Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pile Behavior-Consequences of Geological and Construction Imperfections

Caricato da

Ivan MojicaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pile Behavior-Consequences of Geological and Construction Imperfections

Caricato da

Ivan MojicaCopyright:

Formati disponibili

Pile Behavior—Consequences of Geological

and Construction Imperfections1

Harry G. Poulos, F.ASCE2

Abstract: This paper identifies some of the causes of imperfections in real pile foundations and then examines their possible effects on

pile behavior. The imperfections considered arise from two main sources, natural imperfections caused by the geological circumstances

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

and imperfections related to the construction of the piles. In each case, single piles are considered first, and then pile groups are addressed

separately. Case histories are presented to illustrate the effects on pile performance which are predicted by theoretical analyses. The

analyses with which these examinations are carried out will still inevitably involve some degree of idealization, but at least attempt to

incorporate the key “nonideal” aspects. The paper also discusses the particular problems involved in investigating and analyzing under-

performing pile foundations and reviews some methods by which the consequences of imperfections may be overcome or ameliorated.

DOI: 10.1061/共ASCE兲1090-0241共2005兲131:5共538兲

CE Database subject headings: Pile foundations; Foundation settlement; Construction; Geologic processes.

Introduction assumptions being invalid, at least to some degree. It is important

to understand how nonideal conditions can arise and what effects

In his Presidential Address to the 1st International Conference on they may have on pile behavior. The term “imperfection” will be

Soil Mechanics and Foundation Engineering, Terzaghi 共1936兲 used to describe a nonideal condition in which either the ground,

stated: “…the earth in its natural state is never uniform…Its or the pile as-installed, has a defect or flaw, as compared to the

properties are too complicated for rigorous theoretical ideal situation. It is also essential to be able to cope with the

treatment…Even an approximate mathematical solution of some consequences of imperfections when construction has been com-

menced, or after it is completed, and the performance of the foun-

of the most common problems is extremely difficult.” The sub-

dation system has not met requirements. In some circumstances,

stantial advances in numerical analysis made since that time have,

remedial works may be necessary to correct the foundation sys-

however, allowed theoretical treatment and solution of a wide

tem so that it remains both serviceable and safe.

range of problems to be obtained, and these advances have been

This paper will attempt to identify some of the causes of im-

particularly significant for pile foundations. perfections in real pile foundations, and will then examine their

Despite the availability of these methods to modern-day pile possible effects on pile behavior. In each case, single piles will be

analysts and designers, it is still very common to assume that considered first, and then pile groups will be addressed separately.

“ideal” circumstances prevail and that the earth is essentially uni- The analyses with which these examinations will be carried out

form. For example, it is usual to assume that all soil layers are will still inevitably involve some degree of idealization, but will

horizontal, the founding conditions below all piles are identical, at least attempt to incorporate the key “nonideal” aspects. The

and that all piles in a group are flawless, elastic, and of equal paper will also discuss the particular problems involved in ana-

dimensions and length. Indeed, some methods also make more lyzing and designing underperforming pile foundations, and will

radical assumptions with respect to ideal conditions, namely, that review some methods by which the consequences of imperfec-

the soil behavior is elastic, and that the soil profile is either uni- tions may be overcome or ameliorated.

form with depth or varies in a linear manner. The effects of con-

struction processes on the piles are also frequently ignored or

simplified. Such ideal conditions are rarely, if ever, encountered Process of Idealization

in real life. Both natural geological circumstances and the pro-

cesses involved in construction will generally lead to the above In any geotechnical analysis or design, it is necessary to simplify

the problem in hand and develop an idealized model that incor-

1

Presented at the GeoSupport 2004 Conference, Orlando, FL. porates the key geotechnical and structural features of the prob-

2

Senior Principal, Coffey Geosciences Sydney Australia & Emeritus lem. In particular, there are three aspects of idealization that may

Professor of Civil Engineering, Univ. of Sydney, 8/12 Mars Rd. Ln., be critical:

Cove West, NSW 2066, Australia. E-mail: harry_poulos@coffey.com.au • The representation of the geology of the site;

Note. Discussion open until October 1, 2005. Separate discussions • The assignment of the relevant geotechnical and structural pa-

must be submitted for individual papers. To extend the closing date by

rameters; and

one month, a written request must be filed with the ASCE Managing

Editor. The manuscript for this paper was submitted for review and pos- • The consideration, as far as possible, of the “realities” of the

sible publication on July 7, 2004; approved on November 1, 2004. This problem. Depending on the nature of the problem, it may be

paper is part of the Journal of Geotechnical and Geoenvironmental essential to incorporate such factors as nonlinear pile-soil be-

Engineering, Vol. 131, No. 5, May 1, 2005. ©ASCE, ISSN 1090-0241/ havior, nonlinear pile material behavior, the presence of a

2005/5-538–563/$25.00. water table, layering of the soil profile, loading by structural

538 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

loads, and loading by ground movements.

In all cases, these latter realities should be recognized prior to the

analysis and allowed for. The assessment of appropriate geotech-

nical parameters is a major topic of research, and is often the key

ingredient in the success or failure of a design or analysis. Despite

its importance, this issue will not be the focus of this paper.

In many problems, there may exist “imperfections” that arise

because of natural geological or construction-related reasons, and

which are generally unanticipated deviations from the expected

circumstances. While it may be possible to handle these imper-

fections by appropriate analysis, the main difficulties are that the

designer/analyst may not recognize the existence of the imperfec-

tions during the design process, or else they may only become

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

manifest beyond the design process. Subsequent analysis may

then become either a remedial or a forensic exercise.

In this paper, it will be assumed that the “realities” of pile

analysis will have been recognized and will be incorporated into

the analyses as necessary, and that appropriate geotechnical pa-

rameters have been assessed for the problem. Hence attention will

be focused on the influence of “imperfections” which may not be

recognized at the time of design or construction, but which may

have an important influence on subsequent behavior of the foun-

dation system.

Sources of Imperfection

Fig. 1. Examples of natural 共geological兲 imperfections

The imperfections that may impact on pile foundation perfor-

mance may arise from a number of sources, including natural

sources, inadequate ground investigation, construction, pile load • A soft toe on bored piles due to inadequate base cleaning

testing, and loading during operation. Only the first three sources 共avoidable兲;

will be considered in this paper. However, the influence of other • Defects within the shaft of bored piles 共avoidable兲;

sources of imperfections has been studied by Poulos 共2000兲 in • Inadequate founding conditions 共avoidable兲;

relation to the effects of the testing setup on pile load-settlement • Ground movements developed due to drilling during the con-

performance, while the effects of loading arising from construc- struction process 共generally unavoidable兲;

tion operations during tunneling operations have been explored • Excavation and dewatering effects, especially with remedial

by Chen et al. 共1999兲; and Mroueh and Shahrour 共2002兲. piling projects 共generally unavoidable, but controllable兲; and

• Excessive driving of preformed piles 共avoidable兲.

Natural Geological Sources In general, construction-related imperfections in piles can be

broadly classified into two main categories, structural defects and

These imperfections arise from the geological processes at the

site, which have resulted in the present ground profile. They may

include 共among many others兲 layers which are not horizontal or

continuous, boulders within a soil layer, sloping bedrock, intru-

sions of rock over limited areas of the site, cavities in limestone

rock, or the presence of softer layers below what might be re-

garded as suitable founding strata for the piles. Fig. 1 illustrates

some of these situations.

