Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CPF-JSA-010 Scaffolding Erection ZONE CLASS0

Caricato da

MajdiSahnoun0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

32 visualizzazioni5 pagineTitolo originale

CPF-JSA-010 Scaffolding erection ZONE CLASS0

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

32 visualizzazioni5 pagineCPF-JSA-010 Scaffolding Erection ZONE CLASS0

Caricato da

MajdiSahnounCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

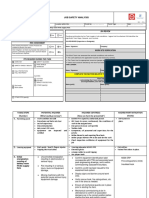

JOB SAFETY ANALYSIS

Réf: – JSA-…….

Facility / Site: Wellsite Location within Site: Permit No: Permit Type: COLD Date:

ZONE CLASS0

Task Description: Scaffolding Erection

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

Yes N/A

or Safe Work Practices been reviewed? Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the significant

Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be modified

Yes No Name / Signature: Nidhal NASRI Company:

to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario- Yes No

BasedRiskAssessmentrequired)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company:MSBI

FALL RESTRAINT COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

I acknowledge that I have reviewed the attached JSA, I understand my roles

LEATHER and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify):

TASK STEPS POTENTIAL HAZARDS CONTROLS HAZARD PORT MITIGATION

(Number) HAZARDS (How can harm be STATES

(What prevented?)

could go

wrong?)

1. Permitting work • Work condition not safe • HSE team to assess continuously the • PTW system

• Procedures and tasks not clear conditions of work in the assigned area • Tool Box Talk

• Lack of supervisory • One person to issue work permits • Certificates

• Miscommunication • Toolbox talks inspection

• Not correct PPE worn • Competency of personnel and supervisory

• Equipment not inspected and for the activity

certified • Define hierarchy and reporting flowcharts

• Define proper PPE to be used for the work

• Check inspection certificates of equipment

for the job

2. Working in Hazardous area Presence of toxic and gas in PTW and TBT before starting work. Emergency Response

the work area Refer to TPS ATEX Zoning Plan

Fire Use of gas detectors

Use non Sparking Tools Ambulance ready to

sparks arrestor for vehicles intervene in case of

emergency

Smoking is prohibited

Cell phone is prohibited Evacuation car on work site

covering POB working in

the area.

3. Manual handling Lifting heavy loads Employing trained and experienced MSBI Emergency response

Sharp edges persons Plan

Pinch point Proper manual handling techniques to be

Slips & trips applied.

Whipping action Presence of mind at all time

Weight & dust Avoid pinch and crush point

Maintain good house keeping

Use of proper PPE’s

Proper tools shall be provided.

Team work if it looks like two or even

three workers would do the job more

effectively and safer than one, then that is

probably true.

Use adequate body position while lifting

or carrying equipment

TBT in place

Insure the presence of mechanical lifting

tools and equipment to avoid manual

handling as much as you can

Body fitness and medical check before

starting the job

4. Using of Man lift Lack of knowledge Workers must undergo the working at MSBI

Untrained / unskilled operators heights Procedure and working at heights Emergency response Plan

Wrong operating practices training.

Over loading Only trained operator to operate the

Failure of equipment equipment

Uncompacted ground Only two personnel allowed on the man

Falling objects basket.

Fall Equipment must be inspected monthly

and colour coded

100% tie-off. Use of full body harness with

2 shock absorbing lanyards.

Tools and equipment to be secured

against falls i.e. tied down, used with

lanyards / string.

Follow the manufacturer’s safe operating

procedures & best practices.

Equipment must be 1 meter away from

the edge of excavation.

Equipment must be position in firm and

level ground before operating

Scheduled awareness / refresher trainings

for operators.

Periodic maintenance / servicing schedule

to be implemented.

Tool box talks to be carried out prior to

equipment operation.

Close supervision when use in critical

erection and lifting

Daily inspections of operators.

Barricade the working radius.

Verify / confirm stability of ground prior to

set up

5. Scaffolding erection Personal Injury/fatality due to hit by Workforce must undergo the Working at MSBI

pipe Height Procedure and Scaffolding Procedure Emergency response Plan

Fall from height Erection and dismantling must be carried •

Pinch and crush injury out by trained scaffolding personnel

Property damage Proper tagging or labelling of scaffolds at all

Falling objects time.

