Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MLA Data Sheet - LNG - Reva

Caricato da

Luis GonzalezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MLA Data Sheet - LNG - Reva

Caricato da

Luis GonzalezCopyright:

Formati disponibili

卓

冠

Manufacturer:Shanghai Eminent Enterprise Development Co., Ltd

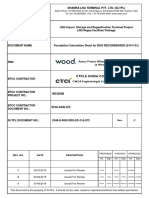

A 2014-July-29 Technical data sheets LEWIS XUHENGYU XUJIE

Date

REV Description of revision Composed By Check by Approved by

DD-MM-YY

Client: Salvador Subcontractor:

Designer: Shanghai Eminent Enterprise Development Co., Ltd

卓

冠

This document is TOXPAH property. It cannot be copied or transmitted to third parties without prior authorization.

Project name:

TUXPAN PORT

Type of documents : Products:

Design plan for Marine loading arm Marine loading arm

Subcontractor's documents identification: Rev. Company Contract

Number

▲

★D 001 A

MLA

Abbreviation:

1.“ ★” D---design document; P----procedure document;

C---inspection of test O---others

2. “▲” QRH----quick release hook GT----gangway tower MLA---Marine loading

arm

Company’s or other entities document No.: Sheet:

DATA SHEET Nº: EIB-ML-1407

DATA SHEET FOR MARINE LOADING

ARMS WITH EMERGENCY RELEASE REQUISITION Nº 1407

REVISION

SYSTEM AND QUICK CONNECT / REVISION A DATE 29-July-14

LINE

DISCONNECT COUPLING

PAGE 2 OF 6

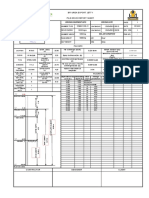

DESCRIPTION Requisition

Data

1

ARM SERVICE Loading BOG LNG/BOG Loading

2 Medium Arms

Gasoline/diesel Loading Arms

3

SCOPE OF SUPPLY

4

Loading Arm X

5

-Base and Riser (Support Column) X

6

Vapour Recovery Arm N/A

7

-Base and Riser (Support Column) N/A

8

Quick Connect / Disconnect Coupling, X

9

-Coupling Spool Piece X

1

0

Local Instrumentation X

1

1

Local Instrument and Control Panel X

1

2

Interconnecting Wiring, including: X

1

3

-Cable Trays X

1

4

-Junction Boxes X

1

5

Complete Hydraulic Power System, X

1

6

-Power Pack(Pump & Motor) X

1

7

-Filters X

1

8

-Accumulators X

1

9

-Cylinders X

2

0

-Hydraulic Pipe work with Fittings X

2

1

Supporting Structure and Platforms N/A

2

2

Folding Stairs N/A

2

3

Painting and Insulation X

2

4

Inspection and Shop Testing X

2

5

Commissioning Spare parts Optional

2

6

Two (2) Years Spare Parts Optional

2

7

Set of Special Tools and Jigs N/A

2

8

2

9

3

0 DESIGN DATA: Table 1. Arm data basic

3

1

Berth Type Diameter Cargo Pipe Working Temperature Operation

No. Material pressure (℃)

(MPa.)

3

2

1 MLA DN400 Gasoline, CS20# 0.69 26 Electro-

diesel oil Hydraulic

3

3

3

4

3

5

3

On-shore flange standard ANSI/150LB/WN/RF/DN400

6

3 On-ship flange standard ANSI/150LB/WN/RF/DN400

7

3

8

3

9

Table 2. Berth data

4 A1 Distance between riser and jetty edge 3.0m

0

4 A2 Distance between riser and surface of flange on-shore m

1

4 A3 Height from center of flange to jetty surface 0.8m

2

4

A4 Height of nearest obstacle on-shore 1.00m

3

4

4

A5 Please submit the drawing of obstacle if any. 5.00m

4 A6 The Min/Max thickness of fender 2.40m

5

4

6

A7 The height difference from jetty surface to 2.67m

4

7

A8 The heighttiptop waterfrom

difference line. jetty surface to the lowest 4.28m

water line.

