Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Power Plant

Caricato da

Vikas BhandareCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Power Plant

Caricato da

Vikas BhandareCopyright:

Formati disponibili

Energy Conservation in Power Plant Sector

596

Power plant

Per Capita Consumption 350 kWh (277 kg of oil equivalent)

Energy Intensity 6 – 8% of power generation

Energy saving potential Rs.3000 Million (US $ 60 Million)

Investment potential on

energy saving projects Rs. 5000 Million (US $ 1000 Million)

Investors Manual for Energy Efficiency

597

POWER PLANT SECTOR

INTRODUCTION

1.0 Energy Scenario

The power sector has always been high on India’s priority as it is a growing sector, offering

tremendous potential for improvements and new investments.

As per the recent projections by CEA, The total generating capacity which is today at about

1,07,000 MW is expected to reach 2,15,000 MW by 2012. The share of various sources in

meeting this requirement is shown in Table-1.

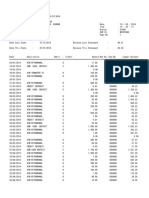

Table 1: Power Sector Growth Projection in MW

Coal Gas Nuclear Hydro Others Total

Installed Capacity

as on Feb 2003 63800 11560 2720 26760 2800 107644

Additional Capacity

to be increased

(2003-2012) 50690 19860 8380 27050 2170 108150

Total Capacity

by 2012 114490 31420 11100 53810 4970 215800

Source: CEA

Economic growth in India crucially depends on the long-term availability of energy in increasing

quantities from sources that are dependable, safe and environmentally friendly.

India, like many other developing countries, is a net importer of energy, 20 per cent of primary

energy needs being met through imports mainly in the form of crude oil and natural gas.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

598

Currently, thermal power plants accounts for major share of about 70%. Coal is the mainstay

fuel in India for power generation. With total coal reserve around 220 billion tones, of which

84.4 billion tonnes are proven, coal will continue to be an assured energy source for the next

century and beyond.

Though coal based plants account for major share in power generation, recently there is an

increasing trend in going for gas-based power plants also, particularly in the private sector.

1.1 Power Generation Capacity

The power generating capacity in India has increased over 80-fold, from 1,362 MW in 1947 to

1,07,644 MW in 2003.

The share of various sources of power generated is pictorially shown in figure 1.

(Source: Ministry of Power)

The industrial sector is the highest consumer of electricity (34 percent) followed by agriculture

(30 percent) and domestic (18 percent) sector.

1.2 Per-Capita Energy Consumption

Per capita energy consumption in India is about 277 Kg of oil equivalent, which is 3.5 per cent

of that in the USA, 6.8 per cent of Japan, 37 percent of Asia and 18.7 per cent of the world

average. Per-capita consumption of electricity for various countries is shown in figure 2.

Figure 2: Per-capita consumption in Kwh

(Source: Ministry of Power)

Investors Manual for Energy Efficiency

599

But, energy intensity, which is energy consumption per unit of GDP, is one of the highest in

comparison to other developed and developing countries. For example, it is 3.7 times that of

Japan, 1.55 times of the USA and 1.5 times of the World average. This signifies that there

is tremendous scope for energy conservation in the country.

1.3 Thermal Power Plants in India

In India, size of thermal power plants started with ratings of 60/70 MW during 1965, which

touched 500MW rating in 1979. At present National Thermal Power Corporation (NTPC) is

planning to install units in the range of 660MW rating, operating with supercritical parameters

at Sipet in Chattishgarh State by the year 2005.

There are about 85 major thermal power plants installed in India. The eastern belt being coal

abundant, major plants are located in that region.

Figure 3: Thermal Power Plants

(Info: http://www.osc.edu/research/pcrm/emissions/thermalemissions)

Apart from private and public utilities and IPP’s, most of the industries have there own captive

generation.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

600

1.3.1 Captive Power Plants

Industrial Sector is the largest consumer of energy. Besides consuming power from Utilities,

a number of industries which are primary producers of infrastructure material such as Aluminium,

Cement, Fertilizers, Iron & Steel, Paper and Sugar etc. have their own captive power plants.

The installation of captive generation plants has been either to supplement the electricity

purchased from the Utilities or for emergency use in case of power outages or for producing

energy from by-product of the industrial process (e.g., Sugar Plants).

Table 3 shows sector wise captive power plant installed in the country.

Table 3: The break up of Captive Power Plants

Installed Percentage of

Sl.No. Name of Industry Capacity TotalInstalled

(MW) Capacity

1 Chemicals, Mineral Oil &

Petroleum 1993 13.86

2 Textile 1884 14.54

3 Aluminium 1742 12.32

4 Iron & Steel 1686 15.78

5 Cement 1466 10.16

6 Fertilizers 1155 9.02

7 Sugar 7862.66

8 Paper 5994.06

9 Heavy & Light Engineering 4532.50

10 Non-Ferrous Metal 4243.94

11 Automobiles 2311.13

12 Food 115 0.53

13 Mining & Quarrying 38 0.68

14 Other Industries 1360 8.82

Total 13932 100.00

Source: CEA

India has a total capacity of 2500 MW thermal based Independent power plants (IPP’s)

Investors Manual for Energy Efficiency

601

CHAPTER II

PROCESS, TECHNOLOGY AND TRENDS

2.1 Technology Trends

Thermal power generation started with ratings of 60/70 MW rating units in the year 1965,

simultaneously raised to 110/120 MW units by the year 1966. The next size of 200/210 MW

plants, which are widely installed all over India from the year 1972 onwards grew into 500 MW

units by the year 1979.

As the unit ratings grew, the boiler parameters supplying steam to such turbines have also

increased. Following table 4 shows the trends in super heater outlet pressures and temperatures

for various unit sizes.