Inadequate Ground Investigation

These imperfections are generally related to those that arise from

natural sources, but are exacerbated because the site is not prop-

erly characterized. Inadequacies are usually related to an insuffi-

cient number or depth of boreholes or probes to identify strati-

graphic variations across the site, or inadequate testing to quantify

the relevant geotechnical parameters. Fig. 2 illustrates a typical

example of such imperfections, and the inaccurate geotechnical

model that can result from them.

Construction

These imperfections arise from processes related to construction

of the piles, either from inadequate construction control or from

inevitable consequences of construction activities. They may in- Fig. 2. Examples of imperfections related to inadequate ground

clude: investigations

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 539

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Analyses Incorporating Imperfections

It is important to recognize the requirements for analyses of piles

which can take account of the imperfections inherent in practical

pile foundations. Such analyses should have the ability to handle

the following aspects:

1. Soil profiles involving nonhorizontal layers;

2. Different soil profiles along different piles within the same

group;

3. Piles of different length or diameter within the same group,

including consideration of interaction among dissimilar piles;

4. Piles containing structural defects or changes in diameter or

size along the length;

5. Piles that are added 共or activated兲 part-way through the load-

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

ing process 共to simulate the installation of remedial piles兲;

Fig. 3. Example of imperfections relation to construction techniques and

6. Loadings imposed from ground movements, as well as from

normal structural loadings.

In addition to these capabilities, the analyses should also be able

to cope with the realities of pile behavior mentioned previously,

geotechnical defects. Structural defects can result in the size, in particular, nonlinear pile-soil response, and also nonlinear pile

strength, and/or stiffness of the pile being less than assumed in material behavior.

design. Such defects have been discussed extensively in the lit- In principle, powerful contemporary numerical analyses, for

erature, particularly with respect to cast-in situ concrete piles, for example, FLAC 共Itasca 1999兲 and PLAXIS 共Brinkgreve and Ver-

example, Hobbs 共1957兲; Thorburn and Thorburn 共1977兲; and meer 1998兲, can take many, if not all, of the above factors into

Reese 共1978兲. Brown 共2004兲 discusses some aspects of construc- account. However, there are often limitations involved in using

tion techniques and materials that can lead to defects or subopti- such programs, related to the time involved in setting up the

mal pile performance. Examples of structural defects include the analyses of large pile groups, and the difficulty of discerning

following: “necking” of the shaft of bored piles, leading to a broad patterns of behavior from parametric studies. There are also

reduced cross-sectional area along part of the pile, poor quality potential problems with the accurate modeling of piles, particu-

control during the construction of bored piles, leading to some larly if a two-dimensional analysis is to be used and details of the

parts of the shaft having lower strength than assumed in design, internal forces and bending moments within the piles are re-

tensile cracking of large diameter bored piles under the influence quired. The writer believes that it may be preferable, at least from

of thermal strains, damage during the driving of timber, precast a practical viewpoint, to employ analyses which may involve a

concrete, or steel piles, leading to reduced strength and stiffness greater degree of approximation, but may be simpler to use and

of parts of the pile, especially near the top or tip of the pile, and more readily adapted to carrying out parametric studies, as well as

bending of slender driven piles. solving real-world problems. It is preferable to consider an im-

Geotechnical defects usually arise from either a misassessment perfection approximately, rather than to ignore it because it can-

of the in situ conditions during design, or else from construction- not be treated rigorously.

related problems, and may include reduced shaft friction and end Table 1 summarizes the capabilities of some of the computer

bearing resistance arising from localized softer or weaker geo- programs whose basis has been published 共although not all are

technical conditions in the vicinity of one or more of the piles in commercially available兲. The list in Table 1 is not meant to be

the group, reduced skin friction, and end bearing resistance aris- exhaustive, but rather, representative, and indicates that none of

ing from construction operations such as the use of bentonite the programs listed is able to incorporate all of the realities and

without due caution, and a “soft base” arising from inadequate imperfections that might arise. Indeed, the only aspect that is

cleaning of the base of bored piles. The latter is one of the most considered by all of the programs listed is axial behavior. How-

common concerns in bored pile construction and is likely to lead ever, a number are capable of considering at least some of the

to a reduction in the stiffness of the soil below the base of the realities and imperfections, albeit for a restricted range of prob-

pile. The ultimate base bearing capacity may not be affected sig- lems. In the following sections, three of these programs,

nificantly, but may require a large movement to be fully mobi- DAMPIG, GEPAN, and PIGS, will be employed to examine some

lized. Several writers have investigated the influence of construc- of the characteristics of pile group behavior when imperfections

tion defects on the shaft friction and end bearing resistance of are present. A more detailed outline of the basis of the PIGS

piles, for example, O’Neill and Hassan 共1994兲; O’Neill 共2001兲; program is given by Poulos 共2002兲.

and Abdrabbo and Abouseeda 共2002兲. O’Neill and Hassan sug-

gest bounds for the effects of construction-related factors and

present a framework for quantifying these parameters for design Imperfections Considered

purposes.

Fig. 3 illustrates an example of the usual idealization of a pile The effects on pile behavior of some of the imperfections arising

which may have both structural and geotechnical defects. In this from nature, inadequate investigation, or inadequate construction

paper, both types of defect will be considered, and it will be procedures will be examined in the following sections. For sim-

demonstrated that the type of defect may play a significant role in plicity, many of the cases examined will be idealized, and atten-

determining the subsequent behavior of that pile and of the pile tion will be focused on load-settlement behavior under axial load-

group containing it. ing. The following cases will be considered:

540 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

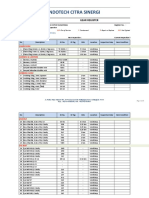

Table 1. Summary of Capabilities of Some Pile Group Analysis Programs

PILGP1 PIGLET FLPIER PIES DAMPIG GEPAN EMPIG PIGS

共O’Neill et al. 共Randolph 共Hoit and McVay 共Poulos 共Poulos 共Xu and Poulos 共Poulos 共Poulos

Factor 1982兲 2003兲 1996兲 1989兲 1997兲 2001兲 1999a兲 2002兲

Axial response 冑 冑 冑 冑 冑 冑 冑 冑

Foundation rotation 冑 冑 冑 — 冑 冑 冑 冑

Lateral response 冑 冑 冑 — 冑 冑 冑 —

Ground movements — — — 冑 — 冑 冑 冑

Nonlinear pile-soil 冑 — 冑 冑 冑 — 冑 冑

Nonlinear pile — — ? — 冑 — — 冑

Different pile length, etc. 冑 — — — — 冑 — 冑

Pile defects — — 冑 冑 i 冑 — i

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Nonhorizontal soil layers — — — — — 冑 — i

Varying soil profiles — — — — — — — 冑

Piles added or removed — — — — — — — 冑

during loading process

Note: 冑⫽capability exists; i⫽factor can be incorporated, but indirectly; and—⫽capability does not exist.

1. Piles bearing on a rock stratum with compressible clay seams on the stiffness and ultimate axial capacity of the pile base;

共natural geological imperfections兲; and

2. Piles founded in a layer underlain by a compressible deposit 2. A pile-soil interaction analysis in which the base load-

共natural imperfections, and possibly imperfections from in- settlement characteristics are input to obtain the pile head

adequate investigations兲; load-settlement behavior.

