Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

T22 Material NTPC PDF

Caricato da

HEMANT KUMAR SAHUTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

T22 Material NTPC PDF

Caricato da

HEMANT KUMAR SAHUCopyright:

Formati disponibili

SIPAT

FIELD QUALITY ASSURANC DEPARTMENT

Weld repair procedure for SA213T22 tubes in 660MW Boiler

Marking :

Mark cutting location on leak tubes.

Leak point

Cutting & Beveling :

Cut the leakage tube and neighbouring Fin.

Perform Beveling the both tubes of the new tube and cut tubes.

Insert the tube and preheating:

Insert the new beveling tube.

Perform Preheating with min Temp.200℃.

SIPAT

Preheating Area

(Min 200℃)

Butt weld : Perform Tube butt welds.

Amperage should be diminished gradually at final weld area and be stop

arc with backward direction.

Crater should be ground at every pass.

No permission of crater treatment on the same location at each pass.

Welding Process : GTAW

Welding Rod: ER80S-B2(1’st root Pass),ER90S-B3 for rest pass.

Amp Range: 120~160

Volt Range: 10~20

Preheat Temp : Min 200.

Inter pass Temp: Max.350

Gas Back Purging: Argon (Recommend)

Final W/D Split(3’d & 4’d weld)

RT: Perform RT(2 shots) on welding positions at 90° angle.

SIPAT

Insert the fin And preheating:

Insert the fin between tubes & keep 2mm gap then Perform Preheating with

min temp.200℃ .

New insert piece

200mm

Preheating Area (Min 200℃)

Preheating around fin area widely within

200mm area.

Fin welding:

Only with GTAW(ER90S-B3)

Min. 2 pass applied.

Final pass should be welded on fin side.

Min.2pass

2

1

1 Fin

2

PT: Perform PT test on butt weld and fin welds

Final Inspection: Identify tube weld surface visually.

SIPAT

Recommendation:

ER80S-B2 welding rod on root pass(1’ st pass) is recommended due to following

reasons.

At the initial design stage, T12 material also was recommended for vertical

wall considering design temp.Therefore usage of welding rod (ER80S-

B2 )equivalent to T12 base material is possible.

In case of urgent repair such as inserting the tube , It is so difficult to apply

back shielding and also increase risk for oxidation and crater crack on welds.

Welding Rod (ER80S-B2) is relatively less sensitive about the SCC than

welding rod(ER90S-B3) considering chemical composition.

As welding Rod (ER80S-B2) is applied on only root pass(1’st Pass) and

balances are filled with ER90S-B3, enough thickness equivalent to base metal

could be formed.

There is no effect on the boiler life cycle because the stress to circumferential

direction on weld area is half of the longitudinal stress.

DHI have used ER80S-B2 on the same repair welds in domestic power plants

----***----

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 04 T22Documento4 pagine04 T22HEMANT KUMAR SAHUNessuna valutazione finora

- 04 T22Documento4 pagine04 T22HEMANT KUMAR SAHUNessuna valutazione finora

- Modified Rankine CycleDocumento1 paginaModified Rankine CycleHEMANT KUMAR SAHUNessuna valutazione finora

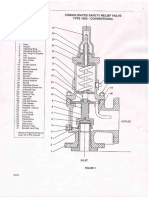

- 07 Soot Blower Safety ValveDocumento1 pagina07 Soot Blower Safety ValveHEMANT KUMAR SAHUNessuna valutazione finora

- 03 T91-1 PDFDocumento3 pagine03 T91-1 PDFHEMANT KUMAR SAHUNessuna valutazione finora