Table 4: Turbine Sizes and Pressure Parameters

Unit Size Steam Flow Super Heater Super heater

(T/H) Outlet Pressure / Re Heater Outlet

(KG/CM2) Temperature (oC)

30 MW 150 63 490

60/70 MW 260 96 540

110/120 MW 375 139 540

200/210 MW 690 137/156 540

250 MW 805 156 540

500 MW 1670 179 540

Source: BHEL

The over all efficiencies of power plants with sub critical parameters fall in the range of 35-

39 percent which can be improved to 45 percent using supercritical parameters with conventional

steam turbines. Using combined cycle mode, the maximum efficiency that can be attained is

about 50 percent.

Table 5 shows the heat rate for various capacities of turbines achieved in power plants.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

602

Table 5: Turbine Sizes and Heat Rate

Unit capacity Turbine inlet Turbine Heat Rate

parameter (Kcal/Kwh)

60/100 MW 90 ata 535oC 2315

110/120 MW 130 ata 535oC 2180

200/210 MW 130 ata 535oC 2025

210/250 MW 150 ata 535oC 1975

500 MW 170 ata 535oC 1950

Source : BHEL

Power plants are adopting several latest technologies to improve the efficiency and operating

practices. Some of the power plants are installed with multi fuel capabilities by design for the

following benefits.

• Flexibility to use depending on availability and price

• To address environmental issues like Nox and Sox reduction

2.2 Clean Coal Technologies

Environmental performance of thermal power plants is accorded tremendous importance to

meet global emission standards and need for balancing development and social obligations.

Clean coal technologies for power generation that posses the potential to contain pollutants

either at the combustion or pre-combustion stage will be the technologies that would eventually

replace the conventional PC firing.

India’s experience in clean coal technology started with the development of AFBC (Atmospheric

Fluidized Bed Combustion) for high ash coals. CFBC (Circulating Fluidized Bed Combustion)

was later introduced to cater to higher capacity power plants and to realize higher efficiency.

Investors Manual for Energy Efficiency

603

It has been a challenge for the Indian power plants to adopt several measures to bring down

the ash disposal and to meet the stringent environmental regulations, some of which are

shown below

• Importing high grade coal

• Lower emission technologies

• Improving efficiency of equipment

Power plants are also exploring various possibilities to utilize the fly ash as by-product for

some processes like

• Utilising in cement preparation as substitute for clinker

• Manufacturing of Flyash bricks

2.2.1 AFBC Boilers

Atmospheric fluidized bed Combustion (AFBC), promises to provide a viable alternative to

conventional coal fired boilers for utility and industrial application.

The advantages of AFBC boilers are

• Suitable to burn variety of fuels

• Combustion efficiency is higher

• It can completely burn fine particle (Fuel size range:6-12 mm)

• Losses due to unburnt are avoided

• Simple auxiliaries i.e., Lower operating cost

2.2.2 CFBC Boilers

Circulating Fluidized Bed Combustion (CFBC) boiler is normally designed for high reliability

and availability with low maintenance.

Some of the advantages of CFBC boilers are

• Thermal efficiency is higher than AFBC

• Technology is suitable to burn a wide range of fuels (high ash coal, high sulphur coal,

lignite, pet, coke, anthracite clum, wood paste, etc.)

• CFBC boiler availability is more than 95%.

• Lesser Sox, Nox emissions

• Auxiliary power consumption of these boilers is relatively lower (do not require high pressure

blowers)

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

604

2.2.3 Super Critical Boilers

Super critical boilers operate at main steam pressures exceeding 225 ata i.e., critical pressure

at which there is spontaneous changeover from liquid phase to vapour phase.

Supercritical units normally operate around pressure of 240-250 ata. The main steam temperature

& reheat temperature for these units are normally in the range of 535-565oC. Boilers with

steam pressures and temperatures beyond 250 ata/565oC are termed as ultra supercritical

boilers.

Some of the excellent features of supercritical boilers are

• Enhanced boiler efficiency

• Operational flexibility to respond quickly to load changes

• Reduced emissions

2.4 Renovation & Modernization

Old power plants are modernized to keep up the operation of the equipment and its efficiencies.

The advantages of Renovation & modernization are

• Enhancement of operational efficiency

• Improvement in Plant Load Factor (PLF)

• Meeting stringent environmental pollution control standards

• Extend plant life

• Capacity augmentation

Some of the renovation and retrofitting techniques that are followed by the power plants are

1. Steam turbine retrofitting (blades replacement and improvement of the labyrinths’ operation

and turbine control system, etc)

2. Improvement of the fuel preparation and firing system

3. Implementation of techniques for further reduction of the Nox emissions and for the flue gas

de-sulphurization

Investors Manual for Energy Efficiency

605

4. Improvement of particles collecting systems

5. Optimization of the existing fuel drying system or implementation of new effective drying

techniques

6. Replacement, rearrangement or size change of heat exchange surfaces

7. Supplementary heat exchange surfaces for further heat recovery from flue gas

8. Improvement of the air preheating system

CHAPTER III

ENERGY SAVING PROJECTS

3.1 Energy Saving & Investment Potential in Power plants

The consumption of electricity by power plant auxiliaries depends on factors such as unit size,

level of technology, plant load factor, fuel quality etc.

The auxiliary consumption in general varies between 3 to 6% for larger plants and close to 10

% for smaller captive power plants.

CII studies indicate that the energy saving potential in small size power plants (CPP’s & IPP’s)

varies between 6% - 10% of auxiliary consumption. It is estimated that the saving potential is

150 MW of power amounting to Rs.300 crores annually.

CII study also indicates that the investment potential for energy efficiency in small size

power plants is Rs.500 crores. This does not include saving potential in utility plants.

