Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 22 Flammable N Combustible Liquid Pipping System N Storage

Caricato da

Ej Alancado0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

28 visualizzazioni43 pagineTitolo originale

Chapter_22_Flammable_n_Combustible_Liquid_Pipping_System_n_Storage

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

28 visualizzazioni43 pagineChapter 22 Flammable N Combustible Liquid Pipping System N Storage

Caricato da

Ej AlancadoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 43

CHAPTER 22

2201.1 - Flammable liquids have flashpoints below 37.8ºC (100ºF) and

vapor pressures not exceeding 2.068 mm Hg at 37.8ºC (40 psia at

100ºF)

2201.2 - Class I Liquids include those with flashpoints below 37.8ºC

and may be subdivided as follows:

Class IA liquids – with flashpoints below 22.8ºC, and boiling points

below 37.8ºC

Class IB liquids – with flashpoints below 22.8ºC, and boiling points at or

above 37.8ºC

Class IC liquids - with flashpoints at or above 22.8ºC, and below 37.8ºC

2201.2.1 - Unstable liquids shall be treated as Class IA liquids

Liquids with flashpoints at or above 37.8ºC

Class II liquid – flashpoint at or above 37.8ºC

Class IIIA liquid – flashpoints at or above 60ºC and below 93ºC

Class IIIB liquid – flashpoints at or above 93ºC

2203.1 - applies to piping systems consisting of pipes, tubing, flexible

connectors, pressure-containing parts, and other devices with flowing

fluid.

2203.2 - This section does not apply to the following:

Tubing or casing on any oil or gas wells

Motor vehicles, aircraft, and boats

Piping within the scope of any applicable boiler and pressure vessel code

2204.1 - The design, fabrication, assembly, test, and expected working

pressures and structural stresses. Conformity with applicable sections of

ANSI B31, American National Standard, Code for Pressure Piping, and the

provisions of this chapter shall be considered prima facie evidence of

compliance with the foregoing provisions.

2204.2 - Piping system shall be maintained liquid tight . A piping system

that has leaks that constitute a hazard shall be emptied of liquid or

repaired in a manner acceptable to the authority having jurisdiction.

2205.1 - Pressure-containing parts as covered in 2203.1 shall meet the material

specifications and pressure and temperature limitations of ANSI B31.3

2205.2 - Ductile (nodular) iron shall meet the specifications of ASTM A395,

Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated

Temperatures.

2205.3 - valves at storage tanks, as required by the 2209.2 and 2209.3, and their

connections to the tank shall be of steel or ductile iron, except as provided for in

2205.3.1, 2205.3.2, or 2205.4

2205.4 - low melting opint materials such as aluminium, copper, and brass,

materials that soften on fire expose such as plastics; or non-ductile material

such as cast iron shall be permitted to be used underground within the pressure

and temperature limitations of ASME B31

2205.5 - Piping, valves, and fittings shall be permitted to have combustible

or non-combustible things

2205.6 - Piping systems of non-metallic materials, including piping

systems incorporating secondary containment, shall be designed and built

in accordance with recognized standards of design or approved

equivalents and shall be built and used within the scope of their approvals

within UL 971, Standard for non-metallic underground piping for

flammable liquids.

2206.1 - Joints shall be made liquid tight and shall be welded, flanged,

threaded, or mechanically attached. They shall be designed and installed

so that the mechanical strength of the joint will not be impaired if

exposed to fire

2206.2 - Listed Flexible connectors shall be permitted to be used and

installed in accordance with 2206.3

2206.3 - Pipe joints dependent upon the friction characteristics or

resiliency of combustible materials for mechanical continuity or liquid-

tightness of piping shall only be used outside of buildings above ground or

below ground.

2207.1 - Piping systems shall be substantially supported and protected against

physical damage and excessive stresses arising from settlement, vibration,

expansion, or contraction. The installation of non-metallic piping shall be in

accordance with the manufacturer’s instruction.

2207.2 - Supports, Piping systems shall be substantially supported and protected

against physical damage and excessive stresses arising from settlement,

vibration, expansion, or contraction.

2207.3 - Pipe Penetrations, Piping that passes through or pierces a dike wall or

the wall of a structure shall be designed to prevent excessive stresses and leakage

due to settlement or fire exposure.

2207.4 - Protection against corrosion, aboveground piping systems that are

subject to external corrosion shall be suitably protected.

