Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E Zonal L HIRF Principles PDF

Caricato da

Eduardo MercadejasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E Zonal L HIRF Principles PDF

Caricato da

Eduardo MercadejasCopyright:

Formati disponibili

Maintainability & Maintenance Engineering + Maintenance Planning & Services

XM33 Training

5.

Zonal & L/HIRF logic

Principles

based on Airbus’ experience

XM33 Training MARCH 07 5- 1

THIS PAGE INTENTIONALLY LEFT BLANK

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 2

XM33 Training MARCH 07 5- 2

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 4

2. Zonal & L/HIRF Analysis 9

3. MWG Review Process 61

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

4. Summary 64

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 3

XM33 Training MARCH 07 5- 3

1.1.Introduction

Objectives

Systems and Powerplant

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

Zonal

Section Section

Structures

Section

MSI--Analyses

MSI SSI--Analyses

SSI Zonal--Analyses

Zonal

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 4

The respective content of the « Systems & PP », « Structures» and « Zonal » sections (or programs) of the MRB

Report is based on the results from the works performed by the different MWGs and the ISC in order to define the

« initial minimum scheduled maintenance requirements », thanks to the MSG-3 method, through the MRB Process

settled for a dedicated a/c program.

XM33 Training MARCH 07 5- 4

1. Introduction – MSG-3 Background

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 5

XM33 Training MARCH 07 5- 5

1. Introduction – MSG-3 Background

Zonal Analysis Procedure

¾ Zonal inspections may be developed from application of the

Zonal Analysis Procedure. This requires a summary review of

each zone on the aircraft and normally occurs as the MSG-3

analyses of structures, systems,and powerplants are being

concluded. These inspections may subsequently be included in

the Zonal Inspections.

¾ In top down analyses conducted under MSG-3, many support

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

items such as plumbing, ducting, Other Structure,wiring, etc.,

may be evaluated for possible contribution to functional failure.

In cases where a general visual inspection is required to assess

degradation, the zonal inspection is an appropriate method.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 6

XM33 Training MARCH 07 5- 6

1. Introduction – MSG-3 Background

Changes of MSG-3 methodology since revision 2

AT A MS G-3

Oper ator/M anuf actu rer

ATA MSG-3

Sched uled

ATA MSG-3 Oper ator/M anuf actu rer Maint en an ce

ATA MSG-3 Oper ator/M anuf actu rer Sched uled Develop ment

Sched uled Maint en an ce

Oper ator/M anuf actu rer Revision 2005.1

ATA MSG-3 Maint en an ce Develop ment

Sched uled

Oper ator/M anuf actu rer Develop ment

Maint en an ce Rev ision 2003.1

Sched uled Develop ment Rev ision 2002.1

Maint en an ce

Develop ment Rev ision 2001.1

Rev ision 2

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Revised sections on:

New sections on: • Enhanced zonal analysis

• Enhanced zonal analysis

• L/HIRF analysis

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 7

Changes of MSG-3 methodology since revision 2

Enhanced Zonal Analysis :

Allows appropriate attention to be given to safety related deterioration of wiring, particularly in zones

with potential for combustible material accumulation

The main intent is to reduce existence of electrical ignition sources and combustible material through

maintenance tasks

Changes in maintenance regulations have been addressed through an Aging Transport Systems

Rulemaking Advisory Committee (ATSRAC)

The Enhanced Zonal Analysis Procedure (EZAP) was developed by the ATSRAC Task 3 Sub-

Committee

L/HIRF Analysis :

The intend of the L/HIRF protection tasks is to reduce the possibility that a single failure cause (e.g.

lightning strike) and the occurrence of a common failure cause such as Environmental or Accidental

Damage (ED/AD) across (functional) redundant channels could impact aircraft airworthiness

XM33 Training MARCH 07 5- 7

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 4

2. Zonal & L/HIRF Analysis 9

2.1 Generic Process

2.2 Standard zonal Analysis

2.3 Enhanced zonal analysis

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

2.4 L/HIRF zonal analysis

2.5 Consolidation/transfer/interface

1. MWG Review Process 61

2. Summary 64

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 8

XM33 Training MARCH 07 5- 8

2.1 Zonal & L/HIRF Analysis - Generic Process

Zonal & L/HIRF general principles

• MSG-3 document treats Zonal & L/HIRF in two independent sections

• Zonal and L/HIRF analyses are performed as one unique procedure

taking advantage of the similarity between both processes

• Zones are sensitive or not sensitive to L/HIRF threats. As per MSG-3,

most of the L/HIRF protection and in particular the aircraft structure

continuity are covered by the Standard Zonal Analysis

The Zonal & L/HIRF analysis consists of the following sub-processes:

• Zone description

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Zonal Analysis:

- Standard Zonal Analysis part (applies to all zones)

- Enhanced Zonal Analysis part (applies to zones with wiring)

• Lightning/High Intensity Radiated Field (L/HIRF) Zonal Analysis

(applies to L/HIRF protection elements)

• Consolidation

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 9

XM33 Training MARCH 07 5- 9

2.1 Zonal & L/HIRF Analysis - Generic Process

Any Airbus aircraft is divided into 9 major zones as follows:

Major Zones (External)

100 Lower half of fuselage (below cabin floor), including radome to ramp

200 Upper half of fuselage (above cabin floor) to end of main deck cargo

compartment

300 Stabilizers and fuselage rear section

400 Power plant (including propeller)

500 LH wing

600 RH wing

700 Landing gear & landing gear doors

800 Doors

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

900 Special use (e.g. external fuel pods…)

Major Sub-Zones (Internal)

Sub-divisions of major zones, e.g. 100 is divided into 110, 120, 130…

Zones (Internal)

Sub-divisions of major sub-zones, e.g.120 is divided into121,122,123...

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 10

XM33 Training MARCH 07 5 - 10

2.1 Zonal & L/HIRF Analysis - Generic Process

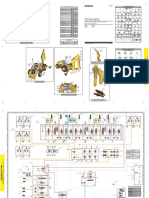

Aircraft zoning principles (A340 example)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 11

XM33 Training MARCH 07 5 - 11

2.1 Zonal & L/HIRF Analysis - Generic Process

Aircraft zoning principles (A340 example)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 12

XM33 Training MARCH 07 5 - 12

2.1 Zonal & L/HIRF Analysis - Generic Process

Aircraft zoning principles (A340 example)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 13

XM33 Training MARCH 07 5 - 13

2.1 Zonal & L/HIRF Analysis - Generic Process

Aircraft zoning principles (A340 example)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 14

XM33 Training MARCH 07 5 - 14

2.1 Zonal & L/HIRF Analysis - Generic Process

Aircraft access panel numbering principles (A340 example)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 15

XM33 Training MARCH 07 5 - 15

2.1 Zonal & L/HIRF Analysis - Generic Process

Zonal Inspection Program (ZIP) principles

The Zonal Inspection Program has one

single level of inspection!