3.2 List of Projects

All energy saving projects are classified in to three categories namely Short term, Medium term

and Long term based on the investment and returns available in each project.

These projects apply to IPP’s & CPP’s and can be easily implemented. Some of these

projects are equally applicable in utility power plants.

3.2.1 Short Term Projects

A) Boilers

1. Install online O2 analyser and improve combustion efficiency of the boilers

2. Arrest air infiltration in boiler flue gas path, particularly economiser and air preheater section

3. Install water heating system for preheating gas through waste heat recovery from Boiler

exhaust

4. Install waste heat recovery system for boiler blow down

5. Install LP steam air heater for FD fan air inlet to boiler

6. Optimise the operating breakdown voltage of ESP’s

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

606

B) Steam & Condensate Systems

1. Avoid steam leakages

2. Insulate all steam and condensate lines

3. Monitor and replace defective steam traps on a regular basis

4. In case coal has higher percentage of fines, ensure wetting is done.

5. Install flash vessels for heat recovery from hot condensate vapours

6. Replace electric heaters with LP steam heaters for RFO tracing lines

C) Electrical Areas

1. Install delta to star converters for lightly loaded motors

2. Use translucent sheets to make use of day lighting

3. Install timers for automatic switching ON-OFF of lights

4. Install timers for yard and outside lighting

5. Install CFL’s for lighting in non-critical areas, such as, toilets, corridors, canteens etc.

6. Group the lighting circuits for better control

7. Operate at maximum power factor

8. Switching ‘OFF’ transformers based on loading

9. Optimise TG sets operating frequency, depending on user needs

10. Optimise TG sets operating voltage

D) Miscellaneous

1. Replace Aluminium blades with FRP blades in cooling tower fans

2. Install temperature indicator controller (TIC) for optimising cooling tower fan operation,

based on ambient conditions

3. Install dual speed motors/ VSD for cooling tower fans

4. Avoid/ minimise compressed air leakages by vigorous maintenance

5. Segregate the service air &

instrument air and optimise optimise operating pressure

6. Reduce system pressure of the compressed air system close to operating pressure of

the users

7. Install variable frequency drive for hot well makeup water pump

8. Install Variable Frequency Drive (VFD) for cooling tower make up pump with water level

control feed back

9. Install Variable Frequency Drive for DM water transfer pump

Investors Manual for Energy Efficiency

607

10. Close Suction Dampers at Stand-By Equipment and Reduce RPM of Dust Extraction

Blowers in the Coal Handling Plant

11. Install the next lower size impeller for the chilled water pumps

12. Avoid idle flow of cooling water in stand by DG sets and compressors

13. Install chlorine dosing and HCL dosing for circulating water

3.2.2 Medium Term Projects

A) Boilers

1. Install economiser/air preheater for boilers

2. Install high temperature deaerator (120°C to 140°C) with suitable boiler feed water pump

to enhance cogeneration

3. Install VSD for SA fan, FD fan and ID fan

4. Install VSD for boiler feed water pump

5. Segregate Intermediate Pressure & High Pressure Boiler Feed Water Pump

6. Install Variable Frequency Drive (VFD) for CCW pump and operate in closed loop control,

based on the discharge header pressure.

7. Reduce Heat rate of gas turbines by optimizing NOx water injection and arresting of

leakages through bypass dampers

8. Install Turbine inlet air cooling to increase power output of gas turbines

9. Install Low excess air burners

10. Reduce one stage of feed water pump or install variable frequency drive with feed back

control to exactly match with the system pressure

11. Install lower head fan for power plant boiler ID fan

B) Steam & Condensate Systems

1. Convert medium pressure steam users to LP steam users to increase co-generation

2. Install condensate recovery systems in air heaters

3. Utilise waste condensate for de-superheating the process steam

4. Install Variable Fluid Coupling or variable frequency drive for condensate extraction pump

5. Utilise flash steam from boiler blow down for deaerator heating

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

608

C) Electrical & Miscellaneous Areas

1. Install maximum demand controller to optimise maximum demand

2. Install capacitor banks to improve power factor

3. Replace rewound motors with energy efficient motors

4. Replace conventional ballast with high efficiency electronic ballasts in all discharge lamps

5. Install Sodium vapour lamps instead of MV lamps for Yard, Street and General Lighting

6. Install LED lamps for panel indication instead of filament lamps

7. Install neutral compensator in lighting circuit

8. Optimise voltage in lighting circuit by installing servo voltage stabilisers

9. Minimise overall distribution losses, by proper cable sizing and addition of capacitor banks

10. Replace V-belts with synthetic flat belts/Cog ‘V’ belts

11. Replace heater - purge type air dryer with heat of compression (HOC) dryer for

compressed air requirement above 500 cfm

12. Replace old and inefficient compressors with screw or centrifugal compressors

3.2.3 Long Term Projects

1. Install VFD for Boiler ID/FD fans

2. Install VFD for Boiler feed water pump

3. Install Circulating Fluidised bed boilers for Efficient combustion

4. Install steam driven equipment to prevent HP steam flow through pressure reducing valves

5. Convert chain grate/spreader stoker boilers to AFBC technology

6. Install high efficiency turbines

7. Install vapour absorption system to utilise LP steam for air-conditioning

8. Install Distributed control system (DCS) for Power Plant Operation and monitoring

Investors Manual for Energy Efficiency

609

3.2 Case Studies

Case Study: 1

Convert Spreader Stoker Boilers to Fluidised Bed Boilers

Background

In the older power plants, the boilers are the conventional stoker boilers.

These boilers were characterised by:

• Higher unburnts in ash

• Lower thermal efficiency

The latest trend has been to install the fluidised bed boilers or conversion of the existing chain

/ spreader stocker boilers, which have the following advantages:

• Coal having high ash content/ low calorific value can be used

• Biomass fuels can also be used

• Lesser unburnts in ash

• Higher thermal efficiency

Hence, the older plants are also in a phased manner, converting their old stoker-fired boilers

to fluidised bed boilers. This case study describes one such project implemented.

