Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gronostajski 1996

Caricato da

Santosh IngoleTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gronostajski 1996

Caricato da

Santosh IngoleCopyright:

Formati disponibili

Journal of

Materials

Processing

Technology

ELSEVIER Journal of Materials ProcessingTechnology60 (1996) 719-722

Production of composites on the base of AICu4 alloy chips

J.Z. Gronostajski, H. Marciniak, A. Matuszak

Institute of Mechanical Engineering and Automation, Technical University of Wroctaw, 50-371 Wroctaw, Lukasiewicza 3/5, Poland

Abstract

This paper describes the experience obtained with the chips of AI and its alloy with addition of small amount of tungsten powder

directly converted into the final product by hot extrusion process. The mechanical and physical properties of A1 and AICu4 based

composites are presented. The effect of tungsten contents and heat treatment on the properties is described. Direct conversion method do

not harmfully affect an environment and produced material can be used as a final product or can be further processed by another plastic

working methods like forging or rolling.

Keywords: chips, direct conversion, extrusion, composite, AI, AICu4

I. Introduction amount of tungsten powder. For comparison the composites of

aluminium with tungsten were also produced.

To avoid the troubles deriving from the conventional

recycling process an alternative processes were elaborated where

chips are cut or milled and by plastic working directly converted

into final products [ 1- 4]. The new processes consumes only 5%

of the energy needed for conventional process ofaluminium scrap 2. Materials and Processing

and does not harmfully affect the environment.

It has been stated that direct conversion of aluminium and its The composites were fabricated as strengthened particles

alloys chips results in good materials characterised by low from the granulated chips of AICu4 alloys or aluminium mixture

porosity, relative density exceeding 95%, high hardness and with tungsten powder of 80 mesh. Chemical composition of

good tensile properties, only slightly lower than those of extruded composites is given in Table 1. The granulation of chips

metallurgically produced materials. was performed by using cutting speed of 4.6 m/s [6]. Aluminium

The correct size and shape of the chips is essential for good chips were cut twice according to their high plasticity and chips

compaction during preliminary pressing operation and further of AICu4 alloy were cut once. Chips smaller than 4 mm were

extrusion. Because the chips, particularly those derived from the applied for further processing. Such prepared chips with different

machining operations, are usually characterised by irregular amount of tungsten powder were mechanically alloyed during 2

elongated and spiral shape, a first recycling operation is cutting of hours for aluminium and 3 hours for A1Cu4 alloy.

chips in milling process into small, regular shaped particles. It After mechanical alloying such prepared mixtures were

creates the possibilities not only to get high compaction but to preliminary pressed applying the pressure of 210 MPa and then

change the chemical composition of the mixture by an addition of hot extruded at 500°C with extrusion coefficient ~, = 4 (~,=ds/df)2

strengthening particles into aluminium or its alloys chips.

and extrusion rate of 10-z m/s. Such low extrusion rate makes

The process can be used for recycling of aluminium chips as possible formation of good diffusion bonds between chips and

well as for fabrication of composites with better properties than

tungsten powder and enables the plastic flow of matrix, materials

those of pure aluminium and its alloys. into pores and holes. After extrusion the following physical and

It has been found, that addition of tungsten powder into mechanical properties were studied: density, hardness (HB), yield

aluminium and AIMg2 alloy chips improves the mechanical and

and ultimate tensile strength, elongation reduction in area and

physical properties of the hot extruded materials like: yield stress,

ultimate tensile strength, hardness and density [5]. Because of too structure. The effect of ageing time at 170°C on the same

small amount of alloying elements, the above AIMg2 composites properties of AICu4 based composites after solution treatment at

cannot be strengthened by heat treatment. This is the reason why 510°C during 1 hour was studied. All the properties were

chips of AICu4 alloy were used for further investigations. They investigated at ambient temperature.

can be heat treated by precipitation ageing. The main aim of the Yield, ultimate tensile strength, elongation and reduction in

paper is to present the possibilities of fabrication of composites area were investigated using the round samples of 8 mm diameter

from AICu4 chips with addition of tungsten powder and to find and base length of 40 mm. The structures were studied by using

how their properties can be changed by heat treatment at different optical and scanning microscope.