General Visual Inspection

(GVI)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Inspection to be carried out from within touching

distance, unless otherwise stated

A mirror may be necessary to ensure visual access

to all exposed surfaces in the inspection area

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 16

XM33 Training MARCH 07 5 - 16

2.1 Zonal & L/HIRF Analysis - Generic Process

Zonal Inspection Program (ZIP) principles

• The Zonal Inspection Program provides the General Visual Inspection

(GVI) requirements for each aircraft zone to inspect system and

powerplant installations for security and general condition and structure

for general condition

• The Zonal Inspection Program is based on dividing the aircraft into

zones. Each zone is usually defined by a clearly defined physical

boundary, e.g. rib, bulkhead, frames, etc…

• Each zone is to be inspected as far as visible with the relevant access

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

open/removed

• The extent of the inspection is defined by the access e.g. identification of

access doors, positioning of flight control surfaces, removal of lining and

insulation, etc…

• Inspections are recommended to be accomplished at or before stated

intervals

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 17

XM33 Training MARCH 07 5 - 17

2.1 Zonal & L/HIRF Analysis - Generic Process

Zonal Inspection Program (ZIP) principles

• Each zone is analysed for type of damage/deterioration to

structure/systems located in the zone which may occur in-service

• Zonal inspection tasks do not provide a summary of all the individual

systems and structural items to be inspected in the affected zone

• Therefore it is considered that a person performing inspections has an

adequate knowledge of overall aircraft construction and systems

• Zones may need more than one inspection at different intervals due to

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

the depth at which the zone is to be examined requiring different levels

of accessibility

- e.g. The cargo compartment requires 3 ZIP inspections each

requiring a different level of access (1.5 MO - door, 5 YE specific

panels and 10YE all access open)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 18

XM33 Training MARCH 07 5 - 18

2.1 Zonal & L/HIRF Analysis - Generic Process

Common Analysis Process

Standard

Zonal

Enhanced Zonal

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

L/HIRF

L/HIRF and Zonal analysis (Standard, Enhanced) procedures have been

combined to make maximum use of similar procedural steps & synergies

between the three zonal analysis parts

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 19

XM33 Training MARCH 07 5 - 19

2.1 Zonal & L/HIRF Analysis - Generic Process

Zonal Inspection Program task levels (ZIP)

• Standard Zonal analysis:

- GVI (General Visual Inspection)

• Enhanced Zonal analysis:

- Stand-alone GVI, a GVI which is not performed as part These visual

of a zonal inspection inspection

- RST (Restoration), cleaning being the most probable

- DET (Detailed Inspection)

requirements

• L/HIRF protection analysis: are covered

- Stand-alone GVI, a GVI which is not performed as part under the

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

of a zonal inspection Zonal

- DET (Detailed Inspection)

- FNC (Functional Check), resistance measurement

Inspection

• Structure & System/Powerplant maintenance Program

requirements transferred for consolidation include: (ZIP)

- GVI (General Visual Inspection)

- VCK (Visual Checks), system/powerplant analysis only

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 20

XM33 Training MARCH 07 5 - 20

2.1 Zonal & L/HIRF Analysis - Generic Process

Enhanced zonal & L/HIRF task levels (ATA20)

• Standard Zonal analysis:

- GVI (General Visual Inspection)

• Enhanced Zonal analysis:

- Stand-alone GVI, a GVI which is not performed as part These non

of a zonal inspection ZIP tasks

- RST (Restoration), cleaning being the most probable

will be listed

- DET (Detailed Inspection)

• L/HIRF protection analysis:

in the

- Stand-alone GVI, a GVI which is not performed as part systems &

powerplant

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

of a zonal inspection

- DET (Detailed Inspection) section

- FNC (Functional Check), resistance measurement (ATA

• Structure & System/Powerplant maintenance chapter 20)

requirements transferred for consolidation include:

- GVI (General Visual Inspection)

- VCK (Visual Checks), system/powerplant analysis only

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 21

XM33 Training MARCH 07 5 - 21

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 3

2. Zonal & L/HIRF Analysis 8

2.1 Generic Process

2.2 Standard zonal Analysis

2.3 Enhanced zonal analysis

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

2.4 L/HIRF zonal analysis

2.5 Consolidation/transfer/interface

1. MWG Review Process 60

2. Summary 63

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 22

XM33 Training MARCH 07 5 - 22

2.1 Zonal & L/HIRF Analysis - Generic Process

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Standard Zonal

Zonal Inspection Program (ZIP) General Visual

Inspections (GVI) to detect visual degradation of the

whole zone content (structure, equipment, wiring,

L/HIRF protection, bonding leads, grounding points...)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 23

XM33 Training MARCH 07 5 - 23

2.3 Zonal & L/HIRF Analysis - Standard Part

Standard zonal analysis principals

• The standard zonal analysis process is based on four parameters:

- Accidental damage

- Environmental damage

- Density

- Importance

• The final rating in the matrix box provides guidance for the inspection

intervals (zonal guidance interval)

• Intervals are defined according to applicable in-service experience

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Access is defined according to zone layout/installation

• It is expected that the area to be inspected is clean enough to minimise

the possibility that accumulated dirt or grease might hide unsatisfactory

conditions

• Any cleaning that is considered necessary should be performed before

the zonal inspection task

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 24

XM33 Training MARCH 07 5 - 24

2.3 Zonal & L/HIRF Analysis - Standard Part

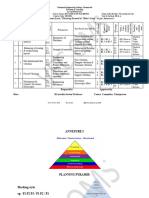

Standard zonal analysis interval guidance rating

ACCIDENTAL ENVIRONMENTAL

DAM AGE DAM AGE

Ground Handling Temperature

Cargo Handling Vibration

Maintenance Humidity

Weather effects Contamination

Foreign objects Chemical (toilet fluids,..) DENSITY

Fluid spillage Others… Low Moderate High

Passenger traffic Low 1 2 3

Others… IMPORTANCE Moderate 2 3 4

N/A=0, Low=1, Moderate=2, High=3 High 3 4 4

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Select the highest rating !

IMPORTANCE/DENSITY FACTOR

1 2 3 4

ED FACTOR

1 >144MO 96-144MO 72-96MO 48-72MO

1 2 3

AD/ED 2 96-144MO 72-96MO 48-72MO 24-48MO

1 1 2 3

AD FACTOR 3 72-96MO 48-72MO 24-48MO 12-24MO

2 2 3 4

FACTOR 4 48-72MO 24-48MO 12-24MO <12MO

3 3 4 4

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 25

XM33 Training MARCH 07 5 - 25

2.3 Zonal & L/HIRF Analysis - Standard Part

Zone accidental & environmental rating

ACCIDENTAL ENVIRONMENTAL

DAM AGE DAM AGE

Ground Handling Temperature Environmental Damage (ED):

Cargo Handling Vibration This rating is a measure of how

Maintenance Humidity much the zone is subject to

Weather effects Contamination temperature, vibration,

Foreign objects Chemical (toilet fluids,..) atmospheric exposure, moisture,

Fluid spillage Others… contamination

Passenger traffic

Others…

N/A=0, Low=1, Moderate=2, High=3

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Although rarely used, the working group is not

Accidental Damage (AD):

limited to the given entries and may decide to

Each given and additionally

add further items to the given list entries

identified potential accidental

• The highest rating will be taken into

damage cause will be rated in

consideration for the overall AD/ED rating

respect of the possibility of

accidental damage to systems

and structure in the zone

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 26

XM33 Training MARCH 07 5 - 26

2.3 Zonal & L/HIRF Analysis - Standard Part

Zone density and importance rating

Density of equipment

• This rating is a measure of how close

the various systems components

(including wiring) are packed in a zone DENSITY

• The density is assessed relative to the Low Moderate High

size of the zone

Low 1 2 3

• It provides indications about:

IMPORTANCE Moderate 2 3 4

- The inspectability of the system

installation and structure High 3 4 4

- The risk of common cause hazard

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

resulting in deterioration of multiple

adjacent items (fire, burst, moisture,

fluid spillage…)

• The density refers to the number of

components and complexity

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 27

XM33 Training MARCH 07 5 - 27

2.3 Zonal & L/HIRF Analysis - Standard Part

Low: PPH: Safety is considered as

• System items whose anomalous behaviour may cause or contribute to failure adversely affected if the

of system function with no effect on aircraft operational capability & pilot failure consequences would

workload but maybe undesirable economic impact and/or comfort reduction prevent the aircraft continued

