Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ME 6004 UCM Cycle Test 3 QP

Caricato da

jones praveenTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ME 6004 UCM Cycle Test 3 QP

Caricato da

jones praveenCopyright:

Formati disponibili

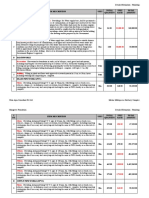

Reg.

No 8 1 4 7

A applications and advantages. (8+5)

TRP Engineering College, Irungalur, Trichy – 621 105 PART C (1*14=14)

Branch : Mech Year / Semester :III / VI 13. a. Describe the working principle and elements of chemical CO4

Cycle Test –III

Date:12.03.2018 Time: 1 hr. 50 Min. machining. Explain in detail the methods of maskant in chemical

Subject Code/Name: ME6004/UCM machining.

(14)

Course Competency

Outcome

ME6004. The concept of Chemical energy based processes and analyzes

4 the process

Answer All the Questions

Part – A (10×2=20)

1 State the principle of chemical machining process CO4

2 Name the etchant used in chemical machining process CO4

3 What is the use of maskant in chemical machining process? CO4

4 What are the requirements of tool materials in ECM process? CO4

5 State the function of electrolyte used in ECM process. CO4

6 List the application of ECM process. CO4

7 What is the difference between ECG and conventional grinding? CO4

8 What are the factors to be considered while designing the tool in CO4

ECM process?

9 State the principle of electro chemical grinding. CO4

10 What is the difference between EDM and ECM? CO4

Part – B (2×13=26)

11 a Describe the principle of ECG and ECH. Discuss about the process CO4

parameter that influence the ECM. (3+3+7)

OR

b Explain ECM process. Explain how a replica of the tool is CO4

obtained. (8+5)

12. a) Explain the working principle of electrochemical grinding and CO4

discuss the process capabilities. (7+6)

OR

b. Describe the ECH equipment with neat sketch and list their CO4

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Chapter Objectives: 2005 Pearson Education South Asia Pte LTDDocumento98 pagineChapter Objectives: 2005 Pearson Education South Asia Pte LTDjones praveenNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Introduction To Engineering MechancisDocumento43 pagineIntroduction To Engineering Mechancisjones praveenNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- WWW - Trp.srmtrichy - Edu.in: Corner StonesDocumento2 pagineWWW - Trp.srmtrichy - Edu.in: Corner Stonesjones praveenNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- M.E. ThermalDocumento47 pagineM.E. Thermalvelmurugan100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Proficiency Brochure For StudentDocumento2 pagineProficiency Brochure For Studentjones praveenNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Title: Force and Motion DefinitionsDocumento5 pagineTitle: Force and Motion Definitionsjones praveenNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- MHKphet SimulartionDocumento6 pagineMHKphet Simulartionjones praveenNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Physical Fitness CertificateDocumento1 paginaPhysical Fitness CertificateRohit JainNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Linear and Angular MeasurementsDocumento38 pagineLinear and Angular Measurementsjones praveen100% (2)

- GE8292 - EM - ASSgDocumento2 pagineGE8292 - EM - ASSgjones praveenNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- GE8292 - EM - ASSgDocumento2 pagineGE8292 - EM - ASSgjones praveenNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Linear and Angular MeasurementsDocumento38 pagineLinear and Angular Measurementsjones praveen100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- (E-Brochure) Ginza HillDocumento6 pagine(E-Brochure) Ginza HillRenald 'Renald' RenaldNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- 2015 Paper 2 Specimen Paper PDFDocumento10 pagine2015 Paper 2 Specimen Paper PDFAhmad Osama MashalyNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Template For Public BiddingDocumento3 pagineTemplate For Public BiddingFederico DomingoNessuna valutazione finora

- Travel Insurance CertificateDocumento9 pagineTravel Insurance CertificateMillat PhotoNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Exercise 3 - Binary Coded DecimalDocumento3 pagineExercise 3 - Binary Coded DecimalNaiomi RaquinioNessuna valutazione finora

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Documento52 pagine03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Good Quality Practices at NTPC KudgiDocumento8 pagineGood Quality Practices at NTPC KudgisheelNessuna valutazione finora

- Sonos 5500 Service ManualDocumento565 pagineSonos 5500 Service ManualScott Fergusson50% (2)

- Manual TP5000Documento206 pagineManual TP5000u177427100% (4)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Manual de Colisión Mazda 626 1986-1987Documento9 pagineManual de Colisión Mazda 626 1986-1987mark rueNessuna valutazione finora

- Unit I Lesson Ii Roles of A TeacherDocumento7 pagineUnit I Lesson Ii Roles of A TeacherEvergreens SalongaNessuna valutazione finora

- GET IELTS BAND 9 SpeakingDocumento54 pagineGET IELTS BAND 9 Speakingm.alizadehsaraNessuna valutazione finora

- Tales of Mystery Imagination and Humour Edgar Allan Poe PDFDocumento289 pagineTales of Mystery Imagination and Humour Edgar Allan Poe PDFmatildameisterNessuna valutazione finora

- Among Us Hack Mod Menu Mod AlwaysDocumento4 pagineAmong Us Hack Mod Menu Mod AlwaysC JNessuna valutazione finora

- Lesson 2 - Graphing Rational Numbers On A Number LineDocumento9 pagineLesson 2 - Graphing Rational Numbers On A Number Linehlmvuong123Nessuna valutazione finora

- G6Documento14 pagineG6Arinah RdhNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Apogee 3800 Service ManualDocumento56 pagineApogee 3800 Service ManualGauss Medikal Sistemler100% (1)

- Data Structures and Algorithms Made Easy-Narasimha KarumanchiDocumento228 pagineData Structures and Algorithms Made Easy-Narasimha KarumanchiPadmalatha Ragu85% (40)

- Life Lessons AssignmentDocumento5 pagineLife Lessons Assignmentapi-332560669Nessuna valutazione finora

- Chap 4 Safety Managment SystemDocumento46 pagineChap 4 Safety Managment SystemABU BEBEK AhmNessuna valutazione finora

- Super Duty - Build & PriceDocumento8 pagineSuper Duty - Build & PriceTyler DanceNessuna valutazione finora

- Mechanical FPD P.sanchezDocumento9 pagineMechanical FPD P.sanchezHailley DensonNessuna valutazione finora

- Standards For Pipes and FittingsDocumento11 pagineStandards For Pipes and FittingsMohammed sabatinNessuna valutazione finora

- QP02Documento11 pagineQP02zakwanmustafa0% (1)

- Stirling Bio Power GeneratorDocumento5 pagineStirling Bio Power GeneratorAvram Stefan100% (2)

- Dislocations and StrenghteningDocumento19 pagineDislocations and StrenghteningAmber WilliamsNessuna valutazione finora

- Controllogix EthernetDocumento136 pagineControllogix Ethernetcnp0705Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Overview 6T40-45 TransmissionDocumento14 pagineOverview 6T40-45 TransmissionLeigh100% (1)

- Chapter 5Documento20 pagineChapter 5Berihu GirmayNessuna valutazione finora

- Steps To Control Water Depletion Jun2019Documento2 pagineSteps To Control Water Depletion Jun2019chamanNessuna valutazione finora