3. A pile founded on a boulder within a soil layer 共natural geo- Fig. 4 shows an idealized case of a single seam below a pile base

logical imperfection兲; that has been analyzed by this approach. It is assumed here that

4. Piles founded in soil profiles of varying thickness 共natural the clay seam has a strength and Young’s modulus 1 / 100 times

geological imperfections兲; that of the rock into which the pile is founded. The finite element

5. Groups containing piles of different length 共imperfections program PLAXIS has been used to compute the reduction in base

from natural, investigation, and/or construction causes兲; capacity and stiffness as a function of the seam thickness and its

6. Piles with structural defects 共construction imperfections兲; depth below the pile, with the results being expressed in terms of

and base capacity and stiffness reduction factors, BCR and BSR, respec-

7. Piles with geotechnical defects 共construction imperfections兲, tively, where

in this case, piles with a “soft toe.”

In each case 共except numbers 4 and 5 for obvious reasons兲, the BCR = ultimate capacity of base with seam/

effects on single pile response will be considered, and then the ultimate capacity of base without seams 共1兲

case of pile groups will be examined.

BSR = stiffness of base with seam/stiffness of base without seam

共2兲

Effects of Thin Seams in Bedrock

The PLAXIS analyses indicate that, as might be expected, the

presence of the clay seam alters the failure mode of the pile base

Single Piles

An issue of considerable concern to pile foundation designers is

the presence of weak seams in the founding layer, below the pile

tip. Kulhawy 共1978兲 has given some consideration to the effects

of geological imperfections on rock mass stiffness and established

a relationship between the equivalent rock mass properties and

the individual rock mass properties of the rock material and the

discontinuities. The influence of discontinuities on bearing capac-

ity has been considered by Kulhawy and Carter 共1992兲. In many

cases, specifications for the construction of bored piles require

probing some distance below the founding level to avoid the pos-

sibility that discontinuities and clay seams underlie the pile base.

Nevertheless, the possibility remains that such seams may remain

undetected, and in the case of driven or jacked piles, the possi-

bilities may be even greater. The effects of such weak seams can

be investigated via numerical analysis procedures such as the fi-

nite element method. However, a more efficient approach is to

carry out a two-stage analysis process:

1. A finite-element analysis to assess the effect of a clay seam Fig. 4. Definition of clay seam imperfection

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 541

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

and shale, where the rock grading depends on the proportion of

clay seam within the depth of influence of the pile base. Fig. 7

compares the reduction in capacity with increasing seam thick-

ness, for two different depths of the seam below the base, and for

sandstone and shale. It can be seen that the theoretical results for

a clay seam 0.2 base diameters below the base agree reasonably

well with the design recommendations from both the above-

mentioned sources. However, the design recommendations appear

to be unduly conservative if the clay seam is well below the pile

base, for example, more than about 0.4 base diameters. Similar

comments can be made in relation to the recommendations of the

Canadian Foundation Engineering Manual, where the thickness of

the clay seam is quantified explicitly.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

From a design viewpoint, the result that is most critical is the

effect of the clay seam on the overall load-settlement behavior of

a pile. Using the computer program PIES, together with the re-

Fig. 5. Example of effect of clay seam on pile base load-settlement sults in Fig. 6, analyses have been carried out for a range of

behavior values of pile length-to-diameter, to assess the overall capacity

and head stiffness reduction due to the presence of a clay seam.

The results are shown in Fig. 8 for a single 1 m diameter pile

significantly. An examination of the displacement fields near fail- situated in a weak rock and founded on a stronger and stiffer rock

ure indicates that the seam provides a path for the failure surface containing a clay seam. Fig. 8共a兲 plots the ratio of ultimate pile

and can lead to a significant reduction in base capacity, as shown capacities with and without the clay seam below the base, while

in Fig. 5 which plots typical load-settlement curves for the pile tip Fig. 8共b兲 shows the corresponding plot for the initial pile head

with and without a clay seam. Fig. 6 shows the reduction factors stiffness. It can be seen that, as the pile length increases, the effect

BSR and BCR as functions of relative depth of the seam and as a of the seam becomes less than for the base alone, since a consid-

function of the seam thickness. It is clear that BCR reduces as the erable amount of load is carried by the pile shaft. For example,

seam thickness increases and as the distance of the seam from the even if a seam with a thickness of 0.3 times the pile diameter

pile base decreases. The effect is particularly dramatic if the clay exists 0.2 diameters below the pile tip, the reduction in pile head

seam is just below the pile base. The reduction in base stiffness is stiffness is only about 30% when the pile length is 20 diameters,

even more dramatic than the reduction in capacity. while the loss of capacity is less than 20%. As might be expected,

It is interesting to compare the theoretical results in Fig. 6 with the greater the proportion of load carried by the pile shaft, the

typical design requirements, for example, those recommended by smaller is the effect of the weak seam on the pile head stiffness

Pells et al. 共1978, 1998兲 for piles socketted into Sydney sandstone and ultimate capacity.

Fig. 6. Influence of clay seam on pile base stiffness and capacity

542 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 7. Comparison between computed and design reduction factors 关adapted from Pells et al. 共1998兲兴

Fig. 8. Example of influence of clay seam on pile capacity and stiffness

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 543

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Pile Groups

It is important to note that a pile group may well be affected more

severely than a single pile by a clay seam. This is because, in

many cases, a group can be represented by an equivalent single

pier containing the piles and the intervening soil 共van Impe 1991;

Poulos 1993兲. In the case of a group, the diameter of the base of

the group is of course larger than that of a single pile, and more of

the applied load is carried by the base of the piles than is the case

for a single pile. Because of the greater equivalent diameter of the

group, the relative depth of a clay seam will be less than is the

case for a single pile, and consequently, the reduction in capacity

and stiffness of the base of the group will be greater than for a

single pile.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

From the examples examined herein, it can be concluded that

the presence of weak seams within the founding layer can be of Fig. 9. Pile base founded in dense sand overlying clay 关after Matsui

共1993兲兴

considerable concern in relation to both the base load capacity

and the base stiffness. However, if the pile carries a significant

part of the load in skin friction, the decrease in pile head stiffness db⫽diameter of pile base. It is also possible to use elastic theory

and load capacity due to the seams is less dramatic, at least until to assess the effects of the underlying layer on the axial stiffness

the shaft capacity has been fully mobilized. When most or all of of the pile base. A series of such solutions is shown in Fig. 10, in

the load is carried by the pile base, the reduction in stiffness can terms of a base stiffness reduction factor, defined as the ratio of

be significant if the seam is relatively thick and located very near the base stiffness with the underlying layer to the base stiffness if

the base of the pile or pile group. Thus, as per the conventional there is no underlying layer. The Young’s moduli of the upper and

wisdom of good site investigation, it is essential to identify and lower layers are E1 and E2, respectively, and Poisson’s ratio for

take account of thin weak seams within the founding layers, pref- each layer is assumed to be 0.3. It can be seen that, as would be

erably via drilling to and beyond the depth of influence of the pile expected, the stiffness of the base decreases as the modulus E2 of

or group prior to determining the final founding level. the underlying layer decreases and as the distance from the pile

base to the underlying layer decreases.

