Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ads Opadry II Coat Moist

Caricato da

Rani YundaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ads Opadry II Coat Moist

Caricato da

Rani YundaCopyright:

Formati disponibili

OPADRY® II Application Data

High Performance Film Coating System

Coating Moisture-Sensitive Products

OBJECTIVES

To determine the coating process conditions which influence moisture uptake by cores.

BACKGROUND

Because of regulatory and safety considerations, there is a global trend to switch from organic to aqueous

solvents in film coating processes. The need to protect moisture-sensitive products during the coating

process is equally important. Therefore, it is imperative to develop film coating formulas and processes that

minimize the ingress of water and its deleterious effects in film-coated dosage forms. This work identified the

important coating process variables which influence water content in film coated tablets.

METHODOLOGY

Film Coating & Equipment

Coating: Opadry® II, high performance film coating system, 85F Orange

Coating Pan: O’Hara Labcoat II fitted with a 24” pan used for all coating trials

Spray Guns: 2 Spraying Systems VAU 4078 with 113293-60 air caps

Pump: Masterflex Model 7523-30 with 96410-15 silicone tubing

Multivitamin Tablet - Uncoated

Shape: Oblong

Weight: 1008.7 mg

Breaking force: 13.4 kp

Thickness: 5.92 mm

Length: 19.21 mm

} n = 20

Moisture Content: 1.4%

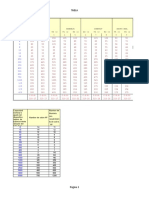

Table 1. Experimental Variables

Variable Name Units Range

Inlet Temperature °C 60 - 90

Spray Rate g/min 35 - 70

Solids Concentration % 15 - 25

ft3/min (cfm) 150 - 350

Air Flow

m3/hr 255 - 595

OPADRY® II -1-

This document is valid at the time of distribution. Distributed 03-Mar-2020 (UTC)

Table 2. Experimental Constants

Variable Name Units Level

Atomization pressure psi/bar 40/2.7

Pattern pressure psi/bar 40/2.7

Pan speed rpm 14

Pan charge kg 20

Guns number 2

Response Variables

Qualitative – Visual Assessment: Cracking, peeling, edge chipping, other defects

Quantitative: Moisture change in the core, surface roughness, gloss

Moisture Content

The starting moisture content of the vitamin tablet was 1.4%.

Tablets were sampled immediately upon the completion of each trial. The tablets were gently crushed and

tested for % loss-on-drying using an Ohaus MB 200 automated moisture balance (115°C for 35 min).

Over the range of experiments, moisture ranged from 0.6% to 2.7%.

RESULTS

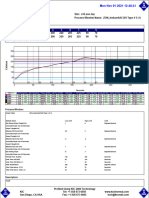

Table 3. Experimental Conditions

Inlet temperature Spray rate Air flow

Run No. % Solids

(deg. C) (g/min) (cfm)

1 90.0 75 25.0 150

2 67.5 65 22.5 200

3 90.0 35 15.0 150

4 90.0 55 25.0 350

5 75.0 35 25.0 150

6 60.0 75 15.0 150

7 82.5 45 22.5 300

8 75.0 75 25.0 350

9 60.0 55 25.0 150

10 60.0 35 25.0 350

11 67.5 65 22.5 300

12 90.0 35 25.0 250

13 82.5 45 22.5 200

14 67.5 45 17.5 300

15 60.0 35 25.0 350

16 75.0 55 15.0 250

17 82.5 65 17.5 200

18 75.0 55 20.0 250

19 60.0 35 15.0 150

20 90.0 75 15.0 350

21 90.0 75 25.0 150

22 82.5 65 22.5 300

23 67.5 45 22.5 200

24 75.0 55 20.0 250

25 60.0 75 25.0 250

26 90.0 35 15.0 350

27 60.0 75 15.0 350

OPADRY® II -2-

This document is valid at the time of distribution. Distributed 03-Mar-2020 (UTC)

Figure 1. Qualitative Results (Trials 6, 9 &19)

Figure 2. Qualitative Results (Trial 26)

Highest airflow (350 cfm/595 m3/hr)

Highest inlet air temperature (90°C)

Still the best appearance

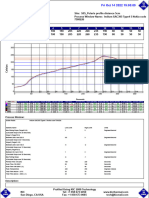

Figure 3. Moisture Content – Regression Analysis

0.6

0.4

0.2

0.0

-0.2

-0.4

-0.6

-0.8

Air Flow Inlet temp. Spray rate Solids

OPADRY® II -3-

This document is valid at the time of distribution. Distributed 03-Mar-2020 (UTC)

