Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A1 PDF

Caricato da

razi khanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A1 PDF

Caricato da

razi khanCopyright:

Formati disponibili

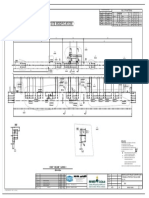

8380510-A1 WELDING PROCEDURE TABLE

BILL OF MATERIAL

0

REV. DRAWING NUMBER WELD WELD WELDING WELD WELD

PROCEDURE

NO. SYMBOL PROCEDURE NO. SYMBOL TEMPLATE UNIT TOTAL

ASSY.MARK GRID LOCATION ELEVATION ASSY. ASSY. MARK TOTAL/UNIT

QTY./ MARK DESCRIPTION GRADE WEIGHT WEIGHT REMARKS

S2(E2)

1. FCAW-007 7. S1(E1) FCAW-015

A1-7 1b-1/Q-P EL.112700 QTY. ASSY. LENGTH

2. FCAW-025

(Kg.) (Kg.)

8. FCAW-075

3. FCAW-011 9.

SAW-025A 1 A1-7 HANDRAIL 698

(FOR BUILT-UP)

4. FCAW-012 10.

SAW-001A 1 A1 PIPE 1.900X.145 536 AP53 2.17 2.17

(FOR BUILT-UP)

5. FCAW-014 11.

SAW-65 1 264 PL10*120 150 A50 1.41 1.41

(FOR BUILT-UP)

6. S(E)

FCAW-026 12. TACK SMAW-038 2 757 PIPE 1.900X.145 336 AP53 1.36 2.72

2 792 PIPE 1.900X.145 268 AP53 1.08 2.17

1 837 PIPE 1.900X.145 1174 AP53 4.75 4.75

2 970 FB40*6 295 A36 0.56 1.11

1 993 FB150*6 718 A36 5.07 5.07

1 1021 PL2*43 43 A36 0.03 0.03

RD 291 34 322

4 1022 1-1/2" SCH.40-90°ELBOW - A234 0.36 1.45 B-SBO-E008

291

647

ASSY. DIMENSION 150x1210x698 ASSY. WEIGHT 20.89 20.89

325

1022 4 BC2-M16051 BOLT 5/8"*51+1N+1W-HG - A307A 0.182 0.73 FIELD BOLTS

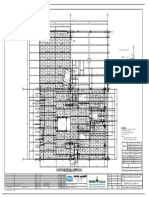

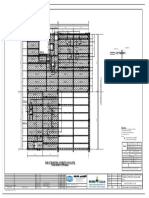

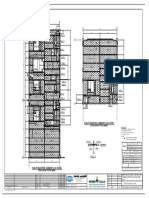

1022 4*D18 837 970

1022

792 A1 792

100

757 757

970 1021

993 1022

264

698 (PIPE 1.900X.145 x 536)

RD 325 325

325

650

EL112700 57

C 1022 57

A1

A1 1174

24

1174

57

57

1022

450

450

426

757

757

1022 792

748 792 792 724

57

57

1022 792

57

57

837

410

325 325

641

993

837

338 970

72

970

72

72

970 970

255

264 4*D18

4*D18

263

993 264 83

25 70 25

83

1021

83

RD

83

RD

10

2

1021 GENERAL NOTES:

15 25 100 25 1. REFER TO SHEET 'A' FOR GENERAL & SHOP NOTES.

C 2. ALL HOLES ARE 18MM DIA (UNO).

C-C 3. ALL DIMENSIONS ARE IN MILLIMETER (UNO).

4. ALL WELD SHALL BE 3MM FILLET CONTINUOUS (UNO).

R=11

5. ALL COPE RADIUS SHALL BE 11mm (UNO)

6. LEGENDS:

- ORIENTATION MARK FOR VERTICAL MEMBER &

TOP MARK FOR HORIZONTAL MEMBER

RD - BASE LINE OF RUNNING DIMENSION = 00

> - DENOTES NO PAINT AREA AS FOLLOW:

FOR PAINTED MATERIAL ONLY:

"MASKING OVER PRIMER IS REQUIRED FOR

MOMENT CONNECTIONS ONLY."