• Structure whose failure or detachment will not compromise continued safe safe flight and landing and/or

flight or landing but where the potentially large size of released elements might cause serious or fatal

needs to be considered injury to human occupants

DENSITY

Moderate:

• Anomalous system behaviour may cause/contribute to failure Low Moderate High

resulting in adverse effect on aircraft operating capability Low 1 2 3

(delays, cancellations, ground/flight interruptions…)

• Structure whose failure or detachment could compromise IMPORTANCE Moderate 2 3 4

continued safe flight or landing High 3 4 4

• Fuel tanks by default to limit frequent access and sub-

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

sequent system disturbance/FOD

High:

• Anomalous system behaviour may cause or contribute to failure resulting in adverse effect on safety

• Structure element whose integrity is essential

• Fuel tank adjacent zones where failure of components (pneumatic system and/or ducting) could cause

localised heating of tank surfaces & consequently increase potential for auto-ignition of fuel

• Fuel leakage zones where temperature as result of failure (e.g. electric motors/transformers overload) could

increase and with potential ignition sources (electrical arcs, friction sparks) present

• Zones where particular risks could affect several system items (hydraulic accumulator burst, wheel/tyre

failure, engine rotor failure, human error…)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 28

XM33 Training MARCH 07 5 - 28

2.3 Zonal & L/HIRF Analysis - Standard Part

Description/Boundaries: Access:

ACC IDEN T AL D AM AGE ENVIRONMENT AL D AM AGE INTERVAL EVALUATION Comm ent s

Ground H andli ng Temper atur e DENSI TY:

Cargo Handling Vibr ati on DENSITY

Maintenanc e Humidi ty

Low Mod erate High

Weather effects Contaminati on

Foreig n objec ts Chemical (toilet fl uids ,..) Low 1 2 3

Fluid s pillage Others … IMPOR TANCE Mod erate 2 3 4

IMPORTANCE :

Pass eng er tr affic

High 3 4 4

Others …

N/A= 0, Low= 1, M oderate= 2, High= 3

Select the highest rating !

IMPOR TANCE/DENSITY F AC TOR

1 2 3 4 Justificati on for Interv al outside the gui dance:

ED F ACTOR

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

1 2 3 1 >144 MO 96-14 4MO 72-96 MO 48-72 MO

1 1 2 3 AD/ED 2 96-14 4MO 72-96 MO 48-72 MO 24-48 MO

AD F ACTOR 3 72-96 MO 48-72 MO 24-48 MO 12-24 MO

2 2 3 4

F ACTOR

3 3 4 4 4 48-72 MO 24-48 MO 12-24 MO <12 MO

Task No. Access Description Level Interval Applicability

GVI

YES Is there an additional NO

Continue with an additional Standard Continue with Enhanced Zonal

specific access/area

Zonal Analysis Evaluation Sheet 1 Analysis Evaluation Sheet 1

to be analysed?

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 29

XM33 Training MARCH 07 5 - 29

7. Zonal Inspection Program

2.3 Zonal & L/HIRF Analysis - Standard Part

¾ The Zonal Inspection Program has inspection parameters in terms of

letter check and calendar time, as follows:

A - Check and multiples up to 4A

C - Check and multiples up to 4C

6Y/5Y and 10Y/12Y

¾The lower thresholds/intervals are mainly driven by the likelihood of

accidental damage and systems reliability aspects. The access is usually

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

limited to specific areas.

¾ The higher intervals usually have a more significant access

requirement and are mainly concerned with the type of damage which

has propagated over time or cycles to the point where it is large enough

to be detected by a GVI.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 30

XM33 Training MARCH 07 5 - 30

2.3 Zonal & L/HIRF Analysis - Standard Part

Standard zonal analysis summary

The Standard Zonal Analysis Part considers:

• Deterioration (e.g. corrosion, accidental damage, wear, ageing,

fatigue…) on systems components & airframe structures

• Any deterioration of bonding & shielding of structure & equipment

(including wiring & L/HIRF protection) detectable by GVI

Evaluation is performed for

• entire zone

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• any additionally dedicated access/area(s) of the zone can be

identified where appropriate

Using rating tables for:

• Density

• Importance Overall rating results in

• Accidental Damage a task interval guidance

• Environmental Damage

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 31

XM33 Training MARCH 07 5 - 31

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 3

2. Zonal & L/HIRF Analysis 8

2.1 Generic Process

2.2 Standard zonal Analysis

2.3 Enhanced zonal analysis

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

2.4 L/HIRF zonal analysis

2.5 Consolidation/transfer/interface

1. MWG Review Process 60

2. Summary 63

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 32

XM33 Training MARCH 07 5 - 32

2.1 Zonal & L/HIRF Analysis - Generic Process

G Route

to O/B

Engine

P Route

Crossover

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Enhanced Zonal M&S

Routes to

• Detect visual wiring degradation not fully Engine

addressed within the scope of the ZIP

• Control accumulation of combustible

material related to wiring ignition fire risk

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 33

XM33 Training MARCH 07 5 - 33

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Enhanced zonal analysis principals

• The Enhanced Zonal Analysis Procedure (EZAP) permits appropriate

attention to be given to electrical wiring installation within a zone

(particularly in zones having the potential for combustible material

being present)

• The logic provides a means to identify applicable and effective tasks to

minimise combustible material accumulation and to address significant

wiring discrepancies that may not be reliably detected through Zonal

Inspection Program (ZIP) tasks

• The enhanced zonal analysis must be performed for all zones that

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

contain wiring

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 34

XM33 Training MARCH 07 5 - 34

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Zone Description/Illustration:

YES NO

contains wiring

?

combustible NO Is wiring

material in the close to both

zone ? primary & back-up NO

hydraulic, mechanical,

YES

or electrical

Describe combustible material in table flight

controls? Answers and explanations to

questions:

Is there YES

an effective task

NO to significantly reduce the Combustible material table

likelihood of accumulation of Material Y/N Comments

L/HIRF NO

combustible Dust

protection elements

materials Lint

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

installed in the

?

zone? Fuel vapour

YES

Fuel leakage

YES

Define task & interval Oil mist

Hydraulic mist

Continue with Enhanced Continue with L/HIRF Standard Zonal Analysis is List if others..

Zonal Analysis Evaluation Zonal Analysis adequate. Continue with Task

Sheet 2 Evaluation Sheet Summary & Consolidation Sheet

Justification for Interval:

Task No. Access Description Level Interval Applicability

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 35

XM33 Training MARCH 07 5 - 35

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Enhanced zonal analysis principals

• Wiring inspectability

• EE Bay?

• Feeder (Route G)?

• Flight compartment?

• Wiring close to both

primary and back-up Dedicated Wiring

Wiring hydraulic, or electrical Inspection

flight controls?

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Tasks that avoid

accumulation of

Combustible material combustibles

(mostly cleaning)

dust, lint, fuel vapours, fuel leakage, insulation

blanket (contaminated), oil mist, hydraulic mist

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 36

XM33 Training MARCH 07 5 - 36

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Contamination with combustible material

Equipment and wiring are subject to dust and lint accumulation due to:

• Air movement (natural, forced; typical areas are recirculation, galley & toilet etc.)