2208.1 - Underground piping shall be installed on a bedding of at least 150mmof

well compacted backfill material

2208.2 - In areas subject to vehicle traffic, the pipe trench shall be of suffice

depth to permit a cover of at least 450mm of well compacted backfill material

and pavement. In paved areas where a minimum of 50mm of asphalt is used,

backfill between the asphalt and pipe shall be permitted to be reduced to

200mm minimum.

2208.3 – In areas not subjected to vehicle traffic, the pipe trench shall be of

sufficient depth to permit a cover of at least 150mm of well-compacted backfill

material.

2208.4 – Piping shall not need to be separated by more than 230mm

2208.5 – Two or more levels of pipes within the same trench shall be separated

by a minimum of 150mm of well-compacted backfill

Piping systems shall contain a sufficient number of valves to operate the system

properly and to protect the equipment. Piping systems in connection with

pumps shall contain a sufficient number of valves to properly control the flow of

fluid

2209.1 – If loading and unloading is done through a common pipe system, a

check valve shall not be required. However, an isolation valve shall be provided.

2209.2 – Each connection to an aboveground tank through which liquid can

normally flow shall be provided with an external or internal valve located as

close as practical to the shell of the tank

2209.3 – Each connection below the liquid level through which liquid does not

normally flow shall be provided with a liquid tight closure such as a valve, plug,

or blind.

2210.1 – Initial Testing. Unless tested in accordance with the applicable sections

of ASME B31, Code for pressure piping, all piping shall be tested before being

covered, enclosed, or placed in use. Testing shall be done hydrostatically to 150%

of the maximum anticipated pressure of the system or pneumatically to 110% of

the maximum anticipated pressure of the system.

2210.2 – Initial Testing Of Secondary Containment Piping. The interstitial

(annular) space of secondary containment-type piping shall be tested

hydrostatically or with air pressure at gauge pressure of 34.5 kPa or shall be

tested in accordance with its listing or with the manufacturer’s instruction.

2210.3 – Testing During Maintenance. Existing piping shall be tested in

accordance with this subsection if there is indication that the piping is leaking.

Piping systems shall be bonded and grounded in accordance with

2211.1.

2211.1 – All metallic equipment such as tanks, machinery, and piping

shall be designed and operated to prevent electrostatic ignitions. All

metallic equipment shall be bonded or grounded.

Tanks and their piping shall be protected by either:

A properly engineered, installed and maintained cathodic protection

system in accordance with recognized standards of design.

Approved of listed corrosion-resistant materials or systems, which may

include special alloys, fiberglass, reinforced plastic, or fiberglass

reinforced plastic coatings

2213.1 – Selection of the type of protection to be employed shall be

based upon the corrosion history of the area and the judgement of the

qualified engineer.

Controlled drains shall be employed to prevent liquids due to leaks

from entering natural water courses, public sewers, or public drains

2214.1 – Emergency drainage systems shall be provided to direct

flammable or combustible liquid leakage and fire protection water to

a safe location

2215.1 – Tanks can be installed aboveground, underground, or, under

certain conditions, inside buildings. Openings and connections to tanks,

for venting, gauging, filling, and withdrawing, can present hazards if they

are not properly safeguarded.

2215.2 – Aboveground Storage Tanks. Storage tanks come in a variety of

design and construction types, they are designed into three general

categories:

Atmospheric tanks (0 – 6.9 kPa)

Low-pressure tanks (6.9 – 103 kPa)

Pressure vessels (103 kPa and above)

2215.2.1 – All aboveground storage tanks shall be built of steel or

concrete, unless the character of the liquid necessitates the use of

other materials.

2215.2.2 – When intended for storing corrosive liquids, the thickness

of the tank shell shall be increased to provide additional metal to

allow for expected service life of the tank.

2215.2.3 – Tanks designed for aboveground use shall not be used as

underground tanks

2215.2.4 – Tanks designed for underground use shall not be used as

aboveground tanks

2215.2.5 – Materials. Tanks shall be designed and built in accordance

with recognized engineering standards for the material of

2216.1 – Foundations for anchor of tanks

2216.1.1 – Tanks shall rest on the ground or on foundations made of concrete,

masonry, piling, or steel.