4

8

C The distance of two nearest loading arm center 3.00m

4

9

5

0

Table 3. Ship data

5

1

B1 The height above water for largest ship emptied 15m

5

2

B2 The height above water for smallest laden ship 1.61m

5

3

B3 The min. distance of manifold flange center to deck of 2.1m

5 B4 ship.

The height of ship’s handrail 1.2m

4

5

5

B5 Transverse drift (off shore) 3.0m

5

6

B6 Fore-and-aft drift (seacoast) 3.0m

5

7

B7 Max/Min. space between manifold flanges Depends on

client

5

8

B8 The min. distance between manifold flanges to 2.5m

shipboard.

5

9

B9 The max distance between manifold flanges to shipboard. 4.6m

6

0

Note:The letter on the table references envelope drawing.

6

1

6

2

Table 4. Combinations of

6

3

Item DN C(m) Combination

6

4

1 N/A

6

5

2

6

6

3

6

7

4

6

8

5

6

9

6

7

0

7

1

Table 5. Environmental data

7

2

Max. and min. temperature 26 ℃

7

3

Max. wind speed 22m /s

7

4

Earthquake Loads 7Grade

7

5

7

6

Table 6. Equipped

7

7

Equipped Option(X)

7

8

Vacuum breaker X

7

9

Purge system N/A

8

0

Safety ladders X

8

1

Adjustable support jack X

8

2

Shut-off Valve N/A

8

3

QC/DC(Quick connect/Disconnect coupler X

8

4

Insulation flange X

8

5

Range limited monitoring System X

8

6

Electrical-Hydraulic drive system X

8

7

Hydraulic Emergency release coupler X

8

8

Electrical Trace N/A

8

9

Steam Trace N/A

9 Painting system

0

yellow□X Nacarat □

White □

9

1

9

2 Table7 Power supply

9

3

Data of power Voltage Hz AC DC Phase Num.

9

4

Motor

9

5

Limited switch

9

6

Electric

9

7

El-hydraulic

9

8

9

9

1

0

0

NOTES: The power supply depends on site

A 29-July- Lewis XUHENGYU XUJIE For RFQ

Revisi Date By Checked Approved Comments

on

DATA SHEET Nº: EIB-ML-1407

REVISION

LINE REQUISITION Nº 1407

Shanghai Eminent Enterprise Development Co., Ltd

REVISION A DATE 29-July-

14

PAGE 5 OF 6

GENERAL

1 DRAWING

2

3

4

5

6

7

8

9

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

5

5

6

0

A 29-July-14 LEWIS XUHENGYU XUJIE For RFQ

Revisio Date By Checked Approved Comments

n

DATA SHEET Nº: E I B - M L - 1 4 0 7

REQUISITION Nº 1 4 0 7

Shanghai Eminent Enterprise Development Co., Ltd

REVISION

LINE

REVISION A DATE 29-July-

14

PAGE 6 OF 6

ENVELOPE

DRAWING

1

2

3

4

5

6

7

8

9

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

5

5

6

0

A 29-July-14 LEWIS XUHENGYU XUJIE For RFQ

Revisio Date By Checked Approved Comments

n

Potrebbero piacerti anche

- Simple distillation and fractional distillation methods explainedDocumento4 pagineSimple distillation and fractional distillation methods explainedManoj KhanalNessuna valutazione finora

- Venture Global Calcasieu Pass, LLC Transcameron Pipeline, LLCDocumento32 pagineVenture Global Calcasieu Pass, LLC Transcameron Pipeline, LLC1mmahoney100% (2)

- Standard Specification: LPG Loading / Unloading ArmDocumento19 pagineStandard Specification: LPG Loading / Unloading ArmANIL KUMAR100% (1)

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocumento2 pagineSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Configuring AutoCADPlant3DIsometricsDocumento48 pagineConfiguring AutoCADPlant3DIsometricsArnold Ochochoque ArcosNessuna valutazione finora

- Specification Sheet MLA PDFDocumento2 pagineSpecification Sheet MLA PDFRobin Abu FaqihNessuna valutazione finora

- GASLOG Singapore GA DWG - Appendix 10Documento2 pagineGASLOG Singapore GA DWG - Appendix 10karthikaNessuna valutazione finora

- Iso 7005-2-1992 Bridas Metálicas - Parte 2. Bridas de Hierro FundidoDocumento39 pagineIso 7005-2-1992 Bridas Metálicas - Parte 2. Bridas de Hierro FundidoLuis GonzalezNessuna valutazione finora

- Baltic Ace ReportDocumento64 pagineBaltic Ace ReportFelipe IlhaNessuna valutazione finora