Previous Status

A power plant had four numbers of spreader stoker boilers, operating to meet steam

requirements of the plant. These spreader stoker boilers, were designed for high calorific value

coal (4780 kCal/kg) with low ash content.

Due to non-availability of this type of coal, these boilers had to be fired with coal of low calorific

value and high ash content. This resulted in the capacity down-gradation and loss in efficiency.

The steam generation was only 14 TPH, as against the design rating of 30 TPH. The boiler

efficiency achieved was only 65%.

Energy saving project

The plant team modified two of the spreader stoker boilers into fluidised bed combustion

boilers.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

610

Benefits of the Project

In addition to the benefits of fluidised bed combustion mentioned earlier, they also enable the

use of biomass fuels, such as saw dust, generated in the chipper house.

The steam generation capacity increased to 27 TPH and the thermal efficiency improved to

78%, with this modification. The improved thermal efficiency has resulted in an annual coal

saving of 5639 MT. Additionally, the use of saw dust (calorific value of about 3000 kCal/kg) has

resulted in an annual coal savings of 3600 MT.

Finalcial Analysis

The annual benefits achieved were Rs.10.50 million. This required an investment of Rs.27.0

million (for the conversion of two spreader stoker boilers to fluidised bed combustion boilers),

which had a simple payback period of 31 months.

Cost benefit analysis

• Annual Savings – Rs 10.50 millions

• Investment – Rs 27.0 millions

• Simple payback - 31 months

Implementation Strategy

The plant took up implementation of the project after a detailed planning with the EPC contractor.

The modification was taken up during the annual shut down (30 days). The shut down had to

be extended to avoid 30 days to complete the project. The commissioning of the new boiler

took about 4 days and there were no problem during implementation.

Investors Manual for Energy Efficiency

611

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

612

Case Study: 2

Install VFD for Boiler ID fans and PA fans

Background

In a major captive power plant, three irculating fluidised bed combustor (CFBC) were in

operation. Each boiler has two ID fans and three PA fans.

• All these fans had higher capacity & head by design and controlled either by IGV’s or

Dampers to meet the operating requirements.

• The IGV opening of the ID fans varied between 50-60%, resulting in tremendous energy

loss. The measured pressure loss across the damper & IGV was of the order of 40-45%

of the total pressure rise of the fan.

Concept of the Project

• The operation of a fan with damper control or IGV control is an energy inefficient practise,

as a part of the energy supplied to the fan is lost across the damper or IGV.

• Also, the operation of a fan operating with IGV or damper control will result in operation of

the fan in an energy inefficient zone on the fan performance curve. Instead the speed of the

fan can be varied to meet the operating condition of the boiler by installing variable frequency

drives.

• The estimated operating efficiency of the fans was in the range of 60% - 65% as against

design efficiency of 80%. It was confirmed that the fans were operating in an energy

inefficient zone.

Energy Saving Project

Variable frequency drives were installed for 6 nos of ID fans and 9 nos of PA fans to control

the speed of the fan with respect to operation of the boiler.

Investors Manual for Energy Efficiency

613

Implementation Strategy

The VFD’s were installed during the stoppage of the plant for maintenance. The plant personnel

were well trained in operation and maintenance of VSD’s (prior to the installation of VFD) and

therefore no problems were faced with implementation. The inlet guide vanes were kept fully

opened after the VFD was installed.

Benefits of the Project

• The advantage of installing a variable frequency drive for the boiler ID fans are as follows:

Energy saving

Precise control of parameters

Financial Analysis

The annual energy savings achieved was Rs 6.0 million and the investment was Rs 10.0

million for installing 15 nos of variable frequency drives, which got paid back in 20 Months.

Cost benefit analysis

• Annual Savings – Rs 6.0 millions

• Investment – Rs 10.0 millions

• Simple payback - 20 months

Replication Potential

Similar projects can be taken up for FD & Secondary air fans also. The project has high

replication potential in majority of the captive power plant and IPPs. For ID, FD, secondary air

and primary air fans

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

614

Investors Manual for Energy Efficiency

615

Case Study: 3

Install steam drives to prevent HP steam flow through pressure reducing valves

Background

• In a major captive power plant, the auxiliary steam requirement was at a pressure of 24 kg/

cm2 and 4100C.

• The quantity of process steam requirement was about 11.5 kg/cm2. To meet the process

requirement the steam from extraction was passed through PRDS.

• When steam pressure is reduced by passing through a pressure reducing valve, the enthalpy

of the steam remains constant. But due to pressure loss, the opportunity for converting the

low grade energy (thermal energy) to high grade energy (mechanical energy) is lost.

• The quantity of steam passed through the pressure reducing valve was varied depending

upon the process requirement.

• Instead of dropping the high pressure to low pressure by throttling, the same energy can

be used for power production.

Energy Saving Project

• The potential available was tapped by installing 2 back pressure steam turbines which were

used for driving the drip pumps (2 Nos.). The exhaust steam from the back pressure turbine

was utilised for auxiliary steam requirements.

Implementation Methodology

In a captive power plant the modification of the plant on a continuous basis is essential. A

stoppage for replacing the motor with a turbine for drip pump was not possible. Therefore 2

new drip pumps with back pressure turbines (300 kW) each were installed and the system

was hooked up during a maintenance shut down. Though the investment was high the stoppage

of plant could be avoided.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

616

Benefits

The implementation of the project resulted in improving the co-generation potential.

Finalcial Analysis

The annual energy savings achieved was Rs 27.5 million and the investment was Rs 12.5

million for installing back pressure turbines, Generator and steam piping, which had a pay

back of 6 Months.

