Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tribological Properties of Aluminium-Based Composite Materials With Dispersed Metallized Graphite Particles

Caricato da

Marilena MereutaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tribological Properties of Aluminium-Based Composite Materials With Dispersed Metallized Graphite Particles

Caricato da

Marilena MereutaCopyright:

Formati disponibili

TRIBOLOGICAL PROPERTIES OF ALUMINIUM-BASED

COMPOSITE MATERIALS WITH DISPERSED METALLIZED

GRAPHITE PARTICLES

Olexandr Shcheretsky, Volodymyr Lakhnenko, Volodymyr

Shcheretsky

Physico-technological Institute of Metals and Alloys of NASU, 34/1 Vernadsky Ave.,

Kyiv-142, 03680, Ukraine, texnolit@i.com.ua

ABSTRACT

Tribological characteristics of composite materials (CM) on the basis of

aluminium-silicon alloy with dispersed metallized particles of graphite are

investigated. Beneficial effect of graphite to serviceability of pair friction is

established. Decreasing of friction coefficient and increasing of wear resistance in

3-5 times are shown.

KEY WORDS: Composite materials, Metallized particles, Wear

1. INTRODUCTION presence of the advanced network of internal

interfacial borders and gradients of the chemical

Modern development of engineering demands potentials arising on these borders is typical. The

more and more perfect tribological materials. There is difference of chemical potentials of substances in a

rising of specific loadings, temperature conditions of matrix and reinforcing phase is driving force of

operation and aggression of environments. Rather processes of interphase interaction, in particular

sharply there is a question of weight reduction of mutual diffusion and chemical reactions. Interphase

devices, increase of durability, reliability and stability interaction renders direct influence on strength of

of properties of materials. However, the resource of connections of components in CM on which depend

increase of properties of standard alloys has not only properties of obtained materials, but also a

practically depleted itself. Therefore for today possibility of their obtaining. Therefore for

materials with heterogeneous and meta-stable development of optimum technological parameters of

structure are more and more widely applied. reception of CM the knowledge of consistent patterns

Composite materials on a basis of aluminium with of interphase interaction in these systems is necessary.

dispersed particles of graphite also can be reckoned to For the solving of this problem a complex of modern

perspective heterogeneous materials [1]. For methods of researches was used: the differential-

obtaining of such materials, property of which will thermal analysis; the quantitative metallography

not change while its work, it is necessary to solve a analysis; the method of a sessile drop for studying

number of difficult technological problems. It is wettability; the method of local X-ray spectral

necessary to provide strong adhesive connections analysis; the X-ray-phases analysis; the chemical

between strengthening phase and a matrix, and analysis. For the successful solving of a problem of

prevent formation of harmful compounds on introduction and equable distribution of dispersed

interphase borders, which can lower physical, particles in aluminium melt the powders of graphite

mechanical and tribological properties of CM, or (50-100 microns) metallized by molybdenum was

cause the degradation of properties of material while used.

its work. Thereto, under operation of composite Metallization of dispersed particles of graphite

materials secondary structures, which will raise or carried out by the method of heating of a mix of the

lower tribological properties, can be formed. corresponded powders in vacuum. It is experimentally

established, that for providing of full wetting of

dispersed particles with aluminium melt the covering

2. MATERIALS AND METHODS OF thickness not less than 1 microns is necessary.

RESEARCH. Forasmuch as molybdenum is an undesirable element

in aluminium alloys the thickness of covering was

Composite materials on the basis of aluminium minimal (1,0-1,5 microns). It is established, that

alloys with disperse particles of graphite are process of drawing of a covering is influenced with

representatives of nonequilibrium systems of whom the following factors: temperature, the content of

oxygen in metallizer, the ratio between particles and [2]. Metallized graphite was entered into standard

metallizer, height of a layer and intensity of mixing of aluminium alloy AL25 (table 1) in amount from 0,5

a reactionary mixture. Using these researches up to 3 % on weight.

technological parameters of metallization were chosen

Table 1 Chemical composition of tested alloys

Content of elements, %

Alloy

Mg Si Mn Cu Ni Ti Sn Al

AL25 1,21 12,12 0,53 2,73 0,98 0,17 0,004 rest

AMO 3-7 0,21 0,14 0,12 3,14 0,08 0,04 6,78 rest

3. EXPERIMENTAL RESULTS

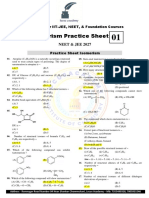

Tribotechnical properties were researched in two

stages. At the first stage investigation was carried out

at the constant speed of sliding equal 2 м/s and in

steps changeable pressure. At the following stage

specimens were tested at the fixed pressure (P = 0,6

MPа) and variable speed of sliding. Alloys AL25 and

АМО 3-7 were used as materials of comparison. Their

chemical compositions are given in table 1. Results of

tests are given on Figures 1-3.

Content of Graphite, %

Fig. 3. Dependence of wear-rate from graphite content

in friction pair of different materials with steel 45.

4. CONCLUSION

Analyzing the obtained results, it is possible to

make an unequivocal conclusion that introduction of

graphite to aluminium alloy renders beneficial effect

Pressure, MPа to its serviceability. There is decrease of friction

Fig. 1. Dependence of friction coefficient and increase of wear resistance in

comparison with an initial alloy in 3-5 times, and in

comparison with antifrictional alloy АМО 3-7 in 2-3

times. Moreover, work of an aluminium composition

with steel counter- specimen does not promote carry

of a basis of a material on its working surface. Test of

specimens at various speed of sliding has shown, that

under low speed (up to 4 м/s) introduction of graphite

reduces the friction coefficient. Presence of graphite

promotes formation of a dividing film which serves as

a solid greasing and reduces contact of metal surfaces,

as results in increase of a level of serviceability of

friction pair.

