Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

U-Shaped Convolutions Circumferentially Welded at Their Crest or Root (Austenitic Steel)

Caricato da

met-calcTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

U-Shaped Convolutions Circumferentially Welded at Their Crest or Root (Austenitic Steel)

Caricato da

met-calcCopyright:

Formati disponibili

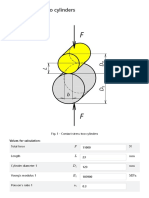

14.5.

8 U-shaped convolutions circumferentially welded at their crest or root (Austenitic

steel)

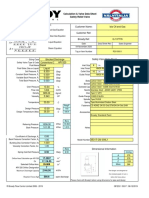

The calculation pressure: P 1,5 [Mpa]

The test pressure: Ptest 2 [Mpa]

The minimum yield strength or 1,0% proof strength at

calculation temperature (bellows): Rp1,0T 450 [Mpa]

The minimum tensile strength (bellows): Rm 800 [Mpa]

Joint coefficient: z 1 []

The minimum yield strength or 1,0% proof strength at

calculation temperature (collar): Rp1,0Tc 355 [Mpa]

The minimum tensile strength (collar): Rmc 470 [Mpa]

The crest convolution radius: ric 50 [mm]

The root convolution radius: rir 50 [mm]

The nominal thickness of one ply: ep 12 [mm]

The number of plies: np 1 []

The number of convolutions: N 4 []

The off-set angle of the sidewalls: α 15 [°]

Length cylindrical part at the root: mi 15 [mm]

Length cylindrical part at the crest: me 10 [mm]

The inside diameter of bellows convolution and end

tangents: Di 1200 [mm]

The convolution height: w 250 [mm]

The end tangent reinforcing collar thickness: ec 0 [mm]

The end tangent length: Lt 35 [mm]

The bellows collar length: Lc 0 [mm]

The modulus of elasticity of bellows material at design

temperature: Eb 210000 [Mpa]

The modulus of elasticity of bellows material at room

temperature: E0 195000 [Mpa]

The Poisson's ratio of the bellows material: νb 0,3 []

The modulus of elasticity of collar material at design

temperature: Ec 210000 [Mpa]

𝑚𝑖𝑛 𝑟 ; 𝑟

≥ 0,9

𝑚𝑎𝑥 𝑟 ; 𝑟 1,000 yes

The internal radius of torus at the crest and root of U-

shaped convolutions:

𝑟 +𝑟

𝑟 =

2

ri 50 [mm]

𝑟 ≥ 3𝑒 36,0 yes

−15° ≤ 𝛼 ≤ +15° yes

𝐷

𝑤≤

3 400,0 yes

The bellows nominal thickness:

𝑒 =𝑛 ∗𝑒

e 12 [mm]

𝐿 − 𝐿 ≤ 0,5 𝑒 ∗ 𝐷 yes

𝑚 ≤ 0,2 𝐷 ∗ 𝑒 26,5 yes

𝑚 ≤ 0,2 𝐷 ∗ 𝑒 26,5 yes

The nominal design stress for normal operating cases

(bellows):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ; ∗ 0,9: 𝑧 ≤ 0,7

1,5 1,2 3

f 300,0 [Mpa]

The nominal design stress for test cases (bellows):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftest 428,6 [Mpa]

The nominal design stress for normal operating cases

(collar):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

fc 236,7 [Mpa]

The nominal design stress for test cases (collar):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftestc 338,1 [Mpa]

The mean diameter of end tangent reinforcing collar:

𝐷 = 𝐷 + 2𝑒 + 𝑒

Dc 1224 [mm]

The mean diameter of bellows convolution:

𝐷 =𝐷 +𝑤+𝑒

Dm 1462 [mm]

The thickness of one ply, corrected for thinning during

forming:

𝐷

𝑒∗ = 𝑒

𝐷

ep* 10,872 [mm]

The bellows thickness, corrected for thinning during

forming:

𝑒∗ = 𝑛 ∗ 𝑒∗

e* 10,872 [mm]

The factor considering the stiffening effect of the

attachment weld and the end convolution on the

pressure capacity of the end tangent:

