Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hitor Tech Sum V4

Caricato da

Zaanaa ZaanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hitor Tech Sum V4

Caricato da

Zaanaa ZaanCopyright:

Formati disponibili

Lorem Ipsum Dolor

[Insert Date]

Technologies impacting lives around the world

Hitor Technologies Summary

September 2015

Hitor Group, Inc. is a green technology aggregator specializing in 4 distinct product lines

as shown in this presentation summary. Our mission is to apply sustainable green

technologies to environmental challenges for a better, cleaner and safer world.

Hitor EV Langenburg Water to Hitor 3D Panel Hitor Ceramic

Power Building Systems

Sustainable Revolutionary water Implementing decades of Ceramic cold spray

technology that filtration and power experience in system for coating &

produces electric production construction with a containing hazardous

vehicles. technology. lightweight system. waste.

Page 2 Page 3 Page 4 Page 5

Opportunity / Competitive Advantages

• Hitor EV project affiliates include years of

first-hand experience building electric trucks

and testing multiple configurations

Hitor EV

• Tremendous opportunity for “Greening”

medium duty fleets in the US and

international markets for medium-duty

electric trucks and busses

• U.S. and International Grants allow fleets to

afford to “demonstrate” the vehicles

• Fleets need and want the economic and

environmental benefits of electric vehicles

• New state and federal mandates are issued

monthly in the US and Europe

• Hitor EV seeks private equity investors for

facility expansion, tooling, staff expansion

• Business Plan provided on request with

required NDA

• NOTE: We plan to partner and JV with many

EV suppliers and producers in the U.S. as well

as Europe, Asia and Africa.

The Hitor EV projects are planned for assembly in Poland in alliance with several JV partners and

financial backers / investment groups.

Hitor Technology Summary 2015 2

LANGENBURG WATER TO POWER TECHNOLOGY

Hitor Group, Inc. is the marketing and distribution partner with

Langenburg Water and Power technology.

Hitor Technology Summary 2015 3

U.S./German Technology Solves Major Environmental Problems

• Water purification, toxin remediation and power generation.

• Generates electrical power - Zero lag - Zero down time - Highly secure.

• Renewable and 100% green. No CO2 emissions or any other pollutants.

• Does not use fossil fuels and is neither nuclear nor hydroelectric.

• Purifies water from any source; industrial, ocean, sewage, fracking waste, etc.

• All pollutants are removed / ionized.

• Water is drinkable, oxygen enhanced, and PH balanced.

• Uniquely small footprint, less than 10% of existing water remediation facilities.

• Example: A 1,000,000 gallons system producing 5MW electricity on 5,000 square feet.

• Includes an integrated self-monitoring control module that tracks status of water, power output and

machinery functions with complete system security.

• Worldwide rollout through U.S. tech-industrial Fortune 100 Company with $45-billion annual Revenue.

• Installation partner is a SE Asian EPC company with over $17-billion annual Revenue.

History

• Technology is being made available for the first time after 40 years in development.

Design tested by major United States Department of Defense (DOD) laboratory.

• System manufactured by a major DOD contractor through license agreement with technology owner.

• Existing U.S. based 1.1 MW ‘Water & Power Unit’. (Electricity for several thousand homes and purifies

250,000 gallons of wastewater per day.)

• Solves major industry problems, reduces costs, preserves ecosystems with associated

• PR boost.

Advantages:

• Creates medical grade drinking water from effluent, regardless of the degree of contamination.

• 100% green, zero emissions.

• Carbon and all other compounds are removed for other use and/or ionized.

• Generates Green electricity for the client and to power the actual cleaning system.

• Resultant water can be customized for uses required.

• Increases quality of water and health for users.

• Provides pathogen resistant water for cleaning without the use of chemicals.

• German engineering, 40 years in development.

• 100% efficient compact design with minimal footprint that can fit almost any application.

