Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fire Hydrant System Design Installation Commisioning and Testing

Caricato da

jaianit89Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fire Hydrant System Design Installation Commisioning and Testing

Caricato da

jaianit89Copyright:

Formati disponibili

Fire hydrant and System Design,

Installation, Commissioning and Testing

PRACTICE NOTE 38-2018

This updates the previous Practice Note-

2014-38 issued June 2014.

Reference to the Building Code of Australia

(BCA) in this Practice Note means Volumes

Pressure at operating hydrants

One and Two of the National Construction The minimum residual pressure required at a

Code Series. hydrant outlet when flowing at a rate of

10L/s, measured at operating hydrants, while

Purpose the required number of hydrants are

operating (refer to Clause 2.3 of AS 2419), is

The purpose of system design, installation

set out in Table 2.2 of the Standard. This

and testing of fire hydrants is to produce a

system that is fully functional in any fire residual pressure is required to overcome

the pressure losses due to the equipment

situation. Designers, installers, testers and

likely to be connected by the local fire

relevant building surveyors (RBS) all play a

authority. exerted

part in ensuring system performance meets

AS 2419.1. The large number of test failures,

system faults and interpretation

Working pressure

inconsistencies indicate a need for a better Working pressure is the maximum pressure

understanding of system design, installation achieved within the system by the fire

and maintenance requirements. authority, the system pumping equipment,

or both, when the most hydraulically

New installations and alterations to existing

disadvantaged hydrant or hydrants are

systems must conform to the Standard and

operated at the design flow. Refer to Clause

the Building Regulations 2018.

7.1 of the Standard when there is a booster

This Practice Note provides further guidance connection installed.

on the design, installation, commissioning

The working pressure of a fire hydrant

and maintenance of fire hydrant

system should be determined by the system

installations.

designer, and clearly indicated at the booster

Design and Installation connection. The Standards Australia

Handbook, SA HB 93, Commissioning of Fire

Fire hydrant systems are required to be Hydrant Systems, sets out a method of

installed in accordance with AS 2419.1 by recording design, installation and operating

Clause E1.3 of the Building Code of Australia capability information relating to a fire

which satisfies Performance Requirement hydrant system.

EP1.3.

Pressure at operating hydrants and working

pressure are two aspects of AS 2419.1 that

require more attention and understanding

when hydrant systems are designed.

Issued June 2018 Page 1 of 5

PN 38 -2018 Fire Hydrant System Design, Installation, Commissioning and Testing

Commissioning and Testing – New Commissioning (flow) test

Installations This test requires simultaneous discharge of

Section 10 of the Standard sets out the the required number of the most

required testing procedures for hydrant hydraulically disadvantaged hydrants, each

systems. The large number of failures that at not less than the required outlet pressure

occur when these tests are conducted and flow, to confirm that the required

indicate a need for a better understanding of minimum total flow rate can be achieved.

system design, installation and maintenance The test results must be adjusted to design

requirements. pressure conditions in order to check

compliance (refer to AS2419.1 Appendix F).

To achieve compliance with AS 2419.1, all

tests as nominated in Section 10 must be Clause 8.5.10 (Test Facility) requires

satisfactorily carried out. The RBS should provision for disposing of test water to a

ensure that independent testing has been suitable drain. This is important when the

carried out and that compliance with the system is subjected to full flow testing,

testing requirements of the Standard is nominally every 3 years. Clause 10.3

demonstrated, or that the Chief Officer emphasises the need to dispose of water

(relevant fire authority) has granted consent without damaging private or public property-

under regulation 129 to non-compliance with hydrants installed in buildings or on roofs are

some or all of the required testing. This must often difficult to test without discharging

occur before issuing an occupancy permit or water onto adjacent properties. Fixed

certificate of final inspection. drainage systems will reduce the possibility

of flood damage.