• Attraction by magnetic fields from electric current surrounding wiring and equipment

Combustible material impact:

• Moisture trapping and subsequent corrosion

• Changes in electrical characteristics (dust &

lint can act as conductor, e.g. with presence of

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

moisture, they can provide a path for a short

circuit)

• Heat insulation which can cause overheat and

premature failure or contribute to fire ignition

• Fire propagation in case of severe dust and

lint accumulation

• Wiring cleaning task are selected based on manufacturer/operators experience

• Airbus has service condition experience from enhanced zonal exercises for legacy (Wide Body, Single Aisle,

Long Range)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 37

XM33 Training MARCH 07 5 - 37

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Dedicated wiring inspection task principles

• It is considered useful to know the standard zonal GVI interval in order

to harmonise the overall access requirements

• The assessment of DENSITY, SIZE and POTENTIAL EFFECT OF FIRE

IN ZONE provides guidance on whether the zonal inspection program

GVI is adequate for all wiring in the zone, or if these GVI task(s) must be

augmented with “stand-alone” GVI(s) or DET inspection(s)

• Most of the wiring is considered adequately addressed with the Zonal

Inspection Program (ZIP) GVI tasks

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Some portion of wiring in the zone/area may require a dedicated

maintenance task (e.g. stand-alone GVI or DET) in respect to potential

fire ignition and/or potential for loss of multiple functions to the extend

that continued safe operation may not be possible

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 38

XM33 Training MARCH 07 5 - 38

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Enhanced Zonal Analysis – Evaluation Sheet 2 Zone(s):

Wiring inspection task level definition XXX/YYY/ZZZ

Zone Title: Enhanced Zonal Analysis Evaluation Sheet 3

INSPECTION LEV EL DEFINITION Size Com ments:

ENTI RE ZO NE DENSITY

(Stand-alone GVI or DET) for dedicated area

Low Moderate High

Small 1 1 2 Dedicated

SIZE Medium 1 2 3 access

Large 3 3 3

Density Com ments: The need for a specific inspection

GVI GVI or

DET

task (Stand-alone GVI or DET) is

SIZE / DENSITY

FACTOR influenced by:

1 2 3

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Size of the zone/area

POTENTIAL Low ZIP ZIP ZIP

EFFECT OF FIRE

ON ADJACENT

• Density of wiring/equipment

Potential Effec t Comme nts :

Moderate ZIP EZA EZA

WIRING AND

SYSTEMS IN THE • Potential effect of fire in the zone

ZIPZONE

GVI for High EZA EZAor EZA

GVI

the whole DET Specific wiring installation

zone within the zone

NO ZIP Y ES

Continue with Enhanced Zonal Continue with L/HIRF Zonal Analysis

Analysis – Evaluation Sheet 3 adequate? Evaluation Sheet 1, if protection installed

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 39

XM33 Training MARCH 07 5 - 39

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Zonal Analysis – Evaluation Sheet 3 Zone(s):

Example EnhancedDedicated wiring inspection task XXX/YYY/ZZZ

Zone Title:

Area Comm ents/Illustration:

ACCIDENTAL ENVIRONMENTAL

…of boundaries and content of

DAMA GE DAMA GE

Groun d Handli ng Temp erature

Cargo Handli ng Vibration

dedicated area Mai ntenance

Weather eff ects

Humidity

Contamination

Foreign ob jects Chemical (toilet f luids,..)

Size Comments:

DEDICATED ARE A DENSITY Fluid spillage Others…

Low Mod erate High Passenger traff ic

Small 1 1 2 Others…

SIZE Med ium 1 2 3 N/A=0, Low=1, Moder ate=2, High =3

Large 3 3 3 Sel ec t the hig hest r ati ng !

Density Comments:

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

ENVIROMENTAL FACTOR

SIZE / DENSITY FACTOR 1 2 3

1 2 3 1 >72 MO 72-48 MO 48-24 MO

ACCIDENTAL

POT ENT IAL Stand 2 72-48 MO 48-24 MO 24-12 MO

Stand Stand FACTOR

Potential Effect Comm ents: EFF ECT OF Mod erate alone 3 48-24 MO 24-12 MO <12 MO

FIRE ON alone G VI alone G VI

GVI

ADJ ACEN T

WIR ING AND Stand Stand Stand

alone G VI alone G VI Justificati on for Interv al outside the gui dance:

SYST EM S IN High alone

THE AR EA GVI DET DET

Task No. Access Description Lev el Interv al Applicability

Continue with an additional Enhanced Y ES Is there an additional specific NO Continue with L/HIRF Zonal Analysis

Zonal Analysis E valuation Sheet 3 access/area to be analysed? Evaluation Sheet 1, if protection installed

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 40

XM33 Training MARCH 07 5 - 40

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Comments on “stand-alone” GVI’s

ZIP GVI Tasks:

• Zonal Inspection Programme GVI does not focus on particular

item or feature (the GVI task defined by the zone reference,

access requirements and interval)

• All system (including wiring) and structure features evident with

the quoted access are subject to the inspection

ATA20 GVI Tasks:

• The term “stand-alone” GVI is used to identify GVI tasks

covering items or features that require particular attention in the

frame of the EZAP and/or L/HIRF analysis

• “Stand alone” GVI tasks focus on items clearly defined by the

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

task description (e.g. “General Visual Inspection of “P“ Wiring

Route installed in the Main Deck Forward Cabin Overhead Area,

LH/RH“)

• “Stand alone” GVI tasks are listed in ATA chapter 20 (System &

Powerplant Section of Maintenance Program)

• Consequently “stand-alone” GVI are the same inspection level as any other ZIP,

SSI or MSI GVI task

• The difference to ZIP GVI tasks is that “stand-alone” GVI’s focus on dedicated

items/issues whereas ZIP GVI’s cover all items visible with the given access

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 41

XM33 Training MARCH 07 5 - 41

2.4 Zonal & L/HIRF Analysis - Enhanced Part

Enhanced zonal analysis summary

The Enhanced Zonal Analysis consists of two main parts:

1. Evaluation of combustible material and possible reduction of arcing

related risk

• All combustible material in the zone is listed

• The related “Description, Answers, Remarks, Comments and Justification”

sections provide clear detail on the assessment

2. The wiring inspection level is evaluated using rating tables for:

• Density Together from the assessment for the inspectability

• Size criteria of a zone /dedicated area

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Potential effect of fire on adjacent wiring and systems in the zone

As result, the analysis identifies if the ZIP GVI is sufficient for the whole

zone plus additional dedicated tasks (GVI-stand alone and/or DET) where

applicable

Note: The actual task interval is based on environment & accidental

damage assessment (as for the ZIP GVI’s)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 42

XM33 Training MARCH 07 5 - 42

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 3

2. Zonal & L/HIRF Analysis 8

2.1 Generic Process

2.2 Standard zonal Analysis

2.3 Enhanced zonal analysis

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

2.4 L/HIRF zonal analysis

2.5 Consolidation/transfer/interface

1. MWG Review Process 60

2. Summary 63

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 43

XM33 Training MARCH 07 5 - 43

2.1 Zonal & L/HIRF Analysis - Generic Process

G Route

(feeders)

P Route

Crossover

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

L/HIRF M&S

• To detect L/HIRF protection degradation Routes to

Engine

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 44

XM33 Training MARCH 07 5 - 44

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

L/HIRF zonal analysis principals

The intend of the L/HIRF

Lightning (L)

protection tasks is to reduce the

possibility that a single failure

cause (e.g. lightning strik e) and

the occurrence of a common

failure cause such as Radio

Environmental or Accidental

Damage (ED/AD) across transmitters Radars

(functional) redundant channels

could impact aircraft (ground &

airworthiness

airborne)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

High Intensity Radiated Fields

(HIRF)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 45

XM33 Training MARCH 07 5 - 45

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

L/HIRF protection principals

Equipment protection

• In addition to the equipment inherent protection (circuit layout and box design),

clamping, filtering and transient protection devices (tranzorbs) prevent damage

from induced voltage/current resulting from L/HIRF encounter

• Hidden failure of these features is unlikely due to:

- High reliability figures of the transient suppressor

- Methodical shop testing after each unscheduled removal

- Build In Test Equipment (BITE)

System architecture

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Is designed to achieve systems safety and availability objectives and contributes

to increase the non-susceptibility of systems to L/HIRF effects

• Main features are:

- Segregation of electrical wiring routes and equipment installation

- Redundancy and dissimilarity.