REFERENCES

1. Chernyshova T. A., Kobeleva L. I., Bolotova L. K., 2001,

Discretely reinforced composite materials with matrixes from

aluminium alloys and them tribotechnical properties. Metals. Vol. 6,

Sliding Speed, m/s pp. 85-98.

2. Shumikhin V.S., Shchertsky O. A., 1997, Obtaining of

Fig. 2. Dependence of wear-rate from sliding speed in composites on the basis of aluminium with disperse metallized

friction pair of different materials with steel 45: 1 – particles. Processes of Casting. Vol. 4, pp. 33-37.

AL25; 2 – AMO 3-7; 3 – AL25 + 1 % С; 4 – AL25 +

2 % С; 5 – AL25 + 3 % С; 6 – AL25 + 4 % С;

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Gelest Formulary: For Personal Care & Color CosmeticsDocumento28 pagineGelest Formulary: For Personal Care & Color Cosmeticszaryab khanNessuna valutazione finora

- Microwave-Assited Rapid and Simplified Hydrogenation of Organic MaterialsDocumento28 pagineMicrowave-Assited Rapid and Simplified Hydrogenation of Organic Materialsmax capetownNessuna valutazione finora

- Chemistry The Central Science 1Documento4 pagineChemistry The Central Science 1Ariane Caranto100% (2)

- Chem Principles 7e ISM Focus 05 Even FINALDocumento62 pagineChem Principles 7e ISM Focus 05 Even FINALSelma MeloNessuna valutazione finora

- Reading A Solubility CurveDocumento4 pagineReading A Solubility CurveMar GomezNessuna valutazione finora

- Specification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceDocumento6 pagineSpecification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceLuthfi ArdiansyahNessuna valutazione finora

- Activated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionDocumento8 pagineActivated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionS Bharadwaj Reddy100% (1)

- Basf Masterbrace p3500 TdsDocumento2 pagineBasf Masterbrace p3500 Tdswidayat81Nessuna valutazione finora

- Chem Class XI ch.01Documento7 pagineChem Class XI ch.01Navin KumarNessuna valutazione finora

- Electron Configuration Chart - NH's PageDocumento5 pagineElectron Configuration Chart - NH's PageMalik Hamza AslamNessuna valutazione finora

- IMDS Entry Manual enDocumento30 pagineIMDS Entry Manual enRanjeetNessuna valutazione finora

- Tests To Detect Adulteration in MilkDocumento5 pagineTests To Detect Adulteration in MilkezhilnarasuNessuna valutazione finora

- Mock 3 Unit 4 QP PDFDocumento30 pagineMock 3 Unit 4 QP PDFMohibur Rahman AbirNessuna valutazione finora

- Msds Cleaning SolventDocumento4 pagineMsds Cleaning SolventMoineeNessuna valutazione finora

- How Is Plastic Made A Simple Step-By-Step ExplanationDocumento12 pagineHow Is Plastic Made A Simple Step-By-Step Explanationsalemg82Nessuna valutazione finora

- Edexcel Biology IGCSE: 2.9: Food TestsDocumento38 pagineEdexcel Biology IGCSE: 2.9: Food TestsMinhajul Islam MahinNessuna valutazione finora

- Is 11255 2 1985Documento12 pagineIs 11255 2 1985VinodVaghaniNessuna valutazione finora

- Aspirin and SoapDocumento4 pagineAspirin and SoapyeeeyyyNessuna valutazione finora

- Think Fuels, Think AftonDocumento8 pagineThink Fuels, Think AftonSerge1976Nessuna valutazione finora

- Química OrgánicaDocumento3 pagineQuímica OrgánicaDaniel Alejandro Quispe CaballeroNessuna valutazione finora

- Manual IiDocumento80 pagineManual Iijast1111Nessuna valutazione finora

- Production of BioplasticDocumento7 pagineProduction of Bioplasticpritesh tamboliNessuna valutazione finora

- Crystal Field TheoryDocumento6 pagineCrystal Field TheoryMAGU_MWENYEWENessuna valutazione finora

- 18 Butterfly Valves A Disc BrayDocumento10 pagine18 Butterfly Valves A Disc BrayAli FananiNessuna valutazione finora

- Microsoft Word - Environmental Audit For A Chemical Industry in GeneralDocumento34 pagineMicrosoft Word - Environmental Audit For A Chemical Industry in GeneralbathalapalliNessuna valutazione finora

- Nickel Aluminum Bronze GuideDocumento9 pagineNickel Aluminum Bronze GuideAnoir AkkariNessuna valutazione finora

- Physical and Chemical Stability and Excipient CompatibilityDocumento12 paginePhysical and Chemical Stability and Excipient CompatibilityRebecca ChenNessuna valutazione finora

- Isomerism PracticeDocumento2 pagineIsomerism PracticeBarshan BanikNessuna valutazione finora

- AstmDocumento24 pagineAstmmanuel landinNessuna valutazione finora

- Struktur Kimia Dan Morfologi Polimer PDFDocumento51 pagineStruktur Kimia Dan Morfologi Polimer PDFpar yantiNessuna valutazione finora