Apart from visual inspection of the

installation (hydrant and hose reel location, Booster connection and pump tests

type and method of installation of pipework

and installation adequacy), the following Where a system incorporates a booster or a

tests are required to confirm system integrity suction point from static storage, verification

and hydraulic adequacy. of performance is required. Pump pressure

and flow tests must be conducted wherever

Hydrostatic test pumps are installed.

Pipework is required to be hydrostatically Where boosters are connected in series with

tested to the greater of 1700 kPa or 1.5 building pumps which allows for the

times the highest working pressure to which connection of a fire brigade appliance in

the system will be subjected, for a period of series with the inlet connection an additional

at least 2 hours. A number of installations test is to be undertaken. The most

have failed this test, due mainly to hydraulically disadvantage hydrant shall

inadequate or undersized flanges and thrust discharge water at the required. While

blocks, or poor workmanship. maintaining the recorded flow rate the

system shall be boosted to achieve an

additional 300kPa at the hydrant outlet. The

pressure on the building pump discharge

pressure gauge at this condition shall not

exceed the system design operating pressure

as displayed at the booster.

Issued June 2018 vba.vic.gov.au Page 2 of 5

PN 38 -2018 Fire Hydrant System Design, Installation, Commissioning and Testing

The tests are carried out by independent Fabricated junctions occur in both copper

testers, using pumps that adequately and steel pipe systems. Early copper pipe

simulate the performance of a fire authority systems used prefabricated joints and later

pump. Verification that reasonable vehicle systems were fabricated on-site. Fabricated

access is available will also be required. steel pipe systems were typically above-

ground systems and used square elbows.

These tests also enable confirmation that the

maximum friction loss of 150 kPa in the Where no test duration is specified in the

pipework between the booster connection Table above, the time should be sufficient to

and the most hydraulically disadvantaged allow all joints in the system to be inspected

hydrant is not exceeded. and should not be less than 2 hours.

Some sources in the table above use terms

Commissioning and testing – such as 'no significant leakage' or 'no

Alterations to existing installation leakage'. In practice, it is very difficult to

Test criteria for new installations may not be achieve complete water tightness.

appropriate for an existing installation. However, leaks should be monitored, as they

Where alterations to an existing installation have the potential to affect the maintenance

are carried out, the RBS should ensure that and reliability of the system. Minor leakage

independent testing has been carried out that does not affect the performance of the

and that it demonstrates compliance with system during a flow test will not impact on

appropriate test criteria, or that the Chief operational firefighting. If the rate of leakage

Officer has granted consent under regulation increases with time, the source of the leak

129 to non-compliance with some or all of should be located and repair work carried

the required testing. out before system failure occurs.

This process must be completed before If the leakage rate is constant and reduces

issuing an occupancy permit or certificate of with a reduction in pressure, the leak is likely

final inspection. to be through a valve bonnet, or similar. In

Where a new booster connection is installed, this case, 'topping up' during a test to

the test criteria applicable to a new system maintain the pressure is acceptable,

must be applied to the whole system served provided that the leakage rate is less than 15

by the booster connection. L/minute.

Where an existing booster connection serves If the hydrostatic test criteria applicable at

new pipework extended from existing the time of installation cannot be

pipework, only the new pipework must meet established, an alternative is to determine

the test criteria applicable to a new system. the working pressure by testing.

However, in order to apply these test criteria Multiply the result by a factor of 1.5 to give a

to the new pipework, some existing hydrostatic test pressure which provides a 50

pipework may need to be upgraded. Refer to per cent safety margin, including an

Appendix 1 -Hydrostatic test allowance for water hammer.

Notes: Where operation dates of legislation

overlap, the highest requirements should be

applied.