7. SHOP HAS TO DO CHAMFER FOR SITE WELDING, WHERE APPLICABLE.

ONE * HANDRAIL * A1-7

DIA. THK

48.3 3.7

DRAWN UMM WU'AL EPC PROJECT DAP-NPK PLANT

INDUSTRIES

STRUCTURAL STEEL DIVISION (ENGINEERING DEPARTMENT)

CHECKED STORAGE & OFFSITES AT RAS AL KHAIR

P.O.BOX 877 DAMMAM 31421, KINGDOM OF SAUDI ARABIA

PHONE: (966) 3 812-1120 FAX: (966) 3 812-1281

ENGINEER P.B. E/F. (PIPE RACK)

CR 2050004215/008 INDUSTRIAL LICENCE NO.1175/5 DATED 25-11-1419H

DRAWING TITLE:

A UNIT OF ZAMIL INDUSTRIAL INVESTMENT COMPANY (A JOINT STOCK COMPANY)

APPROVED

0 02-02-2016 ISSUED FOR FABRICATION EAH NS CWP

HANDRAIL

ZS JOB No.: SS-0838-05-10

A 12-01-2016 ISSUED FOR APPROVAL EAH NS DRAWING NO.: REV.

SCALE

REV DATE DESCRIPTION DRN CKD ENG APP ZS DWG No.: 8380510-A1 NTS A2 8380510-A1 0

A [A.1] * 02/02/2016 * 12:44:55 * A2 * ZJ

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Nkjlkjrofile 2018Documento20 pagineNkjlkjrofile 2018razi khanNessuna valutazione finora

- Nkjlkjrofile 2018Documento20 pagineNkjlkjrofile 2018razi khanNessuna valutazione finora

- Contract PDFDocumento24 pagineContract PDFrazi khanNessuna valutazione finora

- Zamil-Sicc Daily Erection Report 2015-11-09 PDFDocumento1 paginaZamil-Sicc Daily Erection Report 2015-11-09 PDFrazi khanNessuna valutazione finora

- Installation, Operation and Maintenance ManualDocumento8 pagineInstallation, Operation and Maintenance ManualQuaseemakhterNessuna valutazione finora

- Zamil-Sicc Daily Erection Report 2016-02-29Documento1 paginaZamil-Sicc Daily Erection Report 2016-02-29razi khanNessuna valutazione finora

- 471558GGB IomDocumento12 pagine471558GGB IomAdrian Dalida AgawinNessuna valutazione finora

- Heating and Air Conditioning Ent.: 220V/1/60Hz Total Power (W) MOP Ref. Motor Oty. Item Model E.HDocumento3 pagineHeating and Air Conditioning Ent.: 220V/1/60Hz Total Power (W) MOP Ref. Motor Oty. Item Model E.Hrazi khanNessuna valutazione finora

- Installation, Operation and Maintenance Manual: General Safety InformationDocumento12 pagineInstallation, Operation and Maintenance Manual: General Safety Informationrazi khanNessuna valutazione finora

- 183 K SCH Ha 000676 - 001 - C PDFDocumento1 pagina183 K SCH Ha 000676 - 001 - C PDFrazi khanNessuna valutazione finora

- Zamil-Sicc Daily Erection Report 2015-11-09 PDFDocumento1 paginaZamil-Sicc Daily Erection Report 2015-11-09 PDFrazi khanNessuna valutazione finora

- Prince Faisal Bin Sultan Palace: Riyadh - Saudi ArabiaDocumento10 paginePrince Faisal Bin Sultan Palace: Riyadh - Saudi Arabiarazi khanNessuna valutazione finora

- Company: ProfileDocumento20 pagineCompany: Profilerazi khanNessuna valutazione finora

- Zamil-Sicc Daily Erection Report 2015-10-24Documento1 paginaZamil-Sicc Daily Erection Report 2015-10-24razi khanNessuna valutazione finora

- b2060 PDFDocumento1 paginab2060 PDFrazi khanNessuna valutazione finora

- b2059 PDFDocumento1 paginab2059 PDFrazi khanNessuna valutazione finora

- b2058 PDFDocumento1 paginab2058 PDFrazi khanNessuna valutazione finora

- b2061 PDFDocumento1 paginab2061 PDFrazi khanNessuna valutazione finora

- b2057 PDFDocumento1 paginab2057 PDFrazi khanNessuna valutazione finora

- b1716Documento1 paginab1716razi khanNessuna valutazione finora

- 8380111-E191 C01 PDFDocumento1 pagina8380111-E191 C01 PDFrazi khanNessuna valutazione finora

- Q5Documento1 paginaQ5razi khanNessuna valutazione finora

- 8380157-E104 C01Documento1 pagina8380157-E104 C01razi khanNessuna valutazione finora

- Q2Documento1 paginaQ2razi khanNessuna valutazione finora

- 8380111-E125 C01 PDFDocumento1 pagina8380111-E125 C01 PDFrazi khanNessuna valutazione finora

- 8380111-E126 C01 PDFDocumento1 pagina8380111-E126 C01 PDFrazi khanNessuna valutazione finora