𝐿

𝑘 = 𝑚𝑖𝑛 ; 1,0

1,5 𝐷 ∗ 𝑒

k 0,194 []

The convolution pitch:

𝑞 = 4𝑟 + 2𝑒

q 224 [mm]

The cross sectional area of one convolution:

𝜋−2

𝐴= 𝑞 + 2𝑤 ∗ 𝑒 ∗

2

2

A 6825,9 [mm ]

Coefficient:

𝑞

𝐶 =

2𝑤

C1 0,448 []

Coefficient:

𝑞

𝐶 =

2,2 𝐷 ∗ 𝑒 ∗

C2 0,808 []

Coefficient: α0 0,201 []

Coefficient: α1 2,317 []

Coefficient: α2 -5,956 []

Coefficient: α3 7,594 []

Coefficient: α4 -4,945 []

Coefficient: α5 1,299 []

Coefficient:

𝐶 =∝ +∝ 𝐶 +∝ 𝐶 +∝ 𝐶 +∝ 𝐶 +∝ 𝐶

Cp 0,551 []

Coefficient: β0 0,997 []

Coefficient: β1 0,621 []

Coefficient: β2 -0,907 []

Coefficient: β3 2,429 []

Coefficient: β4 -2,901 []

Coefficient: β5 1,361 []

Coefficient:

𝐶 = 𝛽 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶

Cf 1,219 []

Coefficient: γ0 1,001 []

Coefficient: γ1 0,953 []

Coefficient: γ2 3,924 []

Coefficient: γ3 -8,773 []

Coefficient: γ4 10,444 []

Coefficient: γ5 -4,749 []

Coefficient:

𝐶 =𝛾 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶

Cd 1,762 []

The meridional bending stress for calculation pressure:

1 𝑤

𝜎 , 𝑃 = ∗ ∗ ∗𝐶 ∗𝑃

2𝑛 𝑒

σm,b(P) 218,4 [Mpa]

The meridional bending stress for test pressure:

1 𝑤

𝜎 , 𝑃 = ∗ ∗ ∗𝐶 ∗𝑃

2𝑛 𝑒

σm,b(Ptest) 291,2 [Mpa]

The circumferential membrane stress for calculation

pressure: - for intermediate convolutions:

1 𝑞−𝑚 ∗𝐷 +𝑚 ∗𝑤+𝑚 ∗ 𝐷 +𝑒

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝐴 + 𝑒∗ 𝑚 + 𝑚

σθ,I(P) 34,5 [Mpa]

The circumferential membrane stress for test pressure:

- for intermediate convolutions:

1 𝑞−𝑚 ∗𝐷 +𝑚 ∗𝑤+𝑚 ∗ 𝐷 +𝑒

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝐴 + 𝑒∗ 𝑚 + 𝑚

σθ,I(Ptest) 46,0 [Mpa]

The in-plane stress instability stress radio:

𝜎 ,

𝛿=

3𝜎 ,

δ 2,1 []

The in-plane stress instability stress interaction factor:

𝛼 = 1 + 2𝛿 + 1 − 2𝛿 + 4𝛿

α 18,4 []

The circumferential true strain caused by deformation:

For hydraulic or similar processes where the forming is

performed 100% to the outside of the initial cylinder: A

For roll forming processes with 50% forming to the

inside and 50% to the outside of the initial cylinder: B

For half-convolutions manufactured from ring plate by

roller bending or other methods, where the maximum

strain occurs at the inner crest: C

The circumferential true strain caused by deformation: A []

- For hydraulic or similar processes where the forming

is performed 100% to the outside of the initial

cylinder:

𝑊

𝑠 = ln 1 + 2

𝐷

- For roll forming processes with 50% forming to the

inside and 50% to the outside of the initial cylinder:

𝑊

𝑠 = ln 1 +

𝐷

- For half-convolutions manufactured from ring plate

by roller bending or other methods, where the

maximum strain occurs at the inner crest:

𝜋

− 1 2𝑟 + 𝑒

𝑠 = − ln 1 − 2

𝐷 +𝑒

sθ 0,348 []

