Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TR X2 en

Caricato da

Peter Curi QuiñonesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TR X2 en

Caricato da

Peter Curi QuiñonesCopyright:

Formati disponibili

TECHNICAL TRAINING MANUAL

TRAINING

ROCKDRILL

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

2 ( 15 )

TECHNICAL TRAINING MANUAL

PERCUSSION WORKING PRINCIPLE

MODULE 1) PERCUSSION WORKING PRINCIPLE

1.1 WORKING AREAS

1 2

N2

6 3

The piston is at the impact point to the shank.

The high pressure always pressurizes : the front area 1, the accumulator 3 and the inlet port of

the distributor 4 together with the distributor at the right side of the spool.

Just before the impact point, the central part of the piston 5 allows the pilot channel 6 to release

pressure to tank. Therefore the high pressure applies now only on the small area of the distributor.

The spool moves as shown. Rear area 2 is vented to tank.

The recoil impact energy together with the pressure at the front area starts the return process of

the piston.

The piston speed is going to increase according to its reverse travel.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 3 ( 15 )

TECHNICAL TRAINING MANUAL

PERCUSSION WORKING PRINCIPLE

1.2 REAR PILOT POINT

N2

8

6

When the edge 7 of the piston get the position shown, high pressure runs into the pilot channel 6.

The distributor gets pressure on both ends. The larger side 6 moves the spool as shown. High

pressure enters the rear chamber.

Time to stop the piston in its reverse motion the accumulator receives oil from :

• for a while until complete stop from the rear chamber

• the pump

NOTE: according to the rockdrill type, an extra pilot channel can be used. By removing the plug

at the channel 8, pressure pressurizes the pilot channel sooner.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

4 ( 15 )

TECHNICAL TRAINING MANUAL

PERCUSSION WORKING PRINCIPLE

1.3 FORWARD TRAVEL

N2

The piston stops due to the pressure applied in the rear area and re-starts its forward motion.

It must maintain a constant acceleration up to the impact point.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 5 ( 15 )

TECHNICAL TRAINING MANUAL

PERCUSSION WORKING PRINCIPLE

1.4 BEFORE THE IMPACT

N2

This drawing shows the piston close to the impact point to the shank.

At the end of its stroke, the piston moves at the fastest speed, the needed flow is therefore at its

maximum level.

The accumulator supplies instant flow to the rear chamber.

To achieve this optimum speed, the rear area receives oil from :

• the accumulator

• the pump

• oil re-circulating from the front area

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

6 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

MODULE 2) X2 GENERAL ARRANGEMENT

2

HP

1-A

LP

Components

ITEM DESIGNATION

1 Rotation assembly

1-A Hydraulic motor assembly

2 Percussion assembly

3 Flushing head assembly

HP High pressure accumulator

LP Low pressure accumulator, working on return line

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 7 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

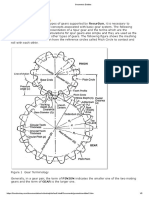

2.1 ROTATION

9

8 8

1

2

10 7

4

6

ITEM DESIGNATION

1 Hydraulic motor assembly

2 Main gear

3 Shank stop

4 Front flange fasten by 4 bolts

5 Set of dust seal, spacer and oil lip seal

6 Bronze driver

7 Set of dust seal, spacer and oil lip seal

8 Bronze bushing for the driver gear

9 Driver gear

10 Bronze bushing for the main gear

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

8 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

2.2 PERCUSSION

2

6

6

2

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 9 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

2.2.1 PISTON AT IMPACT POINT

The position of the central part of the piston let pressure running into pilot channel 6.

In the detail view, we see that the pilot pressure is acting on the largest area of the distributor.

That moves the distributor forward as shown.

The rear chamber 2 connected to tank allows reverse motion.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

10 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

2.2.2 END OF REVERSE MOTION

2

6

6

2

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 11 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

The central groove of the piston allows the pilot pressure 6 to release to tank.

The distributor is moving backward.

High pressure enters in the rear chamber 2.

The piston decelerates then start moving forward again.

At this step, it is of a prime importance to work with a correct inflated accumulator.

Flat accumulator results in very high surge of pressure. They stress all mechanical components

mainly the HP accumulator and percussion bodies.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

12 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

2.3 DISTRIBUTOR OPERATION

PORTS

P R C

P : percussion pressure

R : return

C : pilot channel

REAR CHAMBER PRESSURIZED

The piston in rear position releases the

pressure of the pilot channel to tank.

The percussion pressure is now acting

P R C on the small ring area at the front of the

distributor. It moves as shown allowing

HP to flow in the rear chamber.

When HP runs into the rear chamber, it

pressurizes both ends of the distributor.

As they are of the area they balance

each other.

That does not affect the motion of the

distributor. It continues moving as

shown.

At impact point, the piston allows

P R C percussion pressure to flow into the pilot

channel.

The rear ring area is larger than the front

one, the distributor moves as shown.

The rear chamber is now vented to tank.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 13 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

2.4 DAMPENING SYSTEM

21

20

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S

14 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

Just after the impact point, the piston is moving backward.

Some recoil energy together with the feed thrust force moves the shank in contact with its rear

stop 3.

To prevent any stress within the rotation mechanism, the shank stop moves freely.