The results in Fig. 10 and Eq. 共3兲 can be used to estimate the

Piles in Layer Underlain by Compressible Layer effects of the compressible underlying layer on the behavior of a

single pile. It is found that, as with the case of a clay seam, the

Single Piles overall load-settlement behavior of the pile becomes less sensitive

to the presence of the underlying layer as the proportion of load

One of the most insidious forms of imperfection arising from carried by the shaft increases. Thus, for relatively long slender

natural causes 共and which are not identified by the ground inves- piles, the reduction in ultimate capacity and stiffness may be rela-

tigation兲 is the presence of compressible layers below the pile tip tively small.

founding level. Such layers can have a significant effect on both

the ultimate capacity and stiffness of the pile, especially of the

pile base. Many methods of estimating the bearing capacity of Pile Groups

circular foundations on layered soils have been proposed 关for ex- The results for a single pile may be used to obtain an indication of

ample, Button 共1953兲; Meyerhof 共1976兲; Meyerhof and Sastry the importance of an underlying compressible layer on the group

共1978兲; Giroud et al. 共1973兲; Merifield et al. 共1999兲兴, and such load-settlement behavior. Poulos 共1993兲 and Randolph 共1994兲

solutions have been applied to the estimation of the bearing ca-

pacity of a pile base. A very useful study by Matsui 共1993兲 has

suggested a simplified approach to this problem of a pile tip

founded in a sand layer underlain by a clay layer, as shown in Fig.

9. This work indicates that the depth of influence of the clay layer

below the pile tip is less than had been previously suggested by

Meyerhof and Sastry 共1978兲, who indicated that the compressible

layer should be at least 6 pile base diameters below the pile base

before its effect could be neglected. Matsui’s results may be sum-

marized as follows:

fb = f2 共zc/db 艋 0.5兲 共3a兲

fb = f1 共zc/db 艌 3兲 共3b兲

f b = f 2 + 共0.4zc/db − 0.20兲 · 共f 1 − f 2兲 共3.0 艌 zc/db 艌 0.5兲

共3c兲

where f b⫽ultimate base bearing capacity; f 1⫽ultimate bearing

capacity of upper layer; f 2⫽ultimate bearing capacity of underly- Fig. 10. Stiffness reduction factor for pile base with compressible

ing layer; zc⫽depth of underlying layer below pile base; and underlying layer

544 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

relatively high level, well above a deep layer of compressible

Leda Clay. Fig. 12 shows the stratigraphy of the site and some of

the key engineering properties revealed by the investigations. A

plan of the configuration of the pile group is also shown in Fig.

12. A number of the original boreholes extended to depths up to

236 ft 共72 m兲 without encountering bedrock.

A load test was carried out on a pile similar to that used for the

furnace foundations. At a typical working load of 75 US t 共668

kN兲, the measured settlement was about 0.04 in. 共1.0 mm兲. Ap-

plying normal pile group settlement theory to this result, it was

expected that the settlement of a 32-pile furnace group would be

of the order of 3–6 mm.

Fifteen years of settlement records were available for a bank of

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

five furnaces, and these measurements enabled some interesting

conclusions to be drawn regarding the sources of settlement of the

foundations. Fig. 13 reproduces the measured settlements over the

Fig. 11. Effect of compressible layer on group settlement bank of five furnaces, and reveals the following characteristics:

• The maximum settlement nearly 15 years after construction

was about 73 mm and was continuing to increase;

have shown that the behavior of pile groups can often be approxi- • The measured settlements were an order of magnitude greater

mated well by considering an equivalent pier of equal length and

than those which may have been expected simply on the basis

a diameter which gives a similar perimeter to that of the group.

of the pile load test; and

Using this approximation, it is clear that a compressible underly-

• The settlement of the end furnaces 共Furnace 1 and Furnace 5兲

ing layer will affect a pile group more than it affects a single pile.

was clearly affected by the other furnaces, and showed a sig-

The equivalent diameter of the group is obviously larger, and

more load is transferred to the base of the piles. Thus the relative nificant tilt.

depth of the underlying layer to the base diameter of the equiva- It was estimated by Golder and Osler that, taking into account the

lent pier is smaller, resulting in a greater reduction in base stiff- settlement of the compressible layers below the pile tips, the an-

ness and base capacity. Poulos et al. 共2002兲 have given an ex- ticipated final settlement of the end furnace 共No. 1兲 could be of

ample which shows that the increased settlement due to an the order of 87 mm, consisting of 10 mm of pile group settlement,

underlying layer increases with increasing group size. 13 mm consolidation of the silty clay layer below the pile tips,

It is also possible to examine the effect of a compressible and 64 mm from the deep Leda clay.

underlying layer via a pile group analysis, provided that due care This case clearly demonstrates the importance of taking ac-

is taken with the estimation of the interaction factors to make count of the compressibility of underlying compressible layers

some allowance for the effects of intervening piles between the below the pile tips, and of also considering the interaction among

influencing and influenced piles. The approximate approach sug- adjacent foundations. It also highlights the potential dangers of

gested by Poulos 共1988兲 has been used here, with the soil between relying solely on the results of a single pile load test to predict

the piles assumed to be three times stiffer than the soil near the pile group behavior, without a proper appreciation and character-

pile. For pile groups in a square configuration, with a center-to- ization of the ground conditions.

center spacing of 3 diameters, Fig. 11 shows the computed settle-

ment as a function of the number of piles and the Young’s modu-

lus of the underlying layer. The following observations may be

made:

• The effect of the underlying layer becomes more significant as

the size of the group increases;

• For a 122 group, the settlement may increase by a factor of

about 3.5 when the underlying layer has a modulus of 20 MPa,

compared to the case of a homogeneous founding layer with a

modulus of 100 MPa; and

• If the soil beneath the founding layer is very stiff 共1,000 MPa

in this case兲, the settlement may in be reduced by a factor of 2

compared to the case of a founding layer having a uniform

modulus of 100 MPa.

Fig. 11 thus indicates that the potential exists both to seriously

overestimate the settlement of pile groups if account is not taken

of the presence of stiffer layers at depth, and to seriously under-

estimate the settlement if underlying compressible layers are not

identified or are ignored.

Case History

Golder and Osler 共1968兲 have described an interesting case of a Fig. 12. Stratigraphy and pile group layout for furnace foundation

series of furnace foundations on piles, which were founded at a 关adapted from Golder and Osler 共1968兲兴

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 545

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

1. Jacking of the pile to its final penetration, considering the

boulder to be an enlarged base at the tip of the pile;

2. Removal of the jacking force, thus unloading of the pile; and

3. Reloading of the pile, simulating a static load test on the pile.

In the PIES analysis, the connection between the enlarged base

共boulder兲 was assumed to have very small tensile resistance on

unloading.

Fig. 14 shows the computed load-settlement behavior for the

three stages above. The following points can be noted:

1. On initial jacking, a relatively large resistance is developed

because of the presence of the boulder;

2. On unloading, the pile tip separates from the boulder, and a

gap forms; and

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

3. On reloading in the static load test, the presence of the gap

formed during unloading leads to a reduced resistance until

the pile tip recontacts the boulder. Thus the pile appears to

have a reduced load capacity.

Pile Groups

If such a pile is part of a pile group, it will have a lower axial

stiffness and 共effectively兲 a lower axial capacity than other piles

which are properly founded on a hard stratum. Consequently, the

group will experience an uneven settlement as well as a lateral

displacement. The behavior of groups containing piles of different

lengths or stiffness is considered below.