2216.1.2 – Where tanks are supported above their foundations, tank supports

shall be installed on firm foundations

2216.1.3 – Steel structures or exposed piling for tanks storing Class I, Class II,

or Class IIIA liquids shall be protected by materials having a fire resistance

rating not less than 2 hours.

2216.1.4 – Where a tank is located in an area subject to flooding, provisions

shall be taken to prevent tanks, either full or empty, from floating during a

rise in water level up to the maximum flood stage

2216.2 – Installation of Aboveground Tanks

2216.2.1 – Location with respect to property lines, public ways, and

important buildings on the same property

2216.2.2 – Shell-to-shell spacing between any two adjacent aboveground

tanks

2216.2.3 – Control of spills from aboveground tanks. Every tank contains

a Class I, Class II, or Class IIIA liquid shall be provided with means to

prevent accidental release of liquid from endangering important

facilities and adjoining properly or from reaching waterways.

2216.2.4 – Vent Piping for aboveground tanks. Piping for normal and

emergency relief venting shall be constructed in accordance with 2203.0

2216.2 – Installation of Aboveground Tanks

2216.2.5 – Tanks operating other than vents for aboveground tanks

2216.2.5.1 – Each connection to an aboveground tank through which liquid can

normally flow shall be provided with an internal or external valve.

2216.2.5.2 – Each connection below the liquid level through which liquid does not

normally flow shall be provided with a liquid-tight closure such as a valve, plug, or

blind.

2216.2.5.3 – Openings for gauging on tanks storing Class I liquids shall be provided

with a vapor-tight cap

2216.2.5.4 – Fill pipes that enter the top of a tank shall terminate within 150mm of the

bottom of the tank.

2216.2 – Installation of Aboveground Tanks

2216.2.6 – Requirements for aboveground tanks located in areas subject

to flooding

2216.2.6.1 – Vertical tanks shall be located so that the tops of the tanks extend

above the maximum flood stage by at least 30% of their allowable storage

capacity

2216.2.6.2 – Horizontal tanks that are located where more than 70% of the tank’s

storage capacity will be submerged at the established flood stage shall be

secured.

2216.2.6.3 – Tank vents or other openings that are not liquid-tight shall extend

above the maximum flood stage water level.

2216.2.6.4 – A dependable water supply shall be available for filling an empty or

partially filled tank.

2216.2.6.5 – Spherical or spheroid tanks shall be protected by any of the

2216.3 – Installation of Underground Tanks

2216.3.1 – Location. Excavation for underground tanks shall be made

with due care to avoid undermining of foundations of existing

structures.

2216.3.2 – Burial Depth and Cover

2216.3.2.1 – all underground tanks shall be installed in accordance with the

manufacturer’s instruction and shall be set on firm foundations and surrounded

at least 150mm of noncorrosive inert material.

2216.3.2.2 – underground tanks shall be covered with not less than 600mm of

earth, or with not less than 300mm of earth on top of which shall be place a slab

reinforced concrete not less than 100mm thick.

2216.3.2.3 – Maximum depth of cover shall be specified by the tank

manufacturer and marked on the tank.

2216.3.3 – Vent piping for underground tanks. Vent pipes from

2216.3 – Installation of Underground Tanks

2216.3.4 - Tank openings other than vents for underground tanks.

2216.3.4.1 – Connections for all tank openings shall be liquid tight

2216.3.4.2 – Openings for manual gauging, if independent of the fill pipe, shall

be provided with a liquid-tight cap or cover.

2216.3.4.3 – Fill and discharge lines shall enter tanks only through the top. Fill

lines shall be sloped toward the tank

2216.3.4.4 – Fill pipes that enter the top of a tank shall terminate within 150mm

of the bottom of the tank.

2216.3.4.5 – Filling and emptying and vapor recovery connections for Class I,

Class II, or Class IIIA liquids that are connected and disconnected shall be

located outside of buildings at a location free from any source of ignition.

2216.3.4.6 – Tank openings provided for purposes of vapor recovery shall be

protected against possible vapor release by means of a spring-loaded check

2216.3 – Installation of Underground Tanks

2216.3.5 – Requirements for underground tanks located in areas subject

flooding

2216.3.5.1 – At locations where an ample and dependable water supply is available,

underground tanks containing flammable or combustible liquids, placed so that

more than 70% of their storage capacity will be submerged at the maximum flood

stage, shall be anchored, weighed, or secured as to prevent movement when filled or

loaded with water and submerged by floodwater.