Pipes falling down from the Scaffold platforms must be inspected and

equipment due to lashing failure, etc. tagged by designated competent inspector.

Proper coordination of scaffolding group

during installation /dismantling to other

group.

Persons with vertigo are strictly prohibited

to work at heights.

Ladders must be inspected and colour

coded

100% tie-off. Use of full body harness with 2

shock absorbing lanyards.

Two planks to be used during initial erection

of every lift.

Use of proper PPE’s.

Tools and equipment to be secured against

falls i.e. tied down, used with lanyards /

string.

Throwing of tools and materials are strictly

prohibited, use rope and pulley to hoist up

and lowered materials during erection and

dismantling.

Provide warning signboards and barricade

the working area.

Follow approved design for special

scaffolds.

Scaffolds intended as working platform for

personnel must not carry extra weight other

than the workmen and minimal weight of

materials and tools.

No erection & dismantling work in harsh

weather (wind at 25 mph wind, sandstorm,

foggy, immediately after rainfall)

6. Housekeeping Slips trips fall Segregate the wastes as per the waste MSBI

Environmental impact management procedure Emergency response Plan

7. Working in hot weather Heat stress Provide sufficient amount of water MSBI Emergency

Dehydration Regular break Response Plan

Sunstroke Provide shadowed area

Avoid intense work between 12h &13h

8. Venomous threat Snake bits Extra precaution while performing MSBI Emergency

Scorpion stings activities Response Plan

Name Position Date Signed

Prepared By Farid ZRIDA HSSE site manager

Checked By Area HSSE Supervisor

Approved By

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- JSA-054 Crossing WorksDocumento6 pagineJSA-054 Crossing WorksMajdiSahnounNessuna valutazione finora

- Jsa-046 Highway Crossing and Steel CasingDocumento11 pagineJsa-046 Highway Crossing and Steel CasingMajdiSahnounNessuna valutazione finora

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocumento2 pagineJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- JSA-Use of Temporary Energization (Power Generator)Documento4 pagineJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocumento4 pagineJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Battery FillingDocumento3 pagineBattery FillingMajdiSahnounNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Job Safety Analysis: Required References Jsa ReviewDocumento3 pagineJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNessuna valutazione finora

- Al Asab Hse Presentation June-14Documento15 pagineAl Asab Hse Presentation June-14Sri DharanNessuna valutazione finora

- Harc OffshoreDocumento5 pagineHarc OffshoreMajdiSahnounNessuna valutazione finora

- Electrical Safety of Medical EquipmentDocumento31 pagineElectrical Safety of Medical EquipmentferbuifoNessuna valutazione finora

- DM Guidelines For Electrical Safety PDFDocumento4 pagineDM Guidelines For Electrical Safety PDFHaja FaizunnoorNessuna valutazione finora

- Personal Protective EquipmentDocumento28 paginePersonal Protective Equipmentawal7607100% (1)

- CSP ReferencesDocumento3 pagineCSP Referenceswaleedsalama1Nessuna valutazione finora

- Thrust Boring Procedure PDFDocumento23 pagineThrust Boring Procedure PDFtonful143100% (1)

- OSH QuestionsDocumento18 pagineOSH QuestionsakaiNessuna valutazione finora

- Respiratory Protection GuidelinesDocumento42 pagineRespiratory Protection Guidelineshitm357100% (1)

- Haze Poluttion Management in Malaysia: ForestDocumento4 pagineHaze Poluttion Management in Malaysia: Forestakunaruto92Nessuna valutazione finora

- Chapter 6 Safety and SecurityDocumento23 pagineChapter 6 Safety and SecuritymashurNessuna valutazione finora

- Safe Use of Oxy Acetylene-Code of PracticeDocumento46 pagineSafe Use of Oxy Acetylene-Code of Practicescott2355Nessuna valutazione finora

- PLAN - Health and Safety Plan - RV-MAN-0190 - 1 14-Feb-2012Documento50 paginePLAN - Health and Safety Plan - RV-MAN-0190 - 1 14-Feb-2012Mohammed AdilNessuna valutazione finora

