Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wevj 04 00049

Caricato da

k.saikumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wevj 04 00049

Caricato da

k.saikumarCopyright:

Formati disponibili

World Electric Vehicle Journal Vol.

4 - ISSN 2032-6653 - © 2010 WEVA Page000049

EVS-25

Shenzhen, China, Nov 5-9, 2010

Design of Power System Control in Hybrid Electric

Vehicle

Van Tsai Liu

Department of Electrical Engineering, National Formosa University, Huwei 632, Taiwan

E-mail: vtliu@nfu.edu.tw

Abstract

This paper proposes a design of power system control in the hybrid electric vehicle. It

adopts the isolated DC/DC power converter as the front-end fuel cell and Lithium-ion

battery to supply constant voltage. By micro-controller to detect the hybrid power output,

and the low-pressure hydrogen storage temperature, and the adjustment of the power output

ratio to provide the energy for loading balance. The results can obtain the overall

performance of electric vehicle. It is important to avoid the excessive usage of hydrogen

fuel which causes the phenomenon of storage tank freezing and fuel cell or Lithium-ion

batteries abnormal situation. Display the working data of hybrid power system can achieve

the capability of instant surveillance. For the loading under consideration, the fuel cell and

Lithium-ion battery can supply stable voltage output. Copyright Form of EVS25.

Keywords: hybrid electric vehicle, fuel cell, push-pull converter, Lithium-ion battery

1 Introduction pollution, and can resolve the problem of

depletion for oil stocks[3]. This structure of

Vehicles technology brings convenience in electric vehicle system is based on fuel cells

traffic for humans, but cause serious global for energy supply sources, but was limited

warming, air pollution, depletion of oil by the fuel cell electrochemical reaction rate.

resources and other issues. Therefore, the Therefore, vehicles can not provide an

hybrid and pure electric vehicles is the most instant start and climbing required output

effective way to reduce emissions of carbon power, and the batteries or super capacitors

dioxide, which is about 45% of internal as auxiliary power supply is used to provide

combustion engine vehicle emissions, or a steady output for the load [4].

even non-exhaust emissions [1]. Electric

vehicles system becomes effective solution

to reduce air pollution and fossil fuel [2]. 2 System structure

In recent years, power conversion system of

Based on hybrid power system and energy

fuel cell has been proposed. The fuel cell is

distribution is proposed hybrid electric

used in electric vehicles, the most

vehicle system structure shown in figure 1

compelling reason is that fuel-cell electric

[5-9]. This article uses the fuel cell and

vehicles are electric-drive vehicles as a

lithium-ion battery as power sources, and

source, not only will have no exhaust

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 1

World Electric Vehicle Journal Vol. 4 - ISSN 2032-6653 - © 2010 WEVA Page000050

fuel cell power generation process as : The overload. The circuit design is tally with

low-pressure hydrogen storage bottles specifications, such as Table 1.

provides hydrogen, and through the

appropriate hydrogen pressure regulating

valve to adjust the pressure switch by the

hydrogen fuel cell modules into the house

with the oxygen is electrochemically

converted. Fuel cells and lithium-ion

batteries can not smooth voltage output in

the load change, so must uses the power

converter to output stable voltage for the

motor-driven DC-wheel drive motor. About

power distribution of control design for the

output state that uses the A/D feedback

circuits and pressure sensors to detect the

fuel cell, Lithium-ion battery voltage and

the hydrogen storage bottle pressure. After

the micro-controller via judge that sends

PWM signals to the power distribution Figure 2: The circuit of push-pull converter

circuit. The power converter controls the

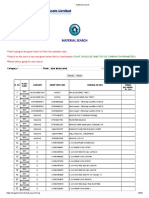

output load ratio of the energy, and Table 1: Push-pull converter specification

completes the complex the overall design of

power electric vehicles. Input voltage DC 26V-40V

Switch frequency 50 kHz

Output voltage DC 50V

Output current 12A

4 Design of complex power

systems control

The hybrid electric vehicles will be

considered for safe driving that depends on

the electric power distribution systems.

