Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme Sec Viii D1 Nma App Ee

Caricato da

ADRIANTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asme Sec Viii D1 Nma App Ee

Caricato da

ADRIANCopyright:

Formati disponibili

APPENDIX EE

HALF-PIPE JACKETS

EE-1 GENERAL rp inside radius of jacket defined in Fig. EE-4, in.

S1p allowable tensile stress of jacket material at de-

The calculation procedure in this Appendix shall be

sign temperature, psi

used only if both of the following conditions apply.

P1p design pressure in jacket, psi. (P1 shall not ex-

(a) There is positive pressure inside the shell or head.

ceed P′.)

(b) There is positive pressure inside the half-pipe The fillet weld attaching the half-pipe jacket to the

jacket. vessel shall have a throat thickness not less than the

smaller of the jacket or shell thickness. Through thick-

ness jacket welds with a fillet shall be considered when

EE-2 HALF-PIPE JACKETS the jacket is in cyclic service.

The maximum permissible pressure P′ in half-pipe

jackets shall be determined from the following formula:

EE-3 JACKETS WITH OTHER

P′ p F /K (1) GEOMETRIES

For other jacket geometries such as shown in Fig.

where EE-5, the permissible pressure P′ may be obtained

P′p permissible jacket pressure, psi from the rules of UG-47 for stayed construction or 9-

Fp 1.5S − S′ 5 for jacketed vessels.

(F shall not exceed 1.5 S)

Sp maximum allowable tensile stress at design tem-

perature of shell or head material, psi Example

S′p actual longitudinal tensile stress in shell or head What is the required thickness of a cylindrical shell

due to internal pressure and other axial forces, subjected to an inside pressure of 190 psi and a half-

psi. When axial forces are negligible, S′ shall pipe jacket pressure of 300 psi? The jacket is in

be taken as PR /2t. When the combination of noncyclic service. Let

axial forces and pressure stress (PR/2t) is such I.D. of shell p 40 in.

that S′ would be a negative number, then S′ allowable stress of shell p 16,000 psi

shall be taken as zero. joint efficiency of shell p 1.0

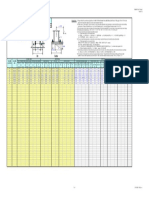

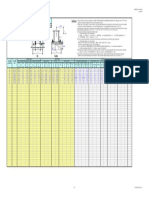

Kp factor obtained from Fig. EE-1, EE-2, or EE-3 half-pipe jacket is NPS 3

Pp internal design pressure (see UG-21) in ves- allowable stress of jacket material p 12,000 psi

sel, psi jacket girth welds are not radiographed

Rp inside shell or head radius, in. corrosion allowance p 0

Dp 2R

The minimum thickness of a half-pipe jacket, when SOLUTION: The required thickness of the shell due

the thickness does not exceed one-half of the inside to internal pressure is calculated from Eq. (1) of UG-

pipe radius or P does not exceed 0.385S1, is given by 27 as

PR

P1 r tp

SE − 0.6P

Tp (2)

0.85S1 − 0.6P1

190 × 20

p

16,000 × 1.0 − 0.6 × 190

where

Tp minimum thickness of half-pipe jacket, in. p 0.24 in.

651

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Fig. EE-1 2001 SECTION VIII — DIVISION 1

FIG. EE-1 NPS 2 PIPE JACKET

652

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

APPENDIX EE — NONMANDATORY Fig. EE-2

FIG. EE-2 NPS 3 PIPE JACKET

653

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Fig. EE-3 2001 SECTION VIII — DIVISION 1

FIG. EE-3 NPS 4 PIPE JACKET

654

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

EE-3 APPENDIX EE — NONMANDATORY EE-3

FIG. EE-4

FIG. EE-5

1

(a) Try t p ⁄4 in.: From Fig. EE-2, with D p 40

in. and t p 1⁄4 in., K p60:

P′ p F /K p (1.5 × 16,000 − 6080) /49

S′ p PR /2tp (190 × 20) /(2 × 0.25)

p 366 psi > 300 psi adequate

p 7600 psi

(c) Try Sch. 5S Pipe:

P′ p F /K p (1.5 × 16,000 − 7600) /60

p 273 psi < 300 psi not adequate t p 0.083 × 0.875 p 0.073 in.