- IGC1 Sample AnswersDocumento7 pagineIGC1 Sample Answerskukuji67% (3)

- Harc Snoop Test OperationDocumento7 pagineHarc Snoop Test OperationMajdiSahnounNessuna valutazione finora

- Cyclone Blockage ClearingDocumento19 pagineCyclone Blockage ClearingAnGahBasHa50% (2)

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Documento5 pagineCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNessuna valutazione finora

- Annex 17 - Induction Nawara ProjDocumento18 pagineAnnex 17 - Induction Nawara ProjMajdiSahnounNessuna valutazione finora

- JSA For Hydro Test Activites GenericDocumento4 pagineJSA For Hydro Test Activites GenericMajdiSahnounNessuna valutazione finora

- HVAC Fans Initial Energisation Battery RoomDocumento3 pagineHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Nawara Project - Introduction of Positive Pressure Hazards and ControlsDocumento1 paginaNawara Project - Introduction of Positive Pressure Hazards and ControlsMajdiSahnounNessuna valutazione finora

- HVAC Fans Initial Energisation Battery RoomDocumento3 pagineHVAC Fans Initial Energisation Battery RoomMajdiSahnounNessuna valutazione finora

- Curriculum For The Painting Industry: Health and Safety at WorkDocumento19 pagineCurriculum For The Painting Industry: Health and Safety at WorkWil Gabuay Jr.Nessuna valutazione finora

- Designing For Safety: A Team Sport: Key ContributorsDocumento33 pagineDesigning For Safety: A Team Sport: Key ContributorsVipin SomasekharanNessuna valutazione finora

- IPM Presentation 010312 FINALDocumento17 pagineIPM Presentation 010312 FINALTerri BimmNessuna valutazione finora

- FULL PRACTICAL 5 NadopodDocumento5 pagineFULL PRACTICAL 5 NadopodBatrisyia IlhamNessuna valutazione finora

- Pentachlorophenol (PCP) in Wood Treatment - Gavri - IuliaDocumento10 paginePentachlorophenol (PCP) in Wood Treatment - Gavri - IuliaIulia GavriNessuna valutazione finora

- Project: Jakarta MRT Project CP - 107 (ELEVATED AREA) DateDocumento27 pagineProject: Jakarta MRT Project CP - 107 (ELEVATED AREA) DateBayu Dwi Wahyu KusumaNessuna valutazione finora

- Halls Code of PracticeDocumento26 pagineHalls Code of PracticeFuzzy_Wood_PersonNessuna valutazione finora

- Miller Syncrowave 500Documento56 pagineMiller Syncrowave 500Manos Rougkalas100% (2)

- Bus Duct Installing HiraDocumento45 pagineBus Duct Installing HiraSufiyan KhedekarNessuna valutazione finora

- The Effectiveness of Hearing Protection Among Construction WorkersDocumento13 pagineThe Effectiveness of Hearing Protection Among Construction WorkerspaulNessuna valutazione finora

- Igc1 Sample QP 2019 v1Documento4 pagineIgc1 Sample QP 2019 v1khalid100% (1)

- HASAP Lima Husky Refinery 0908Documento11 pagineHASAP Lima Husky Refinery 0908Mohamed HadjkacemNessuna valutazione finora

- 6224 Ultra Green 57a (Usa)Documento8 pagine6224 Ultra Green 57a (Usa)German GomezNessuna valutazione finora

- Controlling Hazardous Fumes and Gases During WeldingDocumento2 pagineControlling Hazardous Fumes and Gases During WeldingMohd MustafhaNessuna valutazione finora

- Ihsec Nebosh Igc Flyer - GeneralDocumento4 pagineIhsec Nebosh Igc Flyer - GeneralJows Magtoto-DavidNessuna valutazione finora

- Utpras Rac Servicing NC II Dom. Rac Tesda-Sop-Tsdo-01-F02Documento2 pagineUtpras Rac Servicing NC II Dom. Rac Tesda-Sop-Tsdo-01-F02zonge cruzNessuna valutazione finora