About hybrid power and stability control is

Figure 1: Block diagram of hybrid electric proposed a power distribution system

vehicle control structure shown in figure 3.This

structure consists of two parts:

3 Design of power converter

Figure 2 demonstrates the power converter

is used for the full-bridge rectifier push-pull

converter. The article uses KA3525 as a

drive control IC to control the power

switches (S1,S2) of the conduction and

cut-off time respectively with two PWM

output circuit. Dead time and frequency of

the speed is series-parallel resistor and

capacitor to control. The secondary side of

isolated power conversion is used

optocoupler feedback circuit. Ratio

converter (CT) is used to detect currents

flowing through the power switch, besides,

protect the switch and prevent circuit Figure 3: The structure of power distribution

system

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 2

World Electric Vehicle Journal Vol. 4 - ISSN 2032-6653 - © 2010 WEVA Page000051

1. A/D detection circuit: Based on the 1. If the fuel cell voltage is greater than 26V,

protection of micro-controllers and A/D the Lithium-ion battery voltage is greater

conversion values, which is used the than 32V, and the pressure sensor

optocoupler isolated as a complex feedback voltage is greater than 36V: The

dynamic system feedback. The main fuel cell is controlled at 80% to output,

pressure sensor to detect the pressure of and the Lithium-ion battery is at 20%.

conversion values, moreover, the 2. If the fuel cell voltage is greater than 26V,

lithium-ion battery voltage and fuel-cell the Lithium-ion battery voltage is greater

voltage is obtained to determine than 32V, and the pressure sensor

treatment by the micro-controller for the feedback voltage is less than or equal to

output energy distribution of control 36V: The fuel cell is controlled at 20%

signals. to output, and the Lithium-ion battery is

2. PWM driver circuit: The output control at 80%.

signals are not sufficient to drive power 3. If the fuel cell voltage is less than or

switches for the micro-controller. High equal to 26V, and the Lithium-ion battery

current through circuits to reflux voltage is greater than 32V: The fuel cell

prevention of abnormal result, which is stopped to output, and the

give rise to burn for micro-controller. Lithium-ion battery is controlled to

Therefore, the optically coupled driver output at 100%.

circuit is used to reach power switch 4. If the fuel cell voltage is greater than 26V,

isolation amplified in this article. and the Lithium-ion battery voltage is

This design of approach using the Microchip’s less than or equal to 32V: The fuel cell is

dsPIC30F4011 in A/D, PWM and LCD display controlled to output at 100%, and the

[10]. The main uses AD-based, and samples the Lithium-ion battery is stopped to output.

output voltage in the fuel cell. Lithium-ion 5. If the fuel cell voltage is less than or

battery output voltage and pressure sensors equal to 26V and the Lithium-ion battery

convert voltage signals is as a control power voltage is less than or equal to 32V: The

distribution circuit of the PWM signal output. fuel cell and the Lithium-ion battery is

The signal determines the priority shown in stopped to output.

figure 4. First the fuel cell is No.1 priority, the

next is Lithium-ion batteries, and the last is the Table 2: The state of energy distribution

pressure sensor signal. Table 2 is based on the

sampling that designed states of signal control

that has the following five kinds of:

5 Experiment Results

The input voltage and the output voltage

waveform of the converter are shown in

Figure 4: Block diagram of the energy control

figure 5. This figure shows the non-pumping

strategy for hybrid electric vehicle

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 3

World Electric Vehicle Journal Vol. 4 - ISSN 2032-6653 - © 2010 WEVA Page000052

load conditions of fuel cells and lithium

batteries, because the load current affects

the output voltage level. Therefore, the

power converter needs a stable output

voltage for the load.