Groups Containing Piles of Unequal Length

It is very common for the piles within a group to have different

lengths. Generally, the length differences are not great, and reflect

Fig. 13. Settlement observations along north-south line through

the variable nature of the founding stratum. However, there are

furnaces 1–5 关based on Golder and Osler 共1968兲兴

some circumstances in which significant length differences can

occur, in particular, if the group is founded on a steeply sloping

bedrock stratum 共Poulos 2003a,b兲, or if there are construction

Pile Founded on a Boulder inadequacies, or if one or more of the piles are founded on a

boulder.

An example of the latter source of imperfection occurred in a

Single Piles housing project in Hong Kong. Coring of some of the bored pile

In soil deposits of a colluvial or glacial origin, it is not unusual to foundations indicated that some of the piles were founded at a

have boulders present in soil strata. When piles are driven or higher level, and on less competent rock, than other piles. The

jacked into such strata, it is possible that they will be found on the writer was asked to investigate the consequences of having piles

boulder, rather than extending through to the underlying hard stra- of different length and founding conditions on a pile group con-

tum. Possible consequences of a pile founding on a boulder are as

follows:

1. With driven piles, there may be a false set because the pile

effectively has an enlarged base;

2. With jacked piles, there may be a false indication of the pile

capacity, as the jacking force will incorporate the effect of

the resistance of the boulder as well as the pile itself; and

3. With bored piles, the pile will tend to act as one with an

enlarged base, but having a compressible layer below. This

situation will then be similar to that discussed above for

compressible underlying layers.

To illustrate the possible consequences of a jacked pile being

founded on a boulder, the case of a pile jacked into a dense sand

layer containing boulders will be considered. This example is

based on a real case in the Gold Coast in Queensland Australia,

where the boulders originated from rockfill used to construct an

earlier revetment within a creek bed in which a new major struc-

ture was to be built. The program PIES was used to simulate the Fig. 14. Simulation of installation and subsequent unloading/

following phases of the pile history: reloading of jacked pile on boulder

546 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Table 2. Summary of Computed Response of Bored Pile Group

Axial load Head moment Settlement

Pile number 共MN兲 共MNm兲 共mm兲

13 37.9 0.98 20.5

14 37.2 0.92 23.4

15 35.0 1.02 21.9

16 35.1 0.99 20.5

17 34.9 0.93 23.4

18 30.1 0.94 21.9

ing pressure, and ultimate lateral pile-soil pressure.

The parameters for the analyses 共soil Young’s modulus, ulti-

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

mate shaft friction, ultimate end bearing, and ultimate lateral pile-

soil pressure兲 were derived from the available SPT data using a

Fig. 15. Pile group layout in wing of high-rise building combination of local Hong Kong correlations and also some cor-

relations developed by Decourt 共1995兲. The upper section of the

piles was cased to a depth of 22 m to minimize possible negative

taining six bored piles, and supporting one of four wings of the skin friction.

high-rise building. Each pile had a shaft diameter of 2.5 m, with The results of the DAMPIG analysis of the 6-pile group are

the base belled to a diameter of 3.0 m. The pile layout for this summarized in Table 2 for an applied vertical load of 210 MN.

wing is shown in Fig. 15. The coring indicated that three of the The following observations may be made:

piles, Nos. 14, 17, and 18, were founded about 40 m below the 1. The maximum differential settlement across the group was

surface in conditions similar to those in BHB4, while the other only about 3 mm.

three piles 共Nos. 13, 15, and 16兲 were founded about 48 m below 2. The axial load distribution was nonuniform, with the longer

the surface, in conditions typified by BHB3. The geotechnical piles 共13,14,16兲 taking greater loads than the shorter piles.

models developed for each borehole are illustrated in Fig. 16, 3. Bending moments were induced in the piles, but these were

together with the average standard penetration test 共SPT兲 values found to be considerably less than the design moment capac-

for each layer. ity of the pile sections.

The consequent analysis was carried out in two stages: In addition, a lateral deflection was induced, but was only

1. Analyses of single pile response were undertaken using the about 1.5 mm.

computer program PIES for axial response and DEFPIG for The relatively small effects of the construction imperfections

lateral response. Analyses were carried out for each set of that resulted in piles of unequal length were largely due to the

three piles to obtain the axial and lateral stiffness values. piles being relatively long and the contrast in founding conditions

2. The computer program DAMPIG 共Poulos 1997兲 was then not being great. As a consequence of the analyses carried out, it

used to analyze the behavior of the 6-pile group, using the was decided that no additional remedial works would be neces-

single pile characteristics for each of the two sets of piles, sary in this case.

assuming that the pile cap was rigid.

In each case, account was taken of the realities of nonlinear pile

behavior by specifying limiting values of shaft friction, end bear- Influence of Structural Defects—Necking

of the Shaft

Single Piles

An example of the effect of structural damage on the load-

settlement behavior of a single floating pile is shown in Fig. 17.

Fig. 17. Example of effect of structural defect on load-settlement

Fig. 16. Details of piles analyzed curve for single end bearing pile

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 547

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 18. Load test on pile, showing structural failure 关adapted from Fig. 19. Influence of structural defects on pile head stiffness—

Abdrabbo 共1997兲兴 floating pile 关adapted from Poulos 共1997兲兴

stiffness of structurally defective pile

The structural defect consists of a “neck” in the pile from the pile RKS = 共5兲

stiffness of intact pile

head to a depth of 8 m, the necked area being 10% of the area of

the undamaged pile. Load-settlement curves are plotted for vari- Figs. 19 and 20 plot RKS as a function of the structural integrity

ous values of the compressive strength of the pile material. The factor, FSI, for friction piles and end-bearing piles, respectively. It

applied load P is expressed as a proportion of the ultimate geo- is assumed that the pile has a compressive strength sufficient to

technical capacity Pu of the pile. The following characteristics not fail structurally. In each figure, mean curves are plotted for a

may be noted: defect located at the pile top 共zd / L = 0兲 and at 0.4 times the pile

1. As would be expected, the presence of the defect leads to an length below the top 共zd / L = 0.4兲. The applied load level P / Pu is

increase in settlement; 0.5.

2. For pile strengths in excess of about 100 MPa, the pile re- These figures show that

mains intact structurally, and the settlement increase is rela- 1. Different types of defects give similar values of RKS, if the

tively small; value of FSI is the same;

3. As the pile compressive strength reduces, the pile fails struc- 2. The head stiffness reduction factor RKS decreases as FSI de-

turally, at progressively lower loads, relative to the geotech- creases 共i.e., as the defect becomes more extensive兲;

nical capacity Pu; 3. The reduction in stiffness is more severe when the defect is

4. The onset of structural failure results in a very sudden in- at or near the surface rather than at depth;

crease in settlement; this behavior is consistent with the re- 4. For a given value of FSI, the reduction in pile head stiffness

sults of model pile tests reported by Rao 共1996兲. is generally more severe for an end-bearing pile than a fric-

The latter conclusion is also confirmed in a pile load test on a 15 tion pile; and

m long bored pile reported by Abdrabbo 共1997兲. As shown in Fig.

18, a sudden failure occurred at a load of about 1,200 kN, which

is symptomatic of a fatal structural defect. Integrity testing of this

pile indicated the presence of a major defect at a depth of about 6

m.

In an attempt to provide a more convenient and general mea-

sure of the extent of pile structural defects, a “structural integrity

factor” FSI has been developed by Poulos 共1997, 1999b兲, in which

E dA dL

FSI = 共4兲

EALd

where E⫽Young’s modulus of intact pile; A⫽cross-sectional area

of intact pile; L⫽total pile length; Ed⫽Young’s modulus of dam-

aged portion of pile; Ad⫽cross-sectional area of defective portion

of pile; and Ld⫽length of defective portion of pile. If the pile is

intact, FSI is infinity; if the pile is seriously defective, FSI may be

small 共e.g., 0.1 or less兲, with a lower limit of zero.