Cost benefit analysis

• Annual Savings – Rs 27.5 millions

• Investment – Rs 12.5 millions

• Simple payback - 6 months

Investors Manual for Energy Efficiency

617

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

618

Case Study: 4

INSTALL VAPOUR ABSORPTION HEAT PUMP IN PLACE OF VAPOUR

COMPRESSION SYSTEM

Background

In a captive power plant (of 21 MW capacity) of a large integrated paper plant, certain areas,

viz., the boiler & TG control room, static excitation room, ESP/Ash handling plant control room

and coal handling plant control room required a temperature of 26 ± 2 °C to be maintained.

The total air-conditioning load was 60 TR. Since, this power plant was in the project stage, the

plant team had the option of choosing between a vapour compression system and a vapour

absorption system, for maintaining these conditions. A techno-economic study favoured the

installation of a vapour absorption system.

Concept of the project

The vapour absorption system scores over vapour compression system when

:

• Back pressure steam from a turbine is available

• Any waste source of heat is available on a continuous basis e.g. DG exhaust

• Cost of a electricity is high

In this case study, the turbine had the capacity to accept additional 300 kg/hr of low cost low

pressure steam. This gives an excellent spin-off benefit by generating additional power in the

turbine.

Energy saving project

The plant team installed a 60 TR vapour absorption system for meeting the air conditioning

requirements of the various control rooms. This project was taken up at the design stage itself.

Comparison of Vapour Absorption Vs Vapour Compression

The comparative analysis of a vapour compression system and a vapour absorption system,

for achieving the same amount of air-conditioning, are as follows:

Investors Manual for Energy Efficiency

619

Parameter Units Vapour Vapour

compression absorption

system system

Rating TR 60 60

Power consumption kW 60 60

Steam consumption at

4 ksc kg/h - 300

Annual operating cost * Rs.lakhs 16.80 6.60

Annual savings Rs.lakhs - 10.20

Investment required Rs.lakhs 12.00 19.00

* Operating cost based on steam cost @ Rs.250/MT

and electricity cost @ Rs.3.50/kWh

In addition to the above, other benefits achieved were as follows:

• The room conditions were met as desired

• No maintenance shut down required, since there are no moving parts

Benefits & Financial Analysis

The annual energy saving achieved was Rs.1.0 million. This required an investment of

Rs.1.9 million, which had a simple payback period of 23 months.

Cost benefit analysis

• Annual Savings – Rs 1.0 millions

• Investment – Rs 1.9 millions

• Simple payback - 23 months

Replication Potential

The installation of vapour absorption refrigeration system is in its nascent stage in the Indian

industry. The potential for installation of vapour absorption system in combination with a co-

generation system is tremendous in Indian industry and therefore needs to be pursued.

