Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Brochure en

Caricato da

Filippo MeucciDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Brochure en

Caricato da

Filippo MeucciCopyright:

Formati disponibili

Who is behind LEITWIND

LEITWIND is part of the LEITNER TECHNOLOGIES group, a name which has been a synonym for high perform-

ance technology of ropeways and snow groomers since 1888.

LEITNER TECHNOLOGIES employs more than 2400 people worldwide at its plants in Italy, France, India and

North America, as well as in 70 sales and service points. Since 2000, continuous research and development

coupled with a high degree of technological competence have enabled LEITWIND to take advantage of synergies

between the ropeway and the wind turbines technologies. The resulting turbine is an integration of a direct drive

generator into a wind turbine. In 2003, Leitner produced and installed its first wind turbine prototypes that incor-

porated this revolutionary technology. Starting in 2007, Leitwind began serial production of wind turbines. For

LEITNER’s engineers, the search for quality and simplicity is a primary objective in all of the group’s businesses.

Because simplicity combined with quality guarantees highest reliability and profitability.

Since the company’s inception LEITNER TECHNOLOGIES’s success is based on quality and leading edge technology.

LEITWIND makes the difference

Gearless direct drive

Fewer mechanical and electrical losses greater efficiency

Low maintenance maximum availability

Lower rpms of individual components less wear and tear

Reduced acoustic emission less environmental impact

Synchronous generator with permanent magnets

Self-induced maximum power yield

Simple installation short erection time

Segmented design high reliability

Modular design

Reduced weight of the main components low transportation and installation costs

Components easily accessible low maintenance expense

Product overview LEITWIND SPA LEITWIND GmbH

TA PPE I N E R.

Via Brennero 34 I-39049 Vipiteno (BZ) Perlhofgasse 2 A-2372 Gießhübl

Tel. +39 0472 722111 Fax +39 0472 722586 Tel. +43 2236 866270 Fax +43 2236 893713 55

info@leitwind.com www.leitwind.com info@leitwind.com www.leitwind.com

LTW70 LTW77 LTW80

Cut in wind speed (m/s) 3,0 3,0 3,0

Cut out wind speed (m/s) 25 25 25

Rated power (kW) 2000 (1700) 1500 1500

Hub height (m) 60 61,5 / 65 / 80 60 / 80 / 100

Wind class IA IIA IIA

Synchronous generator with permanent magnet

The generator is the wind turbine’s core compo-

nent. The rotor, hub and generator are directly con-

nected to each other.

Driven by the wind

LEITWIND – Technology sets new standards

The gearless LEITWIND turbine impresses with its simplicity and technological innovation. Research,

development, production, erection and customer support ensure the perfect product.

Efficiency is maximized in every range of performance as mechanical and electrical losses are minimized

thanks to the patented direct drive with a permanent induction synchronous generator. A high degree of avail-

ability and a minimum wear are ensured because of the low rotational speed (rpm) of the reduced number of

high quality rotating parts. The end result is an efficient and powerful wind turbine with low-service-costs, high

durability and maximized profitability.

The control system, developed specifically for the LEITWIND turbine, uses variable rpms and harmonious

pitch control to optimize production in partial and full load ranges.

The frequency converter specifically manufactured for the LEITWIND turbines ensures a high degree of grid

compatibility. This feature allows LEITWIND equipment to operate even within weak and unstable grids.

The compact and modular design of LEITWIND turbines enables fast installations even in locations with

difficult access.

Hub component group Yaw system for wind direction adjustment

The hub incorporates the motors and the The wind direction adjustment is automatically

electronics for the pitch system which con- monitored by the turbine’s control system, pro-

trols each blade individually. viding best performance.

Leitwind technology

Direct drive Generator Cooling

The hub is directly connected to the generator. This The induction performance is completely available

design eliminates the gearbox, which is one of the as energy yield, which is especially advantageous in

weak points of traditional wind power turbines. Due the partial load range.

to less friction the wind turbine is more efficient at

low wind speeds and thus, suitable for low-density Accessibility

wind power areas. The unique hollow rotor shaft allows safe and easy

access for service and maintenance of all parts.

Fewer Rotating Parts

The reduction in the number of rotating parts results in No External Transformer Station Required

higher reliability. The parts rotate slowly – in compari- External structures are unnecessary, since all the

son, the traditional wind turbine rotates just as much power electronics and the transformer can be inte-

in a few months as a LEITWIND turbine in 20 years. grated in the tower base.

Modular Concept Minimized Maintenance and Service

LEITWIND turbines are designed based on a modular The reduction of moving parts and ease of main-

concept that ensures rapid erection and low trans- tenance result in lower operating and maintenance

portation and installation costs. The generator is part costs. Modular design allows replacing of parts of

of the load-bearing structure and contributes to the rotor without having to dismantle the entire gen-

economical weight management. erator.

Innovative Generator High reliability and performance

LEITWIND turbines have a multi-pole synchronous The confluence of proven technology and innovative

generator with permanent magnets. The optimum de- solutions leads to an extremely reliable turbine with

sign makes the LEITWIND turbine most economical. outstanding energy yield.

Greater Power Yield

The use of permanent magnets eliminates the need

for electrical excitation of the generator coils and

improves the turbines’ yield, especially in the partial

load range.

Selected references

Malles, Italy Uthumalai, India Salzstiegl, Austria Mogilishte, Bulgaria

2003/2006 2007 2007 2007/2008

LTW62 IEC IA, LTW77 IEC IIA 2 LTW77 1.5 MW IEC IIA h65 LTW77 1.35 MW IEC IIA h65 3 LTW77 1.5MW IEC IIA h65

Badia Calavena, Italy Montecatini, Italy Vulganello, Italy Pellafol, France

2008 2008/2009 2009 2009

LTW77 1.5 MW IEC IIA h65 6 LTW77 1.5MW IEC IIA h61.5 2 LTW77 1.0 MW IEC IIA h65 2 LTW77 1.5MW IEC IIA h65

Kalluthu, India Grouse Mountain, Canada Kavarna, Bulgaria Kavarna I, Bulgaria

2009/2010 2009 2009/2010 2009

12 LTW77 1.5 MW IEC IIA h65 LTW77 1.5 MW IEC IIA h65 2 LTW80 1.5 MW IEC IIA h80 6 LTW77 1.5 MW IEC IIA h80

Kottai, India Chettikurichi, India Puglia, Italy Kavarna II, Bulgaria

2009/2010 2010 2010 2010

3 LTW77 1.5 MW IEC IIA h65 LTW80 1.8 MW IEC IIA h80 15 LTW 77 1.0 MW IEC IIA h65 6 LTW77 1.5 MW IEC IIA h80

LEITWIND SPA Via Brennero, 34 I-39049 Vipiteno (BZ), Italy Tel. +39 0472 722111 www.leitwind.com

Potrebbero piacerti anche

- Practical Industrial Data Communications: Best Practice TechniquesDa EverandPractical Industrial Data Communications: Best Practice TechniquesValutazione: 5 su 5 stelle5/5 (2)

- Vensys Bro en 190705 RZ WebDocumento36 pagineVensys Bro en 190705 RZ Webمصطفى محمودNessuna valutazione finora

- Suzlon S88 2.1MW Product Brochure PDFDocumento4 pagineSuzlon S88 2.1MW Product Brochure PDFvineeshNessuna valutazione finora

- Its Flame Scanner v1 1Documento12 pagineIts Flame Scanner v1 1foroNessuna valutazione finora

- Energi Entelemi Indonesia - Served by The Excellent - 2022Documento17 pagineEnergi Entelemi Indonesia - Served by The Excellent - 2022Bram AzaryaNessuna valutazione finora

- Three-Phase Induction Motors Empowering The Future: Catalog 03-2013Documento180 pagineThree-Phase Induction Motors Empowering The Future: Catalog 03-2013hardik033Nessuna valutazione finora

- Welding Together: General CatalogueDocumento146 pagineWelding Together: General CatalogueYeison E. MoraNessuna valutazione finora

- Luminaires-VERTECO 3Documento10 pagineLuminaires-VERTECO 3bcyt00Nessuna valutazione finora

- Special Promo 35 - EshopDocumento16 pagineSpecial Promo 35 - EshopkenywkNessuna valutazione finora

- RM AirSeT - NRJCAT20014EN - 0224 PDFDocumento89 pagineRM AirSeT - NRJCAT20014EN - 0224 PDFPaul TurcuNessuna valutazione finora

- EN Eng TandS 0710 PDFDocumento33 pagineEN Eng TandS 0710 PDFAkhmad ZaenudinNessuna valutazione finora

- Rotoweld BrochureDocumento4 pagineRotoweld BrochuresaudimanNessuna valutazione finora

- H2 CatalogDocumento9 pagineH2 CatalogBinChiShikiNessuna valutazione finora

- Trimo 2949 Trimo Ecosolar PVDocumento8 pagineTrimo 2949 Trimo Ecosolar PVBogdan RuxandaNessuna valutazione finora

- Enercon Wind TurbinesDocumento33 pagineEnercon Wind Turbinesismail özdamarNessuna valutazione finora

- BR RLM EVO Screen EN PDFDocumento4 pagineBR RLM EVO Screen EN PDFAngga HardiyantomoNessuna valutazione finora

- Electricity With SimplicityDocumento14 pagineElectricity With SimplicityAman SharmaNessuna valutazione finora

- Jq1530ap 2kw 교체식 평판 레이저 커팅기 사양서 to Vte Ketoan - JqlaserDocumento7 pagineJq1530ap 2kw 교체식 평판 레이저 커팅기 사양서 to Vte Ketoan - Jqlasercons vesNessuna valutazione finora

- Air Underground Fan Technology - BrochureDocumento6 pagineAir Underground Fan Technology - BrochureMINETEKNessuna valutazione finora

- 2018 MULTI V CatalogueDocumento146 pagine2018 MULTI V CatalogueSaviour UdoNessuna valutazione finora

- Teknogen Heat Recovery EN PDFDocumento11 pagineTeknogen Heat Recovery EN PDFsami rustomNessuna valutazione finora

- Wireless Remote Control For Eot Crane Using Avr Micro Controller IJERTCONV5IS20024 PDFDocumento4 pagineWireless Remote Control For Eot Crane Using Avr Micro Controller IJERTCONV5IS20024 PDFsujit kcNessuna valutazione finora

- OptiX RTN 900 Product Description PDFDocumento92 pagineOptiX RTN 900 Product Description PDFimeldoNessuna valutazione finora

- DigiTRON eDocumento60 pagineDigiTRON eRich FurtNessuna valutazione finora

- Latera Acute L Thema Manual Tcnico ENDocumento31 pagineLatera Acute L Thema Manual Tcnico ENwidar.0111Nessuna valutazione finora

- HSC Series: - Rotary Screw Air CompressorsDocumento4 pagineHSC Series: - Rotary Screw Air CompressorsMAZENNessuna valutazione finora

- Taiko ProductsDocumento7 pagineTaiko ProductsAntonio AvilesNessuna valutazione finora

- Petrotec: For General Contracting & Renewable EnergyDocumento31 paginePetrotec: For General Contracting & Renewable Energyhadeer fahmyNessuna valutazione finora

- Flame Scanner Developed by ITS: Reliability Is A Matter of QualityDocumento16 pagineFlame Scanner Developed by ITS: Reliability Is A Matter of QualityQuick sickNessuna valutazione finora

- Tecs HF 0251 1954 200910 GB PDFDocumento43 pagineTecs HF 0251 1954 200910 GB PDFLeuce LaviniuNessuna valutazione finora

- Telecom Energy BrochureDocumento18 pagineTelecom Energy BrochureahmedNessuna valutazione finora

- Flame Scanner Developed by ITS: Reliability Is A Matter of QualityDocumento16 pagineFlame Scanner Developed by ITS: Reliability Is A Matter of QualityMauricio GuanellaNessuna valutazione finora

- GV-300W Greef Wind Turbine Catalgouev1Documento8 pagineGV-300W Greef Wind Turbine Catalgouev1JOE FUNGNessuna valutazione finora

- V80-2.0 MW - VestasDocumento16 pagineV80-2.0 MW - Vestasjamesr277272Nessuna valutazione finora

- Motor IspDocumento136 pagineMotor IspKnjigescribd100% (1)

- Electrospinning From The Laboratory: Rotary-Sliding Power Controlled Collector For Tubular DepositionsDocumento5 pagineElectrospinning From The Laboratory: Rotary-Sliding Power Controlled Collector For Tubular Depositionsstefano.linari4029Nessuna valutazione finora

- Introduction To Data Center v1.0Documento41 pagineIntroduction To Data Center v1.0Yoga SamNessuna valutazione finora

- HYOSUNG Wind Turbine System: Wind Energy Business DivisionDocumento6 pagineHYOSUNG Wind Turbine System: Wind Energy Business DivisionE. Javier Fernandez RodriguezNessuna valutazione finora

- 2 1 SecoGear PDFDocumento64 pagine2 1 SecoGear PDFMuhammad NomanNessuna valutazione finora

- DigiTRON July 2013 PDFDocumento60 pagineDigiTRON July 2013 PDFZhiyong ShanNessuna valutazione finora

- Descritivo TDocumento42 pagineDescritivo TPankaj Singh RawatNessuna valutazione finora

- Prestta P822601 P822602 Standard Cellular Octa Band 20160904Documento3 paginePrestta P822601 P822602 Standard Cellular Octa Band 20160904AjaySoniNessuna valutazione finora

- Shortform DTS0262Documento84 pagineShortform DTS0262gulatimanish1985Nessuna valutazione finora

- Prestta Wlan Embedded Antenna: Key Benefits Design AdvantagesDocumento2 paginePrestta Wlan Embedded Antenna: Key Benefits Design AdvantagesShyam RamanathNessuna valutazione finora

- Mitsubishi Power, Ltd. - Te InformationDocumento2 pagineMitsubishi Power, Ltd. - Te InformationKR PANessuna valutazione finora

- P3 NRJCAT17764EN v16 072019 PDFDocumento122 pagineP3 NRJCAT17764EN v16 072019 PDFHoang Bao ThaiNessuna valutazione finora

- E Line - CA - EN - 052015Documento27 pagineE Line - CA - EN - 052015sydifiaNessuna valutazione finora

- Wind Turbines: Type CertificateDocumento14 pagineWind Turbines: Type CertificatevineeshNessuna valutazione finora

- Pill AeratorDocumento20 paginePill AeratorAhmed NahrawyNessuna valutazione finora

- VRV A Didva1808bDocumento14 pagineVRV A Didva1808bOkta AdityaNessuna valutazione finora

- DESCRIPCIODocumento2 pagineDESCRIPCIOAldo DanteNessuna valutazione finora

- Limit-Torque BroucherDocumento16 pagineLimit-Torque BroucherChakravarthi NagaNessuna valutazione finora

- CEA Katalog2014Documento146 pagineCEA Katalog2014Сања БанковићNessuna valutazione finora

- VRV General KnowledgeDocumento55 pagineVRV General Knowledgekikiichtiar03Nessuna valutazione finora

- Motors and Inverters For Environmentally Friendly Industrial EquipmentDocumento5 pagineMotors and Inverters For Environmentally Friendly Industrial EquipmentquycocNessuna valutazione finora

- Wind Power Sealing Solutions: Trelleborg Se Aling SolutionsDocumento13 pagineWind Power Sealing Solutions: Trelleborg Se Aling SolutionsStephenNessuna valutazione finora

- Ultrasonic Welding MachinesDocumento14 pagineUltrasonic Welding MachinesKostya TytelmaierNessuna valutazione finora

- DCS1800 Bandwidth Adjustable Repeater User Manual (ATDS37F)Documento39 pagineDCS1800 Bandwidth Adjustable Repeater User Manual (ATDS37F)guns1976Nessuna valutazione finora

- Steam Sterilizers Matachana S1000Documento12 pagineSteam Sterilizers Matachana S1000Francisco PinedaNessuna valutazione finora

- Turbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsDocumento4 pagineTurbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsManoj SinghNessuna valutazione finora

- Lecture Notes in Computer Science 4404: Editorial BoardDocumento163 pagineLecture Notes in Computer Science 4404: Editorial BoardFilippo MeucciNessuna valutazione finora

- Pietro Cattaneo: Two Wedding PiecesDocumento5 paginePietro Cattaneo: Two Wedding PiecesFilippo MeucciNessuna valutazione finora

- Lecture Notes in Computer Science 4404: Editorial BoardDocumento163 pagineLecture Notes in Computer Science 4404: Editorial BoardFilippo MeucciNessuna valutazione finora

- TR 42-2015 - PreviewDocumento12 pagineTR 42-2015 - PreviewFilippo MeucciNessuna valutazione finora

- Salary Survey 2019 Europe PDFDocumento197 pagineSalary Survey 2019 Europe PDFFilippo MeucciNessuna valutazione finora

- INRIX TrafficScorecard Global EN LRDocumento1 paginaINRIX TrafficScorecard Global EN LRFilippo MeucciNessuna valutazione finora

- Geothermal0149 PDFDocumento10 pagineGeothermal0149 PDFFilippo MeucciNessuna valutazione finora

- MIDI Interfaces For Organ Pedals and KeyboardsDocumento15 pagineMIDI Interfaces For Organ Pedals and KeyboardsFilippo MeucciNessuna valutazione finora

- LFBP1Documento4 pagineLFBP1VanhoNessuna valutazione finora

- Pri In25k Legenda AllagateDocumento1 paginaPri In25k Legenda AllagateFilippo MeucciNessuna valutazione finora

- Brochure enDocumento9 pagineBrochure enFilippo MeucciNessuna valutazione finora

- The CF Engine Overview: Vehicle Engine Type Indication Performance Torque Emission Level Daf Cf65Documento2 pagineThe CF Engine Overview: Vehicle Engine Type Indication Performance Torque Emission Level Daf Cf65James Kuah100% (1)

- Cooper Surge ArrestorDocumento10 pagineCooper Surge ArrestoripraoNessuna valutazione finora

- Full AssemblyDocumento1 paginaFull AssemblybenNessuna valutazione finora

- Side ToneDocumento3 pagineSide Tonewkkchamara100% (1)

- 10 Ats8w, 11W PDFDocumento4 pagine10 Ats8w, 11W PDFhanief sasongkoNessuna valutazione finora

- High Resolution Indoor & Outdoor LED Display Screens - Di ImpexDocumento11 pagineHigh Resolution Indoor & Outdoor LED Display Screens - Di Impexsmit4diimpexNessuna valutazione finora

- Landers PMS Cost Proposalrev01 - Electric Pro 04apr2023Documento1 paginaLanders PMS Cost Proposalrev01 - Electric Pro 04apr2023IVM PhilsNessuna valutazione finora

- Electrical SafetyDocumento79 pagineElectrical SafetyVishram MaikooNessuna valutazione finora

- Engineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemDocumento7 pagineEngineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemLouis ClarkNessuna valutazione finora

- 1111 Midterm一乙Documento5 pagine1111 Midterm一乙joseph930402Nessuna valutazione finora

- Walker Service Manual MB MC MT MS MW MTDocumento256 pagineWalker Service Manual MB MC MT MS MW MTLoganNessuna valutazione finora

- Laptop HistoryDocumento1 paginaLaptop HistoryEugene DomantayNessuna valutazione finora

- Manual Asus k8nDocumento78 pagineManual Asus k8nAdrianMoureNessuna valutazione finora

- SDG25S-150S-6A Series Service ManualDocumento109 pagineSDG25S-150S-6A Series Service ManualGoolshan BhugalooNessuna valutazione finora

- Solaron Price ListDocumento9 pagineSolaron Price ListShem Cauley CabanayanNessuna valutazione finora

- 270Pk Service Guidelines: Before Getting StartedDocumento6 pagine270Pk Service Guidelines: Before Getting StartedMisael CastroNessuna valutazione finora

- Flusarc-36 Op Main (En)Documento32 pagineFlusarc-36 Op Main (En)George AsuncionNessuna valutazione finora

- 13-2-117 Service BulletinDocumento6 pagine13-2-117 Service BulletinRidwanNessuna valutazione finora

- Automation: PLC S7 1200 Training PanelDocumento1 paginaAutomation: PLC S7 1200 Training PanelLulzim MulliqiNessuna valutazione finora

- Powervault Me4 DGDocumento107 paginePowervault Me4 DGbrayerly143Nessuna valutazione finora

- Memory Design: SOC and Board-Based SystemsDocumento48 pagineMemory Design: SOC and Board-Based SystemsSathiyaSeelaNessuna valutazione finora

- Grundfos Data Booklet: Submersible Pumps, Motors and Accessories 50 HZDocumento7 pagineGrundfos Data Booklet: Submersible Pumps, Motors and Accessories 50 HZsales3 iaescoNessuna valutazione finora

- Design Thinking Fundamental and Its Critical Role in Car DesigningDocumento6 pagineDesign Thinking Fundamental and Its Critical Role in Car DesigningSumit KashyapNessuna valutazione finora

- Bs 6004 BasecDocumento2 pagineBs 6004 BasecMOHAMMED. HAKAMINessuna valutazione finora

- ABB Presentation On Transformer ProtectionDocumento51 pagineABB Presentation On Transformer ProtectionKrishnakant Jashnani100% (1)

- Alert Service Bulletin: EmergencyDocumento13 pagineAlert Service Bulletin: EmergencyRaymond ZamoraNessuna valutazione finora

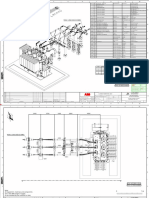

- 26148-220-V1B-EVC0-00088 (003) Patio StatcomDocumento5 pagine26148-220-V1B-EVC0-00088 (003) Patio StatcomDomingo esteban perez ceballoNessuna valutazione finora

- Subaru Forester Service Manual PDFDocumento3.548 pagineSubaru Forester Service Manual PDFNick Nickart100% (7)

- C-Lift® Chain Pulley BlocksDocumento2 pagineC-Lift® Chain Pulley BlocksVarun ShahNessuna valutazione finora

- ESG2002 ControllerDocumento15 pagineESG2002 ControllerPedro Perez La Rosa100% (1)