0924-0136/96/$15.00 © 1996 Elsevier ScienceS.A. All rights reserved

PI10924-0136 (96) 02410-7

720 J.Z Gronostajski et al. / Journal of Materials Processing Technology 60 (1996) 719-722

Table 1.

Chemical composition of composites

Materials Chemical composition, %

Mn M~ Cu W

AIW0 0.00

A1W0.3 - - 0.30

AIW0.6 0.60

AlW0.75 - 0.75

AICu4W0 0.63 0.68 4.32 0.00

AICu4W0.6 0.58 0.74 4.09 0.62

AICu4W0.8 0.72 0.61 4.18 0.80

AICu4W1.6 0.69 0.64 4.27 1.60

3. Results and Discussion while the further increase of tungsten does not change the

hardness of AICu4 alloy.

After the mechanical alloying the mixtures showed low Brinell hardness of both kind of extruded composites is only

density of 1.1-1.5 g/cm3, and to make them more convenient for slightly higher than that of metallurgically produced materials.

hot extrusion preliminary pressing under 210 MPa was applied. Such small increase of hardness can be due to too small amount

of tungsten powder, heterogeneity of tungsten powder

The increase of density to about 2.2 g/cm 3 was obtained by that distribution, residual porosity of extruded composites and regions

operation. without diffusion bonds. Regions with residual porosity are rarely

Significant rearrangement of aluminium particles and visible after hot extrusion, so the changes of hardness is more

tungsten powder resulting in mechanical bonds between them affected by lack of diffusion bonds than by residual porosity.

were observed during pressing operation. Finally, hot extrusion

process resulted in densities exceeding 98% of theoretical density

of metallurgically produced aluminium and AICu4 alloy with

adequate addition of tungsten. 25 100

70 100

20 --'- 98

60 ~ -- ~ A 99 o~ -

50 98 15 ~ 96 ~

,5

O

40 [ 97 '~ 10 ~ : 94 ~,

30 -O- 96 --O-- Elongation

r

~D

'4 5 - ~Redue. area 92

20~ ~ 0 95 ---2k--Relat. density

m __~ ---O--Elong. ~ o 1 I I 90

l0 --"0--- Redue. Area 94

~ Relat. density 0 0.4 0.8 1.2 1.6

0 i 1 93

Content of tungsten W [%]

0 0.2 0.4 0.6 0.8

Content of tungsten [%] Fig. 2 Effect of tungsten contents on the relative density,

elongation and reduction in area of A1Cu4-based composites

Fig. 1 Effect of tungsten contents on the relative density,

elongation and reduction in area of AI-based composites

loo o 50

The effect of tungsten contents on the density of AI based

80 40

composites is shown in Fig. 1 and of AICu4 based composites in

Fig. 2. It can be seen from these figures, that relative density of

the extruded AICu4-based composites is slightly lower than the m - " ¢ __~ 30

relative density of Al-based composites, The density of both >" 40 20 ~

kinds of composites slightly decreases with an increase of

tungsten contents. Such a change of relative density is caused by

worse plastic flow properties of AICu4 alloy than of pure

t ,o

aluminium and by a restrain of plastic flow of matrix materials 0 [ 0

into pores and holes with increasing amount of tungsten particles. 0 0,2 0,4 0,6 0,8

The effect of tungsten contents on the Brinell hardness of Content of tungsten W [%]

both kinds of composites is shown in Figs. 3 and 4. It can be seen

Fig. 3 Effect of tungsten contents on the hardness (HB), yield

from the figures that addition of tungsten up to 0.6%W to pure

strength (YS) and ultimate tensile strength (ITTS) of Al-based

aluminium and A1Cu4 alloy causes small increase of hardness,

composites

J. Z Gronostajski et al. / Journal o f Materials Processing Technology 60 (1996) 719- 722 721

400 140 14

105 ~ ,-, 1 2 ~

300

~ 10

200 70 ~

100

0

--]