Regression

R Square: 0.9874

Adj. R Square: 0.9748

Error %: 1.00

Error Variante: 0.002

Error Std. Dev.(±): 0.041

95% Confidence Limits(±): 0.130

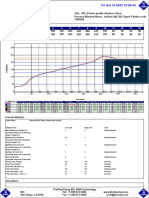

Figure 4. Moisture Content – Response Surface

Tablet Moisture Response Surface

Spray Rate = 35, Solids Concentration = 20

CONCLUSIONS:

1. The water content in cores may actually be reduced during the film coating process.

2. Moisture content decreases with increasing inlet temperature and increasing air flow.

3. Moisture content increases with increasing spray rate.

4. Film coated tablets with excellent appearance and low moisture content may be produced by carefully

selecting coating process parameters.

Reprint of poster presented at SAFYBI – Sept 2005. Authors: Charles Cunningham, Thomas Farrell, and

Adriana Quiroga.

OPADRY® II -4-

This document is valid at the time of distribution. Distributed 03-Mar-2020 (UTC)

© Colorcon, 2009. The information contained in this

For more information, contact your Colorcon representative or call: document is proprietary to Colorcon and may not be

used or disseminated inappropriately.

North America Europe/Middle East/Africa Asia Pacific Latin America

All trademarks, except where noted, are property

+1-215-699-7733 +44-(0)-1322-293000 +65-6438-0318 +54-11-4552-1565 of BPSI Holdings, LLC.

You can also ®

visit our website at www.colorcon.com

OPADRY II -5- ads_opadry_II_coat_moist_v3_05_2009

Powered by TCPDF (www.tcpdf.org)

This document is valid at the time of distribution. Distributed 03-Mar-2020 (UTC)

Potrebbero piacerti anche

- Correccion Resistencia de Aislamiento1Documento1 paginaCorreccion Resistencia de Aislamiento1Jose Antonio Huamani ChuquirimayNessuna valutazione finora

- Using Excel PlotsDocumento12 pagineUsing Excel PlotsGera VillaNessuna valutazione finora

- Graph 8Documento1 paginaGraph 8dil afroza karim LinaNessuna valutazione finora

- TABLE 100.5 Transformer Insulation Resistance Acceptance TestingDocumento2 pagineTABLE 100.5 Transformer Insulation Resistance Acceptance TestingErick MontielNessuna valutazione finora

- 927 Series: ModelsDocumento3 pagine927 Series: ModelsArmando LopezNessuna valutazione finora

- Frequency Distribution For Spot SpeedDocumento1 paginaFrequency Distribution For Spot Speeddil afroza karim LinaNessuna valutazione finora

- Paswara RCTDocumento1 paginaPaswara RCTAkash MittalNessuna valutazione finora

- S05 - Polaris Profile Distance 5cmDocumento1 paginaS05 - Polaris Profile Distance 5cmQuýNguyễnNessuna valutazione finora

- TEMPERATURE CORRECTION FACTOR From ANSI - NETA - MTS - 2015Documento1 paginaTEMPERATURE CORRECTION FACTOR From ANSI - NETA - MTS - 2015ilham akbarNessuna valutazione finora

- Kato/Tadano 25t Truck Crane: Cadman Cranes LTDDocumento5 pagineKato/Tadano 25t Truck Crane: Cadman Cranes LTDRicky CungNessuna valutazione finora

- Metrication Conversion Guide For 318M and 318S: 1A. LengthDocumento10 pagineMetrication Conversion Guide For 318M and 318S: 1A. LengthMudasir DaudNessuna valutazione finora

- S05 - Polaris Profile Distance 10cmDocumento1 paginaS05 - Polaris Profile Distance 10cmQuýNguyễnNessuna valutazione finora

- Effect of Organosolv PretreatmentDocumento13 pagineEffect of Organosolv PretreatmentBadruzamanIbadNessuna valutazione finora

- Etrhb 2Documento2 pagineEtrhb 2Karim IderNessuna valutazione finora

- Fuller: Etrhb Dosage 400KgDocumento2 pagineFuller: Etrhb Dosage 400KgKarim IderNessuna valutazione finora

- W-1-H Zero Halogen, Flexible Heat Shrink Tubing: FeaturesDocumento3 pagineW-1-H Zero Halogen, Flexible Heat Shrink Tubing: FeaturesGopi NathNessuna valutazione finora

- Tabel Data Dan Grafik SondirDocumento6 pagineTabel Data Dan Grafik SondirWawan SetiawanNessuna valutazione finora