(b) Try t p 5⁄16 in.: From Fig. EE-2, with D p 40 r p 3.5 /2 − 0.073 p 1.677 in.

in. and t p 5⁄16 in., K p 49:

The required half-pipe jacket thickness is

S′ p PR /2t p (190 × 20) /(2 × 0.3125)

P1r

Tp

p 6080 psi 0.85S1 − 0.6P1

655

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

EE-3 2001 SECTION VIII — DIVISION 1 EE-3

300 × 1.677 The minimum fillet weld size is equal to 0.083 ×

p

0.85 × 12,000 − 0.6 × 300 1.414 p 0.12 in. Use shell thickness of 5⁄16 in., half-

pipe jacket of NPS 3 Sch. 5S, and fillet weld size of

1

p 0.050 in. OK ⁄8 in.

656

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Potrebbero piacerti anche

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesDa EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNessuna valutazione finora

- Apendice EE Calculo ChaquetaDocumento6 pagineApendice EE Calculo ChaquetaOrlando NavarreteNessuna valutazione finora

- Limpet Coil DesignDocumento10 pagineLimpet Coil Designmaheshspawar0% (1)

- C100 Cryomodule Supply/Return Header Design Per ASME B31.3: An Addendum To JLAB-TN-07-051Documento5 pagineC100 Cryomodule Supply/Return Header Design Per ASME B31.3: An Addendum To JLAB-TN-07-051Menad SalahNessuna valutazione finora

- Thickness API 510Documento11 pagineThickness API 510Aleiser Quevedo Acuña100% (1)

- Vdocuments - MX Limpet Coil CalculationDocumento1 paginaVdocuments - MX Limpet Coil CalculationSirtaj NaseerNessuna valutazione finora

- Docslide. Limpet Coil CalculationDocumento1 paginaDocslide. Limpet Coil CalculationAdrian StoicescuNessuna valutazione finora

- API CalculationsDocumento11 pagineAPI CalculationsMohammed Illiasuddin100% (1)

- ASME VIII CalculationDocumento14 pagineASME VIII CalculationWan Wei100% (1)

- Q & A - Jacketed SystemDocumento2 pagineQ & A - Jacketed Systemreach_arindomNessuna valutazione finora

- Stiffening Ring Cal For Exteneral Press.Documento11 pagineStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Sec Viii D2 Art D-7Documento5 pagineSec Viii D2 Art D-7Manus79Nessuna valutazione finora

- Pressure VesselDocumento6 paginePressure VesselKiranNessuna valutazione finora

- Fea Report Rev 4Documento16 pagineFea Report Rev 4Tauqeer AhmedNessuna valutazione finora

- Q & A - Jacketed SystemDocumento2 pagineQ & A - Jacketed Systemreach_arindomNessuna valutazione finora

- Jacketed PipingDocumento3 pagineJacketed PipingHmd MokhtariNessuna valutazione finora

- Appendix G - Nonmandatory Examples Illustrating The Application of Code Formulas and RulesDocumento20 pagineAppendix G - Nonmandatory Examples Illustrating The Application of Code Formulas and Rulesel_koptan00857693Nessuna valutazione finora

- E-433 - Pipe Stress Analysis Info RevXDocumento13 pagineE-433 - Pipe Stress Analysis Info RevXAlbertoNessuna valutazione finora

- Jacketed PipingDocumento4 pagineJacketed Pipingข้าวเม่า ทอดNessuna valutazione finora

- Asme-Viii Re-Pad Calc's and MoreDocumento15 pagineAsme-Viii Re-Pad Calc's and MoreDavid LambertNessuna valutazione finora

- P302-6 SiraiDocumento2 pagineP302-6 SiraiwillianNessuna valutazione finora

- Steel Column Base Plate AnalysisDocumento1 paginaSteel Column Base Plate AnalysisVega DesNessuna valutazione finora

- Steel Column Base Plate AnalysisDocumento1 paginaSteel Column Base Plate AnalysisVega DesNessuna valutazione finora

- Steel Column Base Plate AnalysisDocumento1 paginaSteel Column Base Plate AnalysisVega DesNessuna valutazione finora

- IP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubesDocumento2 pagineIP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubessajiNessuna valutazione finora

- Analysis of A Hemispherical Head With Nozzle and LocalDocumento3 pagineAnalysis of A Hemispherical Head With Nozzle and LocalCarlito MenesNessuna valutazione finora