The bending component of the true strain caused:

𝑒

𝑠 = ln 1 +

2𝑟 + 𝑒

sb 0,102 []

The strain caused by deformation during

manufacturing:

𝑠 = 1,04 𝑠 + 𝑠

sd 0,377 []

The circumferential membrane stress due to pressure

for calculation pressure (the end tangent):

1 𝐷 +𝑒 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(P) 14,7 [MPa]

The circumferential membrane stress due to pressure

for test pressure (the end tangent):

1 𝐷 +𝑒 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(Ptest) 19,6 [MPa]

The circumferential membrane stress due to pressure

for calculation pressure (collar):

1 𝐷 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,c(P) 15,0 [MPa]

The circumferential membrane stress due to pressure

for test pressure (collar):

1 𝐷 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(Ptest) 20,0 [MPa]

The circumferential membrane stress for calculation

pressure: - for end convolutions:

1 𝑞 − 𝑚 ∗ 𝐷 + 𝑚 ∗ 𝑤 + 𝐿 + 𝑚 /2 𝐷 + 𝑒

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝐴 + 𝑒 ∗ ∗ 𝑚 + 𝐿 + 𝑚 /2

σθ,E(P) 36,5 [MPa]

The circumferential membrane stress for test pressure:

- for end convolutions:

1 𝑞 − 𝑚 ∗ 𝐷 + 𝑚 ∗ 𝑤 + 𝐿 + 𝑚 /2 𝐷 + 𝑒

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝐴 + 𝑒 ∗ ∗ 𝑚 + 𝐿 + 𝑚 /2

σθ,E(Ptest) 48,6 [MPa]

The meridional membrane stress for calculation

pressure:

𝑤

𝜎 , 𝑃 = ∗𝑃

2𝑒 ∗ σm,m(P) 17,2 [MPa]

The meridional membrane stress for test pressure:

𝑤

𝜎 , 𝑃 = ∗𝑃

2𝑒 ∗

σm,m(Ptest) 23,0 [MPa]

Effective stress concentration factor:

for annealed bellows (without cold work) 3

for as-formed bellows (with cold work) 1,5

Effective stress concentration factor: Kf 3 []

𝜎 , 𝑃 +𝜎 , 𝑃 ≤𝐾 ∗𝑓 235,6 yes

𝜎 , 𝑃 +𝜎 , 𝑃 ≤ 𝐾 ∗𝑓 314,2 yes

The bellows axial rigidity:

𝜋 𝑛 𝑒∗ 1

𝐾 = ∗𝐸 ∗ ∗𝐷 ∗ ∗

2 1−𝜈 𝑁 𝑤 𝐶

Kb 8936,3 [N/mm]

Column squirm:

𝜋𝐾

𝑃 , = 0,34 ≥𝑃

𝑁∗𝑞

Ps,c 10,7 [MPa]

The bellows cold-work factor:

1+5∗𝑠 → 𝑠 ≤ 0,2

𝐾 =

2,0 → 𝑠 > 0,2

Kd 2,0 []

The effective proof stress:

𝐾 ∗𝑅 , → 𝐾 =3

𝑅∗ =

0,75 ∗ 𝑅 , → 𝐾 = 1,5

Re* 900,0 [MPa]

In-plane squirm:

𝐴 ∗ 𝑅∗

𝑃, = 𝜋−2

𝐷 𝑞 ∝

Ps,i 5,0 [MPa]

The total stress range due to cyclic loading for

calculation pressure: Δq 5 [mm]

The total stress range due to cyclic loading for test

pressure: Δqtest 10 [mm]

The specified number of fatigue cycles for calculation

pressure: Nspe 100000 []

The specified number of fatigue cycles for test

pressure: Nspetest 500 []

The meridional membrane stress for calculation

pressure:

𝐸 ∗ 𝑒∗

𝜎 , ∆𝑞 = ∆𝑞

2𝑤 ∗ 𝐶

σm,m(Δq) 3,3 [MPa]

The meridional membrane stress for test pressure:

𝐸 ∗ 𝑒∗

𝜎 , ∆𝑞 = ∆𝑞

2𝑤 ∗ 𝐶

σm,m(Δqtest) 6,5 [MPa]