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Documento4 pagineProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNessuna valutazione finora

- Fullerakbou 01Documento2 pagineFullerakbou 01Karim IderNessuna valutazione finora

- Akbou (Sable Saoudi) RN 35: FullerDocumento2 pagineAkbou (Sable Saoudi) RN 35: FullerKarim IderNessuna valutazione finora

- Tabla Correccion TempDocumento1 paginaTabla Correccion TempTwins100% (1)

- CV10 CV15 Brochure 09.01.2021Documento4 pagineCV10 CV15 Brochure 09.01.2021hamadaNessuna valutazione finora

- Milling Mixing SievingDocumento12 pagineMilling Mixing SievingHƯƠNG NGUYỄN LÊ NGỌCNessuna valutazione finora

- s10 Zon TopDocumento1 paginas10 Zon TopQuýNguyễnNessuna valutazione finora

- CNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDocumento4 pagineCNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDouglas SilvaNessuna valutazione finora

- Technical Datas Voltage Drop For Low Voltage CablesDocumento14 pagineTechnical Datas Voltage Drop For Low Voltage CablesFelipe GustavoNessuna valutazione finora

- Caudales de Salida (L/S)Documento12 pagineCaudales de Salida (L/S)Nelson CopaNessuna valutazione finora

- Pressure Vacuum: Pressure: Pressure Gage Vs Transducer Vacuum: Mercury Manometer Vs Vacuum GageDocumento4 paginePressure Vacuum: Pressure: Pressure Gage Vs Transducer Vacuum: Mercury Manometer Vs Vacuum GageIzzah HzmhNessuna valutazione finora

- Table 4.2ADocumento1 paginaTable 4.2ALaura SlaNessuna valutazione finora

- Nómina de Estudiantes: Nota Original Sobre Puntaje CorrespondienteDocumento1 paginaNómina de Estudiantes: Nota Original Sobre Puntaje CorrespondientemamanichaveznohemiNessuna valutazione finora

- Espectro De Diseño Sismico Gbds: Espectro Zona 3-Suelo S4 (1.5 Kg/cm2>σadm ≥ 0.5Kg/cm2)Documento4 pagineEspectro De Diseño Sismico Gbds: Espectro Zona 3-Suelo S4 (1.5 Kg/cm2>σadm ≥ 0.5Kg/cm2)OscarQuirogaNessuna valutazione finora

- Combine CalculationDocumento3 pagineCombine CalculationKamran JUTTNessuna valutazione finora

- Zone 1 Zone 2: Ukuran Ayakan Ukuran AyakanDocumento20 pagineZone 1 Zone 2: Ukuran Ayakan Ukuran AyakanAgus AwwaNessuna valutazione finora

- 3 Peluqueros FormulasDocumento8 pagine3 Peluqueros FormulasAraceli PerezNessuna valutazione finora

- Fuller: Graviers ENG Sable Soumame - Boussada Dosage 250KgDocumento2 pagineFuller: Graviers ENG Sable Soumame - Boussada Dosage 250KgKarim IderNessuna valutazione finora

- Yz STT mg2 20020029Documento4 pagineYz STT mg2 20020029Yogazulfitra RahmaNessuna valutazione finora

- GraphsDocumento10 pagineGraphsAlfonso Hernandez CarmonaNessuna valutazione finora

- Copia de Datos Reologia Prof. LucasDocumento34 pagineCopia de Datos Reologia Prof. LucasALEJANDRA GUTIERREZ SAAVEDRANessuna valutazione finora

- AccuracyDocumento1 paginaAccuracyVineeshNessuna valutazione finora

- Table 3: Voltage Drop: ExampleDocumento1 paginaTable 3: Voltage Drop: Exampletaufiqishak09Nessuna valutazione finora

- General ManagerDocumento7 pagineGeneral Managerოთო აბაშიძეNessuna valutazione finora

- H CG 2018 BrochureDocumento4 pagineH CG 2018 BrochureramatajamaNessuna valutazione finora

- New MTRP: Plug-In Motor Starting RelayDocumento5 pagineNew MTRP: Plug-In Motor Starting RelayMaricel Villafuerte100% (1)

- ISOTERM (Autosaved) (Autosaved) 1Documento64 pagineISOTERM (Autosaved) (Autosaved) 1Fadhilatul AdhaNessuna valutazione finora

- Cam and Follower GuntDocumento20 pagineCam and Follower GuntAurangzebNessuna valutazione finora

- Lectures+24 25+Examples+CompleteDocumento6 pagineLectures+24 25+Examples+CompletePRATEEK SHARMANessuna valutazione finora