• Reduces overall costs (waste, electricity, hygiene)

•

Hitor Technology Summary 2015 4

HITOR 3D PANEL SYSTEM

Hitor Poland manufactures what has proven to be one of the quickest build, sturdiest and most cost

effective construction systems, quickly replacing current costly wood systems. Hitor is acquiring

Garcia Contracting, an International construction company with over 75 years of collective

experience. Garcia has been using the 3D system for decades and believes it is the most effective

system for low cost housing. When completed it forms one continuous structure that is resistant to

heavy winds, earthquakes and other environmental forces. Hitor will be creating a mobile 3D

manufacturing system to handle many of the smaller housing requests (under 2,000 homes) from our

contacts. Garcia will work closely with New Future (our steel and concrete technology partner) to

organize and implement the correct construction system necessary to meet the client’s requirements.

BENEFITS

▪ Saves time and money

▪ Does not require skilled labor for erection of buildings

▪ No specific tools, simple step-by-step

▪ Very fast to construct

▪ Excellent insulation from both heat and cold

▪ Lightweight easy to move and assemble

▪ Little or no foundation costs (saves money)

▪ Once coated with shot-crete cover it becomes a monolithic structure

▪ Exceptional load bearing capabilities

▪ Hurricane and tornado tested and resistant

▪ Manufacture controlled – consistency and strength

▪ Rot, insect and pest resistant

Hitor Technology Summary 2015 5

HITOR CERAMIC FOR HAZARDOUS WASTE

It is estimated that there is over 1 billion tons of toxic

& hazardous waste currently being stored throughout

the world. Every year this number grows

exponentially. This could have very serious negative

impacts on all ways of life if not dealt with quickly and

efficiently. Hitor has identified a technology that can

protect the storage of these wastes for as long as

necessary. Hitor has had meetings with the German

government and a power station. We have samples

manufactured for a follow up presentation. It could

amount to a billion dollar (US) plus opportunity.

Ceramic Cold Spray

The ceramic cold spray technology is currently used by the US military, US government, shipping, construction

and other industries. Hitor will be investing significant money into the development and implementation of a

ceramic cold spray facility in Europe to accommodate the millions of containers of toxic waste that is in need of

replacement or repair.

Hitor has held preliminary talks with governments and agencies regarding the need for a long term solution for

the containment of nuclear & hazardous waste. Once the first opportunity is signed there will be a ‘snow ball

effect’ throughout Hitor Markets globally.

Hitor will be marketing the ceramic cold spray to all of its international contacts focusing on hazardous waste

containment as well as the transportation industry, mining, and military applications. Our plan is to integrate

other Hitor technologies into this solution making it more cost effective, easier to apply and providing safe long

term containment. Each of the segments that require the ceramic cold spray solution, represent a substantial

economic upside benefit for Hitor and its investors.

Hitor Technology Summary 2015 6

Summary

Investment Opportunity

For more information please contact Ken Martin

CEO Hitor Group Inc.

hitorinc@gmail.com

Hitor Technology Summary 2015 7

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Doka Formwork Catalogue 2011Documento516 pagineDoka Formwork Catalogue 2011andrijapopovic82% (11)

- A Haroon Akram-Lodhi and Christobal Kay - Surveying The Agrarian Question (Part 1) Unearthing Foundations, Exploring Diversity PDFDocumento27 pagineA Haroon Akram-Lodhi and Christobal Kay - Surveying The Agrarian Question (Part 1) Unearthing Foundations, Exploring Diversity PDFBagas yusuf kausanNessuna valutazione finora

- The Future of Marketplaces: Initiating A Series of Reports On Marketplaces (Check Marketplaces - Dealroom.co For More Info)Documento36 pagineThe Future of Marketplaces: Initiating A Series of Reports On Marketplaces (Check Marketplaces - Dealroom.co For More Info)Informativo AbiesNessuna valutazione finora

- Acct Statement - XX4579 - 25082023 HDFCDocumento6 pagineAcct Statement - XX4579 - 25082023 HDFCmkbhyperNessuna valutazione finora

- Internship report-IOCLDocumento42 pagineInternship report-IOCLRoopam Saxena83% (6)

- Report of Printing Press UnitDocumento29 pagineReport of Printing Press Unitsmartwayrcp100% (3)

- Case 2 Decision MakingDocumento2 pagineCase 2 Decision MakingMohamed OsamaNessuna valutazione finora