To provide a measure of the pile performance, the “head stiff- Fig. 20. Influence of structural defects on pile head stiffness—end

ness reduction factor” RKS is introduced, where bearing pile 关adapted from Poulos 共1997兲兴

548 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

5. The effects of structural defects begin to be significant for

FSI less than about 1.

Some small-scale model tests on floating piles with diameter dis-

continuities, simulating shaft necking, have been reported by Xu

and Poulos 共2000a,b兲. In these tests, the load-settlement behavior

of piles with and without defects has been recorded, enabling the

reduction in pile head stiffness and capacity to be measured. Fig.

21 shows a comparison between the experimental results and the

theoretical curves in Fig. 19. The agreement is generally reason-

able, with the experimental results being reasonably consistent

with the lower bound curve expressing the relationship between

loss of stiffness and the structural integrity factor FSI.

There have been recent investigations of the effects of defects

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

on axial response using finite element analysis by Petek et al.

共2002兲, who have considered axial behavior, and their work has

confirmed the critical effect that the position of the defect has on

pile performance. Sarhan et al. 共2002兲 and Sarhan and O’Neill Fig. 22. Pile group analyzed 关adapted from Poulos 共1997兲兴

共2002兲 have considered the lateral response of piles with flaws.

Model tests and numerical analyses revealed that a concrete void

occupying 15% of the cross-sectional area of the pile, and pen- Fig. 23 shows the reduction in axial stiffness of the group as a

etrating inside the reinforcement cage, can reduce the flexural function of the proportion of piles which have structural defects.

resistance by about 30% compared to an intact shaft. The shaft This figure reveals the following, and expected, results:

ductility is also affected adversely. 1. The reduction in stiffness is more severe as the percentage of

defective piles increases;

Pile Groups 2. The reduction in stiffness is more severe as the applied load

level increases; and

For the purposes of examining the influence of defective piles on 3. The reduction in stiffness of the group is less than for the

group behavior, a simple hypothetical example has been consid- case of an isolated pile because of the ability of the stiffer

ered, as illustrated in Fig. 22. A group of six bored piles, 1.0 m in undamaged piles in the group to carry a greater proportion of

diameter and 20 m long, is assumed to be installed through a the load.

soft-medium clay layer onto a stiffer stratum. The pile cap is The location of the defective pile has some effect on the average

assumed to be rigid. The ultimate axial geotechnical capacity of axial stiffness of the group. For example, for an applied load level

each pile is 9,425 kN in compression, of which 6,280 kN is de- of 50% of ultimate, when Piles 1 and 2 have defects, the axial

rived from end bearing. The group is subjected to vertical loading stiffness reduction is about 30%, whereas if Piles 1 and 4 are

only, with loads up to 80% of the ultimate capacity of the group defective, the axial stiffness reduction is over 45%.

being applied. Changes in load distribution will occur when defective piles

The basic case of a group with no defective piles has been are present in the group. The load carried by the defective piles

used as the reference case. Consideration has then been given to a decreases, while the intact piles are forced to carry more load. For

group containing piles which have structural defects, with the pile the case of four defective piles, the two intact piles 共numbers 3

being severely “necked,” such that the structural integrity factor and 5兲 carry substantially larger loads than the other piles, and

FSI is 0.25, and the defects commencing from the pile head. For indeed the capacity of Pile 5 is fully mobilized. Nevertheless, in

each defective pile, the reduction in axial stiffness has been de- that case, the corresponding reduction in pile group stiffness is

rived from Fig. 20. only slightly more than 50%, demonstrating that the ability of the

group to redistribute the loads restricts the loss of stiffness.

Fig. 21. Influence of structural defects on pile head stiffness— Fig. 23. Effect of structurally defective piles on axial group stiffness

experiment versus theory 关adapted from Poulos 共1997兲兴

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 549

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 25. End bearing load-settlement relationships for piles on gravel

layer 关adapted from Woo and Moh 共1990兲兴

affected very significantly by the presence of a 25 mm layer of

slime at the pile tip. However, in the other two cases, the load-

settlement curves for the clean and “unclean” bases are quite

similar initially, and only separate significantly when the shaft

Fig. 24. Effect of structurally defective piles on lateral response of resistance is fully mobilized. Thereafter, large settlements are ex-

group under axial loading 关adapted from Poulos 共1999b兲兴 perienced by the piles with the unclean base. The deeper the pile,

the less significant is the effect of the unclean base on the load-

settlement behavior. This characteristic has also been observed

An important feature of group response with defective piles is

previously in relation to the effects of clay seams in rock below a

that, under vertical load, the group will deflect laterally and suffer

pile tip.

a rotation, with bending moments being developed at the pile

The latter two piles involved in the Woo and Moh study have

heads. Fig. 24 shows the computed maximum pile head moment,

been analyzed by the writer using the computer program PIES.

lateral deflection, and rotation as a function of the applied load

The presence of debris at the base has been simulated by a soft

level and the number of defective piles. It will be seen that, once

pile element at the base of the pile, with a Young’s modulus of 30

the applied load level exceeds about 0.35, substantial bending

MPa. The shaft friction and soil modulus values have been chosen

moments can be induced, perhaps exceeding the yield moment of

initially via judgment, with some later adjustment to obtain a

the piles. Significant lateral deflection and rotation are also devel-

better fit to the measured and calculated load-settlement curves

oped. The more asymmetric the location of the defective piles, the

for the piles with a clean base. The same parameters have then

more severe is the induced lateral response effects. For the cases

been used for the piles with the unclean base. Figs. 26 and 27

analyzed, the group with three defective piles 共pile numbers 1, 2,

show comparisons between the measured and calculated load-

and 4兲 appears to generate the most severe lateral response.

settlement curves. It can be seen that the analysis is capable of

Influence of Geotechnical Defects—Piles

with a “Soft Base”

Single Piles

A “soft base” at the toe of a bored pile is usually a result of debris

left from inadequate base cleaning during construction. Because

of its confinement by the surrounding soil, the debris is unlikely

to fail, but it will be expected to deform considerably. A very

instructive case history of the effects of inadequate base cleaning

has been presented by Woo and Moh 共1990兲. They have presented

load-settlement curves for three cases involving inadequate base

cleaning:

• End bearing piles on gravel;

• Piles about 32 m long through variable deposits, bearing in a

gravel layer which is underlain by clay; and

• Piles about 42 m long through variable deposits, bearing in a

fresh 共but fractured兲 sandstone.

The load-settlement curves measured for each of these three cases

are shown in Figs. 25–27. It can be seen from Fig. 25 that the Fig. 26. Effect of base cleanliness on pile performance 关adapted

load-settlement behavior of the piles bearing directly on gravel is from tests of Woo and Moh 共1990兲兴

550 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 28. Observed floor elevation changes over 30 day period

关adapted from Milligan 共1997兲兴

Fig. 27. Effect of base cleanliness on pile performance 关adapted two shear walls near one side of the building. Fig. 28 shows the

from tests of Woo and Moh 共1990兲兴 measured changes in basement floor elevations. Subsequent in-

vestigations showed that not all the caissons were founded on

bedrock, and that the concrete shafts and/or bells had become

identifying the effects of the base debris in increasing the pile contaminated with fill debris, as indicated in Fig. 29. The location

settlement after mobilization of the shaft resistance. of the largest settlements was where a significant amount of fill

The computed load-settlement curves for the geotechnically debris was found at the base of the pile, and the bell had a

defective piles in Figs. 26 and 27 are also consistent with some relatively small enlargement. The structure was subsequently

other field observations. For example, Thorburn and Thorburn demolished.