2217.1 - Scope. Subsection 2217.0 shall apply to installations of tanks

storing Class I, Class II, and Class IIIA liquids in storage tank

buildings.

2217.2 - Location. Tanks and any associated equipment within the

storage tank building shall be so located that a fire in the area shall

not constitute an exposure hazard to adjoining buildings or tanks for

a period of time consistent with the response and suppression

capabilities of the fire-fighting operations available to the location.

2217.2.1 – The minimum distance from exposed property lines and

buildings for tank installations within structures having walls with a fire

resistance rating of less than 2 hours shall be in accordance.

2217.2.2 – Where a storage tank building has an exterior wall facing an

exposure, the distances shall be modified

2217.2.3 – Other equipment associated with tanks, such as pumps, heaters,

filters, and exchangers, shall not be located closer than 7.6m to property lines

where the adjoining property is or can be built upon or to the nearest

important building on the same property that is not integral part of the

storage tank building

2217.2.4 – Tanks in which unstable liquids are stored shall be separated from

potential fire exposures by a clear space of at least 7.6m.

2217.2.5 – Each storage tank building and each tank within the building shall

be accessible from at least two sides for fire fighting and fire control

2217.3 – Construction of Tank Buildings

2217.3.1 – Storage tank buildings shall be constructed so as to maintain

structural integrity for 2 hours under fire exposure conditions and to provide

adequate access and egress for unobstructed movement of all personnel and

fire protection equipment.

2217.3.2 – Buildings or structures shall be at least 2 hour fire resistance rating

except for noncombustible or combustible construction shall be permitted

when protected by automatic sprinklers or equivalent protection.

2217.3.3 – Class I liquids and Class II or Class IIIA liquids heated above their

flash points shall not be stored in basements.

2217.3.4 – Storage tanks shall be separated from other occupancies within the

building by construction having at least 2 hour fire resistance rating.

2217.3 – Construction of Tank Buildings

2217.3.5 – Storage tank buildings shall have exit facilities arranged to prevent

occupants from being trapped in the event of fire.

2217.3.6 – Access isles of at least 0.9m shall be maintained for movement of

fire-fighting personnel and fire protection equipment

2217.3.7 – Clearance between the top of the tank and the building structure

shall be a minimum of 0.9m for buildings protected in accordance with

2217.2.3

2217.4 Ventilation of Tank Buildings

2217.4.1 – Storage tank buildings storing class I liquids, or Class II or

Class IIIA liquids at temperatures above their flashpoints, shall be

ventilated at a rate sufficient to maintain the concentration of vapors

within the building at or below 25& of the lower flammable limit.

2217.4.2 – Ventilation requirements shall be confirmed by calculations

based on the anticipated fugitive emissions, sampling of actual vapor

concentration under normal operating condition, and ventilation at a

rate of not less than 0.3 m3/min of exhaust air for each m2 of solid floor

area

2217.4.3 – Ventilation shall be accomplished by natural or mechanical

ventilation, with discharge or exhaust to a safe location outside the

building.

2217.5 – Drainage from tank buildings

2217.5.1 – Drainage systems shall be designed to minimize fire exposure

to other tanks and adjacent properties or waterways.

2217.5.2 – A facility shall be designed and operated to prevent the normal

discharge of flammable or combustible liquids to public waterways,

public sewers, or adjoining property

2217.5.3 – Except for drains, solid floors shall be liquid tight and the

room shall be liquid tight where the walls join the floor and for at least

100mm above the floor

2217.5.4 – Openings in interior walls to adjacent rooms or buildings shall

be provided with noncombustible, liquid tight raised sills or ramps at

least 100mm in height

2217.5.5 – The containment area shall have a capacity not less than that

2217.6 – Vents for tanks inside tank buildings

2217.6.1 – Vents for tanks inside tank buildings shall be designed to ensure the

vapors are not released inside the building..

2217.6.2 – Vents for tanks inside tank buildings shall be as required in

2215.2.3.1 and 2215.2.3.2, except that emergency venting by the use of roof-to-

shell seam shall not be permitted

2217.6.3 – Piping for normal and emergency relief venting shall meet the

requirements of 2203.0

2217.7 Tank openings other than vents for tanks inside tank buildings

2217.7.1 – Tank openings other than vents for tanks inside tank buildings

shall be designed to ensure that flammable liquids or vapors are note

released inside the building

2217.7.2 – All tank openings that are located at or below the maximum

liquid level shall be liquid tight; those that are located above the

maximum liquid level shall be normally closed and shall be

mechanically secured to prevent release of vapors

2217.7.3 – Each connection through which liquid can gravity flow from a

tank inside a building shall be provided with an internal or external

valve.