Issued June 2018 vba.vic.gov.au Page 3 of 5

PN 38 -2018 Fire Hydrant System Design, Installation, Commissioning and Testing

Maintenance Further information

Fire hydrant systems form part of a building's

essential safety measures. They are required Want to know more?

to be maintained in accordance with Part 15 If you have a technical enquiry, please email

of the Building Regulations 2018. Adequate technicalenquiry@vba.vic.gov.au or

testing and maintenance can highlight design call 1300 815 127.

and installation faults, leading to their

Victorian Building Authority

correction and ensuring that the system is

733 Bourke Street Docklands VIC 3008

functional and reliable.

www.vba.vic.gov.au

Clause 10 of AS 2419.1-2005 sets out details

of the flow rate tests to be recorded. The

RBS should require systems installed in

accordance with this Standard to be

maintained in accordance with AS 1851 as

applicable at time of installation. All flow and

hydrostatic tests should be undertaken in

accordance with AS 2419.1 Section 10 (or the

equivalent criteria applicable at the time the

system was installed), at the recommended

intervals.

Although clause 4.2 of AS 2419 requires the

source of water supply for fire hydrants to be

not less than that necessary to maintain

minimum specified flow rates for a duration

of not less than 4 hours, it is not uncommon

for hydrant systems to be used for a much

longer duration. A major fire could result in

the hydrant system being in continuous use

for a number of days before the fire is

brought under control.

The purpose of system design, installation

and testing is to produce a system that is

fully functional in any fire situation

Issued June 2018 vba.vic.gov.au Page 4 of 5

PN 38 -2018 Fire Hydrant System Design, Installation, Commissioning and Testing

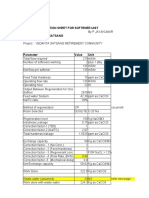

Appendix One –

Hydrostatic test

Operation dates of Source Hydrostatic test pressure

legislation requirements – greater of

1 May 2006 to present AS 2419.1-2005 1700 kPa or 1.5 x highest

working pressure for at least 2

Published 26 November 2006.

hours

Called up in Building Code of

Australia 2006.

1 Nov 1994 AS 2419.1-1994 1700 kPa or 1.5 x highest

working pressure for at least 2

to 1 May 2006 Published 18 July 1994. Called

hours.

up in Building Code of Australia

1990, 1996, 2004 and 2005.

8 April 1991 to AS 2419.1-1988 1400 kPa or 1.5 x highest

working pressure for 2 hours.

31 Oct 19941 Published 17 June 1988. Called

up in Building Code of Australia

1990.

1 Feb 1987 to Victoria Water Supply and System with fabricated branch

Sewerage Plumbing Regulations junctions2 - 1700 kPa.

1 July 19941

1986 (S.R. 330/1986) Other pipework - 700 kPa or

mains pressure.

29 June 1983 Melbourne and Metropolitan System with fabricated branch

Board of Works Act 1958 By- junctions2 - 1700 kPa.

to 1 Feb 1987

Law No. 193: Water Supply (S.R. Other pipework - 700 kPa or

116/1983). mains pressure.

Not called up in AS 2419 - 1980 1400 kPa or 400 kPa greater than

legislation highest working pressure where

Published 31 December 1980.

the working pressure is greater

than 1000 kPa.

Issued June 2018 vba.vic.gov.au Page 5 of 5

Potrebbero piacerti anche

- PN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingDocumento5 paginePN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingKadiri OlanrewajuNessuna valutazione finora

- Hydrant SystemDocumento10 pagineHydrant SystemSheikh Faiz RockerNessuna valutazione finora

- Requirements For Underground Fire Service LinesDocumento4 pagineRequirements For Underground Fire Service LinesAgus Salim AnshoriNessuna valutazione finora

- Fire Sprinkler Design-Part1Documento2 pagineFire Sprinkler Design-Part1Henry SuarezNessuna valutazione finora

- Selecting A Fire PumpDocumento24 pagineSelecting A Fire PumpCelsoRapi50% (2)

- Piping Sensing Line Layout of Fire Pump and Jockey PumpDocumento1 paginaPiping Sensing Line Layout of Fire Pump and Jockey Pumpاحمد الجزار200750% (2)