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

620

Investors Manual for Energy Efficiency

621

CHAPTER IV

Service Agencies in the sector

4.1 List Of Suppliers

1. Bharat Heavy Electricals Ltd (BHEL)

Building BHEL Building

Street Siri Fort Road

City 110 049 New Delhi

Country India

Telephone (+91) 11 - 649 30 31

Facsimile (+91) 11 - 649 30 21

E-Mail lodpms@bhelindustry.com

Internet www.bhelis.com

Description Power Generation and New & Renewable Energy Technologies

2. Thermax Babcock & Wilcox Ltd (TBW)

Building Sagar Complex

Street Mumbai Pune Road

Place Kasarwadi, Nasik Phata

City 411 034 Pune

Country India

Telephone (+91) 20 - 712 57 45

Facsimile (+91) 20 - 712 55 33

E-Mail tbw-web@tbwindia.com

Internet www.tbwindia.com

Description Heat Recovery Steam Generators, Circulating Fluid Bed Boilers,

Grate & Gas Fired Boilers

3. Thermax Ltd

Building Thermax House

Street 4, Mumbai Pune Road

Place Shivaji nagar

City 411 005 Pune

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

622

Country India

Telephone (+91) 20 - 551 21 22

Facsimile (+91) 20 - 551 22 42

E-Mail abunglow@thermaxindia.com

Internet www.thermaxindia.com

Description Boilers & Heaters, Captive Power, Cooling, Water & Waste

Solutions, Air Pollution Control and Chemicals

4. Larsen & Toubro Ltd – EPC Centre

Building Ashish Complex

Steet NH8, Chhani

City 391 740, Vadodara-Gujarat

Country India

Telephone (+91) 265 – 2775317 /2774941-5

Facsimile (+91) 265 - 27773898/5286

E-Mail yps@enc.ltindia.com,

Internet www.lntenc.com

Description Power Projects Development, Renovation & Modernisation,

Hydro Projects

5. Foster Wheeler India Pvt Ltd

Building Prakash Presidium

Street 110, Mahatma Gandhi Road

Place Nungambakkam

City 600 034 Chennai

Country India

Telephone (+91) 44 - 28227341

Facsimile (+91) 44 - 28227340

E-Mail fwenergy@fwc.com

Internet www.fwc.com

Description PC Fired & FBC Boilers, HRSG, Gasifiers

Investors Manual for Energy Efficiency

623

6. TurboTech Precision Engineering Pvt Ltd

Street No 28/29, 2nd Main Road

Place Industrial Town, Rajajinagar

City 560 044 Bangalore

Country India

Telephone (+91) 80 - 320 07 89

Facsimile (+91) 80 - 330 72 27

E-Mail turbo1@vsnl.com

Internet www.turbotech-india.com

Description Manufacturers of Small, Efficient Steam and Gas

Turbines

7. Neptunus Power Plant Services Pvt Ltd (NPPS)

Building 511, Arenja Corner

Street Plot 71, Sector 17

Place Vashi

City 400 705 Navi Mumbai

Country India

Telephone (+91) 22 - 789 32 58

Facsimile (+91) 22 - 790 60 81

E-Mail neptunus@vsnl.com

Internet www.neptunus-power.com

Description Captive Power Plants, Power Generation, Co-

Generation etc

8. Aravinthraajan Energy Systems

Building Madhurams Flat

Street 17/1 Senthil Andavar Street

Place Vadapalani

City 600 026 Chennai

Country India

Telephone (+91) 44 - 484 46 27

Facsimile (+91) 44 - 484 46 27

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

624

E-Mail aessoft@satyam.net.in

Internet www.geocities.com/powerfulsolution/

Description Power Plant System Design and Optimisation

Software

9. Turbo Engineers (TE)

Street 2/C/1, Picnic Garden 3rd Lane

City 700 039 Kolkata

Country India

Telephone (+91) 33 - 343 49 48

Facsimile (+91) 33 - 343 44 11

E-Mail turbo@cal2.vsnl.net.in

Internet www.maxpages.com/turboengineers/

Description Thermal & Hydro Power Generation

10. DUKJIN E & C

Building 277, Nonhyun-Dong

Street Kangnam-GU

City Seoul

Country Korea

Telephone 82-02-3443-0692 to 5

Facsimile 82-02-3443-0696

E-Mail dukjinec@dukjinec.com

Internet www.dukjinec.com

Description Water Treatment & Ultra Filtration system

4.2 List of consultant in the sector

1. TCE Consulting Engineers Limited

Building Sherif Center

Street 73/1 St, Marks Road

City 560 001 Bangalore

Country India

Telephone (+91) 80 – 2274721

Investors Manual for Energy Efficiency

625

Facsimile (+91) 80 - 2274873

E-Mail kini@bangalore.tce.co.in

Internet www.tce.co.in

Description Consultancy Services in Power Generation, Transmission

& Distribution

2. Avant-Garde Engineers and Consultants Pvt Ltd (AGEC)

Street 68a, Porur-Kundrathur High Road

Place Porur

City 600 116 Chennai

Country India

Telephone (+91) 44 - 482 87 17

Facsimile (+91) 44 - 482 85 31

E-Mail avantgarde@vsnl.com

Internet www.avantgarde-india.com

Description Concept to Commissioning of Renewable Energy Projects

3. FICHTNER Consulting Engineers (India) Private Ltd

Street 64, Eldams Road

City 600 018 Chennai

Country India

Telephone (+91) 44 – 2435 9158

Facsimile (+91) 44 – 2434 4579

E-Mail mail@chn.fichtner.co.in

Internet www.fichtner.co.in

Description Consultancy Services in Gas & Thermal Power Plants

4. Acon Power Consultants

Street 45 Satyanand Vihar

District Rampur

City 482 008 Jabalpur

Country India

Telephone (+91) 761 - 66 72 61

Confederation of Indian Industry - Energy Management Cell

Energy Conservation in Power Plant Sector

626

Facsimile (+91) 761 - 66 42 07

E-Mail acon@sancharnet.in

Internet www.acon4power.com

Description Engineering Consultancy Services, Specializing in Power

(Thermal/Hydro/Non-Conventional Energy Source)

5. Mitsui Babcock Energy (India) Private Ltd

Building Alsa Tower

Street 186-187 Poonamalle High Road

Place Kilpauk

City 600 101 Chennai

Country India

Telephone (+91) 44 - 26612901

Facsimile (+91) 44 - 26612907

E-Mail jmcphail@mitsuibabcock.com

Internet www.mitsuibabcock.com

Description Thermal Power Plants

6. L&T - Sargent & Lundy Ltd

Building L&T-Energy Centre

Street Near Chhani Jakat Naka

District Baroda

City 390 002 Vadodara

Country India

Telephone (+91) 265 - 77 23 90

Facsimile (+91) 265 - 79 52 35

E-Mail ltsl@ltecd.ltindia.com

Internet www.lntsnl.com

Description Complete Consultancy Services in the Field of Power

Generation from Concept to Commissioning for Power

Projects

Investors Manual for Energy Efficiency

627

7. Mantech Synergies Pvt Ltd

Street 73, Sardar Patel Road

Place Guindy

City 600 032 Chennai

Country India

Telephone (+91) 44 - 220 02 45

Facsimile (+91) 44 - 220 02 46

E-Mail mantech@vsnl.com

Internet www.mantechsynergies.com

Description Project Development Consultants for Independent Power

Projects from 100 MW to 350 MW

8. Energy Economy & Environmental Consultants

Street #506, 15th Cross

Place Indiranagar 2nd Stage

City 560 038 Bangalore

Country India

Telephone (+91) 80 - 525 61 71

Facsimile (+91) 80 - 525 91 72

E-Mail eeec@vsnl.com

Description Consulting Services for Cogeneration Plants, Distribution Loss

Reduction, Waste Minimisation

Confederation of Indian Industry - Energy Management Cell

Potrebbero piacerti anche

- CBC Building Wiring Installation NC IIDocumento72 pagineCBC Building Wiring Installation NC IIFaysbuk KotoNessuna valutazione finora

- Coal Fired Boiler - PrincipalsDocumento145 pagineCoal Fired Boiler - PrincipalsArfan AnwarNessuna valutazione finora

- 210 MW PowerplantDocumento63 pagine210 MW PowerplantPratik Makwana100% (1)

- BMDocumento12 pagineBMAbhishek KumarNessuna valutazione finora

- ELC Work DescriptionDocumento36 pagineELC Work DescriptionHari100% (1)

- Boiler Operation Engineer (BOE) Viva QDocumento12 pagineBoiler Operation Engineer (BOE) Viva QChetram Meena100% (1)

