Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hyd10098234 Inst Sheetaccumax 12 3 BTN Eg PDF

Caricato da

testTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hyd10098234 Inst Sheetaccumax 12 3 BTN Eg PDF

Caricato da

testCopyright:

Formati disponibili

user manual

AccuMax 1, 2, & 3 button units

™

with E-gap Eductors

10098234 Rev B 3/17

index

1.00 introduction page

package contents 2

safety precautions 2

2.00 installation

installation/operation 3

3.00 parts list

parts list / diagrams 4

4.00 troubleshooting 5

introduction

package contents:

1. Proportioner unit - ASSE 1055 and cUPC approved.

2. Supply tubing

3. Foot valve assembly & weight for each eductor

4. Discharge tube for each eductor

5. Metering tip kit(s)

6. Mounting anchor kit

7. Hose hook for discharge tube(s) - Models with 3.5 GPM eductors only

8. Instruction sheet

safety precautions

WARNING please read precautions thoroughly before operation. Must meet all applicable local codes and regulations.

THANK YOU FOR YOUR INTEREST IN OUR PRODUCTS

Please use this equipment carefully and observe all warnings and cautions.

*******************************************NOTE*****************************************

WEAR protective clothing and eyewear when dispensing chemicals or other materials or when working in the

vicinity of all chemicals, filling or emptying equipment, or changing metering tips.

observe safety and handling instructions of the chemical manufacturer.

direct discharge away from you or other persons or into approved containers.

ALWAYS dispense cleaners and chemicals in accordance with manufacturer‘s instructions. Exercise CAUTION when

maintaining your equipment.

reassemble equipment according to instruction procedures. Be sure all components are firmly screwed or

latched into position.

KEEP equipment clean to maintain proper operation.

ATTACH only to water tap outlets (25 PSI Minimum, 85 PSI Maximum and Maximum water temperature 120° F).

NOTE if the unit is used to fill a sink, or the discharge hose can be placed into a sink. The unit must be mounted

so that the bottom of the cabinet is above the overflow rim of the sink.

Page 2 10098234 Rev B 3/17

installation / maintenance

1. Find suitable place close to water source for unit. Mounting bracket should be installed approx. 5’ from the floor. Level bracket

and mark holes. Drill 9/32” holes and install mounting anchors and screws in bracket.

2. Remove cabinet cover and hang cabinet on bracket. Mark hole for lower cabinet screw. Remove cabinet and drill 9/32” hole.

Install anchor and screw in lower cabinet hole. When mounting unit, do not mount more than 5 feet from the floor. Also, never

mount your concentrate container higher than the unit. Keyhole slots are also provided in the cabinet back if the mounting bracket

won’t be used.

3. Select a metering tip (see next section), and insert into hose barb on eductor body. (Repeat for all eductors.)

4. Supply tube should reach from hose barb on eductor to bottom of the concentrate container. Cut supply tube provided to length required.

Slide a ceramic weight over one end of tube and slide a foot valve into the same end of the tube. (Prepare a tube for each eductor.)

5. Push other end of supply tube over the hose barb/metering tip on the eductor. (Repeat for all eductors.)

6. Place foot valve ends of supply tubes into concentrate containers. REMEMBER TO CHECK FOOT VALVE STRAINERS REGULARLY

FOR CLOGGING: CLEAN IF NECESSARY.

7. A short discharge tube is used with the 1GPM eductor; minumum tube length is 8 inches (20cm) for proper operation.

Longer tubes (4 feet) are used with a 3.5 GPM eductor. Slide end of tube over eductor discharge outlet. (Repeat for all eductors.)

Hooks may be installed on longer tubes to allow discharge tube to conveniently hang from dispenser when not in use.

8. Replace cabinet cover. Guide supply tubes through slots in sides of cabinet cover. Push the sides in, behind the latch holes, to snap the

cover in place. The two screws provided may be installed in the holes in the cabinet sides to prevent easy removal of cover.

operation

1. Connect water supply hose of at least 3/8” ID to water inlet swivel. (Minimum 25 PSI pressure, with water running, is required for proper

operation.) Connect opposite end of hose to water supply. Turn water supply on.

2. Purge air from the system by depressing the buttons briefly. There may be some water discharge from the eductor vents until the air is

purged.