The meridional bending stress for calculation pressure:

5𝐸 ∗ 𝑒 ∗

𝜎 , ∆𝑞 = ∆𝑞

3𝑤 ∗ 𝐶

σm,b(Δq) 172,8 [MPa]

The meridional bending stress for test pressure:

5𝐸 ∗ 𝑒 ∗

𝜎 , ∆𝑞 = ∆𝑞

3𝑤 ∗ 𝐶

σm,b(Δqtest) 345,6 [MPa]

The total stress range due to cyclic loading for

calculation pressure:

𝑄 = 0,7 ∗ 𝜎 , 𝑃 +𝜎 , 𝑃 + 𝜎 , ∆𝑞 +𝜎 , ∆𝑞 ∗

σeq 682,0 [MPa]

The total stress range due to cyclic loading for test

pressure:

𝑄 = 0,7 ∗ 𝜎 , 𝑃 +𝜎 , 𝑃 + 𝜎 , ∆𝑞 +𝜎 , ∆𝑞 ∗

σeqtest 1144,1 [MPa]

The allowable number of fatigue cycles for calculation

pressure:

,

𝐸 9283,3

𝜎 ≥ 1080𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝐸 𝜎 − 372,3

,

𝐸 10259,4

𝜎 < 1080𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝜎 − 297,9

𝐸

𝐸

𝜎 ≤ 297,9𝑀𝑃𝑎: 𝑁 = 10

𝐸

𝑁 ≥𝑁

Nalw 112445 []

The allowable number of fatigue cycles for test

pressure:

,

𝐸 9283,3

𝜎 ≥ 1080𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝜎 − 372,3

𝐸

,

𝐸 10259,4

𝜎 < 1080𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝜎 − 297,9

𝐸

𝐸

𝜎 ≤ 297,9𝑀𝑃𝑎: 𝑁 = 10

𝐸

𝑁 ≥𝑁

Nalwtest 6830 []

The cumulative fatigue damage index:

𝑁 𝑁

𝐷= + ≤1

𝑁 𝑁

D 0,96 []

Potrebbero piacerti anche

- Mech Vii Experimental Stress Analysis (10me761) Notes 1Documento127 pagineMech Vii Experimental Stress Analysis (10me761) Notes 1Praveen Palthur67% (3)

- U-Shaped Reinforced Bellows (Austenitic Steel)Documento10 pagineU-Shaped Reinforced Bellows (Austenitic Steel)met-calcNessuna valutazione finora

- Figure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13Documento4 pagineFigure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13met-calcNessuna valutazione finora

- "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Documento4 pagine"Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNessuna valutazione finora

- Expansion Bellows Design CalculationDocumento1 paginaExpansion Bellows Design CalculationvvpvarunNessuna valutazione finora

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Documento2 pagineFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNessuna valutazione finora

- PVengDocumento3 paginePVengDiana SoareNessuna valutazione finora

- Optimization Design of The U-Shaped Metal BellowsDocumento5 pagineOptimization Design of The U-Shaped Metal BellowsdaymonNessuna valutazione finora

- ThickAndThin JointsDocumento31 pagineThickAndThin JointsHùng Mạnh NguyễnNessuna valutazione finora

- Optimization and Standardization of Flanged and Flued Expansion Joint DesignDocumento32 pagineOptimization and Standardization of Flanged and Flued Expansion Joint DesignPankaj SinglaNessuna valutazione finora

- Contact Stress Two CylindersDocumento3 pagineContact Stress Two Cylindersmet-calcNessuna valutazione finora

- Expansion Bellow Tech ComparisonDocumento10 pagineExpansion Bellow Tech ComparisonSabariMechyNessuna valutazione finora

- Threaded Holes (11.4.3.3) EN 13445-3Documento1 paginaThreaded Holes (11.4.3.3) EN 13445-3met-calcNessuna valutazione finora

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Documento5 pagineFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNessuna valutazione finora

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocumento9 paginePressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNessuna valutazione finora

- CAESAR II-Applications GuideDocumento302 pagineCAESAR II-Applications GuideTakChi_LamNessuna valutazione finora