共1977兲 quote the example of an 18 m long, 600 mm diameter This case demonstrates the vital importance of proper con-

bored pile, which performed satisfactory under a test load of 1.16 struction techniques in bored pile construction to avoid imperfec-

times the required working load, but appeared to fail 共settle ex- tions which may ultimately lead to destruction of the structure

cessively兲 at 1.5 times the working load. It was found subse- that the piles were intended to support. It was also perhaps unfor-

quently that the base was resting on about 0.6 m of natural debris tunate that the structure and the pile caps were not more rigid, as

共small lumps of soft clay兲 which had fallen from the unlined there appeared to be little ability for load redistribution to occur in

portion of the bore, thus giving a soft base condition. this case, and the highly imperfect pile thus appeared to be unable

to transfer load on to less imperfect piles.

Pile Groups

Case History of Two Buildings in Hong Kong

Groups of piles in which some contain geotechnical imperfections

behave in a similar way to those with piles containing structural Construction of two adjoining residential high-rise blocks in Sha-

defects. While the failure of geotechnically defective piles is less tin, Hong Kong commenced in mid-1999. The 41-story blocks

abrupt than for those with structural defects, the overall group were each supported on 18 bored piles, 2.3 m in shaft diameter,

behavior is more forgiving because of the redundancy provided with a base belled out top of 3.8 m. Fig. 30 shows a plan of the

by the group. The consequences of having defective piles will two blocks 共denoted as Blocks D and E兲, while a typical geotech-

again depend on their location, and if the defective piles are con- nical profile for a section at the site is shown in Fig. 31. The piles

centrated in a particular part of the group, there may be a signifi-

cant rotation induced in the group, with consequent lateral deflec-

tions and induced moments in the piles.

An interesting case history of the consequences of having geo-

technically defective piles has been reported by Milligan 共1997兲.

During construction of a 13-story building, settlement of the

foundations led to cracking and severe distress of the partially

completed structure. The building was approximately rectangular

in shape 共15 m by 60 m in plan兲, with the structural loads carried

by shear walls down to drilled shaft 共caisson兲 foundations. The

shafts were 750 mm in diameter, and extended through mixed

clayey fill and dense glacial till to shale bedrock, the upper sur-

face of which was fractured and weathered. The bases of the

caissons were belled by hand to diameters ranging between 1 and

2 m. The caissons were backfilled with concrete and were

unlined.

Settlement was observed about 6 months after completion of

the caissons, and as the building height increased, so did the Fig. 29. Partial section showing details observed during investigation

settlements. The excessive settlement was concentrated in one or 关adapted from Milligan 共1997兲兴

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 551

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 30. Foundation plan for high-rise buildings

were designed as end bearing piles, to be founded in Grade II 2000. The conclusions of the independent consultant carrying out

共slightly weathered兲 granite, at a depth ranging between about 35 the coring and the assessment of pile conditions are summarized

and 46 m. in Table 3.

When the buildings had reached the 17th story, a program of It can be seen that only four of the total of 36 piles were

settlement monitoring was commenced on the buildings, follow- compliant with the construction specifications which required

ing concerns about pile construction practices with some other founding on Grade II rock. The pile lengths were up to 14 m short

projects in Hong Kong. Two to three months later, it was ob- of bedrock level. In addition to the geotechnical deficiencies, six

served that both buildings were settling unevenly, with each block of the concrete cores that were taken from the piles and tested

tending to tilt as a rigid body. A program of investigatory coring showed low uniaxial compressive strengths, ranging between 22.5

through the bored piles was subsequently instigated in December and 2 MPa, compared to the nominal strength of 35 MPa.

1999, and this program revealed a number of deficiencies in both Fig. 32 shows typical time-settlement readings for one of the

the pile length and the founding conditions at the base of the blocks, the locations being as shown in Fig. 30. It is interesting to

piles, and construction was halted at the 34th floor, very early in note that the coring investigation works caused a temporary ac-

Fig. 31. Geotechnical profile along Section 1-1

552 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

Table 3. Summary of Inferred Pile Founding Conditions from Coring

Number of piles

Pile founding condition Block D Block E

Pile founded on Grade II rock 3 1

Thin sediment layer between pile base and rock 5 1

Sediment below pile base, underlain by inferior rock 5 4

Pile founded on inferior rock, without sediments 1 12

Thick layer of soft material below pile base 4 0

celeration in settlement of the buildings, and was an important

factor in the decision to suspend construction. Indeed, about 30

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

mm of additional settlement at Block E was attributed to the

coring process.

Fig. 32. Time-settlement records for four typical points—Block E

Because of concerns about the integrity of the existing foun-

dation system, extensive investigations were carried out by sev-

eral parties to assess whether it would be feasible to carry out

remedial work to the foundation system so that construction could mencement of settlement measurements after the 17th floor

be completed with an adequate level of confidence in the integrity had been reached. In this calibration, the observed additional

of the foundations. The writer carried out one of these investiga- settlements due to the coring process were excluded from the

tions, and took the following approach. total settlements, so that only settlements due to the building

• Geotechnical models were developed for each of the 36 piles, load were considered.

based on the site investigation data and the information de- • Reasonable fits between measured and calculated uneven

rived from the coring investigation. settlement were obtained, using soil modulus values of be-

• Analyses were carried out, using the program PIGS, to com- tween 2.8N and 4.2N MPa, where N = SPT value. Fig. 33

pute the relationship between building tilt and building height. shows the computed and measured settlements from Floors 17

The interaction between the two buildings was considered, and to 34, for Block E, and for three sections.

the geotechnical properties of the various layers were adjusted • Using the fitted model, PIGS was then used to investigate a

关according to the standard penetration test 共SPT兲 values兴 to number of alternative future options, including:

obtain a fit with the measured increases in tilt since the com- 1. Construction with the existing foundation system.

Fig. 33. Measured and calculated settlements—Block E

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005 / 553

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

2. Construction with up to 66 new steel H-piles installed in existing structure and foundation system are likely to be

prebored holes, and extending 9 m into the Grade II granite. more immediate and severe than with a “greenfield” site.

An extended pile cap would be constructed to link the old For these reasons, it is worthwhile to give some attention to the

and new foundation elements, and this would require up to 5 problems of investigation, design, and construction within an ex-

m excavation and some dewatering. isting foundation system, and to examine in some detail the pos-

3. Truncation of the buildings so that the existing foundation sible consequences of inadequate control of the resulting ground

system would be adequate without any further enhancement. movements.