- Piping Lay Out For Fire Sprinkler System - An OverviewDocumento6 paginePiping Lay Out For Fire Sprinkler System - An OverviewFitsum BulloNessuna valutazione finora

- Atmospheric Foam TankDocumento5 pagineAtmospheric Foam TankAndro SidhomNessuna valutazione finora

- Fire PumpDocumento10 pagineFire Pumppandu_chemeng100% (1)

- Water Distribution ManualDocumento20 pagineWater Distribution ManualOxfamNessuna valutazione finora

- Sidewall SprinklerDocumento6 pagineSidewall SprinklerAhrian BenaNessuna valutazione finora

- Fire FightingDocumento50 pagineFire FightingJagadeesh KandasamyNessuna valutazione finora

- Fire Protection System Study Rev. BDocumento3 pagineFire Protection System Study Rev. BEcho Ardyone83% (6)

- Fire Fighting Design Brief ReportDocumento16 pagineFire Fighting Design Brief ReportRanu AgarwalNessuna valutazione finora

- Sprinkler Hydraulic Calculation (Manual Worksheet)Documento5 pagineSprinkler Hydraulic Calculation (Manual Worksheet)pankajbhatt3760% (1)

- Calculate Jockey Pump Capacity in Fire Fighting SystemDocumento1 paginaCalculate Jockey Pump Capacity in Fire Fighting SystemkarpakkiNessuna valutazione finora

- Sprinkler System ComponentsDocumento68 pagineSprinkler System Componentsjosediaz141Nessuna valutazione finora

- Nitrogen IG100 Fire Supression DESIGN CALCULATION-15Documento2 pagineNitrogen IG100 Fire Supression DESIGN CALCULATION-15anwerquadriNessuna valutazione finora

- NY2167 Basics+of+Building+Fire+Protection+DesignDocumento31 pagineNY2167 Basics+of+Building+Fire+Protection+DesignFaris AyadNessuna valutazione finora

- BOQ Fire Fighting (Hydrant) System R0 18-03-2020Documento7 pagineBOQ Fire Fighting (Hydrant) System R0 18-03-2020balabhaviniNessuna valutazione finora

- CP 52 PresentationDocumento27 pagineCP 52 Presentationalvinchuan0% (1)

- FM200 - Technical SpecificationDocumento14 pagineFM200 - Technical SpecificationSubharajkNessuna valutazione finora

- Inergen Sizing CalculationDocumento3 pagineInergen Sizing CalculationStephanie Webb0% (1)

- 6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFDocumento1 pagina6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFHaitham MohammadNessuna valutazione finora

- Fire Fighting Isometric Layout PlanDocumento1 paginaFire Fighting Isometric Layout Planامان للأستشارات الهندسيةNessuna valutazione finora

- Hydraulic Calculation of Sprinkler System (Rev.c)Documento10 pagineHydraulic Calculation of Sprinkler System (Rev.c)Tuong Nguyen Duc MinhNessuna valutazione finora

- Fire Pump Sizing and Selectio1Documento14 pagineFire Pump Sizing and Selectio1Rahul Deva100% (2)

- Ms 1489 Part 1 1999 Section 9Documento1 paginaMs 1489 Part 1 1999 Section 9kan_chan_01Nessuna valutazione finora

- Manual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Documento16 pagineManual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Jerry TomNessuna valutazione finora

- Fire TankDocumento30 pagineFire TankPraveen Kumar100% (1)

- Sprinklers PDFDocumento43 pagineSprinklers PDFpil7194Nessuna valutazione finora

- Design Report (HK)Documento22 pagineDesign Report (HK)Ravi Bhushan100% (1)

- Fire Pump SelectionDocumento13 pagineFire Pump SelectionMarjhel HalligNessuna valutazione finora

- Viking Residential Sprinkler Installation GuideDocumento18 pagineViking Residential Sprinkler Installation Guidesina_84Nessuna valutazione finora

