes and exit 72

FCU 1315 en(us) Page 67 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

– Record measurements

With this option you define under which of the 20 available measurement

points the records should be saved.

Use the following buttons:

To change digit

To confirm the

change

Cancel and back

Use the following buttons:

To change digit

To confirm the

change

Cancel and back

makes up to 20 freely definable measurement points available. On

delivery, the measurement points are set to .

You can change these names at will (maximum 6 characters), as described

under .

Use the following buttons:

Change to the next

measurement point

To confirm the

change

Cancel and back

FCU 1315 en(us) Page 68 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

Select to create a new file in the internal FCU memory under the

new measurement point. Press and the display will jump to .

Confirm again by pressing .

Use the following buttons:

Change the

selection

To confirm the

change

Cancel and back

- Display free memory

Under , you can check the current free internal memory capacity

of the FCU in %. If there is no more memory available, no measurement

records can be saved.

Copy the measurement records that you have already read out as described

on page 77 in chapter "Reading out USB interface measured values". Then

delete those records in the internal memory with as described

on page 64.

For example: 97% free memory.

Use the following buttons:

To confirm the change

Cancel and back

FCU 1315 en(us) Page 69 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

– Change name of measurement point

Under you can modify the designation of the measurement point

to meet your wishes. You have a maximum of 6 characters available for the

measurement point designation.

Example: TEST01, EXCAVATOR, CRANE, etc.

Use the following buttons:

Change to the next

option in the menu

To confirm the

change

Cancel and back

Use the following buttons:

Change to the next

option in the menu

To confirm the

change

Cancel and back

Use the following buttons:

Change the current

character

Select another

character

To confirm the

change

Cancel and back

FCU 1315 en(us) Page 70 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

The following characters will appear, when the button is

pressed, wrapping around at the end.

The empty space is located between 9 and A and can be adjusted only from

the 6th position to the left. This means that you can enter a name with less

than 6 characters.

- Set temperature unit

Under you set the units for displaying the fluid temperature. You

have the choice between degrees Celsius °C and degrees Fahrenheit °F.

Use the following buttons:

Change to the next

option in the menu

Confirm

Cancel and back

Use the following buttons:

Change the

selection

Confirm

Cancel and back

FCU 1315 en(us) Page 71 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Select operating level / configuration menu

- Cancel

discards all changes and exits the Measuring menu.

Use the following buttons:

Change to the next

option in the menu

Confirm

Cancel and back

– Save data

With , you save all changes and exit the Measuring menu.

Use the following buttons:

Change to the next

option in the menu

Confirm

Cancel and back

FCU 1315 en(us) Page 72 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Performing measurements

Performing measurements

1. Check all the hydraulic and electrical connections to the FCU.

2. Now press the green "Pump ON" switch.

3. The pump feeds fluid to be analyzed through the FCU.

After the set measurement duration, the result will be shown on the

display, and the status LED will light up green, steadily.

FCU 1315 en(us) Page 73 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

Reading internal measurement memory

All measurements are kept in internal memory, with a reference to the

measurement point, until deliberately deleted by means of the

function.

The internal memory has a capacity of > 30000 lines = measurement

records.

To transfer the data, the target system (e.g. PC or USB stick) has to have at

least 10 MB of capacity free.

The FCU provides you with the following interfaces for reading the

measurement memory:

Available interfaces For details, see page:

Reading out measured values via DATA 75

interface

Reading out USB interface 77

Reading out measured values via Bluetooth 81

interface

FCU 1315 en(us) Page 74 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

Reading out measured values via DATA interface

The FCU has a DATA interface for transferring the measurement data. The

FCU communicates over FCU using the HSI protocol.

Connecting FCU with a CSI-B-2 kit

The FCU can be connected to a PC using the CSI-B-2 kit.

Pins used on the DATA interface (HYDAC Sensor Interface – HSI)

The HSI interface has a 5-pin M12x1 connection plug in accordance with

DIN VDE 0627.