- Welding Neck Flanges 1Documento3 pagineWelding Neck Flanges 1bikkelbobNessuna valutazione finora

- dtl17813h PDFDocumento15 paginedtl17813h PDFhbookNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Documento30 pagineHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Eng-CalculationsNessuna valutazione finora

- Analisis of Stress in BellowsDocumento101 pagineAnalisis of Stress in BellowsOswaldo GuerraNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Documento24 pagineHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNessuna valutazione finora

- Expansion Joint PDFDocumento65 pagineExpansion Joint PDFZoranNessuna valutazione finora

- NozzlePRO 14.1NewFeatures-2019ReleaseDocumento13 pagineNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftNessuna valutazione finora

- Contact Stress of Cylinder On Flat SurfaceDocumento3 pagineContact Stress of Cylinder On Flat Surfacemet-calcNessuna valutazione finora

- PRES-1 External Presure Design - 07.02.16Documento37 paginePRES-1 External Presure Design - 07.02.16mithuwanNessuna valutazione finora

- When Is An Expansion Bellows Required in A Heat ExchangerDocumento3 pagineWhen Is An Expansion Bellows Required in A Heat ExchangerTiHoRNessuna valutazione finora

- Test Report Long-Term Ring Bending Strain (SB)Documento4 pagineTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNessuna valutazione finora

- Investigations of Butterfly Control Valve Flow CharacteristicsDocumento16 pagineInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Butter Valve Thickness PDFDocumento10 pagineButter Valve Thickness PDFAnand KumarNessuna valutazione finora

- Piping Flexibility CheckingDocumento5 paginePiping Flexibility Checkingeko123Nessuna valutazione finora

- Sizing CalcDocumento1 paginaSizing CalcHilary AbaratuNessuna valutazione finora

- Blind Flange (10 Bar)Documento7 pagineBlind Flange (10 Bar)SyedZainAliNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocumento1 paginaChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNessuna valutazione finora

- Nozzle StressDocumento25 pagineNozzle StressvamsiNessuna valutazione finora

- Dimensions of Restriction Orifice Plates For ASME b16Documento5 pagineDimensions of Restriction Orifice Plates For ASME b16Mohamed Salah SolimanNessuna valutazione finora

- Calculo de Brida Segun ASMEDocumento29 pagineCalculo de Brida Segun ASMEakarcz6731Nessuna valutazione finora

- Flange CouplingDocumento17 pagineFlange CouplingROCKY DUBEYNessuna valutazione finora

- 0.0bolt Torque Calculation - R0Documento9 pagine0.0bolt Torque Calculation - R0Darshan PanchalNessuna valutazione finora

- (DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enDocumento8 pagine(DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enNaveen Suresh KumarNessuna valutazione finora

- The Use of Two Nuts To Prevent Self LooseningDocumento4 pagineThe Use of Two Nuts To Prevent Self LooseningManojkumar ThilagamNessuna valutazione finora

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Documento4 pagineFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNessuna valutazione finora

- Bellow Using FemDocumento9 pagineBellow Using FemSonam Behl KambojNessuna valutazione finora

- Hydrodynamic Calculation Howell-Jet ValveDocumento17 pagineHydrodynamic Calculation Howell-Jet Valvemet-calcNessuna valutazione finora

- Avarus Data Sheet AVST A200CNDocumento2 pagineAvarus Data Sheet AVST A200CNcrvenicajNessuna valutazione finora

- 3PSME001Documento18 pagine3PSME001Mihir JhaNessuna valutazione finora

- LiftingLugStress Rev 1.5Documento20 pagineLiftingLugStress Rev 1.5ilijarskNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento31 pagineHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNessuna valutazione finora

- Acme Lead Screw Calculator - Unified - ASME - ANSI - B1.5 - 1988Documento1 paginaAcme Lead Screw Calculator - Unified - ASME - ANSI - B1.5 - 1988Aditya GhormadeNessuna valutazione finora

- Vortex Excitation of Metal BellowsDocumento8 pagineVortex Excitation of Metal BellowsMourad BenabderrahmaneNessuna valutazione finora