- Idn27943 - SCN1200 F2.5 - Ga+alDocumento2 pagineIdn27943 - SCN1200 F2.5 - Ga+alAbdul JabbarNessuna valutazione finora

- Tailoring Autocad P&Id and Autocad Plant 3DDocumento194 pagineTailoring Autocad P&Id and Autocad Plant 3DjaimeNessuna valutazione finora

- 980g Wheel Loader 2kr00001-Up (Machine) Powered by 3406c Engine (Sebp2395 - 140) - Systems & ComponentsDocumento7 pagine980g Wheel Loader 2kr00001-Up (Machine) Powered by 3406c Engine (Sebp2395 - 140) - Systems & ComponentsHassan HamdyNessuna valutazione finora

- A ESIA Yemen Section 3 Revision 1Documento42 pagineA ESIA Yemen Section 3 Revision 1Denstar Ricardo SilalahiNessuna valutazione finora

- Bomb CalorimeterDocumento2 pagineBomb CalorimeterBikash ChoudhuriNessuna valutazione finora

- PDFDocumento129 paginePDFSatt PaingNessuna valutazione finora

- Mooring & Breasting Jetty IVDocumento16 pagineMooring & Breasting Jetty IVDwiki AdriyantoNessuna valutazione finora

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocumento10 pagineWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195Nessuna valutazione finora

- Active Fire Protection Philosophy for Neste RDCG ProjectDocumento50 pagineActive Fire Protection Philosophy for Neste RDCG Projectreza abriNessuna valutazione finora

- CCCC Harbour Bureau 2: Bridge Girder LauncherDocumento1 paginaCCCC Harbour Bureau 2: Bridge Girder LauncherBudi MaryantoNessuna valutazione finora

- Rovuma LNG Macroeconomic StudyDocumento45 pagineRovuma LNG Macroeconomic Studyrahul nagareNessuna valutazione finora

- DNV GL ETO-2017 Maritime Forecast To 2050Documento82 pagineDNV GL ETO-2017 Maritime Forecast To 2050Pritish Tandon100% (2)

- SC Project References List 2021Documento5 pagineSC Project References List 2021Ferry YusufNessuna valutazione finora

- Liquip Gantry Plugs: Title: PurposeDocumento5 pagineLiquip Gantry Plugs: Title: PurposePatricio AguilarNessuna valutazione finora

- SATIP-W-011-01 Rev 8Documento10 pagineSATIP-W-011-01 Rev 8saravananmenmathiNessuna valutazione finora

- 200 20 Mo SPC 0003 - D1Documento23 pagine200 20 Mo SPC 0003 - D1Nishant GuptaNessuna valutazione finora

- Reliable LNG Loading ArmDocumento2 pagineReliable LNG Loading Armarmando0212-1Nessuna valutazione finora

- Gas and Oil Pipeline Project SkidsDocumento18 pagineGas and Oil Pipeline Project SkidsrichardchiamNessuna valutazione finora

- Fluor 2013 CW Case StudyDocumento6 pagineFluor 2013 CW Case StudyImad MobayedNessuna valutazione finora

- HQSM12-Q13-103-001-A4 ITP E-101 AB - HQSM Commented 21.02.2020 PDFDocumento11 pagineHQSM12-Q13-103-001-A4 ITP E-101 AB - HQSM Commented 21.02.2020 PDFfdfazfzNessuna valutazione finora

- Introduction to ACC Cement CompanyDocumento36 pagineIntroduction to ACC Cement CompanyPrabir Kumar PatiNessuna valutazione finora

- Preliminary Quotation of Design, Supply, Delivery, Commissioning, Transportation, Testing, Inspection For LNG Truck Loading SkidDocumento32 paginePreliminary Quotation of Design, Supply, Delivery, Commissioning, Transportation, Testing, Inspection For LNG Truck Loading SkidAyesha KiranNessuna valutazione finora

- NMX I 248 Nyce 2005Documento140 pagineNMX I 248 Nyce 2005Luis GonzalezNessuna valutazione finora

- MTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018Documento3 pagineMTM - KMPP-00-PRC-TB-067 Loading Arms Technical Bid Evaluation Rev C-July 16,2018AliZenatiNessuna valutazione finora