2217.7.4 – Each liquid transfer connection on any storing Class I or Class

II liquids inside buildings shall be provided with a normally closed

2217.7 Tank openings other than vents for tanks inside tank buildings

2217.7.5 – Openings for manual gauging of Class I or Class II liquids, if

independent of the fill pipe, shall be provided with a vapor tight cap or

cover.

2217.7.6 – Fill pipes that enter the top of a tank shall terminate within

150mm of the bottom of the tank.

2217.7.7 – The inlet of the fill pipe and the outlet of a vapor recovery line

for which connections to tank vehicles and tank cars are made and

broken shall be located outside of buildings at a location free from any

source of ignition and not less than 1.5m away from any building

opening

2217.7.8 – Tanks storing Class I, Class II, or Class IIIA liquids inside

buildings shall be equipped with a device , or other means shall be

Installation of electrical utilization equipment and wiring shall meet

the requirements of the Philippines Electrical Code – this is used to

determine the extent of classified locations for the purpose of

installation of electrical equipment.

2217.10.1 – An approved means shall be provided to promptly notify

those within the plant and the available public or mutual aid fire

department of any fire or other emergency,

2217.10.2 – areas with potential exists for flammable liquid shall

include the following methods: a) Personnel observation or patrol;

and b) Monitoring equipment that indicates a spill or leak has

occurred in an unattended area.

Fire fighting equipment is equipment designed to extinguish fires or

protect the user from fire. It may be used by trained fire fighters,

untrained users at the scene of a fire, or built into a building's

infrastructure (such as a sprinkler system). Fighting equipment

includes not only fire hoses and fire extinguishers but also fire-

resistant protective clothing, fire-resistant gloves, respirators, and

communication equipment.

Fire prevention and control, the prevention, detection, and

extinguishment of fires, including such secondary activities as

research into the causes of fire, education of the public about fire

hazards, and the maintenance and improvement of fire-fighting

equipment.

Keep the automatic shutoff valve free and unobstructed. A disabled

automatic shutoff prevents the valve from closing to prevent an

overfill.

Pay close attention before, during, and after product delivery to help

the delivery person avoid overfilling your UST.

Immediately report spills to your implementing agency.

High waters can dislodge unanchored tanks causing spills and

environmental and property damage.

Loose propane tanks may explode, potentially causing serious

injuries.

Buried tanks can be pushed to the surface by the buoyant effect of soil

saturated by water. Floating tanks become battering rams, causing

additional property damage.

When an unanchored tank in your basement is moved by flood

waters, the supply line can tear free and your basement can become

contaminated by oil.

Tank handling activities during closure may involve such tasks as

hazard recognition and AST system; overseeing or verifying cleaning

of the storage tank system; dismantling an AST; removal of ancillary

equipment and piping system; demolishing or excavating foundation

and containment structure; ventilating and rendering an AST

inoperative when the tank is closed and left on-site; and initial, on-

site staging of soil and debris.

Accurate inventory records or a leak detection program shall be

maintained on all Class I liquid storage tanks for indication of

possible leakage from the tanks or associated piping.

Flammable and combustible liquids are packaged, shipped, and

stored in bottle, drums, and other containers ranging in size up to

225L. Additionally, liquids are shipped and stored in intermediate

bulk up to 3000L and portable intermodal tanks up to 20,818L.

Storage requirements for these containers are covered in the NFPA 30

chapter on “Container and Portable Tank Storage.”

Outdoor containers storage should be located in such a manner as to

reduce the spread of fire to other materials in storage, adjacent buildings,

or neighboring properties. The storage area should be graded in a manner

to divert possible spills away from buildings or other exposures, or curbing

should be used to contain spills.