- Management Accounting Information For Managing and Creating Value 7th Edition Smith Test BankDocumento25 pagineManagement Accounting Information For Managing and Creating Value 7th Edition Smith Test BankJaredEdwardsjbwp100% (59)

- Case 2: Vale - Dividends Versus FCFE: Aswath DamodaranDocumento24 pagineCase 2: Vale - Dividends Versus FCFE: Aswath DamodaranEXII iNessuna valutazione finora

- A Project Report On Advertising Strategy of TATA MotorsDocumento86 pagineA Project Report On Advertising Strategy of TATA MotorsAbhishek KangeNessuna valutazione finora

- 4540-1688749640236-Unit 17 - Business Process Support 2022Documento17 pagine4540-1688749640236-Unit 17 - Business Process Support 2022sanjeevan2376Nessuna valutazione finora

- Public Sector Undertakings, Government of Kerala - 2021Documento217 paginePublic Sector Undertakings, Government of Kerala - 2021abinsasi.99Nessuna valutazione finora

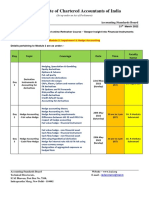

- The Institute of Chartered Accountants of India: Accounting Standards BoardDocumento2 pagineThe Institute of Chartered Accountants of India: Accounting Standards BoardHitesh KarmurNessuna valutazione finora

- Entrepreneurship Module No. 4: Week 4: 1st Quarter Topic: The Business SearchDocumento7 pagineEntrepreneurship Module No. 4: Week 4: 1st Quarter Topic: The Business SearchLlyod Francis LaylayNessuna valutazione finora

- Nayan Internship - Affiliation - Report MsiDocumento22 pagineNayan Internship - Affiliation - Report MsiToufiq NayanNessuna valutazione finora

- Evaluation Criteria - BPCDocumento7 pagineEvaluation Criteria - BPCsinghvijaykNessuna valutazione finora

- Chapter 9Documento49 pagineChapter 9shainexlotusNessuna valutazione finora

- 20210705211046summer Placement Report 5.7.21Documento6 pagine20210705211046summer Placement Report 5.7.21Manu SinghNessuna valutazione finora

- Twitter Case StudyDocumento13 pagineTwitter Case StudyAhmer FarooqNessuna valutazione finora

- Aspects of Supply Chain ManagementDocumento7 pagineAspects of Supply Chain ManagementKamal SanguriNessuna valutazione finora

- 1 s2.0 S2405918822000095 MainDocumento22 pagine1 s2.0 S2405918822000095 MainOumema AL AZHARNessuna valutazione finora

- A Study On Customer Satisfaction Toward Maggi NoodlesDocumento46 pagineA Study On Customer Satisfaction Toward Maggi NoodlesChandan SrivastavaNessuna valutazione finora

- A Dialogue Between A Shopkeeper and A Customer Buying ShoesDocumento4 pagineA Dialogue Between A Shopkeeper and A Customer Buying ShoesJade CabaNessuna valutazione finora

- QMT425 - Assignment 1Documento5 pagineQMT425 - Assignment 1Azwan AyopNessuna valutazione finora

- OpTransactionHistoryUX510 06 2023Documento5 pagineOpTransactionHistoryUX510 06 2023srm finservNessuna valutazione finora

- Research Proposal ReportDocumento5 pagineResearch Proposal ReportMEERA JOSHY 1927436Nessuna valutazione finora

- Reading 15 Analysis of Dividends and Share Repurchases - AnswersDocumento31 pagineReading 15 Analysis of Dividends and Share Repurchases - Answerstristan.riolsNessuna valutazione finora

- Find Your Dream Finance Job: Explore The Best Opportunities On Our Finance Jobs PortalDocumento11 pagineFind Your Dream Finance Job: Explore The Best Opportunities On Our Finance Jobs PortalMaryNessuna valutazione finora

- Internship Report On Building Construction 1Documento39 pagineInternship Report On Building Construction 1Milki MesayNessuna valutazione finora

- Critical ReflectionDocumento1 paginaCritical ReflectionPatrina SamuelNessuna valutazione finora