- Installation-Operation-Maintenance Manual For Foam Proportioning System - DPSDocumento10 pagineInstallation-Operation-Maintenance Manual For Foam Proportioning System - DPSRoshin99Nessuna valutazione finora

- Sprinkler CalculationDocumento13 pagineSprinkler CalculationHuynh Ngoc Nghia100% (4)

- Fire Supression SystemDocumento37 pagineFire Supression SystemStephen Odon Fasto100% (1)

- Fire Pumps Sensing LinesDocumento1 paginaFire Pumps Sensing LinesTanvir AhmedNessuna valutazione finora

- FM200Documento6 pagineFM200zshehadehNessuna valutazione finora

- LYE Book Fitting ms1919Documento16 pagineLYE Book Fitting ms1919khai rule100% (1)

- Hose ReelDocumento9 pagineHose Reelkristian08Nessuna valutazione finora

- Testing and Commissioning of Fire Fighting System Hose Reel and Sprinkler SystemDocumento4 pagineTesting and Commissioning of Fire Fighting System Hose Reel and Sprinkler SystemRaj Kamal67% (6)

- Fire Water Curtain Installation PDFDocumento2 pagineFire Water Curtain Installation PDFKapal TerbangNessuna valutazione finora

- Fire Flow CalculationDocumento2 pagineFire Flow Calculationcoolsummer1112143Nessuna valutazione finora

- Foam CalculationsDocumento8 pagineFoam Calculationsahmed salemNessuna valutazione finora

- Lift Pump CalculationDocumento10 pagineLift Pump CalculationMaxmore KarumamupiyoNessuna valutazione finora

- Is.15301.2003 Installation and Maintenance of Fire Fighting PumpsDocumento13 pagineIs.15301.2003 Installation and Maintenance of Fire Fighting PumpsSimon ChouNessuna valutazione finora

- TAC For Sprinkler SystemDocumento128 pagineTAC For Sprinkler SystemRaj Kamal80% (5)

- Sprinkler CalculationDocumento9 pagineSprinkler Calculationmeeng201467% (3)

- Fire Pump Design CalculateDocumento131 pagineFire Pump Design CalculateMaria Victoria Morales Galindez100% (3)

- Fire Hydrant SystemDocumento15 pagineFire Hydrant SystemVineet Sharma0% (2)

- Design Basis - Fire Fighting SystemDocumento3 pagineDesign Basis - Fire Fighting SystemDeepakRamNessuna valutazione finora

- Fire Pump Capacity Standard CalcDocumento8 pagineFire Pump Capacity Standard Calck0nquerorNessuna valutazione finora

- Sprinkler Cal Info Hong KongDocumento13 pagineSprinkler Cal Info Hong KongDarren Leong50% (2)

- Fire Pump Sizing and CalculationsDocumento5 pagineFire Pump Sizing and CalculationsNikhil NambiarNessuna valutazione finora

- ANSUL Aircraft HangarsDocumento8 pagineANSUL Aircraft Hangarsاحمد الجزار2007100% (1)

- Water Demand Fire Flow Calculation Hydraulic ModelingDocumento110 pagineWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNessuna valutazione finora

- Fire Hydrant TestDocumento3 pagineFire Hydrant TesthfrankieNessuna valutazione finora

- Ensuring LNG Liquefaction Facilities Sys PDFDocumento12 pagineEnsuring LNG Liquefaction Facilities Sys PDFdhurjatibhuteshNessuna valutazione finora

- C1719-11 (Vacuum) Test Prior To BackfillDocumento2 pagineC1719-11 (Vacuum) Test Prior To Backfilldiego rodriguezNessuna valutazione finora

- Subject: Bill of Quantities - DG - MAKE OF MATERIALS SL - No Description Makes in Alphabetical OrderDocumento1 paginaSubject: Bill of Quantities - DG - MAKE OF MATERIALS SL - No Description Makes in Alphabetical Orderjaianit89Nessuna valutazione finora