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- 19 Sea Inlets and Overboard Discharges: 17.5 Group II Piping FlangesDocumento2 pagine19 Sea Inlets and Overboard Discharges: 17.5 Group II Piping FlangesDorin SavaNessuna valutazione finora

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- 23 21 13 Hydronic Piping Systems QA QCDocumento5 pagine23 21 13 Hydronic Piping Systems QA QCAsmara KanthiNessuna valutazione finora

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- PSME CodeDocumento163 paginePSME Coderaymart caluag100% (1)

- Inspection of The SystemsDocumento12 pagineInspection of The SystemsTulen CabuldinNessuna valutazione finora

- 02720Documento9 pagine02720uddinnadeemNessuna valutazione finora

- Annex Building SPINKLER & FAS TECH SPEC PDFDocumento21 pagineAnnex Building SPINKLER & FAS TECH SPEC PDFmanishxlriNessuna valutazione finora

- Pex SpecsDocumento24 paginePex SpecsYazan TamimiNessuna valutazione finora

- CC102 Construction Materials and Application (Dry N Wet Risers)Documento30 pagineCC102 Construction Materials and Application (Dry N Wet Risers)Adron LimNessuna valutazione finora

- Appendix A - 1 - 28Documento1 paginaAppendix A - 1 - 28Ahmad Ramin AbasyNessuna valutazione finora

- PLPGA Safety Code 2000Documento48 paginePLPGA Safety Code 2000Jong EugenioNessuna valutazione finora

- Laying of Water Supply Pipes Prior To ConnectionDocumento7 pagineLaying of Water Supply Pipes Prior To ConnectionRaghavanARNessuna valutazione finora

- General-Duty Valve For Fire Protection PipingDocumento6 pagineGeneral-Duty Valve For Fire Protection PipingdiribaNessuna valutazione finora

- Galvanized Tank BrochureDocumento5 pagineGalvanized Tank Brochurem4004Nessuna valutazione finora

- SSG App C Des Con Guide - pdf4Documento7 pagineSSG App C Des Con Guide - pdf4Shohidul IslamNessuna valutazione finora

- Section 15250 - Mechanical InsulationDocumento8 pagineSection 15250 - Mechanical Insulationrizviabbas2012Nessuna valutazione finora

- KOROSIDocumento35 pagineKOROSISaiful BahriNessuna valutazione finora

- Particular SpecificationsDocumento5 pagineParticular SpecificationsMohammed HammadNessuna valutazione finora

- Specifications For Rectangular Aboveground Storage TanksDocumento3 pagineSpecifications For Rectangular Aboveground Storage TanksadammzjinNessuna valutazione finora

- Particular Specifications Plumbing and Sanitary Work: 1.0 GeneralDocumento19 pagineParticular Specifications Plumbing and Sanitary Work: 1.0 GeneralCherryl Chrissie JamesNessuna valutazione finora

- Good Din FIRE FIGHTING SYSTEM DESCRIPTIONDocumento4 pagineGood Din FIRE FIGHTING SYSTEM DESCRIPTIONJan LerNessuna valutazione finora

- Series 1500 Cooling Tower SpecificationDocumento9 pagineSeries 1500 Cooling Tower SpecificationLorenaNessuna valutazione finora

- Oman Hvac Component SpecificationDocumento20 pagineOman Hvac Component SpecificationSalley BukhariNessuna valutazione finora

- Section 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Documento52 pagineSection 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Andy PhoenixNessuna valutazione finora

- Api 575 NotlariDocumento12 pagineApi 575 NotlariErdi ErdoganNessuna valutazione finora

- Underground Chilled Water System August 132014Documento12 pagineUnderground Chilled Water System August 132014umair186Nessuna valutazione finora

- Pre Insulated Duct SpecificationDocumento6 paginePre Insulated Duct SpecificationGlishna Peushan Widanapathirana0% (1)

- 23 22 00 - Steam and Condensate Piping and PumpsDocumento6 pagine23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNessuna valutazione finora

- Ac Units Technical Specifications Annex ADocumento44 pagineAc Units Technical Specifications Annex Aengr.genaNessuna valutazione finora

- Deepak Patil: Fire Fighting Description and WmsDocumento5 pagineDeepak Patil: Fire Fighting Description and WmsDeepak PatilNessuna valutazione finora

- Inspection, Repair, Alteration, and Rerating of In-Service Piping SystemsDocumento3 pagineInspection, Repair, Alteration, and Rerating of In-Service Piping Systemskhaled saadnehNessuna valutazione finora

- Plumbing Specifications: 185 N. Domingo St. San Juan City M.M. LocationDocumento10 paginePlumbing Specifications: 185 N. Domingo St. San Juan City M.M. LocationPaulo Pancho100% (3)