- Calculo Brida Ejemplo PV - EliteDocumento8 pagineCalculo Brida Ejemplo PV - ElitePedro Montes MarinNessuna valutazione finora

- ASME UG 37 Nozzles PDFDocumento6 pagineASME UG 37 Nozzles PDFlatif.deNessuna valutazione finora

- Blind Plate THK - Hydro PDFDocumento3 pagineBlind Plate THK - Hydro PDFNaveen JeevaNessuna valutazione finora

- Discrete Element Method to Model 3D Continuous MaterialsDa EverandDiscrete Element Method to Model 3D Continuous MaterialsNessuna valutazione finora

- Junction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7Documento4 pagineJunction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7met-calcNessuna valutazione finora

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Documento3 pagineJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcNessuna valutazione finora

- Unstiffened Cylinders en 13445-3 - 8.5.2Documento4 pagineUnstiffened Cylinders en 13445-3 - 8.5.2met-calcNessuna valutazione finora

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocumento4 pagineUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNessuna valutazione finora

- Light Stiffeners EN 13445-3 - 8.6.4.1.2Documento10 pagineLight Stiffeners EN 13445-3 - 8.6.4.1.2met-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Documento24 pagineHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNessuna valutazione finora

- Threaded Holes (11.4.3.3) EN 13445-3Documento1 paginaThreaded Holes (11.4.3.3) EN 13445-3met-calcNessuna valutazione finora

- Nuts (11.4.3.2) EN 13445-3Documento1 paginaNuts (11.4.3.2) EN 13445-3met-calcNessuna valutazione finora

- Spherical Shells (7.4.3) EN 13445-3Documento3 pagineSpherical Shells (7.4.3) EN 13445-3met-calcNessuna valutazione finora

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocumento3 pagineRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Documento19 pagineHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNessuna valutazione finora

- Hydrodynamic Calculation Howell-Jet ValveDocumento17 pagineHydrodynamic Calculation Howell-Jet Valvemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Spherical ValveDocumento40 pagineHydrodynamic Calculation Spherical Valvemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocumento23 pagineHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNessuna valutazione finora

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Documento23 pagineHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNessuna valutazione finora

- Multi-Stage ValveDocumento2 pagineMulti-Stage Valvemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Howell-Bunger ValveDocumento34 pagineHydrodynamic Calculation Howell-Bunger Valvemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Needle ValveDocumento23 pagineHydrodynamic Calculation Needle Valvemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Documento31 pagineHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNessuna valutazione finora

- Contact Stress of Cylinder On Flat SurfaceDocumento3 pagineContact Stress of Cylinder On Flat Surfacemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Documento28 pagineHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNessuna valutazione finora

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Documento5 pagineFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNessuna valutazione finora

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Documento4 pagineFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNessuna valutazione finora

- Allowable Stress: R Mpa C SDocumento1 paginaAllowable Stress: R Mpa C Smet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento31 pagineHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNessuna valutazione finora

- Contact Stress Two CylindersDocumento3 pagineContact Stress Two Cylindersmet-calcNessuna valutazione finora

- Conical Shells (7.6.4) EN 13445-3Documento3 pagineConical Shells (7.6.4) EN 13445-3met-calcNessuna valutazione finora

- Contact Stress of The Cylinder in The Cylindrical SocketDocumento3 pagineContact Stress of The Cylinder in The Cylindrical Socketmet-calcNessuna valutazione finora

- BucklingDocumento2 pagineBucklingmet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento18 pagineHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNessuna valutazione finora

- Multi-Hole CageDocumento7 pagineMulti-Hole Cagemet-calcNessuna valutazione finora

- Hydrodynamic Calculation Gate Valve (Through Conduit)Documento14 pagineHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNessuna valutazione finora

- Allowable Hertz PressureDocumento1 paginaAllowable Hertz Pressuremet-calcNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Documento18 pagineHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNessuna valutazione finora

- The Flow Characteristic On The Position of The DriveDocumento7 pagineThe Flow Characteristic On The Position of The Drivemet-calcNessuna valutazione finora