3. Push button to start flow of desired water/concentrate solution, and hold until supply tube is primed (filled). Then push the button whenever

dispensing is desired, and release button to stop flow of solution. If you wish to be able to lock the button in the “on” position:

Depress button and slide button lock up. To unlock, depress button and release.

4. It is essential that the discharge hose not be obstructed. If discharge is restricted, water will flow out the eductor

vents. Do not start to operate the dispenser with liquid in the discharge tube.

tip chart APPROXIMATE DILUTIONS

AT 40 PSI FOR WATER-THIN PRODUCTS (1.0 CP)

Metering Tip Selection:

The final concentration of the dispensed solution is related to both the size of the Tip Orifice Ratio (per Eductor Flow)

metering tip opening and the viscosity of the liquid being siphoned. For water-thin Color Size 1 GPM 3.5 GPM

products, the chart at right can be used as a guideline. If product is noticeably thicker

than water, consult the Measurement of Concentration Procedure below to achieve your No Tip .187 3:1 3.5:1

desired water-to-product ratio. Because dilution can vary with water temperature and

pressure, actual dilution achieved can only be ascertained by using the Measurement Grey .128 3:1 4:1

of Concentration Procedure. The clear, undrilled tip is provided to permit drilling to Black .098 3:1 4:1

size not listed should you need a dilution ratio that falls between standard tip sizes.

Beige .070 4:1 8:1

NOTE: A 1 GPM eductor is grey; a 3.5 GPM eductor is yellow. Refer to parts diagram Red .052 5:1 14:1

if unfamiliar with names of system components.

Measurement of Concentration: White .043 7:1 20:1

You can determine the dispensed water-to-product ratio for any metering tip size

and product viscosity. All that is required is to operate the primed dispenser for a Blue .040 8:1 24:1

minute or so and note two things: the amount of dispensed solution, and the amount Tan .035 10:1 30:1

of concentrate used in preparation of the solution dispensed. The water-to-product

ratio is then calculated as follows: Green .028 16:1 45:1

Orange .025 20:1 56:1

Dilution Ratio (X:1) where X = Amount of Mixed Solution — Amount Concentrate Drawn Brown .023 24:1 64:1

Amount of Concentrate Drawn Yellow .020 32:1 90:1

Dilution Ratio, then, equals X parts water to one part concentrate (X:1). If the test Aqua .018 38:1 128:1

does not yield the desired ratio, choose a different tip and repeat the test. Alternative

methods to this test are 1) pH (using litmus paper), and 2) titration. Contact your Purple .014 64:1 180:1

concentrate supplier for further information on these alternative methods and the Pink .010 128:1 350:1

materials required to perform them.

Page 3 10098234 Rev B 3/17

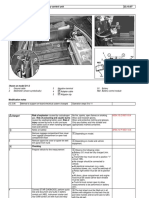

parts list / diagrams

9

a b c d

10

11

12a,b

5 4 3 2 1 13 15 16

6 7 14a,b

17

8 18

19

Key Part No. Description Key Part No. Description

1 238100 Strainer washer 9 10075980 Valve parts kit

2 10082830 Swivel collar (molded) a. diaphragm b. armature

c. spring d. valve bonnet

3 10082802 Swivel stm 1 btn (molded)

10 10079010 Spring

10082811 Swivel stem 2 btn (molded)

11 10079000 Magnet

4 10075902 Nipple, plastic 3/8“ (2 btn models)

10075903 Nipple, plastic 3/8“ (3 btn models) 12a 290 1.0 GPM eductor assembly

10075950 O-ring (two required per nipple) b 291 3.5 GPM edcutor assembly

5 10098573 Kit, Pipe plug & o-ring 13 3401-R Hose barb assembly*

included in edcutor assemblies

6 10091035 Wall bracket

14a 10088822 1 GPM discharge tube with

7 10096641 Button, Low flow, teal flooding ring (8“)

10096644 Button, High flow, teal 14b 90048495 3.5 GPM discharge tube with

8 10098539 Cabinet set, 1 button Lo flow unit flooding ring (4‘)