- Platong Gas II Project Description-V1Documento9 paginePlatong Gas II Project Description-V1api-3720369100% (7)

- Delivering Clean Energy Safely: Final Presentation on Internship ProgramDocumento39 pagineDelivering Clean Energy Safely: Final Presentation on Internship ProgramReinaldo Ongky Billy AnandoNessuna valutazione finora

- CV Oil & Gas EngineerDocumento5 pagineCV Oil & Gas EngineerpoetoetNessuna valutazione finora

- Terminal ProjectsDocumento37 pagineTerminal ProjectssubashNessuna valutazione finora

- Benzen - UllmannsDocumento32 pagineBenzen - UllmannsgucciNessuna valutazione finora

- Fuel Oil Transit Terminal Situbondo: Preliminary StudyDocumento17 pagineFuel Oil Transit Terminal Situbondo: Preliminary StudyDoni AndreanaNessuna valutazione finora

- DSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Documento56 pagineDSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Panha PorNessuna valutazione finora

- MEmaco N 907 - Al ZourDocumento1 paginaMEmaco N 907 - Al Zouraruncg2Nessuna valutazione finora

- SPCC T CV Cal 0001 R1Documento10 pagineSPCC T CV Cal 0001 R1Panha PorNessuna valutazione finora

- QGX and QCSDocumento41 pagineQGX and QCSRaed Naim KhammashNessuna valutazione finora

- Giignl 2015 Annual ReportDocumento29 pagineGiignl 2015 Annual ReportElena0% (1)

- T 14.419.003 SH1 AA - CEF - Signed PDFDocumento33 pagineT 14.419.003 SH1 AA - CEF - Signed PDF이상기Nessuna valutazione finora

- CCC Excellence Awards Bulletin Recognizes Top PerformersDocumento38 pagineCCC Excellence Awards Bulletin Recognizes Top PerformersamalNessuna valutazione finora

- Mumbai Trans Harbour Link Package 1 Sewri Interchange Pavement DesignDocumento9 pagineMumbai Trans Harbour Link Package 1 Sewri Interchange Pavement Designasif_22ukNessuna valutazione finora

- ARCHIRODON PETROJET INSPECTION PLANDocumento2 pagineARCHIRODON PETROJET INSPECTION PLANBelal hassanNessuna valutazione finora

- Liquefied Natural Gas Terminals: Services and SolutionsDocumento7 pagineLiquefied Natural Gas Terminals: Services and SolutionsJohnNessuna valutazione finora

- Adani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaDocumento34 pagineAdani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaphanikrishnabNessuna valutazione finora

- LRT3 Cable Approval for Construction ProjectDocumento4 pagineLRT3 Cable Approval for Construction ProjectHafiz NurahimNessuna valutazione finora

- Johanes AgusDocumento41 pagineJohanes AgusGerry Dwi PutraNessuna valutazione finora

- 2023 02 09 - IWP A03 WP5.3 000 FI LC 101 CV01 101 - Rev1Documento16 pagine2023 02 09 - IWP A03 WP5.3 000 FI LC 101 CV01 101 - Rev1Priyanshu UpadhyayNessuna valutazione finora

- 4차 Technical Proposal 견적 기준Documento40 pagine4차 Technical Proposal 견적 기준m khaeronNessuna valutazione finora

- Bfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/HourDocumento1 paginaBfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/Hour唐亮Nessuna valutazione finora

- 070204-FD-001.rev 2 - 31-01-2008 BoukjeDocumento41 pagine070204-FD-001.rev 2 - 31-01-2008 BoukjeGP100% (1)

- Load-Out, Transportation and Installation Design Basis: 7. StructureDocumento1 paginaLoad-Out, Transportation and Installation Design Basis: 7. StructurefructoraNessuna valutazione finora

- TBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsDocumento5 pagineTBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsGeta Oisis Arya PutraNessuna valutazione finora

- Ship-Shore Link Systems GuideDocumento17 pagineShip-Shore Link Systems GuideJeffryNessuna valutazione finora

- AMIPURDocumento28 pagineAMIPURHugo ArmandoNessuna valutazione finora

- HAL 96-112 105389.023-Rep-Basic Design Report - FINAL - housestyled-BASH-pages-96-112 PDFDocumento17 pagineHAL 96-112 105389.023-Rep-Basic Design Report - FINAL - housestyled-BASH-pages-96-112 PDFcomsindo commodity survey indonesiaNessuna valutazione finora