- Mesan MXR-KM (F-K) Guide Specs r2Documento4 pagineMesan MXR-KM (F-K) Guide Specs r2Renu TekumudiNessuna valutazione finora

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDocumento8 pagineDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNessuna valutazione finora

- Rowan University Design Guide 2013Documento4 pagineRowan University Design Guide 2013zeliteNessuna valutazione finora

- Chapter 12: House Drains & House SewersDocumento5 pagineChapter 12: House Drains & House SewersMr. DummyNessuna valutazione finora

- M.engineering - Piping SystemsDocumento55 pagineM.engineering - Piping SystemsKordalhs KyriakosNessuna valutazione finora

- Annex H (Summary API 650) : 1. MaterialDocumento6 pagineAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdNessuna valutazione finora

- Completion Equipment1Documento32 pagineCompletion Equipment1MUHAMMAD AKRAMNessuna valutazione finora

- 11/29/19 Design No. - SECTION 15580 Feedwater EquipmentDocumento20 pagine11/29/19 Design No. - SECTION 15580 Feedwater EquipmentJhoNessuna valutazione finora

- Section 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2008 Page 11-1Documento49 pagineSection 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2008 Page 11-1buturcasNessuna valutazione finora

- P2 Rules For Piping Design, Construction and Testing P2: End of SectionDocumento37 pagineP2 Rules For Piping Design, Construction and Testing P2: End of Sectionjaydee45Nessuna valutazione finora

- O&M - SanitaryDocumento6 pagineO&M - SanitaryAzian KhalilNessuna valutazione finora

- GRP Tank SpecDocumento5 pagineGRP Tank SpecRamesh arumugamNessuna valutazione finora

- 40Documento4 pagine40Muhammad Umer ArshadNessuna valutazione finora

- QCS-2010 Section 19 Part 2 Water DistributionDocumento12 pagineQCS-2010 Section 19 Part 2 Water Distributionbryanpastor106100% (1)

- Technical Specifications - FPSDocumento18 pagineTechnical Specifications - FPSMC EstimationNessuna valutazione finora

- Topic: Freeze Protection For Pipes, Fittings and Valves UPC/3/#1Documento2 pagineTopic: Freeze Protection For Pipes, Fittings and Valves UPC/3/#1ibnrafeeqNessuna valutazione finora

- Multi-Column Water Tank Construction Specifications Tank Contractor: Phoenix Fabricators and Erectors, LLCDocumento8 pagineMulti-Column Water Tank Construction Specifications Tank Contractor: Phoenix Fabricators and Erectors, LLCJorge León IllanesNessuna valutazione finora

- SECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)Documento4 pagineSECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)vuhalamNessuna valutazione finora

- Section 15250 - Pipe, Duct, and Equipment InsulationDocumento7 pagineSection 15250 - Pipe, Duct, and Equipment InsulationnanajmeeNessuna valutazione finora

- WST CorGal SPEC 0803-WT-CHRDocumento4 pagineWST CorGal SPEC 0803-WT-CHRAlejandro TrujilloNessuna valutazione finora

- Piping Q.C Ag& UgDocumento12 paginePiping Q.C Ag& UgGokulPrasad88% (8)

- PLUMBINGDocumento19 paginePLUMBINGCharles NdunguNessuna valutazione finora

- Technical SpecificationDocumento12 pagineTechnical SpecificationYousuf KamalNessuna valutazione finora

- SPC Occ 221423 MeDocumento4 pagineSPC Occ 221423 Metarekhisham1234Nessuna valutazione finora

- QCS-2010 Section 20 Part 2 Internal Drainage WorksDocumento8 pagineQCS-2010 Section 20 Part 2 Internal Drainage Worksbryanpastor106Nessuna valutazione finora

- Specification For Phenolic Duct Works SystemsDocumento2 pagineSpecification For Phenolic Duct Works Systemspsn_kylmNessuna valutazione finora

- Process and Utility Piping DesignDocumento22 pagineProcess and Utility Piping DesignSAKURAIZENNessuna valutazione finora

- Volvo D6D Shop ArmedDocumento45 pagineVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- b16 34Documento121 pagineb16 34Gustavo Fama100% (2)

- Wap-7 Drawing DrequiredDocumento8 pagineWap-7 Drawing DrequiredM PankajNessuna valutazione finora