- Return MappingDocumento13 pagineReturn MappingArunNessuna valutazione finora

- Mobasher Stang ShahDocumento12 pagineMobasher Stang ShahSarfraz MunirNessuna valutazione finora

- Design of Machine Elements 4Documento115 pagineDesign of Machine Elements 4Dr. Aung Ko Latt100% (1)

- MADocumento71 pagineMALuis CorreiaNessuna valutazione finora

- Creep and ShrinkageDocumento3 pagineCreep and ShrinkageYaselaNessuna valutazione finora

- Chapter9 Laterally Restrained BeamsDocumento28 pagineChapter9 Laterally Restrained Beamsengineerkranthi405575% (4)

- ASME PaperDocumento17 pagineASME PaperChristopher BrownNessuna valutazione finora

- Geng 2017Documento6 pagineGeng 2017robinwilson888Nessuna valutazione finora

- Lecture Notes - Linear Elasticity TheoryDocumento43 pagineLecture Notes - Linear Elasticity Theoryzcapg17Nessuna valutazione finora

- Structural Conceptualization1 RevisedDocumento155 pagineStructural Conceptualization1 RevisedLəonardo SasingNessuna valutazione finora

- Static FailureDocumento10 pagineStatic FailureQ_TNessuna valutazione finora

- Helical Pil e Behaviour and Load TransferDocumento7 pagineHelical Pil e Behaviour and Load TransferViorel GaitaNessuna valutazione finora

- 3D Nonlinear Modeling of Buried Continuous Pipeline Subjected To Ground CompressionDocumento10 pagine3D Nonlinear Modeling of Buried Continuous Pipeline Subjected To Ground CompressionGoce VasilevskiNessuna valutazione finora

- Types of Elements Used in Finite Element AnalysisDocumento6 pagineTypes of Elements Used in Finite Element AnalysisTayyab ZafarNessuna valutazione finora

- Pan - 2018 - A Review of Lattice Type Model in Fracture MechanicsDocumento28 paginePan - 2018 - A Review of Lattice Type Model in Fracture MechanicsPra SuryaNessuna valutazione finora

- Creep Test PDFDocumento4 pagineCreep Test PDFAman KumarNessuna valutazione finora

- Lecture 4 (EC4 Version)Documento67 pagineLecture 4 (EC4 Version)ikanyu79100% (1)

- 3.W-ch 3-Static FailureDocumento139 pagine3.W-ch 3-Static FailureErcan TokerNessuna valutazione finora

- MacadamDocumento14 pagineMacadamRakesh7770Nessuna valutazione finora

- Creep PDFDocumento236 pagineCreep PDFoshadhivNessuna valutazione finora

- Tce Guidlines For Steel Structure Members As Per Is 800Documento78 pagineTce Guidlines For Steel Structure Members As Per Is 800neeraj100% (6)

- Material Spec SheetsDocumento21 pagineMaterial Spec SheetsAdityaDeshmukhNessuna valutazione finora

- Andrianov 2012 Composites Part B EngineeringDocumento5 pagineAndrianov 2012 Composites Part B EngineeringKancharla KiranNessuna valutazione finora

- Aditya Rahul Final Report PDFDocumento110 pagineAditya Rahul Final Report PDFarchitectfemil6663Nessuna valutazione finora

- BS EN 13412-2006 ScanDocumento12 pagineBS EN 13412-2006 ScanZechariah HamouiNessuna valutazione finora

- Aluminium CatalogueDocumento56 pagineAluminium CatalogueSantosh PatilNessuna valutazione finora

- EML3500 CH 5 SlidesDocumento114 pagineEML3500 CH 5 SlidesSameOldHat100% (2)

- Problem Set 3-Chapter 6 - Failure Theories-Selected ProblemsDocumento22 pagineProblem Set 3-Chapter 6 - Failure Theories-Selected ProblemsIsmail DoğanNessuna valutazione finora

- Crack Propagation and ArrestingDocumento67 pagineCrack Propagation and ArrestingThomas JoseNessuna valutazione finora