This article uses micro-controller to detect

the fuel cell voltage. The Lithium-ion

battery voltage and output pressure

hydrogen storage bottle of hydrogen

through the A/D feedback circuit to judge

hybrid voltage output. Control signals

decided the distribution of electrical energy

in the system, and display distribution

system state of the current power at work, as

shown in figure 6-9. (b)

Figure 6: At normal state, (a) Power control

signal (b) Status of display

(a)

Figure 5: Input voltage, output voltage, and

output inductor current waveforms. (Step

change from 0 to 600W)

(b)

Figure 7: At hydrogen lack state, (a) Power

control signal (b) Status of display

(a)

(a)

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 4

World Electric Vehicle Journal Vol. 4 - ISSN 2032-6653 - © 2010 WEVA Page000053

(b) Figure 10: Complete diagram of hybrid electric

vehicle

Figure 8: At fuel cell abnormality, (a) Power

control signal (b) Status of display

(a) Figure 11: Fuel cell and Lithium-ion battery

power output curve at normal state

(b)

Figure 9: At Lithium-ion battery abnormality, (a)

Power control signal (b) Status of display Figure 12: Fuel cell and Lithium-ion battery

power output curve at hydrogen lack state

Figure 10 is the complete with the hybrid

electric vehicle. At various loads and power

status measure the fuel cell and the

lithium-ion battery output power, as shown

in figure 11-14. From the figure could

discover that the fuel cell and lithium-ion

battery power distribution status and the

whole hybrid system are feasible.

Figure 13: Fuel cell and Lithium-ion battery

power output curve at fuel cell abnormality

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 5

World Electric Vehicle Journal Vol. 4 - ISSN 2032-6653 - © 2010 WEVA Page000054

[4] K. Rajashekara, “Propulsion system

strategies for fuel cell vehicle”, Fuel Cell

technology for Vehicles, PT-84, pp. 179-187,

SAE publication, Warren dale, PA, 2001.

[5] P. Rodatz, G. Paganelli, A. Sciarretta and L.

Guzzella, “Optimal power management of an

experimental fuel cell/super capacitor-

powered hybrid vehicle,” Control Engineering

Practice Vol. 13, Jan, 2005, pp 41-53.

[6] Ke Jin, Xinbo Ruan, Mengxiong Yang and

Min Xu,“A Hybrid Fuel Cell Power System,”

Figure 14: Fuel cell and Lithium-ion battery

IEEE of Industrial Electronics, April 2009.

power output curve at Lithium-ion battery

abnormality [7] J. Bauman and M. Kazerani ,“A Comparative

Study of Fuel-Cell–Battery,

Fuel-Cell–Ultracapacitor, and Fuel-Cell–

6 Conclusion Battery–Ultracapacitor Vehicles,” IEEE

TRANS. ON VEHICULAR TECHNOLOGY,

Renewable energy is the new trend of the

vol. 57, NO. 2, MARCH 2008.

times. The green energy vehicles is used by

the national attention in the environmental [8] P. Thounthong, S. Rael, B. Davat and I.

awareness and oil rising, which put forward Sadli,“A Control Strategy of Fuel

a number of different electric vehicle Cell/Battery Hybrid Power Source for

architecture. The power converter is used to Electric Vehicle Applications,” 37th IEEE of

regulation devices for the fuel cell and Power Electronics Specialists Conference,

lithium-ion battery output voltage in this June 2006, pp. 1 – 7.

article, and completing design of the power

distribution control for hybrid power system [9] B.Fuchs, Lafond, O. Rondineau, S. and

load energy. The hydrogen storage bottle Himdi, M., “An Analytical Optimization

prevented freeze and increased travel Method for Improved Fuel Cell-Battery-Ultra

mileage and safety for this hybrid electric capacitor Power train,”Microwave Theory and

vehicle architecture. Final, the Techniques, IEEE Transactions on, vol. 54, June

micro-controller is used to read the fuel cell 2006, pp. 2292 – 2300.

modules, the hybrid power distribution

system and the working conditions [10] Ba-You Zen,"dsPIC digital signal

displayed to show in LCD, which controllers Principles and Applications-

immediately can combine to use of state MPLAB C30 Development Practice", macro

power. Friends of the Library Development Co., Ltd.,

in October 2006.