- SEC 15490 Swimming PoolsDocumento8 pagineSEC 15490 Swimming Poolsjaianit89Nessuna valutazione finora

- Water Softner Design VedantaDocumento5 pagineWater Softner Design Vedantajaianit89Nessuna valutazione finora

- Sun Sine Smart Solar Power Generator/ Micro Inverter - "SPG 350"Documento2 pagineSun Sine Smart Solar Power Generator/ Micro Inverter - "SPG 350"jaianit89Nessuna valutazione finora

- Pure Sine Wave Inverter: P O P ODocumento2 paginePure Sine Wave Inverter: P O P Ojaianit89Nessuna valutazione finora

- Commercial Bldg-BOQ Without RatesDocumento35 pagineCommercial Bldg-BOQ Without Ratesjaianit89Nessuna valutazione finora

- 9.cipet Boys Hoste-BoqDocumento19 pagine9.cipet Boys Hoste-Boqjaianit89Nessuna valutazione finora

- Checklist of Layout For Port Blair Planning Area PDFDocumento2 pagineChecklist of Layout For Port Blair Planning Area PDFjaianit89Nessuna valutazione finora

- Pie Chart Representing Segment-Wise RevenueDocumento2 paginePie Chart Representing Segment-Wise Revenuejaianit89Nessuna valutazione finora

- Syngineering Water MBR Vs SBR PDFDocumento5 pagineSyngineering Water MBR Vs SBR PDFjaianit89Nessuna valutazione finora

- Checklist of Building Plan For Port Blair Planning Area PDFDocumento3 pagineChecklist of Building Plan For Port Blair Planning Area PDFjaianit89Nessuna valutazione finora

- 20150402522.electrical SLD-Model PDFDocumento1 pagina20150402522.electrical SLD-Model PDFjaianit89Nessuna valutazione finora

- Pie Chart Representing Segment-Wise RevenueDocumento2 paginePie Chart Representing Segment-Wise Revenuejaianit89Nessuna valutazione finora

- Documents Formalities Required For The Issuance of A B C&D Class Contractor CardsDocumento8 pagineDocuments Formalities Required For The Issuance of A B C&D Class Contractor Cardsjaianit89100% (1)

- Time Maintenance - Log Book: RI/OR/MLB/02Documento1 paginaTime Maintenance - Log Book: RI/OR/MLB/02jaianit89Nessuna valutazione finora

- TB08104003E Tab 1Documento152 pagineTB08104003E Tab 1priyanka236Nessuna valutazione finora

- MEP DatabookDocumento668 pagineMEP Databookjaianit8986% (7)

- Head Calculation For Sewage Transfer Pump - 19.05.2012 FinalDocumento2 pagineHead Calculation For Sewage Transfer Pump - 19.05.2012 Finaljaianit89Nessuna valutazione finora

- Is 3414 1968 PDFDocumento30 pagineIs 3414 1968 PDFjaianit89100% (1)

- Is 1838 3 2011 PDFDocumento12 pagineIs 1838 3 2011 PDFjaianit89Nessuna valutazione finora

- Is 278 2009 PDFDocumento11 pagineIs 278 2009 PDFjaianit89Nessuna valutazione finora

- Is 2751 1979 PDFDocumento41 pagineIs 2751 1979 PDFjaianit89Nessuna valutazione finora

- Estimating Flow Characteristics of Different Weir PDFDocumento17 pagineEstimating Flow Characteristics of Different Weir PDFrhinonanaNessuna valutazione finora

- Proyecto Ingles (Genny Esmeralda Guerrero Bacca)Documento2 pagineProyecto Ingles (Genny Esmeralda Guerrero Bacca)Neify RoseroNessuna valutazione finora

- Self Watering Planter PresentationDocumento13 pagineSelf Watering Planter Presentationapi-500694538Nessuna valutazione finora