- Engineering & Marine StructuresDocumento13 pagineEngineering & Marine Structuresامين الزريقيNessuna valutazione finora

- Mk2+ Dual Wallform To Retaining Wall: Shade CorporationDocumento15 pagineMk2+ Dual Wallform To Retaining Wall: Shade CorporationJuan Dela CruzNessuna valutazione finora

- D.37. M000272-5131018-FP-Central Cooling Piping DiagramDocumento5 pagineD.37. M000272-5131018-FP-Central Cooling Piping Diagramzatryo dwayasadaNessuna valutazione finora

- Js Insight Gas Form CDocumento64 pagineJs Insight Gas Form CSomayajula SuryaramNessuna valutazione finora

- OIL CBM Brochure 2015Documento3 pagineOIL CBM Brochure 2015prasetyoNessuna valutazione finora

- Security Level 2 Annexure(1) TEG1-1135-002Sheet 2 of 15Documento15 pagineSecurity Level 2 Annexure(1) TEG1-1135-002Sheet 2 of 15sushilNessuna valutazione finora

- Gangway Mechanical DataDocumento8 pagineGangway Mechanical DatariandiNessuna valutazione finora

- 077135C 061 DD 0131 1407 1 0 PDFDocumento2 pagine077135C 061 DD 0131 1407 1 0 PDFมิตร อันมาNessuna valutazione finora

- Densitometer BuildingDocumento7 pagineDensitometer BuildingCharles HutabaratNessuna valutazione finora

- Centrifugal Pump Data Sheet: Doc. No.Documento6 pagineCentrifugal Pump Data Sheet: Doc. No.Mahdi KazemiNessuna valutazione finora

- 06 06 2020 14.30.38Documento1 pagina06 06 2020 14.30.38Luis GonzalezNessuna valutazione finora

- 06 06 2020 14.25.18Documento1 pagina06 06 2020 14.25.18Luis GonzalezNessuna valutazione finora

- 06 06 2020 14.30.38Documento1 pagina06 06 2020 14.30.38Luis GonzalezNessuna valutazione finora

- 2B 100 1 1 V Et 0001 PDFDocumento13 pagine2B 100 1 1 V Et 0001 PDFLuis GonzalezNessuna valutazione finora

- Lista para Materiales Valvulas 8 Enero2020Documento806 pagineLista para Materiales Valvulas 8 Enero2020Luis GonzalezNessuna valutazione finora

- Maintaining Process Temperature: KeywordsDocumento13 pagineMaintaining Process Temperature: KeywordsLuis GonzalezNessuna valutazione finora

- Details of Flange BlindsDocumento4 pagineDetails of Flange BlindsLuis GonzalezNessuna valutazione finora

- Esc PVC 1PVC 01Documento2 pagineEsc PVC 1PVC 01Luis GonzalezNessuna valutazione finora

- MSS SP 80 - 1997 Válvs de Bronce de Comp, Globo, Ángulo y Retención PDFDocumento27 pagineMSS SP 80 - 1997 Válvs de Bronce de Comp, Globo, Ángulo y Retención PDFLuis GonzalezNessuna valutazione finora

- Esc PVC 1PVC 01 PDFDocumento2 pagineEsc PVC 1PVC 01 PDFLuis GonzalezNessuna valutazione finora

- MSS SP 6 PDFDocumento6 pagineMSS SP 6 PDFOSIIQPGRISNessuna valutazione finora

- Table BrenchDocumento11 pagineTable BrenchLuis GonzalezNessuna valutazione finora

- NRF 139 PemexDocumento36 pagineNRF 139 PemexLuis GonzalezNessuna valutazione finora

- MSS SP 85 - 1994 Válvs de Hierro Fundido de Globo y Ángulo, de Extrs Bridados y Roscados PDFDocumento12 pagineMSS SP 85 - 1994 Válvs de Hierro Fundido de Globo y Ángulo, de Extrs Bridados y Roscados PDFLuis GonzalezNessuna valutazione finora

- MSSP-97 Conexs Ramal Refzs, Forjs, de Ac Al C, Extrs I S, Roscadas y Solds A TopeDocumento14 pagineMSSP-97 Conexs Ramal Refzs, Forjs, de Ac Al C, Extrs I S, Roscadas y Solds A TopeLuis GonzalezNessuna valutazione finora