- Powerplant QuestionsDocumento19 paginePowerplant QuestionsAshok KumarNessuna valutazione finora

- 0 - Best Practices in Thermal Power Stations in IndiaDocumento186 pagine0 - Best Practices in Thermal Power Stations in IndiaRajesh RanjanNessuna valutazione finora

- BOE IntroductionDocumento18 pagineBOE IntroductionAnsuman Sen SharmaNessuna valutazione finora

- Super Critical FinalDocumento26 pagineSuper Critical FinalShaheena Khan100% (2)

- Controls in Air-Fuel Circuit: - Combustion Control - Furnace Draught ControlDocumento65 pagineControls in Air-Fuel Circuit: - Combustion Control - Furnace Draught ControlArjun V Prasanthan100% (1)

- Powerplant PerformanceDocumento161 paginePowerplant PerformancePhanindra Kumar J100% (1)

- An Overview of CFBC Boiler: By-Mukesh JhaDocumento88 pagineAn Overview of CFBC Boiler: By-Mukesh Jhabalaji krishnan100% (2)

- Installation and User's Guide For AIX Operating SystemDocumento127 pagineInstallation and User's Guide For AIX Operating SystemPeter KidiavaiNessuna valutazione finora

- Implementation of Energy Conservation Act and BEE Action PlanDocumento33 pagineImplementation of Energy Conservation Act and BEE Action PlanRohan PrakashNessuna valutazione finora

- Bhel Turbine Operation Manual 500 MWDocumento2 pagineBhel Turbine Operation Manual 500 MWAlam50% (2)

- Thermal PowerDocumento44 pagineThermal PowerAnonymous W9VINoTzaNessuna valutazione finora

- Energy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFDocumento33 pagineEnergy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFtolga ALTINTAŞ100% (1)

- NTPC PresentationDocumento222 pagineNTPC PresentationReaderRRGHT100% (2)

- Thermal Power Plants and Future Scope Batch 2Documento194 pagineThermal Power Plants and Future Scope Batch 2Govinda Kabra100% (1)

- Complete NTPC ReportDocumento111 pagineComplete NTPC ReportSunil Kumar SinghNessuna valutazione finora

- GS Bindra BHEL Ultra Supercritical Power Plants PDFDocumento46 pagineGS Bindra BHEL Ultra Supercritical Power Plants PDFBKumrNessuna valutazione finora

- NTPC ReportDocumento53 pagineNTPC ReportAnkit Rajput50% (2)

- Boiler Operation On DcsDocumento4 pagineBoiler Operation On Dcsarif100% (2)

- Performance Evaluation and Optimization of Air Preheater in Thermal Power PlantDocumento9 paginePerformance Evaluation and Optimization of Air Preheater in Thermal Power PlantIAEME PublicationNessuna valutazione finora

- Thermal Power Plant Training Training Report-Aniket KaushalDocumento44 pagineThermal Power Plant Training Training Report-Aniket KaushalAniket Kaushal88% (16)

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDocumento4 pagineRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargNessuna valutazione finora

- Revit 2019 Collaboration ToolsDocumento80 pagineRevit 2019 Collaboration ToolsNoureddineNessuna valutazione finora

- Computational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantDocumento19 pagineComputational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantSylvester marxNessuna valutazione finora

- LMI For Internal AuditsDocumento16 pagineLMI For Internal Auditspreetivishwakarma100% (1)

- STEAG Energy Services India - Profile References-Rev 5 10 15Documento43 pagineSTEAG Energy Services India - Profile References-Rev 5 10 15Prasad Rajendra100% (1)

- Steam Power Plant (PLTU)Documento5 pagineSteam Power Plant (PLTU)Aldi ErzanuariNessuna valutazione finora

- Best Practices Adopted in Operation at Nabha Power Limited, Rajpura, PunjabDocumento20 pagineBest Practices Adopted in Operation at Nabha Power Limited, Rajpura, PunjabVikranth ChintaparthiNessuna valutazione finora

- Super Critical Power PLANTSDocumento33 pagineSuper Critical Power PLANTSSankar Achary100% (1)

- Suspension (PC) Combustion: Chungen YinDocumento47 pagineSuspension (PC) Combustion: Chungen YinAakash RanjanNessuna valutazione finora

- Agreement Deed BangladeshDocumento8 pagineAgreement Deed BangladeshVabna EnterpriseNessuna valutazione finora

- Air Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantDocumento66 pagineAir Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantRaushan Kumar100% (1)

- Blending of Coals in Power StationsDocumento20 pagineBlending of Coals in Power StationsPankaj GuptaNessuna valutazione finora

- Boilers of Thermal Power PlantsDocumento150 pagineBoilers of Thermal Power PlantsanasawaisNessuna valutazione finora

- Combustion Optimization Study in U#2 (By Ex BHEL Boiler Expert M. Somasundaram)Documento44 pagineCombustion Optimization Study in U#2 (By Ex BHEL Boiler Expert M. Somasundaram)karikalcholan m100% (1)

- Paper On Super Critical Technology and Analysis For Indian EnvironmentDocumento163 paginePaper On Super Critical Technology and Analysis For Indian EnvironmentBoben anto C100% (3)

- Unit 1: Introduction To PPE: A) Power GenerationDocumento55 pagineUnit 1: Introduction To PPE: A) Power GenerationArun PatilNessuna valutazione finora

- National Power Training Institute New Delhi: B. TechDocumento14 pagineNational Power Training Institute New Delhi: B. TechAditya PandeyNessuna valutazione finora

- Presentation of Thermal Power PlantDocumento46 paginePresentation of Thermal Power PlantMadan Gopal Rao67% (3)

- Conference - Digitisation of Power PlantsDocumento4 pagineConference - Digitisation of Power PlantsPriyanka RawatNessuna valutazione finora