- Vertical Turbine Pump InformationDocumento10 pagineVertical Turbine Pump Informationraghu_mn100% (1)

- Underwater WindmillDocumento21 pagineUnderwater Windmillbhagyashree behera100% (1)

- Ujjain - Landscape PlanningDocumento10 pagineUjjain - Landscape PlanningVidyotma SinghNessuna valutazione finora

- (Type The Document Title) : Significance of The StudyDocumento6 pagine(Type The Document Title) : Significance of The StudyKristelle Charlotte CruzNessuna valutazione finora

- Evidence The Story of Bottled WaterDocumento2 pagineEvidence The Story of Bottled WaterPaula MelissaNessuna valutazione finora

- BoroBlock Linings - Glass Lining For InsulationDocumento4 pagineBoroBlock Linings - Glass Lining For InsulationN P SrinivasaraoNessuna valutazione finora

- PROBES-75 Guidelines For Developing Greenbelts PDFDocumento210 paginePROBES-75 Guidelines For Developing Greenbelts PDFNur DiansyahNessuna valutazione finora

- H2 Folding Hatch Covers - Original - 30544Documento8 pagineH2 Folding Hatch Covers - Original - 30544Milan SjausNessuna valutazione finora

- Harar Water Supply and Sanitation Project1234567Documento97 pagineHarar Water Supply and Sanitation Project1234567aberra100% (3)

- Fundamentals of Plumbing DesignDocumento60 pagineFundamentals of Plumbing DesignBianca MendozaNessuna valutazione finora

- 4 Pressure BuoyancyDocumento8 pagine4 Pressure BuoyancythinkiitNessuna valutazione finora

- OAI551-Environment and Agriculture Question BankDocumento9 pagineOAI551-Environment and Agriculture Question BankMohamed Raees100% (1)

- Plastic Settlement Cracks in ConcreteDocumento6 paginePlastic Settlement Cracks in ConcreteJayamal InduruwaNessuna valutazione finora

- Flue Gas AnalysisDocumento41 pagineFlue Gas AnalysisKingrad1100% (1)

- Module 5 - Pipe Cutting and JoiningDocumento14 pagineModule 5 - Pipe Cutting and JoiningKrizia InteligandoNessuna valutazione finora

- w2 C Mira Atom Erd Bar ValveDocumento2 paginew2 C Mira Atom Erd Bar ValvejayteNessuna valutazione finora

- ASCE Library E-Books and StandardsDocumento14 pagineASCE Library E-Books and StandardsHassan SleemNessuna valutazione finora

- Direct SeedingDocumento23 pagineDirect SeedingMarvin Bustamante100% (1)

- L14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Documento26 pagineL14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Laxmi Kant Prasad100% (1)

- Advisory Note SMDocumento48 pagineAdvisory Note SMAmrita BhatnagarNessuna valutazione finora

- Jacques Cousteau: Jacques Cousteau, in Full Jacques-Yves Cousteau, (BornDocumento4 pagineJacques Cousteau: Jacques Cousteau, in Full Jacques-Yves Cousteau, (BornanguesanNessuna valutazione finora

- Method Statement For Installation of Grill, Diffuser & LouversDocumento51 pagineMethod Statement For Installation of Grill, Diffuser & LouversAnandu Ashokan100% (1)

- A BVVVDocumento10 pagineA BVVVDigvijayNessuna valutazione finora

- The Earths ClimatesDocumento14 pagineThe Earths ClimatesApril Rose AyubanNessuna valutazione finora

- Basis of Design NarrativeDocumento25 pagineBasis of Design NarrativeNandan RajeNessuna valutazione finora

- Coal Runoff Analysis Complete ReportDocumento32 pagineCoal Runoff Analysis Complete ReportArif SusetyoNessuna valutazione finora

- Englefield Electronic Bidet SeatDocumento1 paginaEnglefield Electronic Bidet SeatjeffNessuna valutazione finora