- HOVAL Scheda Tecnica Caldaia Ultragas 35 650Documento54 pagineHOVAL Scheda Tecnica Caldaia Ultragas 35 650PgNessuna valutazione finora

- SS Stub End Thickness CalculationDocumento1 paginaSS Stub End Thickness CalculationSrinivas KadivetiNessuna valutazione finora

- Hydraulic Lines and FittingsDocumento23 pagineHydraulic Lines and FittingsMohammed Al-OdatNessuna valutazione finora

- Comparative Study of Tube To Tubesheet Welding Qualification On Heat ExchangerDocumento14 pagineComparative Study of Tube To Tubesheet Welding Qualification On Heat Exchangerডঃ শুভম চ্যাটার্জীNessuna valutazione finora

- Jacketing With Tedlar - PVF Both Al and SS AlloyDocumento1 paginaJacketing With Tedlar - PVF Both Al and SS AlloyVishnu DuttaNessuna valutazione finora

- Control Valves: Environmental Pit Box GBMY 5050M2 SeriesDocumento4 pagineControl Valves: Environmental Pit Box GBMY 5050M2 SeriesMujahid SardarNessuna valutazione finora

- Preliminar: CenpesDocumento32 paginePreliminar: CenpesAlan ReisNessuna valutazione finora

- Manual Bomba KoomeyDocumento95 pagineManual Bomba KoomeyDiego De JesusNessuna valutazione finora

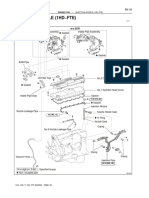

- 08erm Injector 1HD FTEDocumento15 pagine08erm Injector 1HD FTEbrettNessuna valutazione finora

- Air Heaters ManualDocumento13 pagineAir Heaters ManualalakaniNessuna valutazione finora

- Section - Multi-Column Elevated Water Storage TankDocumento6 pagineSection - Multi-Column Elevated Water Storage Tankali gholiaNessuna valutazione finora

- Super Duplex Stainless Steel PipesDocumento3 pagineSuper Duplex Stainless Steel Pipeskumar sandeepNessuna valutazione finora

- SS-15 BB II-H Wellhead SystemDocumento20 pagineSS-15 BB II-H Wellhead Systemianherzog100% (1)

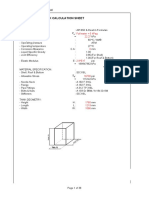

- Master Vdocuments - MX Rectangular Tank CalculationDocumento38 pagineMaster Vdocuments - MX Rectangular Tank CalculationVipul GandhiNessuna valutazione finora

- Pfi Estandard PDFDocumento1 paginaPfi Estandard PDFedwinramonNessuna valutazione finora

- Control de Presión - Manual de Operacin P70 P72 Y P170Documento17 pagineControl de Presión - Manual de Operacin P70 P72 Y P170danari25Nessuna valutazione finora

- Vic-Tap II Hole Cutting Tool For 4 - 8"/100 - 200mm Carbon Steel PipeDocumento1 paginaVic-Tap II Hole Cutting Tool For 4 - 8"/100 - 200mm Carbon Steel PipeHeiderHuertaNessuna valutazione finora

- Metec Design and Construction Engineers India (P) LTD: Itc LimitedDocumento21 pagineMetec Design and Construction Engineers India (P) LTD: Itc LimitedBalaNessuna valutazione finora

- EZ-Scan 6: Magnetic Wheel Linear Axis EncoderDocumento2 pagineEZ-Scan 6: Magnetic Wheel Linear Axis EncoderrubiodegoNessuna valutazione finora

- Wellpoint PumpDocumento2 pagineWellpoint Pumpakash nair100% (1)

- 2019 CMCDocumento550 pagine2019 CMCTony OquendoNessuna valutazione finora

- Datasheet - Boiler-Superheater-EconomizerDocumento1 paginaDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNessuna valutazione finora

- Piping Color CodesDocumento12 paginePiping Color Codesrajpal146Nessuna valutazione finora

- Brochure (Traffic Signs)Documento2 pagineBrochure (Traffic Signs)Lytat FactoryNessuna valutazione finora

- TENARIS Pipes-For-Civil-Industrial-InstallationDocumento28 pagineTENARIS Pipes-For-Civil-Industrial-InstallationNîakâm UshuaiaNessuna valutazione finora