- Asme Sec Viii D2 Art D-2 PDFDocumento10 pagineAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesNessuna valutazione finora

- ASME VIII CalculationDocumento15 pagineASME VIII CalculationJoao Osmar Correa100% (1)

- Asme Secc 8Documento9 pagineAsme Secc 8mario valenzuelaNessuna valutazione finora

- Pressure Vessel Handout (1) WeldingDocumento14 paginePressure Vessel Handout (1) Weldingshushay hailuNessuna valutazione finora

- Boiler Tube CalculationsDocumento5 pagineBoiler Tube Calculationsanh thoNessuna valutazione finora

- 1 2929598Documento3 pagine1 2929598Hemant SolankiNessuna valutazione finora

- RB64-20 Discussion of SN Considerations in The Design of Reproduce Head Preamp Comb Jun64Documento15 pagineRB64-20 Discussion of SN Considerations in The Design of Reproduce Head Preamp Comb Jun64geeta deviNessuna valutazione finora

- 2 0 Introduction-Concept of StressDocumento7 pagine2 0 Introduction-Concept of Stressdarshan rathodNessuna valutazione finora

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-32Documento2 pagineAsme BPVC 2021 Section Viii Div. 1-2 - Ug-32canizales70Nessuna valutazione finora

- Lifting LugDocumento4 pagineLifting Lugsjkang0226100% (4)

- PDF Mcdes1 Review Sample Problems Pressure Vessel Springs Flywheel - CompressDocumento20 paginePDF Mcdes1 Review Sample Problems Pressure Vessel Springs Flywheel - CompressNorman Baldevarona JR.Nessuna valutazione finora

- Simple Stress: Analysis of Internal ForcesDocumento12 pagineSimple Stress: Analysis of Internal ForcesLester Neil LomodNessuna valutazione finora

- Input EchoDocumento6 pagineInput EchohgagNessuna valutazione finora

- Design of Pressure VesselDocumento27 pagineDesign of Pressure VesselJose BijoyNessuna valutazione finora

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Documento6 pagineDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4Nessuna valutazione finora

- Mec03-Problems (Stress and Strain)Documento11 pagineMec03-Problems (Stress and Strain)Benedict LucilaNessuna valutazione finora

- Sec Viii D1 Ma App 27Documento2 pagineSec Viii D1 Ma App 27fermin.ortueta183Nessuna valutazione finora

- HW#1Documento6 pagineHW#1Emily OhNessuna valutazione finora

- FE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas EngineeringDocumento2 pagineFE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas EngineeringherisiswantogoNessuna valutazione finora

- EXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10Documento16 pagineEXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10jtai1983Nessuna valutazione finora

- Asme Ug-27, Ug-32 & Appendix 1Documento5 pagineAsme Ug-27, Ug-32 & Appendix 1แบด พิษ100% (2)

- ASME PCC-1 APP O - 411-E-103 - TS FLGDocumento56 pagineASME PCC-1 APP O - 411-E-103 - TS FLGmohamed.eldesouky9120Nessuna valutazione finora

- Estudo de Caso - Asme 2398Documento6 pagineEstudo de Caso - Asme 2398biancogallazziNessuna valutazione finora

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Documento7 pagineUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNessuna valutazione finora

- Asme Viii Calculation Xls PDF FreeDocumento28 pagineAsme Viii Calculation Xls PDF FreeMisbachul ChoirNessuna valutazione finora

- Asme Viii Calculation Xls PDF FreeDocumento28 pagineAsme Viii Calculation Xls PDF FreeMisbachul ChoirNessuna valutazione finora

- Cylindrical Compression Helix Springs For Suspension SystemsDa EverandCylindrical Compression Helix Springs For Suspension SystemsNessuna valutazione finora

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyDa EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNessuna valutazione finora

- Asme Viii d1 Ma Appendix 4Documento8 pagineAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- CWE Price ListDocumento1 paginaCWE Price ListADRIANNessuna valutazione finora

- Asme Sec Viii D1 Ma App 9 PDFDocumento9 pagineAsme Sec Viii D1 Ma App 9 PDFADRIANNessuna valutazione finora

- Section Viii d1 Ma App 1Documento18 pagineSection Viii d1 Ma App 1Mdsr HasanNessuna valutazione finora