10098540 Cabinet set, 1 button Hi flow unit 15 690014 Metering tip kit

10098541 Cabinet set, 2 button Lo flow unit

10098542 Cabinet set, 2 button Hi flow unit 16 500870 Tubing 1/4“ x 7‘

10098543 Cabinet set, 2 button Lo & Hi flow unit 17 509900 Weight

10098836 Cabinet set, 3 button, 3 Lo flow unit 18 10089410 Footvalve -Viton (EPDM also

10098837 Cabinet set, 3 button, 3 Hi flow unit available. Order 10076302)

10098838 Cabinet set, 3 button, 1 Lo, 2 Hi flow unit

10098839 Cabinet set, 3 button, 2 Lo, 1 Hi flow unit 19 10080730 Hose hook dark grey (standard)

Not Shown:

641751 Security screws (for cabinet sides)

Page 4 10098234 Rev B 3/17

troubleshooting

Problem Cause Solution

1. No discharge a. No water a. Open water supply

b. Excessive water pressure b. Install regulator if water pressure (with

water running) exceeds 85 PSI

c. Clogged water inlet strainer c. Disconnect inlet water line and clean

strainer

d. Magnetic valve not functioning d. Install valve parts kit

e. Eductor clogged e. Clean* or replace

2. No concentrate draw a. Clogged foot valve a. Clean or replace

b. Metering tip or eductor has scale b. Clean (descale)* or replace

build-up

c. Low water pressure c. Minimum 25 PSI (with water running)

required to operate unit properly

d. Discharge tube and/or flooding ring not d. Push tube firmly onto eductor discharge

in place hose barb, or replace tube if it doesn‘t

have a flooding ring

e. Concentrate container empty e. Replace with full container

f. Clogged water inlet strainer f. Disconnect inlet water line and clean

strainer

g. Inlet hose barb not screwed into g. Tighten, but do not overtighten

eductor tightly

h. Air leak in pick-up tube h. Put clamp on tube or replace tube if brittle

3. Excess concentrate draw a. Metering tip not in place a. Press correct tip firmly into barb on

eductor

b. Chemical above eductor b. Place concentrate below eductor

4. Failure of unit to turn off a. Water valve parts dirty or defective a. Clean or replace with valve parts kit

b. Magnet doesn‘t fully return b. Make sure magnet moves freely

Replace spring if short of weak

c. Push button stuck c. Remove button and clean cabinet/button

to remove excess dirt lodged in slide

recess

5. Excess foaming in discharge a. Air leak in pick-up tube a. Put clamp on tube or replace tube if brittle

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water.

This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet,

firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling)

by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until

solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction

tube into concentrate.

Hydro Systems Company Phone 513-271-8800

3798 Round Bottom Road Fax 513-271-0160

Cincinnati, OH 45244 U.S.A. Web hydrosystemsco.com

Page 5 10098234 Rev B 3/17

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- F2970.1558734-1 Trampoline CourtDocumento22 pagineF2970.1558734-1 Trampoline CourtKannan LakshmananNessuna valutazione finora

- ES3000 Instruction Book Revision 4Documento26 pagineES3000 Instruction Book Revision 4test100% (2)

- Radiology Final QuestionsDocumento52 pagineRadiology Final QuestionsRashed Shatnawi50% (4)

- Pedro Flores El Chapo TrialDocumento19 paginePedro Flores El Chapo TrialChivis MartinezNessuna valutazione finora

- Assembly Instructions: Made in GermanyDocumento30 pagineAssembly Instructions: Made in GermanytestNessuna valutazione finora

- EINE8198 SEGMBROCHSOCIALFOODSPREAD72 DPIFILEminimizerDocumento10 pagineEINE8198 SEGMBROCHSOCIALFOODSPREAD72 DPIFILEminimizertestNessuna valutazione finora

- Hyd10098234 Inst Sheetaccumax 12 3 BTN Eg PDFDocumento5 pagineHyd10098234 Inst Sheetaccumax 12 3 BTN Eg PDFtestNessuna valutazione finora

- Lkuv 2 SPDocumento6 pagineLkuv 2 SPtestNessuna valutazione finora

- LKUV 2 Air Relief Valve PDDocumento3 pagineLKUV 2 Air Relief Valve PDtestNessuna valutazione finora

- Lkuv 2 SPDocumento6 pagineLkuv 2 SPtestNessuna valutazione finora

- Flowserve KammerDocumento8 pagineFlowserve KammertestNessuna valutazione finora