References

Author

[1] Sin-Wang Ye, Wen-Jin Li, "electric vehicles

zinc - zinc-air battery anode recovery Associate Professor: Van

technology with the introduction", Industrial Tsai Liu

Materials 146, February 1999. Department of Electrical

Engineering, National

[2] C. C. Chan, “The past, present and future of Formosa University

electric vehicle development”, in Proc. IEEE Tel: +886-56315607

Int. Conf. Power Electronics and Drive Fax: +886-56315609

Systems, 1999, vol. 1, pp. 11-13. He is currently an

associate professor in the

[3] W. Turner, M. Patten, D. Vines, J. Jones, and department of electrical engineering,

T. Maxwell, “Modeling a PEM fuel cell for National Formosa University, Yunlin,

use in a hybrid electric vehicle”, 49th IEEE Taiwan. His research interests include

Vehicular Technology Conference, Vol. 2, intelligent control, high voltage gain

16-20 May, 1999, pp.1385 – 1388. converter, battery management system.

EVS25 World Battery,Hybrid and Fuel Cell ElectricVehicle Symposium 6

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 160425122829Documento49 pagine160425122829k.saikumarNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Digital Marketing Specialization - Capstone Project: Prepared By: Praveen SinhaDocumento36 pagineDigital Marketing Specialization - Capstone Project: Prepared By: Praveen Sinhak.saikumarNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Digital Marketing Plan: Increasing Bosch Power Tools Sales OnDocumento23 pagineDigital Marketing Plan: Increasing Bosch Power Tools Sales Onk.saikumarNessuna valutazione finora

- Digital Marketing Client & Brand Analysis - G&B: Strategy Driving Your Customers To Shop A Competitor? September 2015Documento21 pagineDigital Marketing Client & Brand Analysis - G&B: Strategy Driving Your Customers To Shop A Competitor? September 2015k.saikumarNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Industrial Goods and Services, Construction and Maintenance, and Home Improvement CustomerDocumento4 pagineIndustrial Goods and Services, Construction and Maintenance, and Home Improvement Customerk.saikumarNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Capstone Project-Grainger and Bosch: Digital Marketing CampaignDocumento25 pagineCapstone Project-Grainger and Bosch: Digital Marketing Campaignk.saikumar100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- WWW - Tme.eu: Transfer Multisort ElektronikDocumento3 pagineWWW - Tme.eu: Transfer Multisort Elektronikk.saikumarNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- GMAT Geometry Worksheet - 2D, 3D and Coordinate GeometryDocumento13 pagineGMAT Geometry Worksheet - 2D, 3D and Coordinate Geometryk.saikumarNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 100+ Free SEO Tools & ResourcesDocumento5 pagine100+ Free SEO Tools & Resourcesk.saikumarNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- DataminerDocumento8 pagineDataminerk.saikumarNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- JBJBDocumento116 pagineJBJBk.saikumarNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Linecard 2018 EnglDocumento32 pagineLinecard 2018 Englk.saikumarNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Bangloren ISG PDFDocumento303 pagineBangloren ISG PDFk.saikumarNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- CVCVDocumento42 pagineCVCVk.saikumarNessuna valutazione finora

- Power Supplies: (HQ) #937, SN Arcade, 21st Main Road, 9TH Cross, JP Nagar 2nd Phase Bangalore - 560078 INDIADocumento10 paginePower Supplies: (HQ) #937, SN Arcade, 21st Main Road, 9TH Cross, JP Nagar 2nd Phase Bangalore - 560078 INDIAk.saikumarNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Study of Power System Security in Indian Utility 62 Bus SystemDocumento10 pagineStudy of Power System Security in Indian Utility 62 Bus SystempjNessuna valutazione finora