- MSS SP 99 PDFDocumento12 pagineMSS SP 99 PDFOSIIQPGRISNessuna valutazione finora

- Keystone K-Lok 360-370 Data SheetDocumento12 pagineKeystone K-Lok 360-370 Data SheetMnttoMecNessuna valutazione finora

- Trim Number Chart API ValveDocumento2 pagineTrim Number Chart API Valvemoorthymech1979Nessuna valutazione finora

- NRF-048 03 Diseño de Instalaciones Electricas en Plantas Ind - Es.enDocumento85 pagineNRF-048 03 Diseño de Instalaciones Electricas en Plantas Ind - Es.enLuis GonzalezNessuna valutazione finora

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDocumento20 pagineValve Selection & Specification Guide For Building Services: Ahead of The FlowpaniyaNessuna valutazione finora

- Important India's Potential For Second Generation Biofuel Technology PDFDocumento38 pagineImportant India's Potential For Second Generation Biofuel Technology PDFSushmaSahuNessuna valutazione finora

- Connection of The STAG-300Documento1 paginaConnection of The STAG-300Anonymous IkfTLYBNessuna valutazione finora

- Aluminum Metal Matrix CompositesDocumento3 pagineAluminum Metal Matrix CompositesazeemdcetNessuna valutazione finora

- Indice de Aciditate ASTM Nou METROHM - AN-PAN-1037Documento2 pagineIndice de Aciditate ASTM Nou METROHM - AN-PAN-1037Corina StanculescuNessuna valutazione finora

- Compressor Installation InstructionsDocumento2 pagineCompressor Installation Instructionsrobbin3024803Nessuna valutazione finora

- Marinediesel Duramax 300 HP 500 HPDocumento2 pagineMarinediesel Duramax 300 HP 500 HPMaurizio BernasconiNessuna valutazione finora

- 3789 Rannie Gaulin 5 3020 05 09 2012 USDocumento2 pagine3789 Rannie Gaulin 5 3020 05 09 2012 USJeffrey OngNessuna valutazione finora

- 关键词 英语 4.8更新Documento14 pagine关键词 英语 4.8更新袁袁Nessuna valutazione finora

- Nilfisk Neptune 5Documento21 pagineNilfisk Neptune 5Sofia Pinheiro100% (1)

- Data Sheet No. 13.07 - 480 - 485 - 490 Safety Valve PDFDocumento1 paginaData Sheet No. 13.07 - 480 - 485 - 490 Safety Valve PDFGiftObionochieNessuna valutazione finora

- Air CompressorDocumento7 pagineAir CompressorNishant JeeNessuna valutazione finora

- BG Gas PDFDocumento6 pagineBG Gas PDFAntonio BrionesNessuna valutazione finora

- Vorecon Variable Speed Planetary Gear PDFDocumento40 pagineVorecon Variable Speed Planetary Gear PDFsandy4u2k2Nessuna valutazione finora

- Afriyie UE20045213 ICE AssignmentDocumento11 pagineAfriyie UE20045213 ICE AssignmentFrancis OfosuNessuna valutazione finora

- Thermtech - Small Industrial Boiler (SIB)Documento6 pagineThermtech - Small Industrial Boiler (SIB)Maulik PatelNessuna valutazione finora

- Trans SyncroDocumento138 pagineTrans SyncroVassilis KyriakopoulosNessuna valutazione finora

- Critical engineering watch informationDocumento100 pagineCritical engineering watch informationRj DeciertoNessuna valutazione finora

- Manual de Operación ONANDocumento37 pagineManual de Operación ONANFernando PadillaNessuna valutazione finora

- Rev B PDFDocumento66 pagineRev B PDFkarldeusNessuna valutazione finora

- Homework 1Documento3 pagineHomework 1meeshoe90% (1)

- Deuterium Deposits Make Philippines "The Richest Country in The World"Documento6 pagineDeuterium Deposits Make Philippines "The Richest Country in The World"Richard BalaisNessuna valutazione finora

- Beacon Morris BMEF Unit HeaterDocumento2 pagineBeacon Morris BMEF Unit HeaterPam HenkelNessuna valutazione finora

- Catalogue Shotcrete MachineDocumento6 pagineCatalogue Shotcrete MachineSushmit SharmaNessuna valutazione finora