- 8380111-E190 C01 PDFDocumento1 pagina8380111-E190 C01 PDFrazi khanNessuna valutazione finora

- 8380157-E105 C01Documento1 pagina8380157-E105 C01razi khanNessuna valutazione finora

- 8380111-E191 C01 PDFDocumento1 pagina8380111-E191 C01 PDFrazi khanNessuna valutazione finora

- 8380111-E190 C01 PDFDocumento1 pagina8380111-E190 C01 PDFrazi khanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- DSR 12-13Documento279 pagineDSR 12-13Chandrashekhar ChopdekarNessuna valutazione finora

- SFD N004 2013 PDFDocumento21 pagineSFD N004 2013 PDFMohamed Abo-ZaidNessuna valutazione finora

- Thermo Exam QuestionsDocumento4 pagineThermo Exam QuestionssiskieoNessuna valutazione finora

- Working of New Design of Door Closer: Research PaperDocumento7 pagineWorking of New Design of Door Closer: Research Paperabdelnabi zaghloulNessuna valutazione finora

- 5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFDocumento4 pagine5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFrhomadonaNessuna valutazione finora

- Sheet PilingDocumento12 pagineSheet PilingTanvi Rane100% (1)

- PLUMBING AND SANITARY FIXTURES GUIDEDocumento53 paginePLUMBING AND SANITARY FIXTURES GUIDEKristine Malbas100% (1)

- Poor Concrete Construction Methods and Workmanship Are Responsible For The Failure of Buildings and StructureDocumento4 paginePoor Concrete Construction Methods and Workmanship Are Responsible For The Failure of Buildings and StructurepengniumNessuna valutazione finora

- Georges Pompidou CenterDocumento3 pagineGeorges Pompidou CenterGrendelle BasaNessuna valutazione finora

- ME 323 Homework 2 ProblemsDocumento4 pagineME 323 Homework 2 ProblemsPotatoes123Nessuna valutazione finora

- Thermodynamics Problems PDFDocumento21 pagineThermodynamics Problems PDFSubhash KorumilliNessuna valutazione finora

- MODULE 3 - Pertinent Building Laws and RegulationsDocumento45 pagineMODULE 3 - Pertinent Building Laws and RegulationsCammyNessuna valutazione finora

- DMRC - Ground Anchors - Info Sheet PDFDocumento2 pagineDMRC - Ground Anchors - Info Sheet PDFVardhanNessuna valutazione finora

- 52 Week PPM Planner Template-15 Jul 14Documento26 pagine52 Week PPM Planner Template-15 Jul 14safetydellNessuna valutazione finora

- Summary Bill of Quantities: Project Identifying InformationDocumento15 pagineSummary Bill of Quantities: Project Identifying InformationRussel Renz de MesaNessuna valutazione finora

- Technozen Quiz MaterialDocumento35 pagineTechnozen Quiz MaterialKarthi100% (1)

- Singapore National Annexure To Eurocode 8 PDFDocumento21 pagineSingapore National Annexure To Eurocode 8 PDFPankaj MunjalNessuna valutazione finora

- DESIGN OF PRESSURE VESSEL Full Report DEDocumento48 pagineDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- TDS - Bronco Pre HDPE Membrane (S)Documento3 pagineTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNessuna valutazione finora

- Alloy Steel Round BarDocumento10 pagineAlloy Steel Round BarSingarao KattaNessuna valutazione finora

- Reels: CatalogueDocumento24 pagineReels: CatalogueMatteo BaldassariNessuna valutazione finora

- Power ThermDocumento17 paginePower ThermFah RoziNessuna valutazione finora

- iRSVP 3100 Data Sheet.Documento2 pagineiRSVP 3100 Data Sheet.Gỗ MộcNessuna valutazione finora

- SG653PB1 ADocumento5 pagineSG653PB1 ADANILO MEDINA OSORIONessuna valutazione finora

- 2099 Robor Corrugated Liet PDFDocumento2 pagine2099 Robor Corrugated Liet PDFJosef StrydomNessuna valutazione finora

- BOQ For Bought Out Items (Condensate & Flash) PDFDocumento1 paginaBOQ For Bought Out Items (Condensate & Flash) PDFsppatilNessuna valutazione finora

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocumento3 pagineStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusNessuna valutazione finora

- Technical Data Sheet: Hanson Construction AggregatesDocumento9 pagineTechnical Data Sheet: Hanson Construction AggregatesShaiful ZamriNessuna valutazione finora

- Enviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)Documento1 paginaEnviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)ssdprojects RexNessuna valutazione finora

- Nano CompositeDocumento26 pagineNano Compositenandan akNessuna valutazione finora