- University of Cambridge International Examinations Cambridge International Level 3 Pre-U Certificate Principal SubjectDocumento40 pagineUniversity of Cambridge International Examinations Cambridge International Level 3 Pre-U Certificate Principal SubjectbobNessuna valutazione finora

- Continuously Variable Transmission - CVTDocumento18 pagineContinuously Variable Transmission - CVTPratheep Srinivas100% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Dmart Supply Chain Management 0 Inventory Management ModuleDocumento13 pagineDmart Supply Chain Management 0 Inventory Management Moduleaarushisoral1Nessuna valutazione finora

- Lyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicDocumento42 pagineLyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicCj Lucero50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- ISO-50001-JK-WhiteDocumento24 pagineISO-50001-JK-WhiteAgustinusDwiSusantoNessuna valutazione finora

- QP GuidlineDocumento282 pagineQP GuidlinerupeshNessuna valutazione finora

- Capital Markets ProjectDocumento54 pagineCapital Markets Projectjaggis1313100% (4)

- Waste Minimization Practices in The Petroleum Refining IndustryDocumento9 pagineWaste Minimization Practices in The Petroleum Refining IndustryTaha Lemdjed BelahçeneNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Instruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDDocumento438 pagineInstruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDEpsp MedNessuna valutazione finora

- LUMS Daily Student The H' WordDocumento16 pagineLUMS Daily Student The H' WordKhawaja DaudNessuna valutazione finora

- PORAM Standard SpecificationDocumento3 paginePORAM Standard SpecificationAristonNessuna valutazione finora

- Varianta Test Competenta Mai 2009Documento5 pagineVarianta Test Competenta Mai 2009Florina LepadatuNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Leroy Somer D510C AVRDocumento54 pagineLeroy Somer D510C AVRabuzer1981Nessuna valutazione finora

- Emergency Alternative Mode of Oxygen Generation: Confidential 1Documento30 pagineEmergency Alternative Mode of Oxygen Generation: Confidential 1Mendoud SofianeNessuna valutazione finora

- Egev ProhsDocumento2 pagineEgev ProhsOscar Campos TarazonaNessuna valutazione finora

- Atoms and Elements, Compounds and Mixtures - ExercisesDocumento8 pagineAtoms and Elements, Compounds and Mixtures - ExercisesLim Kok PingNessuna valutazione finora

- As 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElDocumento7 pagineAs 1038.14.2-2003 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Major and Minor ElSAI Global - APAC100% (1)

- Simbologia PDFDocumento1 paginaSimbologia PDFMartin Abraham Perez UriasNessuna valutazione finora

- Engine Variable On Flame PropagationDocumento10 pagineEngine Variable On Flame PropagationDebarpan SahaNessuna valutazione finora

- VW Diesel GateDocumento10 pagineVW Diesel GateMarius AndrieșNessuna valutazione finora

- FMC-FCC Single-Layer Roller Kilns FMC-FCCDocumento12 pagineFMC-FCC Single-Layer Roller Kilns FMC-FCCCeramic TilesNessuna valutazione finora

- 1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineDocumento1 pagina1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineFuad AnwarNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- In and Ex System DescDocumento5 pagineIn and Ex System DescAli KuncoroNessuna valutazione finora

- Attenuation ProjectDocumento12 pagineAttenuation Projectapi-352698073Nessuna valutazione finora

- Rail Overview Brochure CumminsDocumento16 pagineRail Overview Brochure CumminsYuraNessuna valutazione finora

- Flexible Displays Using TFT'SDocumento16 pagineFlexible Displays Using TFT'SRaghavendra RaghavNessuna valutazione finora

- Online - Chapter 2Documento10 pagineOnline - Chapter 2Gladys CanterosNessuna valutazione finora

- Ship Shaft EarthingDocumento12 pagineShip Shaft EarthingEdi LeeNessuna valutazione finora

- Heavy Equipment Tooling, Test & MeasurementDocumento26 pagineHeavy Equipment Tooling, Test & MeasurementA A Napis TeaNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)