/

--o--YS

--~-HB

--t~--UTS

P

J

I I I o ~ 4

0 0,4 0 ,g 1,2 1,6 o

2 l- - g ~ E l o n g . ~Reduc. area

Content of tungsten W [%]

Fig. 4. Effect of tungsten contents on the hardness (HB), yield

I

0 3 6 9 12

strength (YS) and ultimate tensile strength (UTS) of AlCu4-based

composites Ageing time [h]

The effect of tungsten on the yield and ultimate tensile Fig. 6. Effect of ageing time on elongation and reduction in

strength of composites is shown in Figs 3 - 4. The yield and area of heat treated AICu4-based composites with contents 0.8%

ultimate tensile strength slightly increase with contents of

tungsten in both kinds of composites. The increase of tungsten

contents causes the decrease of elongation and reduction in area

of both kinds of composites, but the decrease is higher in A1Cu4 ,50 350

based composites than in Al-based composites (Figs. 1 -2). The

yield, ultimate tensile strength, elongation and reduction in area

of composite materials are not significantly different than those of 130 ~ l ~ 250 ~__~

metallurgically produced materials. On the one hand the tungsten

particles and aluminium oxides lead to an increase of the yield ~ 120 200

and tensile strength and to a decrease of the plastic properties of

composites by hardening effect. In the same time the tungsten 110 150

leads to a decrease of density by restriction of matrix flow into

pores and that way it has a contrary effect on the above 100 100

mentioned properties of both kinds of composites. 0 3 6 9 12

The effect of heat treatment on the changes of mechanical

properties of the A1Cu4-based composite with 0.8% W is shown Ageing time [hi

in Figs. 5 and 6. It can be seen, that with the from these figures

ageing time to about 8 hours there is a decrease of elongation and Fig. 7. Effect of ageing time on the mechanical properties of

reduction in area and an increase of yield stress, ultimate tensile AICu4 composite

strength and hardness. But the yield stress and ultimate tensile

strength reach their maximum values at slightly shorter time (6

hours). Comparing the effect of similar heat treatment of AICu4- 20 100

based composite without tungsten contents [7] (Fig. 7 - 8) with

the above described it can be stated, that the course of ageing

process in both materials is similar, but the values of yield stress,

ultimate tensile strength and hardness are higher in composite

then those in pure A1Cu4 alloy. The opposite tendency is 14 70

observed for the values of plastic properties of both kinds of

composites.

m 12--~--I:].--Elong. ~l-l~da~HB~ - 60

500 180

l0 ~ i i 50

150

~ 400

300

120

0 3

Ageing

6

time [h]

9 12

90 Fig. 8. Effect of ageing time on the elongation and hardness (HB)

200 of AICu4 alloy

60

;~ 100 ~[----O~YS ~ U T S ~HB[ 30

0 i I i 0 The surface of recycled extruded bars has relatively good

0 3 6 9 12 quality, what is of big importance for practical applications of

these materials.

Ageing time [h] Observation of structures (Fig. 9) and tensile fractures (Fig.

Fig. 5. Effect of ageing time on the mechanical properties of I 0) revealed relativity good strength of the diffusion bonds and

heat treated AICu4-based composites with contents 0.8% W typical features of plastic fractures.

722 J.Z Gronostajski et aL / dournal of Materials Processing Technology 60 (1996) 719-722

low porosity and relative density exceeding 98%. Good diffusion

bonds and very low porosity of extruded composites are due to:

- high extrusion temperature which enables the plastic flow of

an extremely plastic matrix into pores and voids,

- relatively low extrusion rates which extend the time of

plastic flow of the matrix material into pores and time of

diffusion transport as well.

Hardness and mechanical properties of A1 and AlCu4-based

composites with tungsten are not significantly different than those

of metallurgically produced materials, what is mainly due to the

opposite effect of addition of tungsten on the density and

hardening.

Heat treatment of A1 and AICu4-base composites with

tungsten causes the increase of the strength and decreases plastic

properties of composites.