- Asme Sec Viii d1 Ma App 8Documento2 pagineAsme Sec Viii d1 Ma App 8Jesus Ruiz RomanNessuna valutazione finora

- Asme Sec Viii D1 Ma App 5Documento4 pagineAsme Sec Viii D1 Ma App 5ADRIANNessuna valutazione finora

- Asme Sec Viii D1 Ma App 6Documento2 pagineAsme Sec Viii D1 Ma App 6ADRIANNessuna valutazione finora

- Asme Sec Viii D1 Nma App ADocumento8 pagineAsme Sec Viii D1 Nma App AADRIANNessuna valutazione finora

- Non-Mandatory Appendix MDocumento5 pagineNon-Mandatory Appendix MMuhammed Abo-FandoodNessuna valutazione finora

- ASME Sección VIII D1 Mandatory Appendices 7Documento3 pagineASME Sección VIII D1 Mandatory Appendices 7Sidney LinsNessuna valutazione finora

- Asme Sec Viii D1 Nma App y PDFDocumento15 pagineAsme Sec Viii D1 Nma App y PDFADRIANNessuna valutazione finora

- File 1002Documento3 pagineFile 1002Binay K SrivastawaNessuna valutazione finora

- Asme Sec Viii D1 Ma App 3Documento4 pagineAsme Sec Viii D1 Ma App 3ADRIANNessuna valutazione finora

- Asme Sec Viii D1 Nma App KDocumento2 pagineAsme Sec Viii D1 Nma App KADRIANNessuna valutazione finora

- Asme Sec Viii D1 Nma App L PDFDocumento57 pagineAsme Sec Viii D1 Nma App L PDFADRIANNessuna valutazione finora

- 51 App DDocumento1 pagina51 App DCarlos SelbachNessuna valutazione finora

- Asme Sec Viii D1 Nma App AaDocumento40 pagineAsme Sec Viii D1 Nma App AaADRIANNessuna valutazione finora

- ASME Sección VIII D1 Non Mandatory Appendices EDocumento1 paginaASME Sección VIII D1 Non Mandatory Appendices ESidney LinsNessuna valutazione finora

- Asme Sec Viii D1 Nma App F PDFDocumento1 paginaAsme Sec Viii D1 Nma App F PDFADRIANNessuna valutazione finora

- Viii-1 - App S PDFDocumento3 pagineViii-1 - App S PDFvikasNessuna valutazione finora

- Appendix T Temperature Protection: (A) Any Pressure Vessel in A Service Where It CanDocumento1 paginaAppendix T Temperature Protection: (A) Any Pressure Vessel in A Service Where It CanBinay K SrivastawaNessuna valutazione finora

- Appendix C Suggested Methods For Obtaining The Operating Temperature of Vessel Walls in ServiceDocumento1 paginaAppendix C Suggested Methods For Obtaining The Operating Temperature of Vessel Walls in ServiceBinay K SrivastawaNessuna valutazione finora

- Asme Sec Viii D1 Nma App CC PDFDocumento1 paginaAsme Sec Viii D1 Nma App CC PDFADRIANNessuna valutazione finora

- Asme Sec Viii D1 Nma App H PDFDocumento2 pagineAsme Sec Viii D1 Nma App H PDFADRIANNessuna valutazione finora

- Sec. VIII Div 1 Apen 1Documento16 pagineSec. VIII Div 1 Apen 1ADRIANNessuna valutazione finora

- Asme Sec Viii d1 Nma App G-Appendix G-Suggested Good Practice Regarding Piping Reactions and Design of Supports and AttachmentsDocumento2 pagineAsme Sec Viii d1 Nma App G-Appendix G-Suggested Good Practice Regarding Piping Reactions and Design of Supports and Attachmentscarlosllanes2010Nessuna valutazione finora

- Asme Sec Viii D1 Nma App RDocumento2 pagineAsme Sec Viii D1 Nma App RADRIAN100% (2)

- Asme Sec Viii D1 Nma App P PDFDocumento2 pagineAsme Sec Viii D1 Nma App P PDFADRIANNessuna valutazione finora

- Method StatementDocumento13 pagineMethod StatementGrace tpplNessuna valutazione finora

- Atm With JavaDocumento24 pagineAtm With Javakirti_gupta100% (1)