- REMOVALDocumento1 paginaREMOVALtestNessuna valutazione finora

- Keofitt Micro Port User ManualDocumento22 pagineKeofitt Micro Port User ManualtestNessuna valutazione finora

- Stainless-Steel-Ball-Valves F262 Pentair Seat Seal ReplacementDocumento4 pagineStainless-Steel-Ball-Valves F262 Pentair Seat Seal Replacementred patriotNessuna valutazione finora

- Keofitt Micro Port User ManualDocumento22 pagineKeofitt Micro Port User ManualtestNessuna valutazione finora

- MA2000 Service EU MLDocumento41 pagineMA2000 Service EU MLtestNessuna valutazione finora

- Keofitt Micro Port User ManualDocumento22 pagineKeofitt Micro Port User ManualtestNessuna valutazione finora

- Link L5 Assessment AKDocumento11 pagineLink L5 Assessment AKJoanna MajczykNessuna valutazione finora

- RTL8185 Windows7 FixDocumento2 pagineRTL8185 Windows7 FixJamesHackNessuna valutazione finora

- History of PTCLDocumento4 pagineHistory of PTCLswealumair86Nessuna valutazione finora

- Alcatel 350 User Guide FeaturesDocumento4 pagineAlcatel 350 User Guide FeaturesFilipe CardosoNessuna valutazione finora

- Jurnal Aceh MedikaDocumento10 pagineJurnal Aceh MedikaJessica SiraitNessuna valutazione finora

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocumento11 pagineIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediNessuna valutazione finora

- Lesson 5 The 19th Century PhilippinesDocumento5 pagineLesson 5 The 19th Century PhilippinesJoquem PamesaNessuna valutazione finora

- ADEC Al Maali International Private School 2015 2016Documento18 pagineADEC Al Maali International Private School 2015 2016Edarabia.com100% (1)

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocumento8 pagineICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- 1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterDocumento10 pagine1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterJhancarlos Carrasco MNessuna valutazione finora

- Kiribati, Gilbertese BibleDocumento973 pagineKiribati, Gilbertese BibleAsia BiblesNessuna valutazione finora

- Concept Deck de BosBoerderij - Dec2023Documento32 pagineConcept Deck de BosBoerderij - Dec2023Bruna San RomanNessuna valutazione finora

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonDocumento16 pagineUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- Anuj Singh ResumeDocumento4 pagineAnuj Singh ResumeAnuj BaghelNessuna valutazione finora

- ME 205 - Statics Course Syllabus: Fall 2015Documento4 pagineME 205 - Statics Course Syllabus: Fall 2015Dhenil ManubatNessuna valutazione finora

- Anselm's Ontological Argument ExplainedDocumento8 pagineAnselm's Ontological Argument ExplainedCharles NunezNessuna valutazione finora

- Holiday Tradition Lesson PlanDocumento2 pagineHoliday Tradition Lesson Planapi-458585393Nessuna valutazione finora

- Clare Redman Statement of IntentDocumento4 pagineClare Redman Statement of Intentapi-309923259Nessuna valutazione finora

- What Is A Dry Well?Documento4 pagineWhat Is A Dry Well?eullouNessuna valutazione finora

- Datasheet PIC1650Documento7 pagineDatasheet PIC1650Vinicius BaconNessuna valutazione finora

- LUTS Spot TestDocumento2 pagineLUTS Spot TestHardiTariqHamma100% (1)

- OE & HS Subjects 2018-19Documento94 pagineOE & HS Subjects 2018-19bharath hsNessuna valutazione finora

- FMS 1Documento27 pagineFMS 1bishal dattaNessuna valutazione finora

- MARS Motor Cross Reference InformationDocumento60 pagineMARS Motor Cross Reference InformationLee MausNessuna valutazione finora

- Burning Arduino Bootloader With AVR USBASP PDFDocumento6 pagineBurning Arduino Bootloader With AVR USBASP PDFxem3Nessuna valutazione finora

- Checking battery control unitDocumento3 pagineChecking battery control unitjuanNessuna valutazione finora

- 3: Batteries: I Ne NR+RDocumento3 pagine3: Batteries: I Ne NR+RIsrael EdeagheNessuna valutazione finora