It makes contact to the dampening piston 20. The pressurized chamber 21 should absorb the

recoil/feed energy.

20

21

From the HP line through supply hole, percussion pressure can enter the dampening chamber.

The dampening piston 20 get full HP pressure at its rear working area.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_X2 - EN 03 04 F.S 15 ( 15 )

TECHNICAL TRAINING MANUAL

X2 GENERAL ARRANGEMENT

The dampening piston will be immediately placed back in correct position.

21

Correct position means that the dampening piston by moving forward is going to place the shank

back at its nominal (normal) striking position.

In the above drawing, we can see the dampening piston now in forward position.

Due to the very high speed, if it wants to move too far ahead, the longest holes will release the

chamber pressure 21 to tank (refer to enlarged detail view).

The long (return) and the short (pressure) holes ensure a total control of the dampening piston

position.

NOTE: the pressurized chamber 21 must be large enough to handle all working conditions: feed

thrust force together with percussion recoil energy.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Low Cost HousingDocumento5 pagineLow Cost HousingReigna SantillanaNessuna valutazione finora

- (SPN) On J1939 Data LinkDocumento107 pagine(SPN) On J1939 Data LinkAM76Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Guest AccountingDocumento8 pagineGuest Accountingjhen01gongonNessuna valutazione finora

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Documento18 pagineABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatNessuna valutazione finora

- Importance of Team Work in An OrganizationDocumento10 pagineImportance of Team Work in An OrganizationMohammad Sana Ur RabNessuna valutazione finora

- Research On Surface Roughness by Laser CDocumento5 pagineResearch On Surface Roughness by Laser CfatmirhusejniNessuna valutazione finora

- Choosing The Right HF Welding Process For Api Large Pipe MillsDocumento5 pagineChoosing The Right HF Welding Process For Api Large Pipe MillsNia KurniaNessuna valutazione finora

- Understanding FreeRTOS SVCDocumento11 pagineUnderstanding FreeRTOS SVCshafi hasmani0% (1)

- MLCP - Area State Ment - 09th Jan 2015Documento5 pagineMLCP - Area State Ment - 09th Jan 201551921684Nessuna valutazione finora

- Project Proposal - Articulation SessionsDocumento8 pagineProject Proposal - Articulation SessionsJhay-are PogoyNessuna valutazione finora

- Sterling PumpeDocumento20 pagineSterling PumpesrdzaNessuna valutazione finora

- D.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Documento5 pagineD.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Pritam Kumar Singh100% (1)

- Introduction and Instructions: ForewordDocumento20 pagineIntroduction and Instructions: ForewordDanang WidoyokoNessuna valutazione finora

- Fashion Designing Sample Question Paper1Documento3 pagineFashion Designing Sample Question Paper1Aditi VermaNessuna valutazione finora

- 1.2 Installation of SSH Keys On Linux-A Step-By Step GuideDocumento3 pagine1.2 Installation of SSH Keys On Linux-A Step-By Step GuideMada ChouchouNessuna valutazione finora

- Multicomponent Distillation Shortcut MethodDocumento5 pagineMulticomponent Distillation Shortcut MethodDiegoAndréVegaDávalosNessuna valutazione finora

- 2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP GlycerinDocumento1 pagina2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP Glycerinchristian muñozNessuna valutazione finora

- Spectrochem Chemindex 2016 17Documento122 pagineSpectrochem Chemindex 2016 17Nivedita Dube0% (1)

- Sampling PowerpointDocumento21 pagineSampling PowerpointMuhammad Furqan Aslam AwanNessuna valutazione finora

- Statement of Facts:: State of Adawa Vs Republic of RasasaDocumento10 pagineStatement of Facts:: State of Adawa Vs Republic of RasasaChristine Gel MadrilejoNessuna valutazione finora

- Metabolic SyndromeDocumento4 pagineMetabolic SyndromeNurayunie Abd HalimNessuna valutazione finora

- AutoCAD Civil 3D Performance Optimization 2Documento5 pagineAutoCAD Civil 3D Performance Optimization 2Renukadevi RptNessuna valutazione finora

- Media ReportDocumento46 pagineMedia ReportAndrew AB BurgoonNessuna valutazione finora

- Geometric Entities: Basic Gear TerminologyDocumento5 pagineGeometric Entities: Basic Gear TerminologyMatija RepincNessuna valutazione finora

- Agenda 9Documento46 pagineAgenda 9Bala Gangadhar TilakNessuna valutazione finora

- Branding HS TalksDocumento17 pagineBranding HS TalksumairNessuna valutazione finora

- Routing Fundamentals: How A Juniper Device Makes Forwarding DecisionsDocumento8 pagineRouting Fundamentals: How A Juniper Device Makes Forwarding DecisionsLarsec LarsecNessuna valutazione finora

- CH7Documento34 pagineCH7Abdul AzizNessuna valutazione finora

- 1 Introduction To Pharmaceutical Dosage Forms Part1Documento32 pagine1 Introduction To Pharmaceutical Dosage Forms Part1Joanna Carla Marmonejo Estorninos-Walker100% (1)

- Chapter 3 - A Top-Level View of Computer Function and InterconnectionDocumento8 pagineChapter 3 - A Top-Level View of Computer Function and InterconnectionChu Quang HuyNessuna valutazione finora