It was found that the first option was not feasible. In principle,

the second option, involving enhancement of the foundation sys-

Investigation Issues

tem with H-piles, would provide a satisfactory solution. However,

the risks involved in carrying out the remedial foundation works Investigations to identify possible causes of foundation perfor-

beneath heavily loaded buildings were considered to be unaccept- mance irregularity may involve some form of drilling adjacent to,

able, particularly in view of the potential for significant ground or through, the existing pile foundations. Both forms of drilling

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

movements to be generated during the enhancement works. Trun- may have deleterious effects on the piles being investigated. As

cation of the buildings was assessed to be technically feasible, but previously mentioned, the drilling of holes adjacent to piles will

was not considered to be economically feasible by the owner generally cause vertical and lateral ground movements and these

because of the stigma of having two lower-rise buildings 共12 or will act upon the nearby piles, inducing additional stresses and

13 stories high兲 within a larger group of much taller buildings. movements. These effects may be particularly severe if the

In a decision that was widely publicized in Hong Kong, the ground is highly stressed. Coring through the pile itself may also

decision was taken to demolish both buildings, and this was car- create difficulties for the existing foundation, via the following

ried out in 2001–2002. This was therefore a rather extreme case mechanisms:

of the consequences of a series of construction imperfections, • Unbalanced fluid pressures inside the core hole and outside the

leading to three undesirable conditions: pile. These may cause loosening or even piping of the soil

• Piles with a soft base; beneath the pile toe when “breakthrough” is achieved and the

• Piles with variable founding conditions; and underlying soil is soft or loose. In turn, the settlement of the

• Piles of variable length within a group. pile may then be exacerbated.

• SPT testing of the soil below the pile base may cause further

disturbance if it is not carried out carefully, and the SPT rods

Coping with the Consequences of Imperfections are withdrawn too quickly, thus causing a suction within the

during and after Construction soil surrounding the hole.

Thus the investigation process itself may help to accentuate the

problem being investigated. Such a mechanism was thought to

Introduction have contributed to the additional settlements of up to 30 mm

It would appear essential that monitoring of the foundation be- during the previously mentioned investigation of defective bored

havior be carried out during and after construction, so that any piles in a high-rise building in Hong Kong. Clearly, it is impera-

irregularities can be identified at the earliest possible opportunity, tive that such possible “side effects” of the investigation are an-

and appropriate investigation works, and if necessary remedial ticipated and that appropriate cautionary measures are adopted to

works, can be undertaken. The later problems are uncovered, the minimize the negative impact of these side effects.

more difficult and costly remedial action is likely to be.

In new foundation construction, there is usually relatively un- Design Issues

impeded access to the site and to the areas in which the new

foundation system is to be constructed. However, the environment There are at least three key design issues that may need to be

around or within an existing foundation system which is being addressed when designing remedial works for pile foundations

investigated and/or upgraded may pose several constraints and which have been demonstrated to be inadequate or are not per-

problems, and the following characteristics can be anticipated: forming to expectations:

1. Access to the area may be very difficult and may limit the • Correction of uneven settlements, if the foundation has already

range of construction methods that can be employed; undergone excessive tilting or differential settlement, or is

2. The ground will often be highly stressed, and thus changes in likely to do so during or after the remedial works;

the stress regime due to investigation or construction may • Design of remedial or enhancement works, which may include

result in larger ground movements than would be the case in repair of defective piles, the installation of additional piling, or

a “greenfield” situation; extension of the pile cap to obtain additional capacity and

3. The foundation system will generally be loaded, and it is stiffness; and

therefore necessary to try and assess these existing loads so • Consideration of the load sharing between the existing piles

that a more realistic design can be carried out. One cannot and the additional foundation elements. It is possible that ex-

assume 共as so often happens in new design兲 that the founda- cessive load may be carried by the additional elements, unless

tion system is stress-free and load-free; the design can incorporate means of controlling the distribu-

4. Existing piles will generally be subjected to some measure of tion of loads in the upgraded system.

restraint from the building which they are supporting, via These issues are discussed in more detail below.

attachment to pile caps and the overall foundation system;

5. Strict control of investigation and construction processes are Correction of Uneven Settlement

likely to be more critical, but more difficult to achieve, than

with “greenfield” situations; and Methods of correcting uneven settlements of buildings can be

6. The consequences of uncontrolled ground movements on the divided broadly into two categories:

554 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / MAY 2005

J. Geotech. Geoenviron. Eng. 2005.131:538-563.

1. “Hard” methods, which rely on the application of some form

of direct force to the building; and

2. “Soft” methods, which rely on processes which produce cor-

rective foundation movements by inducing appropriate

ground movements.

In both cases, the treatment can be carried out to lower the build-

ing on the “high” side, or alternatively, to raise the low side of the

building. In both cases, the treatment may be accompanied by

some form of foundation strengthening or remediation on the

“low” side. Amirsoleymani 共1991a,b兲 lists six different methods

that have been used to reduce or eliminate differential settlement

and tilting. Three methods involve lifting of the low side of the

structure, while three involve lowering of the high side.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 01/22/15. Copyright ASCE. For personal use only; all rights reserved.

“Hard” Methods

1. Application of Force by Anchor Stressing. This method in-

volves the installation of a series of strategically located an-

chors within the foundation system. The anchors are grouted

into a suitable hard stratum at depth below the building. The

anchors are then stressed 共typically to 60–75% of their ulti- Fig. 34. Details of soil extraction scheme for grain silo on mat

mate capacity兲 to obtain a corrective tilt to the foundation. In foundation 关adapted from Amirsoleymani 共1991b兲兴

some cases, repeated stressing and destressing may have a

beneficial effect in developing additional corrective tilting.

2. Application of Additional Loading. This method involves the plumb position. Amirsoleymani 共1991a兲 describes the use of

application of additional loading on the high side of the foun- mechanical jacking to correct the settlement of a storage

dation by water or other means. There are often limitations tank, and the use of chemical grouting to restore a piled

on the amount of loading that can be applied because of foundation that tilted and failed after a deep excavation

height limitations within the structure, and the limitations nearby caused piping of sand near the pile tips. An expansive

that may be imposed by the limited strength of the structure admixture was used in the grout to promote uplift of the

itself. columns, which were raised by 28 mm. Maffei et al. 共2001兲

3. Cutting of Piles. This method involves the cutting of some describe a case of a tall building in Sao Paulo in which the

piles supporting the high side of the building to promote load uneven settlement causing a tilt of 2.2° was corrected by

transfer to other piles on the high side and hence promote constructing a new pile foundation and jacking the low side

beneficial settlement. When the process has been completed up against these piles to transfer load from the old to the new

and the settlements have ceased, the piles may be reattached foundation system.

so that they may carry part of the future loadings. The cutting 6. Fracture Grouting. This method involves the use of a grout

of the piles is in itself a process that requires considerable under controlled high pressure to fracture the soil and cause

care so that the cut pile is not destroyed in the process. A uplift of the foundation. Amirsoleymani 共1991a兲 has de-

method that has been developed in Hong Kong involves the scribed a case of a five-story warehouse in which 210 mm of

partial cutting of both sides of the pile, the placement of differential settlement was corrected by hydraulic fracturing

jacks to support the upper and lower parts of the pile and through 24 tubes installed into rock below the foundation.

carry the load existing in the pile, and then the cutting away Cement lenses 50–100 mm in thickness were found to have

of the remaining central portion of the pile which is freed of been formed by the fracture grouting.

load prior to the cutting by the jacks. This process has been

used in conjunction with anchor stressing in correcting a

“Soft” Methods

building in Hong Kong. Unfortunately, because of legal con-

straints, it is not possible to present details of this case. 1. Soil Extraction. In this method, soil is excavated from be-

4. Jetting of the Soil Beneath Pile Tips. There have been anec- neath or between the piles on the high side. This process