- Systems and functions monitoring (comparison, data coherence)

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 46

XM33 Training MARCH 07 5 - 46

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

L/HIRF protection principals

Aircraft structure continuity

• Is ensured by metal to metal contact, bonding leads and meshes for composite

structure

• Degradation (corrosion, broken strands…) is covered by the standard zonal

analysis

Braided conduits and race ways (wings)

• Provide wiring protection in exposed areas

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Degradation is partially addressed with the standard zonal analysis and with

dedicated GVI and DET wiring inspection tasks defined through the enhanced

zonal

• The zonal L/HIRF protection analysis procedure will allow identification of

inspection tasks to augment these inspections

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 47

XM33 Training MARCH 07 5 - 47

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

L/HIRF protection principals

Aircraft structure continuity: Electrical wiring protection:

• Metal to metal contact • Overbraiding/raceways in exposed

areas (wings, engines, landing

• Metallic grid screen (mesh,

gear, belly fairing, …)

strip) on composite

Standard zonal,

• Bonding leads enhanced zonal &

L/HIRF analysis

Structure &

System & Standard zonal & standard zonal

powerplant analysis L/HIRF analysis analysis Standard zonal analysis

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Equipment protection: Systems architecture:

• Boxes designed with good EM • Segregation and routing of

attenuation electrical wiring routes

• Inputs and outputs fitted with • Different location of equipments

filters and transient

• Redundancy and dissimilarity

suppression devices

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 48

XM33 Training MARCH 07 5 - 48

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

MSG-3 zonal L/HIRF protection analysis scope

Exposed areas:

Electrical wiring protection:

• Open areas (landing gear, wing trailing • Overbraiding/raceways in exposed

edge, …)

areas (wings, engines, landing

• Under low conductive material (titanium,

stainless steel, composite)

gear, belly fairing…)

Wiring installed in the following areas are

protected:

• Wings

• Engine

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Horizontal/vertical tail plane

• Nose and main landing gear legs and gear

compartment

• Radome

• Sponson

• Fairings

• Tail area

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 49

XM33 Training MARCH 07 5 - 49

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

Zone(s):

L/HIRF Zonal Analysis – Evaluation Sheet

XXX/YYY/ZZZ

Zone Title:

L/HI RF key c haracteristics: INSPECTION LEVEL INSPECTION INTER V AL

DENSITY ACCI DENTAL DAMAGE ENVIRO NME NTAL DAM AGE

Low Mod erate High Ground Handling Temperature

Stand

Low ZIP ZIP

alone G VI

Cargo Handling Vibration

L/HIRF ZIP or Maintenance Humidity

PROTECTION Stand Stand

Stand Weather effects Contamination

DETERIORA TION alone G VI alone G VI

CRITERIA High alone G VI Foreign objects Chemical (toilet fluids...)

DET DET DET

FNC FNC FNC Fluid spillage Others…

Passenger t raffic

Others…

End of Zonal Analy sis. Y ES ZIP N/A=0, Low=1, Moder ate=2, High =3

Continue with Task Summary applicabl e

& Consolidatio n Sheet ? Select the highest rating !

NO

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Determine Insp ection

Requireme nts for ED/AD ENVIRO NME NTAL FACTO R

1 2 3

Description/Illustra tion: 1 >72MO 72-48MO 48-24MO

ACCI DENTAL

2 72-48MO 48-24MO 24-12MO

DAM AGE FACTO R

3 48-24MO 24-12MO <12MO

Justificati on for Interv al:

Tas k No. Acc ess Description Level Interval Applicability

Continue with an additio nal L/HIRF Zonal Analy sis Y ES Are additional protection NO End of L/HIRF Zonal Analy sis. Continue with

Ev aluation Sheet f or additional specif ic protection items items to be inspected? Task Summary & Consolidation Sh eet

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 50

XM33 Training MARCH 07 5 - 50

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

Type certificate relationship

Requirements/ L/HIRF Assurance Plan is usually

compliance implemented under the responsibility of the

Civil Type Certificate holder and serves two

purposes:

• To confirm that the design of the L/HIRF

Assurance protection is adequate to maintain Type

plan Certification objectives throughout aircraft life,

(TBD) and

• To identify specific locations within the

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

L/HIRF protection system where there may

Continued

be a need for scheduled maintenance in

Airworthiness

order to address any systematic deterioration

Type Certification that could eventually impact the Type

process Certification protection level

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 51

XM33 Training MARCH 07 5 - 51

2.5 Zonal & L/HIRF Analysis - L/HIRF Part

Zonal L/HIRF protection analysis summary

The L/HIRF zonal analysis consists of 2 main parts

1. Assessment of required inspection level:

• Density and potential effect of L/HIRF protection deterioration define

required level (ZIP or dedicated ATA chapter 20 L/HIRF task)

2. Evaluation of specific L/HIRF protection element if required

• Density and potential reduction of overall L/HIRF protection define

required level (GVI stand alone, DET or FNC for each additional specific

task)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• The task interval is based on assessment of environment & accidental

damage similar to the enhanced zonal analysis

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 52

XM33 Training MARCH 07 5 - 52

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 3

2. Zonal & L/HIRF Analysis 8

2.1 Generic Process

2.2 Standard zonal Analysis

2.3 Enhanced zonal analysis

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

2.4 L/HIRF zonal analysis

2.5 Consolidation/transfer/interface

1. MWG Review Process 60

2. Summary 63

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 53

XM33 Training MARCH 07 5 - 53

2.6 Zonal & L/HIRF Analysis - Consolidation

Failure modes not identified

through the SSI/MSI

analysis but naturally

inspected by the zonal

• Failure modes identified

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

through the SSI/MSI

analysis but naturally

inspected by the zonal

(e.g. corrosion, obvious

deterioration)

• MSI/SSI tasks transferred

into the zonal program

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 54

XM33 Training MARCH 07 5 - 54

2.6 Zonal & L/HIRF Analysis - Consolidation

AIRCRAFT STRUCTURE

SIGNIFICANT STRUCTURE Y Significant?

N OTHER

NON

STRUCTURE

Metallic or MET ALL IC

MET ALL IC STRUCTUR E STRUCTUR

Non Met allic?

E

ACC IDEN T AL D AM AGE

AN AL YSIS

SSI analysis

ACC IDEN T

ED/C PC P AL

AN AL YSIS DAM AGE

TRANSFER

AN AL YSIS

To be

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

SSI’s

SAF E

LIFE

Saf e L ife or DAM AGE considered

Dam ag e TOL ER ANT

STRUCTU

RE

Tolerant? STRUCTUR E ED by Zonal WG

(“Ag ing”)

AN AL YSI

S

Definit ion of FAT IGU E

SAF E LIFE

LIMIT S

DAM AGE Zonal Analysis

AN AL YSIS

• The Zonal Analysis covers the entire aircraft regardless of the SSI selection

• Thus the complete aircraft structure is considered by the zonal analysis!!!