- Cable THW 90 CeperDocumento2 pagineCable THW 90 CeperManuel PelaesNessuna valutazione finora

- Alcon (Snap-In) GSP SeriesDocumento6 pagineAlcon (Snap-In) GSP Seriesghort55Nessuna valutazione finora

- Copia de Taller1mecanicaagsDocumento72 pagineCopia de Taller1mecanicaagsFlor de AlhelíNessuna valutazione finora

- Siflon Drugs: Sy. No. 25/4, Rachanapalli (V)Documento4 pagineSiflon Drugs: Sy. No. 25/4, Rachanapalli (V)bharath kumarNessuna valutazione finora

- 02 Sieve Analysis FormDocumento1 pagina02 Sieve Analysis FormChristian Louie DecenaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 pagineModel CB 15-100 HP Boilers: Sound LevelsebaversaNessuna valutazione finora

- Sysnchronous Generator Transient Analysis2Documento18 pagineSysnchronous Generator Transient Analysis2mnsatyaniNessuna valutazione finora

- Cond AluminioDocumento40 pagineCond Aluminiorodolfoordiguez_70Nessuna valutazione finora

- MOHAMADOU AWALOU PGE 5 Forage 16A181EMDocumento13 pagineMOHAMADOU AWALOU PGE 5 Forage 16A181EMAwalou MohamadNessuna valutazione finora

- Slider Crank Mechanism (AutoRecovered)Documento6 pagineSlider Crank Mechanism (AutoRecovered)Jàwád QûreShïNessuna valutazione finora

- Wabco Mechanical LSVDocumento8 pagineWabco Mechanical LSVmarranNessuna valutazione finora

- Section 05 - RB 7Documento1 paginaSection 05 - RB 7sanshinde10Nessuna valutazione finora

- Local Media6127522884523757127Documento15 pagineLocal Media6127522884523757127Marque Adrian EncinaNessuna valutazione finora

- Government Publications: Key PapersDa EverandGovernment Publications: Key PapersBernard M. FryNessuna valutazione finora

- MainDocumento5 pagineMainRani YundaNessuna valutazione finora

- Kandungan Kimia Biji Labu KuningDocumento3 pagineKandungan Kimia Biji Labu KuningRani YundaNessuna valutazione finora

- Roll Compaction Dry Granulation RCDG TecDocumento18 pagineRoll Compaction Dry Granulation RCDG TecRani YundaNessuna valutazione finora

- Powder Technology: Heechan Cho, Jihoe Kwon, Kihong Kim, Myoungwook MunDocumento10 paginePowder Technology: Heechan Cho, Jihoe Kwon, Kihong Kim, Myoungwook MunRani YundaNessuna valutazione finora

- Formulation and Design of Probiotic Supplements For Rheumatoid Arthritis PatientsDocumento8 pagineFormulation and Design of Probiotic Supplements For Rheumatoid Arthritis PatientsLauraNessuna valutazione finora

- Stability of Oral Liquid Preparations of Methylergometrine: Original ArticlesDocumento5 pagineStability of Oral Liquid Preparations of Methylergometrine: Original ArticlesRani YundaNessuna valutazione finora

- Powder Technology: Aditya U. Vanarase, Juan G. Osorio, Fernando J. MuzzioDocumento10 paginePowder Technology: Aditya U. Vanarase, Juan G. Osorio, Fernando J. MuzzioRani YundaNessuna valutazione finora

- Roll Compaction Dry Granulation RCDG TecDocumento18 pagineRoll Compaction Dry Granulation RCDG TecRani YundaNessuna valutazione finora

- Pellet Design: Daru GratuitaDocumento36 paginePellet Design: Daru GratuitaRani YundaNessuna valutazione finora

- Mixing and Formulation of Low Dose DrugsDocumento16 pagineMixing and Formulation of Low Dose DrugsJulia BottiniNessuna valutazione finora

- Using Spray Dried Lactose Monohydrate in Wet Granulation Metho - 2013 - Powder TDocumento16 pagineUsing Spray Dried Lactose Monohydrate in Wet Granulation Metho - 2013 - Powder TRani YundaNessuna valutazione finora

- 7660 39417 5 PBDocumento7 pagine7660 39417 5 PBVeda SahasikaNessuna valutazione finora

- PDFDocumento6 paginePDFRani YundaNessuna valutazione finora

- Powder Technology: Aditya U. Vanarase, Juan G. Osorio, Fernando J. MuzzioDocumento10 paginePowder Technology: Aditya U. Vanarase, Juan G. Osorio, Fernando J. MuzzioRani YundaNessuna valutazione finora