- Best 60 Power Plant Information Booster Points - AskpowerplantDocumento17 pagineBest 60 Power Plant Information Booster Points - AskpowerplantRaju MaityNessuna valutazione finora

- Presented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaDocumento30 paginePresented By-T.Mahendra Reddy Ankur Sahoo Shubham VarmaShubham VermaNessuna valutazione finora

- Thermal Plant Control Instrumentation IDocumento41 pagineThermal Plant Control Instrumentation IVishal KhachaneNessuna valutazione finora

- Andhra Pradesh Boilers IDocumento2 pagineAndhra Pradesh Boilers IPrakash KakaniNessuna valutazione finora

- Why Efficiency in Thermal Power Plant Is LowDocumento1 paginaWhy Efficiency in Thermal Power Plant Is LowNallathambiNessuna valutazione finora

- Ennore Thermal Power StationDocumento14 pagineEnnore Thermal Power StationRajesh Kumar100% (2)

- Regulatory and Comm Aspects of Power Generation - 24.06.2019Documento56 pagineRegulatory and Comm Aspects of Power Generation - 24.06.2019dks12Nessuna valutazione finora

- ResumeDocumento7 pagineResumeponthirumaranNessuna valutazione finora

- CEP - SavingDocumento6 pagineCEP - SavingManoj UpadhyayNessuna valutazione finora

- Thermal Power StatonDocumento15 pagineThermal Power StatonShiv ashish sharmaNessuna valutazione finora

- History of Thermal Power PlantsDocumento9 pagineHistory of Thermal Power PlantsAnonymous gr5Pr9AVNessuna valutazione finora

- Thermal Power Plant BasicDocumento19 pagineThermal Power Plant Basicravikant singhNessuna valutazione finora

- Module 1 Energy Scenario - AuditDocumento136 pagineModule 1 Energy Scenario - AuditNeha B50% (2)

- Industrial Training Report 4Documento26 pagineIndustrial Training Report 4Bantisaini SainiNessuna valutazione finora

- 1.1 Energy OverviewDocumento53 pagine1.1 Energy OverviewDurg Singh AjarNessuna valutazione finora

- Enms in Power PlantDocumento18 pagineEnms in Power PlantNasional GotongroyongNessuna valutazione finora

- Brief Report On NTPCDocumento7 pagineBrief Report On NTPCChandra ShekharNessuna valutazione finora

- Captive Power PlantDocumento26 pagineCaptive Power PlantAshish Thakur100% (1)

- S I L I C O N: Save The Energy Save The WorldDocumento23 pagineS I L I C O N: Save The Energy Save The WorldSmit ShahNessuna valutazione finora

- Diseño PDFDocumento7 pagineDiseño PDFLina M GutierrezNessuna valutazione finora

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocumento4 pagineISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNessuna valutazione finora

- The Concept of ElasticityDocumento19 pagineThe Concept of ElasticityVienRiveraNessuna valutazione finora

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDocumento64 pagineMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrNessuna valutazione finora

- Descriptive Statistics - SPSS Annotated OutputDocumento13 pagineDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHINessuna valutazione finora

- Bank Statement SampleDocumento6 pagineBank Statement SampleRovern Keith Oro CuencaNessuna valutazione finora

- BreezeAIR 8000 Data SheetDocumento2 pagineBreezeAIR 8000 Data Sheetalfasukarno100% (1)

- Sales Manager Latin AmericaDocumento3 pagineSales Manager Latin Americaapi-76934736Nessuna valutazione finora

- Gis Tabels 2014 15Documento24 pagineGis Tabels 2014 15seprwglNessuna valutazione finora

- CY8 C95 X 0 ADocumento32 pagineCY8 C95 X 0 AAnonymous 60esBJZIj100% (1)

- Small Signal Analysis Section 5 6Documento104 pagineSmall Signal Analysis Section 5 6fayazNessuna valutazione finora

- Minor Ailments Services: A Starting Point For PharmacistsDocumento49 pagineMinor Ailments Services: A Starting Point For PharmacistsacvavNessuna valutazione finora

- Alternator: From Wikipedia, The Free EncyclopediaDocumento8 pagineAlternator: From Wikipedia, The Free EncyclopediaAsif Al FaisalNessuna valutazione finora

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Documento7 pagineAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudNessuna valutazione finora

- Chapter 2 A Guide To Using UnixDocumento53 pagineChapter 2 A Guide To Using UnixAntwon KellyNessuna valutazione finora

- Epenisa 2Documento9 pagineEpenisa 2api-316852165100% (1)

- Engagement Letter TrustDocumento4 pagineEngagement Letter Trustxetay24207Nessuna valutazione finora

- Kayako Support Suite User Manual PDFDocumento517 pagineKayako Support Suite User Manual PDFallQoo SEO BaiduNessuna valutazione finora

- COGELSA Food Industry Catalogue LDDocumento9 pagineCOGELSA Food Industry Catalogue LDandriyanto.wisnuNessuna valutazione finora

- PHP IntroductionDocumento113 paginePHP Introductionds0909@gmailNessuna valutazione finora

- STM Series Solar ControllerDocumento2 pagineSTM Series Solar ControllerFaris KedirNessuna valutazione finora

- Lecture 1Documento11 pagineLecture 1Taniah Mahmuda Tinni100% (1)

- Floor Paln ModelDocumento15 pagineFloor Paln ModelSaurav RanjanNessuna valutazione finora

- EASY DMS ConfigurationDocumento6 pagineEASY DMS ConfigurationRahul KumarNessuna valutazione finora

- Document 3Documento3 pagineDocument 3AdeleNessuna valutazione finora

- A Religious LeadershipDocumento232 pagineA Religious LeadershipBonganiNessuna valutazione finora