Surfaces of recycled AI and AICu4-based composites with

tungsten are of good quality and pores are not visible with naked

Fig. 9. Distribution of tungsten particles and small pores in eye what is impoi'tant for practical applications. The elements

AICu4 matrix in composites containing 1.6 % W produced from metallurgical A1 and A1 alloys can be

manufactured from AI and AICu4-based composites produced by

direct conversion of chips.

Direct conversion method do not harmfully affects the

environment and produced material can be further processed by

another plastic working methods like forging or rolling.

References

[1] G. Lazzaro, C Atzori, Light Metals, 41 (1992) 1379.

[2] M. Stepien, W. Wlosinski, Przeg. Mechaniczny, 5-8 (1991)

33 (in Polish).

[3] C.S. Shrama, T. Nakagawa, Annals o f the CIRP, 25/1 (1977)

121

[4] J.Z. Gronostajski, J. Kaczmar, M. Marciniak and A.

Matuszak, Proc.2nd. Int. Conf The Recycling o f Metals,

Fig. 10. Fracture surface of AlCu4-base composite containing Amsterdam (1994) 287.

O.62 % W [5] J.Z. Gronostajski, J. Kaczmar, M. Marciniak and A.

Matuszak, Proc. Int. Conf Adv. Mat.&Proc. Techn.., M.S.J.

Hashmi (ed.), Dublin (1995) 63.

4. C o n c l u s i o n s [6] J.Z. Gronostajski, J. Kaczmar, M. Marciniak and A.

Matuszak, Mechanik, 8/9 (1994) 284 (in Polish)

Production of composites by direct conversion of A1 and [7] J.Z. Gronostajski, J. Kaczmar, M. Marciniak and A.

A1Cu4-alloy granulated chips with tungsten powder into final Matuszak, Proc. Int. Sci. Conf Adv. Mat. & Teehnol.,

products by hot extrusion results in materials characterised by Gliwice-Zakopane (1995) 133.

Potrebbero piacerti anche

- AIDEF Special Circular No 171 Dated 08-07-2020Documento6 pagineAIDEF Special Circular No 171 Dated 08-07-2020Santosh IngoleNessuna valutazione finora

- Irtirilc : StaldardDocumento14 pagineIrtirilc : StaldardSantosh IngoleNessuna valutazione finora

- Mil STD 3004 2Documento70 pagineMil STD 3004 2Santosh IngoleNessuna valutazione finora

- Mil DTL 382DDocumento8 pagineMil DTL 382DSantosh IngoleNessuna valutazione finora

- A R C H I V E S The Influence of The Cryogenic ProDocumento7 pagineA R C H I V E S The Influence of The Cryogenic ProSantosh IngoleNessuna valutazione finora

- Children EducationDocumento5 pagineChildren EducationSantosh IngoleNessuna valutazione finora

- Impact, Effct and Future of Individual As Well As Organisation Post Rtp3.0Documento12 pagineImpact, Effct and Future of Individual As Well As Organisation Post Rtp3.0Santosh IngoleNessuna valutazione finora

- Life Is PreciousDocumento1 paginaLife Is PreciousSantosh IngoleNessuna valutazione finora

- Assignment 3 Solutions PDFDocumento11 pagineAssignment 3 Solutions PDFSantosh IngoleNessuna valutazione finora

- Is 737 2008Documento18 pagineIs 737 2008Arjuna ReddyNessuna valutazione finora

- Charles MaderDocumento12 pagineCharles MaderSantosh IngoleNessuna valutazione finora

- Stec Pamphlet ListDocumento1 paginaStec Pamphlet ListSantosh Ingole75% (4)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Material Selection Consideration For ReactorsDocumento6 pagineMaterial Selection Consideration For ReactorsMiera Yushira YusoffNessuna valutazione finora

- Solvation, Association and DissociationDocumento14 pagineSolvation, Association and DissociationYuppie RajNessuna valutazione finora

- Nodia and Company: Gate Solved Paper Civil Engineering 2007Documento17 pagineNodia and Company: Gate Solved Paper Civil Engineering 2007Raj BakhtaniNessuna valutazione finora