- FINAL - Evaluation of Protective Relay Performance - REEES-2010 ITMDocumento21 pagineFINAL - Evaluation of Protective Relay Performance - REEES-2010 ITMjaythakar8887Nessuna valutazione finora

- Research and Thesis On Earthing System in LV NetworksDocumento87 pagineResearch and Thesis On Earthing System in LV NetworksEngr Gulfam80% (5)

- What Is The Seismic Design Philosophy of BuildingsDocumento2 pagineWhat Is The Seismic Design Philosophy of BuildingsHerman Roberto HernándezNessuna valutazione finora

- Ten Greatest Achievement of Mechanical Engineers To Society and The ScienceDocumento4 pagineTen Greatest Achievement of Mechanical Engineers To Society and The ScienceRex SabersonNessuna valutazione finora

- DownloadDocumento68 pagineDownloadMuhammed A. Mahdi0% (1)

- Lesson Plan in Science Perpetuation of Life I. Learning ObjectivesDocumento3 pagineLesson Plan in Science Perpetuation of Life I. Learning ObjectivesRachel Lorenzo SaldoNessuna valutazione finora

- SMAW 10 - Q1 - W2 - Mod2Documento16 pagineSMAW 10 - Q1 - W2 - Mod2Romeo Dela RosaNessuna valutazione finora

- ABB Robotic Arc WeldingDocumento12 pagineABB Robotic Arc Weldinganidarius301100% (1)

- Ehb Ta 072-240 1008 PDFDocumento40 pagineEhb Ta 072-240 1008 PDFsaulNessuna valutazione finora

- CAD Notes - Opening PagesDocumento4 pagineCAD Notes - Opening PagesEugineNessuna valutazione finora

- Daftar Buku Mechanical Engineering, ManufacturingDocumento398 pagineDaftar Buku Mechanical Engineering, ManufacturingsatoNessuna valutazione finora

- 2017 2019Documento796 pagine2017 2019NéstorNessuna valutazione finora

- RonnieDocumento4 pagineRonnieRonnie KinyanjuiNessuna valutazione finora

- Understanding of The ScopeDocumento2 pagineUnderstanding of The ScopeSijo JoyNessuna valutazione finora

- Ducts For Irrigation WorkADM SpecficationDocumento3 pagineDucts For Irrigation WorkADM Specficationbuddy1971Nessuna valutazione finora

- "The Big Bang Experiment": A Seminar Report ONDocumento4 pagine"The Big Bang Experiment": A Seminar Report ONshuaibmohhamNessuna valutazione finora

- Reinforced Concrete Mechanics Design SolDocumento315 pagineReinforced Concrete Mechanics Design Solariani710Nessuna valutazione finora

- Transcript PattranithDocumento1 paginaTranscript Pattranithapi-598948089Nessuna valutazione finora

- Engineering ManualDocumento519 pagineEngineering ManualDinesh PudasainiNessuna valutazione finora

- Electrical and Computer EngineeringDocumento45 pagineElectrical and Computer EngineeringAklilu Hailu50% (2)

- Estimation of Safe Vertical Load Capacity of Pile For Normal ConditionDocumento4 pagineEstimation of Safe Vertical Load Capacity of Pile For Normal ConditionVasanthakumarNessuna valutazione finora

- Design of Machine Element Lecture 1Documento45 pagineDesign of Machine Element Lecture 1Loay MohammedNessuna valutazione finora

- Exercise Piping ASME B31Documento7 pagineExercise Piping ASME B31Weniton OliveiraNessuna valutazione finora

- Terminal Markings ConnectionsDocumento9 pagineTerminal Markings ConnectionsMuhammad Haris Baig100% (1)

- Day2 - Control Drawing BuilderDocumento19 pagineDay2 - Control Drawing BuilderNiyi Adetunji100% (1)

- Different Approaches in Modeling of RC Shear Wall: A ReviewDocumento15 pagineDifferent Approaches in Modeling of RC Shear Wall: A Reviewrahimmulla100% (2)

- Module 11 Applications in Engineering MechanicsDocumento9 pagineModule 11 Applications in Engineering MechanicsWolf LordNessuna valutazione finora

- Software Engineering Unit-Ii Two Marks Questions: 1. Define Requirements AnalysisDocumento2 pagineSoftware Engineering Unit-Ii Two Marks Questions: 1. Define Requirements AnalysisJyo ReddyNessuna valutazione finora