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 55

XM33 Training MARCH 07 5 - 55

2.6 Zonal & L/HIRF Analysis - Consolidation

The zonal inspection will detect obvious unsatisfactory

conditions/discrepancies (accidental damage,

environmental deterioration, fatigue damage, ageing,

general condition of fasteners, ) in all visible “structure”

(primary, secondary, fairing, panels, doors, …)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 56

XM33 Training MARCH 07 5 - 56

2.6 Zonal & L/HIRF Analysis - Consolidation

Basic systems & power plant principal

Systems evaluations are based upon the functional failures and the failure causes

Function Functional Failure Failure effects Causes

(Normal (How an item failed to (What is the result of (Why the functional

characteristic perform its function) the functional failure) failure occurs)

actions of an item)

The cause show functional

Pipework and wiring are part of system installation, degradation characteristics:

but the related failure causes are normally not

• Mechanical fault

considered by system analysis

• Electrical fault

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

All tubing, wiring installed in a zone is subject to • Failing in open or closed position

the zonal analysis and the resulting ZIP GVI

• Open or short circuit

together with all other system and structure

• Jammed linkage

However, the systems working group may select • Contaminated orifice

MSI tasks for specific wiring/tubing in particular

• Broken housing

cases

• etc.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 57

XM33 Training MARCH 07 5 - 57

2.6 Zonal & L/HIRF Analysis - Consolidation

The zonal inspection will detect obvious unsatisfactory

conditions/discrepancies (due to accidental damage,

environmental deterioration, ageing, ...) for all visible

“system” components (wiring, tubing, actuators,

computers, sensors, …)

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 58

XM33 Training MARCH 07 5 - 58

2.7 Zonal & L/HIRF Analysis - Transfer

Transfer requirement acceptance criteria

Systems/powerplant and structure program GVI items may be

considered as being covered by the ZIP as long as the following

criteria are met:

• The access requirements of the MSI/SSI are the same as or less

severe than the ZIP task in the same area

• The ZIP task is performed as frequently or more frequently than

the thresholds/intervals of the relevant MSI / SSI

A list of all transferred MSI task(s) and SSI task(s) covered by the

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Zonal Program is available for reference (e.g. MRBR appendix)

Therefore, a dedicated inspection is not required for these SSI task(s)

and MSI task(s) if the equivalent ZIP task is performed

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 59

XM33 Training MARCH 07 5 - 59

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 4

2. Zonal & L/HIRF Analysis 9

3. MWG Review Process 61

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

4. Summary 64

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 60

XM33 Training MARCH 07 5 - 60

3. MWG Review Process

Working bodies: Reports/documents:

Operators INDUSTRY POLICY AND

Manufacturers STEERING PROCEDURES

Airworth. COMMITTEE HANDBOOK

Authorities

Operators

Manufacturers MAINTENANCE MSG-3

Airworth. WORKING ANALYSES

Authorities GROUPS

Operators

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

Manufacturers INDUSTRY MRB Report

Airworth. STEERING PROPOSAL

Authorities COMMITTEE

Airworth.

Authorities MAINTENANCE MAINTENANCE

REVIEW REVIEW BOARD

BOARD (MRB) REPORT

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 61

MRB Process and Working Groups

The guidelines that may be used by industry during its development and revision of the initial

minimum scheduled maintenance/inspection are established in the following document:

EASA Administrative & Guidance Material (AGM), Section 2, Part 2, Chapter 16:

'Procedures for Maintenance Review Boards‘ (dated 01Dec.98).

According to these guidelines, the organization that develops the MRB Report consists of

the following working bodies:

Industry Steering Committee (ISC)

Maintenance Working Groups (MWG)

Maintenance Review Board (MRB)

XM33 Training MARCH 07 5 - 61

5.2 Composition of the Maintenance Working Group

ADVISORS MEMBERS

Airworthiness Authorities Chair Person

(MRB)

• Is appointed by Airbus

• Represents the • Is accepted by the ISC

authorities in the group

• Participates in an

advisory capacity

Customer

Representatives

• Operators

ISC Advisor

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

• Represents the ISC in Manufacturer

the group Representatives

• Is nominated to advise • Airframe manufacturer

on policy issues. MWG members and advisors

should possess an adequate • Engine manufacturer

level of knowledge and • Major suppliers

experience.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 62

XM33 Training MARCH 07 5 - 62

Zonal & L/HIRF logic - Principles

Table of Contents

1. Introduction 4

2. Zonal & L/HIRF Analysis 9

3. MWG Review Process 61

© AIRBU S DEUT SCHLAND GM BH. Al l rights reserved. Confidential and proprietary document.

4. Summary 64

XM33 Tr aini ng - Z onal & L/HIR F Logic - Princi ples MARCH 07 Pag e 63

XM33 Training MARCH 07 5 - 63

4. Summary

The Zonal Analysis is a integrated approach with:

• Combined description section

• Zonal analysis with standard and enhanced issues clearly identified in dedicated

sections (the standard section covering certain L/HIRF issues)

• Integrated zonal L/HIRF analysis part

• Final consolidation

The actual zonal analysis consists of 3 main parts:

1. Standard zonal analysis – to develop the ZIP general visual inspections

2. Enhanced zonal analysis – addressing potential fire risk of wiring and related

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

accumulation of combustible material concern for in service aircraft

3. Zonal L/HIRF analysis – to develop related tasks in terms of susceptibility to

degradation (accidental damage / environmental deterioration)

The consolidation will derive

• Harmonised zonal analysis results for both, the ZIP and ATA-20 tasks

• The Zonal Inspection Programme (ZIP) including the transfers from systems &

structure

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 64

XM33 Training MARCH 07 5 - 64

© AIRBUS S.A.S. All rights reserv ed. Conf idential and

propri etary document.

This docume nt and all inf ormation containe d herei n is the sole

property of AIRBUS S.A.S.. No intellectual property rights are

granted by the deliv ery of this document or the disclosure of

its content. This document shall not be reproduced or

disclosed to a third party without the express written consent

of AIRBUS S.A.S. This document and its content shall not be

used f or any purpose other than that f or which it is supplied.

The statements made herein do not constitute an off er. They

are based on the mentioned assumptions and are expresse d

in good f aith. Where the supporting grounds f or these

statements are not shown, AIRBUS S.A.S. will be pleased to

explain the basis thereof .

AIRBUS, its logo, A300, A310, A318, A319, A32 0, A321,

A330, A34 0, A350, A40 0M a re registere d trademarks.

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 65

XM33 Training MARCH 07 5 - 65

THIS PAGE INTENTIONALLY LEFT BLANK

© AIR BUS DEUTSCHL AND GM BH. A ll rights reserved. Confidential and proprietary document.