- HMT Unit 2Documento22 pagineHMT Unit 2Muthuvel MNessuna valutazione finora

- Fluid AssignmentDocumento23 pagineFluid AssignmentYush KumarNessuna valutazione finora

- OTC-29534-MS Strain-Life Fatigue Analysis For HPHT Equipment: Theory To ValidationDocumento17 pagineOTC-29534-MS Strain-Life Fatigue Analysis For HPHT Equipment: Theory To Validationcamilo777Nessuna valutazione finora

- Properties of SemiconductorsDocumento34 pagineProperties of SemiconductorsMohammad Gulam AhamadNessuna valutazione finora

- Steel Design 1Documento26 pagineSteel Design 1Gracielle NebresNessuna valutazione finora

- Experimental Elasticity 2ed - SearleDocumento218 pagineExperimental Elasticity 2ed - Searlejrfisico2011Nessuna valutazione finora

- Molecular StructureDocumento33 pagineMolecular Structurefitria faizNessuna valutazione finora

- Olaf Zöllner - ChupagemDocumento41 pagineOlaf Zöllner - Chupagemkishxcx100% (1)

- Solidification and Liquation CrackingDocumento6 pagineSolidification and Liquation CrackingNnamdi Celestine Nnamdi100% (2)

- Cns2456 2 Polyethylene (PE) Pipes and Fittings - Part 2: PipesDocumento17 pagineCns2456 2 Polyethylene (PE) Pipes and Fittings - Part 2: PipesJulianNessuna valutazione finora

- 02 SAMSS 011 FlangesDocumento30 pagine02 SAMSS 011 FlangesALI100% (2)

- Pipe Stress Analysis Using Ansys APDLDocumento21 paginePipe Stress Analysis Using Ansys APDLjsmnjasminesNessuna valutazione finora

- 2001 - Creep Crack Growth in A SGF RF PP CompositeDocumento5 pagine2001 - Creep Crack Growth in A SGF RF PP CompositeSubramani PichandiNessuna valutazione finora

- Introduction To Materials Science and EngineeringDocumento14 pagineIntroduction To Materials Science and EngineeringFNessuna valutazione finora

- Material Selection Process For Gas Turbine Blade, Disk and Shaft With EquationsDocumento25 pagineMaterial Selection Process For Gas Turbine Blade, Disk and Shaft With EquationsMuhammad Hammad Zahid75% (4)

- Is 1734 1-20 1983 PDFDocumento78 pagineIs 1734 1-20 1983 PDFison0% (1)

- MT Syllabus-Micro FabDocumento2 pagineMT Syllabus-Micro FabAnonymous dL8dsCncNessuna valutazione finora

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocumento5 pagineEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNessuna valutazione finora

- PhysicsDocumento12 paginePhysicsAwez FahadNessuna valutazione finora

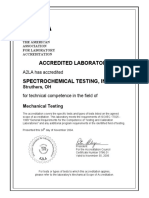

- Accredited Laboratory: A2LA Has AccreditedDocumento2 pagineAccredited Laboratory: A2LA Has AccreditedRene Alfonso BeltranNessuna valutazione finora

- M924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocumento1 paginaM924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNessuna valutazione finora

- Chapter 13Documento67 pagineChapter 13sanrorobbyNessuna valutazione finora

- Chemistry of Newer MaterialsDocumento30 pagineChemistry of Newer MaterialsDr. Dhondiba Vishwanath100% (1)

- DSM-0310.0 WC10Co4Cr SintCrushDocumento3 pagineDSM-0310.0 WC10Co4Cr SintCrushNabil SalimNessuna valutazione finora

- A Review of Graphene-Based Electrochemical MicrosupercapacitorsDocumento22 pagineA Review of Graphene-Based Electrochemical MicrosupercapacitorsPratik SarkarNessuna valutazione finora

- Annex 3.D Strength Parameters PDFDocumento9 pagineAnnex 3.D Strength Parameters PDFicemage1991Nessuna valutazione finora