Pin Assignment

1 Not connected

2 Not connected

3 Not connected

4 GND

5 HSI

FCU 1315 en(us) Page 75 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

Connecting FCU with HMG 510 / HMG 3000 / HMG 4000

The following portable data recorders (FCU) can be used to give a readout of

the DATA via the HMG interface:

- HMG 510 (with firmware version 2, release 15 or higher)

- HMG 3000 (with firmware version 2, release 1 or higher)

For further details, see the operating instructions for the HMG.

FCU 1315 en(us) Page 76 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

Reading out USB interface measured values

Copying measurements onto a USB data stick

Compatibility with other USB memory sticks cannot be guaranteed as the

FCU communicates directly with the microprocessor. This means that

communication errors cannot be corrected in software, like, for example, on a

PC with an operating system.

We recommend using the HYDAC USB

memory stick, which we successfully tested

for many PC/operating system combinations.

We accept no guarantee or liability for the (looks something like this)

functionality and compatibility of the USB

For HYDAC part no., see

memory stick with your system. We do

page 111, chapter "Selecting

not offer support or replacements in this

accessories"

case

Saved measurements can be copied to the USB memory stick supplied with

the unit. After copying to the USB stick, the data still exists in the internal

memory.

During the download, no measurement data are stored in the internal

memory.

After another download, the measuring data for the duration of the download

are missing.

You have to explicitly delete the data in the internal memory of the FCU. See

the menu option on page 64.

Before using the USB stick for the first time, we recommend that you format

it. To do that, insert it into a free USB port on your PC. Then change to the

file manager (e.g. Explorer) and format the stick in FAT32 format. You will

find details of this in the documentation of your operating system.

There must be at least 10 MB of free memory available on the USB stick.

To save your measurements on the USB memory stick, proceed as follows:

1. Open the cover to the USB

connection by turning it

counterclockwise (1) and then lifting

it (2).

FCU 1315 en(us) Page 77 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

2. Insert the USB memory stick into the

socket. Note that the stick only fits

one way around.

It must be easy to insert the USB

stick into the socket.

3. After inserting the USB memory

stick, the FCU will detect it and

immediately start copying the

measurement data.

4. In the " " display, you

can see the number of measurement

records to be copied (e.g. 339)

The " " display

shows the number of records to be

viewed (e.g. 4).

5. If the FCU detects existing records

on the USB memory stick, the

following message will appear on the

display.

Example: The FCU has found the

record number 4 on the USB

memory stick.

This function is especially suited to

the synchronization of the copied

data with the FCU's internal

memory. The existing records will be

displayed.

6. After successfully copying the

records, the following message will

appear on the display.

FCU 1315 en(us) Page 78 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

7. Now remove the USB memory stick

from the socket by gently pulling it

upwards.

8. Close the cover to the USB

connection (1) by turning it clockwise

(2).

FCU 1315 en(us) Page 79 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

- Data transmission failed

If a fault occurs during the copy

procedure, or if you remove the USB

memory stick from the socket before the

procedure is complete, the following

message will be output on the display.

To remedy faults, proceed as follows:

Step

Description

1. Insert the USB memory stick in your PC and delete all data.

2. Put the USB stick back in the USB socket of the FCU. The

download will start automatically

->a. If the error recurs -> proceed to Step 4.

3.

->b. If the error does not recur -> proceed to Step 11.

4. Insert the USB stick in your PC and reformat it.

5. Put the USB stick back in the USB socket of the FCU. The

download will start automatically

->a. If the error recurs -> proceed to Step 7.

6.

->b. If the error does not recur -> proceed to Step 11.

7. Use a different compatible USB memory stick.

8. Put the USB stick back in the USB socket of the FCU. The

download will start automatically

->a. If the error recurs -> proceed to Step 10.

9.

->b. If the error does not recur -> proceed to Step 11.

10. Contact the HYDAC Service department.

11. The download has been successfully completed

FCU 1315 en(us) Page 80 / 132

BeWa FCU1315 V400 4168086 en-us 2017-02-28.docx 2017-02-28

Reading internal measurement memory

Reading out measured values via Bluetooth interface

The FCU Bluetooth interface is based on Bluetooth Version 1.2, Class 3.

This means that: