Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Internal Audit Checklist of Scrap Material

Caricato da

Vijay Kumar VaranasiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Internal Audit Checklist of Scrap Material

Caricato da

Vijay Kumar VaranasiCopyright:

Formati disponibili

Internal Audit Checklist of Scrap Material

Details

Written by Super User

Category: Uncategorised (/index.php)

C Published: 31 August 2013

< Hits: 43792

· SCRAP MATERIAL

· Ensure that a separate space / scrap yard is earmarked for keeping the scrap material. The scrap yard should have an

enclosure and a gate with a lock and key.

· Ensure that a proper record is kept of receipts, issues, opening and the closing balances quantity of each item of scrap in

the scrap yard

· Check that proper slips are kept at the point of generation of scrap and at the receiving end ie the scrap yard. At the

generation point(s) the output / production / scrap generation slip should be made in 2 copies giving details of the item of

scrap and the Qty of scrap.

· The weighment / measurement / counting can take place either at the point(s) of generation or at the scrap yard.

However, the scrap generation slip should contain the details of the quantity. The slips should have a serial control and

should be authorised by a responsible person. The scrap yard should receive the material on the basis of slip and enter

the receipt in the scrap register. Weighment should be carried out at the scrap yard if not already made at the production

floor. The weighment should be carried out in the presence of a person each from the scrap yard and the production.

Thus the scrap yard entries for receipt of scrap should be made on the basis of generation slips only. The issues entries

should be made on the basis of sales invoices raised on customers / issue slips for consumption within the plant.

· It should be ensured that the entries in respect of receipts and issues in the Scrap Stock Register are made on the basis

of generation slips / Sales invoices / issues slips.

· The generation slips / Sales invoices / issue slips should be authorised by a responsible person.

· Scrap Generation points should be identified and a booklet of generation slips with a serial control given at each

generation point. The scrap yard person should sign on one copy of the slip as an acknowledgement of having received

the scrap qty as given in the slip and return the slip back to the generation point. The second copy of the slip is to be

retained at the scrap yard.

· For sale of scrap ensure that a comparative chart of offers / quotations is prepared and the Sales order is made in the

name of the best quoted party. All the offers / quotations should be properly evaluated.

· Scrap sale should be effected on spot payment terms - cash / DDs at the time of delivery. Ensure that full amount is

collected from the customer before the material is allowed to be lifted.

· Ensure that Sales Tax / excise duty is properly charged in the Sales Invoice.

· Ensure that no debit balances appear in the Sundry Debtors ledger in respect of scrap customers.

· Ensure proper counting / weighment / measurement of scrap at the Scrap generation point(s) / Scrap yard.

· The Scrap Stock Register should be kept updated at all times.

· A gate pass should be issued at the time of despatch of material from the Scrap Yard and the gate pass should then be

checked at the exit gate by the security.

· A periodical physical verification of scrap stock in scrap yard should be made and the physical Qty tallied with the book

quantity. The discrepancies, if any should be reported.

· The total scrap generation as per the Scrap Stock Register should be tallied with the quantity of scrap generation of

various types as shown by the costing data. Comment if any difference / discrepancy is observed.

Potrebbero piacerti anche

- ScrapDocumento2 pagineScrapAnjana AvoodaiappanNessuna valutazione finora

- Vendor Registration FormDocumento3 pagineVendor Registration FormSristhi RustagiNessuna valutazione finora

- Flowchart of Work Flow Document For A Manufacturing CompanyDocumento2 pagineFlowchart of Work Flow Document For A Manufacturing CompanyNicasio AquinoNessuna valutazione finora

- Store ProcessDocumento5 pagineStore ProcessGAMALAT ELSAYED100% (1)

- .0 Inspection of Input MaterialsDocumento22 pagine.0 Inspection of Input MaterialsSPH PURCHASENessuna valutazione finora

- Stock Management PolicyDocumento7 pagineStock Management PolicySatish Pareek100% (1)

- Warehouse Rack Inspection ChecklistDocumento1 paginaWarehouse Rack Inspection ChecklistWaqasNessuna valutazione finora

- Stock Verification Groups in Ordnance FactoriesDocumento10 pagineStock Verification Groups in Ordnance FactoriescomplexnoNessuna valutazione finora

- Sop For SopDocumento11 pagineSop For SopMorsad AnamNessuna valutazione finora

- T-ENG CardDocumento14 pagineT-ENG CardViswaChaitanya NandigamNessuna valutazione finora

- AV-ST-SOP-003 Scrap Disposal From WarehouseDocumento2 pagineAV-ST-SOP-003 Scrap Disposal From WarehouseGadismuNessuna valutazione finora

- Physical Stock Taking ReportDocumento2 paginePhysical Stock Taking ReportvelNessuna valutazione finora

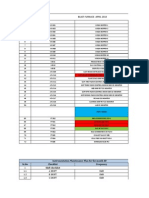

- Blast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFDocumento11 pagineBlast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFShiva Prakasam PernetiNessuna valutazione finora

- Inventory Audit ChecklistDocumento1 paginaInventory Audit Checklistchirag bhatiaNessuna valutazione finora

- Inventory Audit Procedures - AccountingToolsDocumento2 pagineInventory Audit Procedures - AccountingToolsMd Rakibul HasanNessuna valutazione finora

- 5S Organization ChartDocumento1 pagina5S Organization Chartrishi gautam100% (1)

- Alovebali: SOP HTST MachineDocumento7 pagineAlovebali: SOP HTST MachinePt Putra W SNessuna valutazione finora

- Quality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1Documento55 pagineQuality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1faroakNessuna valutazione finora

- General: (A) (B) (C) (D) (E)Documento3 pagineGeneral: (A) (B) (C) (D) (E)Md. Romman IslamNessuna valutazione finora

- Repair Audit ChecklistDocumento2 pagineRepair Audit Checklistandruta1978100% (2)

- FIN-03. Receiving ProcedureDocumento5 pagineFIN-03. Receiving ProcedureVu Dinh ThietNessuna valutazione finora

- Compliance Audit Checklist - ERP ElementDocumento4 pagineCompliance Audit Checklist - ERP ElementKrishnan NatarajanNessuna valutazione finora

- PP Chapter08Documento23 paginePP Chapter08Dahouk MasaraniNessuna valutazione finora

- MM WM NotesDocumento37 pagineMM WM NotesRakesh Kumar BeheraNessuna valutazione finora

- 5S Audit FormDocumento2 pagine5S Audit Formsigmasundar100% (1)

- Store SopDocumento6 pagineStore SopRAJESH KUMAR100% (1)

- Line and Equipment Opening / Oil Draining ProcedureDocumento4 pagineLine and Equipment Opening / Oil Draining ProcedureRASHEED YUSUFNessuna valutazione finora

- Combined SOP For Finance and Accounting Operations - Siddhi & Sarika Prachiti-BSCPLDocumento6 pagineCombined SOP For Finance and Accounting Operations - Siddhi & Sarika Prachiti-BSCPLsamatajoilNessuna valutazione finora

- Lean Warehouse - Short ReportDocumento2 pagineLean Warehouse - Short ReportJanus100% (1)

- Work Order Standard Operating ProcedureDocumento10 pagineWork Order Standard Operating ProcedureJemar B. BagnateNessuna valutazione finora

- Standard Operating Procedure (SOP) For Vendor Creation in SAPDocumento2 pagineStandard Operating Procedure (SOP) For Vendor Creation in SAPMRL Accounts100% (1)

- SOP For Material Inward - Inspection - AccountingDocumento2 pagineSOP For Material Inward - Inspection - AccountingSuleman KhanNessuna valutazione finora

- Warehouse ProcedureDocumento2 pagineWarehouse ProcedurePravin Patil0% (1)

- Audit Program Finished-Goods-Inventory Audit ... - Accountancy PDFDocumento7 pagineAudit Program Finished-Goods-Inventory Audit ... - Accountancy PDFHalsey Shih TzuNessuna valutazione finora

- Discard PolicyDocumento2 pagineDiscard Policycrass system50% (2)

- PP Chapter 8 EditedDocumento31 paginePP Chapter 8 EditedRáńéśh NeshNessuna valutazione finora

- SOP Guide Scrap DisposalDocumento4 pagineSOP Guide Scrap DisposalZain Mohiuddin89% (9)

- WMM1Documento94 pagineWMM1Reymart SangalangNessuna valutazione finora

- S.O 729 and S.O.730 Dated 21-08-1995-SDocumento48 pagineS.O 729 and S.O.730 Dated 21-08-1995-SParmod SiwachNessuna valutazione finora

- Case example: Inventory control system automates trading company operationsDocumento2 pagineCase example: Inventory control system automates trading company operationslekhanh_y2kNessuna valutazione finora

- Process Flowchart - Gadget SamyakDocumento9 pagineProcess Flowchart - Gadget SamyakVinay BhandariNessuna valutazione finora

- Stock Keeping and Annual Stock VerificationDocumento3 pagineStock Keeping and Annual Stock VerificationSharnbasappa WaleNessuna valutazione finora

- Draft Bin CardDocumento1 paginaDraft Bin CardAnonymous t3CoRw7P100% (1)

- Scrap ProcessDocumento5 pagineScrap Processnostalgia 22100% (1)

- Form IA-002A (Audit Plan) (07-13-2012)Documento2 pagineForm IA-002A (Audit Plan) (07-13-2012)granburyjohnstevens100% (1)

- Cross Docking ProcedureDocumento2 pagineCross Docking ProcedureKumar Rajadhyaksh67% (3)

- Standard Operating ProcedureDocumento5 pagineStandard Operating ProceduredugdugdugdugiNessuna valutazione finora

- Daily Factory Cleaning Sheet ChecklistDocumento5 pagineDaily Factory Cleaning Sheet ChecklistSaroj KatwalNessuna valutazione finora

- Organization of Stores DepartmentDocumento3 pagineOrganization of Stores DepartmentAb techNessuna valutazione finora

- In Process Quality Control (IPQC) PlanningDocumento3 pagineIn Process Quality Control (IPQC) PlanningMuhammad Harriz Mohd Hasan100% (1)

- RCSD Audit Facilities ManagementDocumento31 pagineRCSD Audit Facilities ManagementmarybadamsNessuna valutazione finora

- Post Incident Damage Assessment ChecklistDocumento9 paginePost Incident Damage Assessment ChecklistFerdinand M. TurbanosNessuna valutazione finora

- Metro Fabrics Raw Material Receiving ProcedureDocumento2 pagineMetro Fabrics Raw Material Receiving ProcedureHaseem Ali100% (1)

- ZTE Material Return FormDocumento2 pagineZTE Material Return FormAnonymous HVwXwzh2aNessuna valutazione finora

- StorekeeperDocumento2 pagineStorekeeperAbdirisaq MohamudNessuna valutazione finora

- List of InstrumentsDocumento3 pagineList of Instrumentsmuthuswamy77Nessuna valutazione finora

- Inventory Management Unit IIDocumento42 pagineInventory Management Unit IIMUDITSAHANINessuna valutazione finora

- GRN Entry for Goods Receipt ProcessingDocumento8 pagineGRN Entry for Goods Receipt ProcessingVinay SinghNessuna valutazione finora

- Internal Audit Checklist of Stores & SparesDocumento5 pagineInternal Audit Checklist of Stores & SparesRojan ShresthaNessuna valutazione finora

- Internal Audit Checklist of Utilities - Water and Power - Electricity CostDocumento1 paginaInternal Audit Checklist of Utilities - Water and Power - Electricity CostVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Dispatch of Goods & Receipt of Material PDFDocumento2 pagineInternal Audit Checklist of Dispatch of Goods & Receipt of Material PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Administration Deptt - PDFDocumento5 pagineInternal Audit Checklist of Administration Deptt - PDFVijay Kumar VaranasiNessuna valutazione finora

- Checklist of Fixed Asset Register PDFDocumento1 paginaChecklist of Fixed Asset Register PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Accounts Deptt - PDFDocumento3 pagineInternal Audit Checklist of Accounts Deptt - PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Bank Reconciliation Statement PDFDocumento1 paginaInternal Audit Checklist of Bank Reconciliation Statement PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Dispatch of Goods & Receipt of Material PDFDocumento2 pagineInternal Audit Checklist of Dispatch of Goods & Receipt of Material PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Bank Reconciliation Statement PDFDocumento1 paginaInternal Audit Checklist of Bank Reconciliation Statement PDFVijay Kumar VaranasiNessuna valutazione finora

- Checklist of Fixed Asset RegisterDocumento1 paginaChecklist of Fixed Asset RegisterVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Accounts Deptt - PDFDocumento3 pagineInternal Audit Checklist of Accounts Deptt - PDFVijay Kumar VaranasiNessuna valutazione finora

- Internal Audit Checklist of Administration Deptt - PDFDocumento5 pagineInternal Audit Checklist of Administration Deptt - PDFVijay Kumar VaranasiNessuna valutazione finora

- MIS Audit ChecklistDocumento17 pagineMIS Audit ChecklistVijay Kumar VaranasiNessuna valutazione finora

- MIS Audit ChecklistDocumento17 pagineMIS Audit ChecklistVijay Kumar VaranasiNessuna valutazione finora

- Skimming Scanning Extensive Reading Intensive ReadingDocumento12 pagineSkimming Scanning Extensive Reading Intensive Readingm umair zahirNessuna valutazione finora

- E-Way Bill - Issued by CbicDocumento5 pagineE-Way Bill - Issued by Cbicbhavesh chaudhariNessuna valutazione finora

- Quiz in AuditingDocumento2 pagineQuiz in AuditingRose Medina Baronda100% (1)

- Discover What Disruptive Innovation Means and Its Two TypesDocumento3 pagineDiscover What Disruptive Innovation Means and Its Two TypesNick Alwynson TandayagNessuna valutazione finora

- Measuring Economic Changes Over TimeDocumento34 pagineMeasuring Economic Changes Over TimeVictor Seelan100% (1)

- National Income - Definitions - Lovish KakkarDocumento2 pagineNational Income - Definitions - Lovish KakkarAjuni ShahNessuna valutazione finora

- Periodic Method-Joseph MerchandiseDocumento8 paginePeriodic Method-Joseph MerchandiseRACHEL DAMALERIONessuna valutazione finora

- Tutorial 1 AnswerDocumento4 pagineTutorial 1 AnswersofiaNessuna valutazione finora

- Investigate The Use of Solar Energy Into Small Houses For Sustainable LivingDocumento27 pagineInvestigate The Use of Solar Energy Into Small Houses For Sustainable LivingChristianLouisNoquisNessuna valutazione finora

- Santander: A Story of GrowthDocumento30 pagineSantander: A Story of GrowthJavier PalaciosNessuna valutazione finora

- Sammy's Motor Repair Shop faces new competitionDocumento3 pagineSammy's Motor Repair Shop faces new competitionSVPSNessuna valutazione finora

- Ch23 UnemploymentDocumento7 pagineCh23 UnemploymentmohammedalnahmiNessuna valutazione finora

- Quality Management - Ch.9 2Documento15 pagineQuality Management - Ch.9 2manarNessuna valutazione finora

- Buying Behavior and Production Planning Issues Affect Apparel Lead TimesDocumento2 pagineBuying Behavior and Production Planning Issues Affect Apparel Lead TimesJyoti RawalNessuna valutazione finora

- Marketing Role Letter Andrew ChngDocumento8 pagineMarketing Role Letter Andrew ChngDavid TanNessuna valutazione finora

- Ambit - Zomato - PRE-IPO Note - Sky Is The Limit - 05may2021Documento29 pagineAmbit - Zomato - PRE-IPO Note - Sky Is The Limit - 05may2021Praveen PNessuna valutazione finora

- 2017-MSU-Agricultural Power and Energy Sources-BlackDocumento47 pagine2017-MSU-Agricultural Power and Energy Sources-BlackJordan YapNessuna valutazione finora

- Full Thesis PDFDocumento132 pagineFull Thesis PDFRusselasadNessuna valutazione finora

- What Are The Factors To Consider in Location and Farm Site SelectionDocumento4 pagineWhat Are The Factors To Consider in Location and Farm Site Selectionronalit malintadNessuna valutazione finora

- Compensation PolicyDocumento20 pagineCompensation Policyমুসফেকআহমেদনাহিদ75% (4)

- $5 To $100k in 100 Days Game Plan Daily Target 20 Pips/200 Points DailyDocumento3 pagine$5 To $100k in 100 Days Game Plan Daily Target 20 Pips/200 Points DailyDonfack Fone100% (1)

- Chapter 2 Project Management Section 2.1 Critical Path Method (CPM) Using Activity On Arrow Example 2.1 Black Eyed Peas (I)Documento5 pagineChapter 2 Project Management Section 2.1 Critical Path Method (CPM) Using Activity On Arrow Example 2.1 Black Eyed Peas (I)Michael BunyiNessuna valutazione finora

- Brochure World Directory PB ZN Mines 2019 PDFDocumento3 pagineBrochure World Directory PB ZN Mines 2019 PDFjose tomas barriosNessuna valutazione finora

- Financial Management 2Documento7 pagineFinancial Management 2Rashmi RanjanaNessuna valutazione finora

- Ejercicio 1.4. Passion Into ProfitDocumento4 pagineEjercicio 1.4. Passion Into ProfitsrsuaveeeNessuna valutazione finora

- A. Describe A New Theory of Cognitive Development in ChildrenDocumento4 pagineA. Describe A New Theory of Cognitive Development in Children25. Qonita QotrunnadaNessuna valutazione finora

- ProfileDocumento11 pagineProfileSPACELINK AERO SERVICESNessuna valutazione finora

- Principles of Accounting RevisionDocumento99 paginePrinciples of Accounting RevisionHoang Khanh Linh NguyenNessuna valutazione finora

- Langkawi Discovery Park development timelineDocumento1 paginaLangkawi Discovery Park development timelineZharel AhmadNessuna valutazione finora

- Course WorkbooksDocumento8 pagineCourse Workbookszseetlnfg100% (2)