- 21974Documento6 pagine21974Rani YundaNessuna valutazione finora

- Mixing and Formulation of Low Dose DrugsDocumento16 pagineMixing and Formulation of Low Dose DrugsJulia BottiniNessuna valutazione finora

- MainDocumento5 pagineMainRani YundaNessuna valutazione finora

- 21974Documento6 pagine21974Rani YundaNessuna valutazione finora

- Metal Workers BizHouse - UkDocumento3 pagineMetal Workers BizHouse - UkAlex BekeNessuna valutazione finora

- List of Fatigue Standards and Fracture Standards Developed by ASTM & ISODocumento3 pagineList of Fatigue Standards and Fracture Standards Developed by ASTM & ISOSatrio Aditomo100% (1)

- Manual of Sensorless Brushless Motor Speed Controller: Pentium SeriesDocumento4 pagineManual of Sensorless Brushless Motor Speed Controller: Pentium Seriesfosavo5839Nessuna valutazione finora

- Water Filling MachineDocumento15 pagineWater Filling Machinepallab D RozarioNessuna valutazione finora

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocumento3 pagine1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaNessuna valutazione finora

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocumento7 pagineW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyNessuna valutazione finora

- Vanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019Documento118 pagineVanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019mick byrnes100% (1)

- Clinical Biomechanics: Leigh W. Marshall, Stuart M. McgillDocumento4 pagineClinical Biomechanics: Leigh W. Marshall, Stuart M. McgillMichael JunNessuna valutazione finora

- Smart Grid TechnologyDocumento43 pagineSmart Grid Technologyarnav LakshkarNessuna valutazione finora

- Surface Finish Measurement NotesDocumento32 pagineSurface Finish Measurement NotesAneez ShresthaNessuna valutazione finora

- Daftar PustakaDocumento3 pagineDaftar PustakaMel DaNessuna valutazione finora

- Manuscript FsDocumento76 pagineManuscript FsRalph HumpaNessuna valutazione finora

- Project ReportDocumento14 pagineProject ReportNoah100% (7)

- Essential Calculus Skills Practice Workbook With Full SolutionsDocumento528 pagineEssential Calculus Skills Practice Workbook With Full SolutionsGerardo Navarro Sánchez94% (65)

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Documento4 pagineRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNessuna valutazione finora

- Notes Transfer of Thermal EnergyDocumento12 pagineNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- BIO 201 Chapter 11 LectureDocumento34 pagineBIO 201 Chapter 11 LectureDrPearcyNessuna valutazione finora

- Wcdma Idle Mode (Ericsson)Documento29 pagineWcdma Idle Mode (Ericsson)Hosein ShahbaziNessuna valutazione finora

- Warehouse Management Solution SheetDocumento2 pagineWarehouse Management Solution Sheetpatelnandini109Nessuna valutazione finora

- Basics of Population EducationDocumento4 pagineBasics of Population EducationLAILANIE DELA PENANessuna valutazione finora

- Goa Daman & Diu Factory Rules PDFDocumento141 pagineGoa Daman & Diu Factory Rules PDFmrudang1972100% (1)

- The Process: by Andy ZoppeltDocumento4 pagineThe Process: by Andy ZoppeltMark Stephen HuBertNessuna valutazione finora

- Test09 Eoc Algebra2 ReducedDocumento33 pagineTest09 Eoc Algebra2 ReducedkristymadimikeNessuna valutazione finora

- Diagnostic Imaging of The Pharynx and Esophagus: Key PointsDocumento33 pagineDiagnostic Imaging of The Pharynx and Esophagus: Key PointsChutcharwan JintasoponNessuna valutazione finora

- 08 - 2061 USTR 2222a (1) Supor EKVDocumento24 pagine08 - 2061 USTR 2222a (1) Supor EKVHassan Houdoud0% (1)

- Esterification Oil of WintergreenDocumento8 pagineEsterification Oil of WintergreenMaria MahusayNessuna valutazione finora

- Youth Camp Registration Form-2022Documento1 paginaYouth Camp Registration Form-2022FlerkNessuna valutazione finora

- Entero SequencesDocumento12 pagineEntero SequencesKelvin SueyzyNessuna valutazione finora

- TheBasicsofBrainWaves - RS PDFDocumento4 pagineTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaNessuna valutazione finora

- 3M Novec 1230 Fire Protection Fluid FAQDocumento8 pagine3M Novec 1230 Fire Protection Fluid FAQEden CansonNessuna valutazione finora