XM33 Trai ning - Z onal & L/HIRF Logic - Principl es MARCH 07 Pag e 66

XM33 Training MARCH 07 5 - 66

Potrebbero piacerti anche

- 05 - Zonal & L-HIRF PrinciplesDocumento64 pagine05 - Zonal & L-HIRF PrinciplesAsaadNessuna valutazione finora

- Service Schematics: Exploded View and Component DisposalDocumento11 pagineService Schematics: Exploded View and Component Disposalosmar rafael monsalve valenciaNessuna valutazione finora

- A Holistic Workflow For Evaluating and Developing SRR - CypherDocumento23 pagineA Holistic Workflow For Evaluating and Developing SRR - CypherQingming MaNessuna valutazione finora

- C IandC - C1 (6) - BFPTDocumento31 pagineC IandC - C1 (6) - BFPTBayu Dwi AsmaraNessuna valutazione finora

- Mechanical Professional ElectiveDocumento310 pagineMechanical Professional ElectivearunrajNessuna valutazione finora

- M03 - Other MPD SourcesDocumento18 pagineM03 - Other MPD SourcesA WongNessuna valutazione finora

- ml2010 SeriesDocumento5 pagineml2010 SeriesPedro DudesonNessuna valutazione finora

- Technique: Introduction To PromptDocumento3 pagineTechnique: Introduction To PromptBianca MacedoNessuna valutazione finora

- O&M Manual - GL314F3Documento224 pagineO&M Manual - GL314F3frank_538254342100% (2)

- rh-19 Schematic 1 0Documento9 paginerh-19 Schematic 1 0phlimsyboy100% (1)

- 21 BSW Os ENDocumento45 pagine21 BSW Os ENYash BhatnagarNessuna valutazione finora

- M04 - Systems and Power PlantDocumento73 pagineM04 - Systems and Power PlantA WongNessuna valutazione finora

- ID-18-00029 B RSUD Bontang Ingenuity Elite 180411 ID0376Documento6 pagineID-18-00029 B RSUD Bontang Ingenuity Elite 180411 ID0376Bboyz AdhitNessuna valutazione finora

- Syllabus For All Open Electives Btech Programmes Faculty of E&t 18 RegDocumento181 pagineSyllabus For All Open Electives Btech Programmes Faculty of E&t 18 RegSAPTARSHI BHATTACHARYA (RA2011003010182)Nessuna valutazione finora

- Section 2: 2-1 General Description PE/TRD/CN/0303 12.02/EN March, 2000Documento6 pagineSection 2: 2-1 General Description PE/TRD/CN/0303 12.02/EN March, 2000hungpm2013Nessuna valutazione finora

- US - Complete Sinumerik Operate MillingDocumento386 pagineUS - Complete Sinumerik Operate MillingAndre PizarroNessuna valutazione finora

- 18mee304t - Dfma SyllabusDocumento3 pagine18mee304t - Dfma SyllabusSachidhanandam MNessuna valutazione finora

- M05 StructuresDocumento78 pagineM05 StructuresA WongNessuna valutazione finora

- Sample - Syllabus Template Revised - 13.07.2022Documento3 pagineSample - Syllabus Template Revised - 13.07.2022Sowmmiya UNessuna valutazione finora

- FP Tech I Curriculum 22 Aug 2013Documento121 pagineFP Tech I Curriculum 22 Aug 2013Meenal SwarnakarNessuna valutazione finora

- Nokia: © 2003 NMP Only For Training and Service PurposesDocumento11 pagineNokia: © 2003 NMP Only For Training and Service PurposesMirza SalikNessuna valutazione finora

- Transport 5G Considerations IEEE 5G Summit: July 2018 Reza Vaez-Ghaemi, PH.DDocumento34 pagineTransport 5G Considerations IEEE 5G Summit: July 2018 Reza Vaez-Ghaemi, PH.DNicholas WilsonNessuna valutazione finora

- 9.55655-01-2007 - Septum Carton Tarred FeltDocumento12 pagine9.55655-01-2007 - Septum Carton Tarred Feltclaudio5475100% (1)

- Syllabus For All Professional Electives Btech Programmes School of Computing 18 RegDocumento241 pagineSyllabus For All Professional Electives Btech Programmes School of Computing 18 RegMonica Bhavani MNessuna valutazione finora

- Mil PRF 39012 68D PDFDocumento10 pagineMil PRF 39012 68D PDFabdulkadir ali0% (1)

- IDN210090 - REVA - Detail Drawing RSUD KonaweDocumento6 pagineIDN210090 - REVA - Detail Drawing RSUD KonaweRyo FerbianNessuna valutazione finora

- Syllabus - Automotive EnginesDocumento2 pagineSyllabus - Automotive EnginesChatrapal SinghNessuna valutazione finora

- Forward Lighting Systems: General InformationDocumento31 pagineForward Lighting Systems: General InformationGus SalazarNessuna valutazione finora

- FarosDocumento31 pagineFarosAnonymous 0omT4xhXNessuna valutazione finora

- Downloaded From Manuals Search EngineDocumento677 pagineDownloaded From Manuals Search Engineclaudi94Nessuna valutazione finora

- Lenovo Ziji2 Ella - Sovp - MB La-A811p r10 - 0321Documento54 pagineLenovo Ziji2 Ella - Sovp - MB La-A811p r10 - 0321Vivek VarshneyNessuna valutazione finora

- Garrison11ce IM Ch03Documento3 pagineGarrison11ce IM Ch03Rita OlgichNessuna valutazione finora

- Vehicle DynamicsDocumento2 pagineVehicle DynamicsChatrapal SinghNessuna valutazione finora

- Lesson PlanDocumento2 pagineLesson PlanJagrati ChatterjeeNessuna valutazione finora

- Day 5 PCM Technical Basis 4 and M&EDocumento16 pagineDay 5 PCM Technical Basis 4 and M&EnadifaNessuna valutazione finora

- Huaweigpon PDFDocumento1 paginaHuaweigpon PDFRobNessuna valutazione finora

- Cat Dcs Sis ControllerDocumento2 pagineCat Dcs Sis ControllerAlif nur prabowoNessuna valutazione finora

- Solid State Device SyllabusDocumento2 pagineSolid State Device Syllabusnikunj sharmaNessuna valutazione finora

- Assembler Part 2Documento77 pagineAssembler Part 2Kirankumar PattiNessuna valutazione finora

- Nissan Atlas F23 Workshop ManualDocumento1.177 pagineNissan Atlas F23 Workshop Manualcamclarkson520083% (6)

- SyllabusDocumento2 pagineSyllabusDiksha NasaNessuna valutazione finora

- SRM Institute of Science & Technology - Academic Curricula (2018 Regulations) - ControlDocumento2 pagineSRM Institute of Science & Technology - Academic Curricula (2018 Regulations) - ControlEric LonewolfNessuna valutazione finora

- SNP: Structured Neuron-Level Pruning To Preserve Attention ScoresDocumento13 pagineSNP: Structured Neuron-Level Pruning To Preserve Attention Scoreshykprx8j2fNessuna valutazione finora

- Oper - Man - Unit 105 - Rev01Documento88 pagineOper - Man - Unit 105 - Rev01Hadj MeknassiNessuna valutazione finora

- Hmi CNG SpecDocumento15 pagineHmi CNG SpecSantosh MordeNessuna valutazione finora

- Module 9 Shift Registers (Student)Documento8 pagineModule 9 Shift Registers (Student)Ghana KumaranNessuna valutazione finora

- Caterpillar 422E 428E 434E 442E 444E Backhoe Loader Hydraulic SystemDocumento4 pagineCaterpillar 422E 428E 434E 442E 444E Backhoe Loader Hydraulic SystemAlfred Kojo Nassarah83% (6)

- GPON Technology Poster PDFDocumento1 paginaGPON Technology Poster PDFGreg MorrisNessuna valutazione finora

- Sistema Electrico 330D Motor c-9 330 PDFDocumento2 pagineSistema Electrico 330D Motor c-9 330 PDFJilbher MorenoNessuna valutazione finora

- Fmea DesignDocumento29 pagineFmea DesignEmperor89100% (2)

- 19PEEO65T - Fundamentals of Cloud Computing SyllabusDocumento2 pagine19PEEO65T - Fundamentals of Cloud Computing SyllabusSanthosh Kumar PNessuna valutazione finora

- TSL1401Documento8 pagineTSL1401Chế ThiệnNessuna valutazione finora

- Olympus IMT-2 Microscope - Service ManualDocumento36 pagineOlympus IMT-2 Microscope - Service ManualMahnaz BakhshiNessuna valutazione finora

- Modular Alarm Platform 5000 Expert Training 2019 en v1Documento77 pagineModular Alarm Platform 5000 Expert Training 2019 en v1nurkas999Nessuna valutazione finora

- AC 08 B DOM 2018-2019 OddDocumento2 pagineAC 08 B DOM 2018-2019 Oddsar_tpgitNessuna valutazione finora

- Redundancy Mechanisms: HSR, Standby, MRP EtcDocumento27 pagineRedundancy Mechanisms: HSR, Standby, MRP EtcBruno BatistaNessuna valutazione finora

- Smart IoDocumento2 pagineSmart Iotranhuutri1987quangngaiNessuna valutazione finora

- 14 - Integration Management - 2013 V5Documento5 pagine14 - Integration Management - 2013 V5DougNessuna valutazione finora

- Ifm As-Interface Catalogue GB 08Documento283 pagineIfm As-Interface Catalogue GB 08paulNessuna valutazione finora

- CMP Etops IaeDocumento224 pagineCMP Etops IaeEduardo MercadejasNessuna valutazione finora

- Airline - Integration - With - Airbus - IS - v1 4Documento25 pagineAirline - Integration - With - Airbus - IS - v1 4Eduardo MercadejasNessuna valutazione finora

- Ecam Bscu Sys 2 Fault Airbus TfuDocumento3 pagineEcam Bscu Sys 2 Fault Airbus TfuEduardo MercadejasNessuna valutazione finora

- PMA DER 2nd Edition PDFDocumento38 paginePMA DER 2nd Edition PDFEduardo MercadejasNessuna valutazione finora

- SIL 00-028 r42 PDFDocumento163 pagineSIL 00-028 r42 PDFEduardo Mercadejas100% (1)

- SB PolicyDocumento5 pagineSB PolicyEduardo MercadejasNessuna valutazione finora

- Taking Delivery of Your Airbus Booklet September 2017 PDFDocumento100 pagineTaking Delivery of Your Airbus Booklet September 2017 PDFEduardo MercadejasNessuna valutazione finora

- Walk Around PDFDocumento9 pagineWalk Around PDFEduardo MercadejasNessuna valutazione finora

- KIRLOSKAR - Valves Price List 01.03.2012Documento3 pagineKIRLOSKAR - Valves Price List 01.03.2012Ramachandra Sahu0% (3)

- Winter Prep - An Ounce of Prevention .Documento20 pagineWinter Prep - An Ounce of Prevention .TomboNessuna valutazione finora

- Unit I IntroductionDocumento15 pagineUnit I IntroductionMUKILANNessuna valutazione finora

- Traverse Type C - 1015568Documento1 paginaTraverse Type C - 1015568Loki TroliNessuna valutazione finora

- Shrapnel White PaperDocumento42 pagineShrapnel White PaperdelgiudiceinvestimentiNessuna valutazione finora

- Chapter # 3: Process DescriptionDocumento7 pagineChapter # 3: Process DescriptionAhmed HassanNessuna valutazione finora

- Se 4Documento15 pagineSe 4Nabin TimsinaNessuna valutazione finora

- Scripting Guide - Porting ManualDocumento7 pagineScripting Guide - Porting ManualYashanshu GautamNessuna valutazione finora

- AI 10 Prompts WorksheetsDocumento8 pagineAI 10 Prompts WorksheetsSafeelloNessuna valutazione finora

- FASSI F40B каталог деталей PDFDocumento35 pagineFASSI F40B каталог деталей PDFSergeyNessuna valutazione finora

- ANL252 SU2 Jul2022Documento52 pagineANL252 SU2 Jul2022EbadNessuna valutazione finora

- IMT Technical Technical Specifications Specifications: Articulating Cranes Articulating CranesDocumento2 pagineIMT Technical Technical Specifications Specifications: Articulating Cranes Articulating CranesMiguel Angel Vazquez ServinNessuna valutazione finora

- Aug. 13, 2020 Activity 1 by LJ Diane TuazonDocumento2 pagineAug. 13, 2020 Activity 1 by LJ Diane TuazonLj Diane TuazonNessuna valutazione finora

- 2018 Owner'S Manual and Maintenance Information: For Your Safety, Read Carefully and Keep in This VehicleDocumento458 pagine2018 Owner'S Manual and Maintenance Information: For Your Safety, Read Carefully and Keep in This VehicleAlejandro GonzalezNessuna valutazione finora

- CIVL 4750 Numerical Solutions To Geotechnical Problems: I: TA: T V: Tuesday/ C ODocumento3 pagineCIVL 4750 Numerical Solutions To Geotechnical Problems: I: TA: T V: Tuesday/ C OChoffo YannickNessuna valutazione finora

- CS Project Tic-Tac-Toe Game UsingDocumento10 pagineCS Project Tic-Tac-Toe Game UsingThanyaNessuna valutazione finora

- Chapter 2 - Project Integration ManagementDocumento38 pagineChapter 2 - Project Integration ManagementSankalp NavghareNessuna valutazione finora

- Getachew Yimer PDFDocumento119 pagineGetachew Yimer PDFAmos Korme100% (1)

- Catalogo CGM.3Documento44 pagineCatalogo CGM.3Rui Miguel Viegas CardosoNessuna valutazione finora

- Photolab-X: Gaurang Binani (20Bcs5154) Ritik Kumar Kharwar (20Bcs5126) SWAPNIL (20BCS5150) Bhavesh Dwivedi (20Bcs5162)Documento19 paginePhotolab-X: Gaurang Binani (20Bcs5154) Ritik Kumar Kharwar (20Bcs5126) SWAPNIL (20BCS5150) Bhavesh Dwivedi (20Bcs5162)Gaurang BinaniNessuna valutazione finora

- EEE 332lecture Note 09 Digital Modulation TechniquesDocumento101 pagineEEE 332lecture Note 09 Digital Modulation TechniquesMidnight alphaNessuna valutazione finora

- ReportLab - PDF Processing With Python - Michael DriscollDocumento362 pagineReportLab - PDF Processing With Python - Michael DriscollRodrigo Orobio100% (1)

- Pemetaan Potensi Wilayah Pengembangan Sapi Potong Di Kabupaten SitubonDocumento11 paginePemetaan Potensi Wilayah Pengembangan Sapi Potong Di Kabupaten SitubonZuardiNessuna valutazione finora

- Laboratory Design Projects For A Freshman Digital Electronics CourseDocumento8 pagineLaboratory Design Projects For A Freshman Digital Electronics CourseRamshaNessuna valutazione finora

- IEEE - C37.04g - 1986 HV Circuit Breakers TestDocumento2 pagineIEEE - C37.04g - 1986 HV Circuit Breakers TestjuaninjaNessuna valutazione finora

- Requirement For T&C Purpose HPUniSZADocumento1 paginaRequirement For T&C Purpose HPUniSZAAwalJefriNessuna valutazione finora

- Xray2Go Manual Portable X-Ray SystemDocumento36 pagineXray2Go Manual Portable X-Ray SystemEbb Bay100% (1)

- Part 1 - Design: Water Supply Code of Australia Agency RequirementsDocumento12 paginePart 1 - Design: Water Supply Code of Australia Agency RequirementsTailieukythuat DataNessuna valutazione finora

- Business Result Advanced PDF - Google SearchDocumento2 pagineBusiness Result Advanced PDF - Google SearchVimal Rajan0% (2)

- DHI-XVR8808 16S Datasheet20171221Documento3 pagineDHI-XVR8808 16S Datasheet20171221Claudio CeretoNessuna valutazione finora